In any septic tank (with the exception of simple storage tanks), biological processes are used in the process of wastewater treatment. The decomposition of organic matter occurs as a result of the activity of various microorganisms. However, in different septic tank models, the conditions for the reproduction and development of bacteria may differ. To improve the quality of cleaning, you can make a biofilter for a septic tank with your own hands. Let's look at how you can make and install a homemade biofilter for a septic tank.

Natural processes are usually used to treat domestic wastewater. Including biological decomposition of organic matter. The use of biological filters in septic tanks can significantly increase the degree of wastewater treatment.

Such a septic tank is especially recommended for small areas where it is not possible to arrange extensive filtration fields. And if the area of the filtration fields is not large enough, the drainage layer will quickly become clogged, and the wastewater will not be able to be properly cleaned.

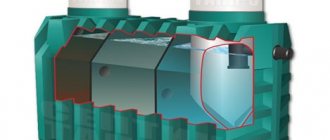

Design of a septic tank with a biofilter

A septic tank with a biofilter usually consists of three compartments:

- Septic chamber. This compartment serves as a receiving chamber; in addition, large inclusions settle to the bottom here;

- Secondary settling tank. This is an intermediate chamber in which secondary settling and removal of smaller inclusions occurs;

- A biological filter is installed in the third chamber. This is a load with a large specific area used for the propagation of bacterial colonies.

When passing through a biological filter, wastewater is, firstly, mechanically purified, and, secondly, aerobic and anaerobic purification processes occur. As a result, practically pure water is sold for output, which can be sent for disposal without fear for preserving the ecology of the site.

Advice! A septic tank with a biofilter is always a horizontal installation. For objective reasons, it is impossible to make a vertical septic tank with a biological filter.

Principle of operation

To make a biofilter, an inert material is used, most often expanded clay, granular polymer, plastic three-dimensional mesh or brushes with polymer bristles. This material is used to “disperse” microorganisms – bacteria, protozoa, yeast.

In addition to bulk loading made of expanded clay, other options can be used:

- granules made of polymeric materials;

- volumetric mesh made of plastic or eraser brushes with a large amount of fibers.

As a result of the activity of microorganisms, sludge is formed, which gradually accumulates in the biological filter chamber. Therefore, for normal operation of the septic tank, it is necessary to periodically pump out the sludge and wash the load. If washing is not done on time, the filtration rate will decrease over time and the quality of cleaning will decrease.

Advice! To reduce the need for major rinsing of the biofilter, it is recommended to regularly use special biological products for septic tanks.

In essence, a biofilter is a filtration field, only it has compact dimensions, since in conventional filter fields bacteria are located only in the upper (soil) layer, but in a biological one they are located throughout the entire volume.

How the system works

The cleaning system with a biofilter with aerobic bacteria works as follows:

- In the first settling tank, the wastewater is separated into sediment, consisting of large inclusions, fats that float to the surface, and wastewater without large inclusions and fats.

- After the wastewater has settled in the first tank, it flows into the second, most often it is a biofilter. The wastewater flows through expanded clay, that is, the water is mechanically purified from the remaining small fractions.

- Aerobes live in the biofilter, which accelerate the process of decomposition of organic substances.

- For the productive work of microorganisms, the biofilter is equipped with a ventilation system.

- After purification with a biofilter, the wastewater is once again settled in the third compartment or enters infiltrators, where final purification of the water occurs and its subsequent discharge into the ground.

What types of biofilters are there?

All biological filters can be divided into groups according to two criteria:

- Based on the type of microorganisms used, aerobic and anaerobic biofilters are distinguished. When installing the first, good ventilation is necessary. Filters with anaerobic loading are installed in sealed containers;

- Depending on the type of loading performed, filters with dry or wet loading are distinguished. In the first case, the filter is periodically supplied with purified liquid. With the wet loading type, the chamber with the biofilter is completely filled with the liquid being purified.

Installation of soil treatment systems

Let's consider the stages of earthworks that are necessary to organize a filtration field for a septic tank and infiltrator.

The soil cleanup area must be impressive. Typically, a system of 2-5 pipes is installed, the length of which usually does not exceed 25 meters. The distance between the pipes is at least 1.5 meters, and the laying depth must exceed the freezing level of the soil. A layer of crushed stone is laid at the bottom of the trench; a drainage collector will pass here. The pipe should be laid at an angle of 2 cm per meter to ensure adequate gravity flow of the liquid. A layer of fine sand is poured over the drainage. Distribution channels are placed at the top, which come out of the well. They are also filled with crushed stone, and geotextiles are laid on top of the ditches. The topmost layer can be made of finished lawn; it is permissible to fill the system with soil. The filtration field for a septic tank must have gas outlet pipes that rise at least 50 cm above the ground. They are equipped with visors. The location of the soil treatment zone is at least 5 meters from the house, at least 30 meters to open water intake sources for clay soils and 50 meters for sandy soils. There should be no bushes or trees in the filtration zone, and vehicle traffic is prohibited. The soil in the fields is replaced every 5-10 years.

The system uses 110 mm perforated pipes.

The infiltrator is placed in series with the septic tank. It is a plastic case that does not contain a bottom. Stiffening ribs protect it from deformation. The distance from the well to the infiltrator tank should be about 1 meter.

When choosing a device, the volume and number of containers are taken into account. The capacity of the infiltrator must exceed the salvo release from the well by three times. It is also important to consider the absorbency of the soil (it is higher in sand).

At the excavation stage, the groundwater level is taken into account. The depth of the hole must be above this level, otherwise your system will float in the spring and fall. For installation, a small trench is dug, 50 cm larger than the dimensions of the container. Next, we proceed to laying the filtration layer. We put geotextiles on the bottom, pour sand and crushed stone of the middle fraction. The thickness of the pillow is 40 cm.

It is not recommended to exceed this value, as the filtration rate will drop sharply.

An infiltrator is placed on top of the pillow. Its dimensions allow you to carry out this stage independently, without the help of equipment. Pipes are connected to the container: the outlet from the well, the overflow for the second device (if there is one) and the gas outlet to the soil surface. After checking the tightness of the system, cover it with geotextiles and fill it with soil.

So, the system with an infiltrator is easy to install and saves space on the site. In addition, it does not require excavation work to replace filter layers of soil.

Advantages and disadvantages

Like all other devices, biofilters have their pros and cons. Among the advantages it is worth highlighting:

- No restrictions when using biological filters;

- Compactness. Not every site has the opportunity to allocate an area for filtration fields, so in such conditions a biofilter is the best option;

- Easy installation and ease of use;

- Autonomy. Septic tanks with biofilters do not require a power connection;

- No odors.

The disadvantages of using a filter are:

- Higher cost compared to a conventional septic tank;

- Certain requirements for the composition of wastewater. When using biological filters, disinfectants must not be poured down the drain;

- In order for the biofilter to work effectively, you need to regularly add special biological products;

- When using septic tanks with biological filters, sewer system downtime must not be allowed. If the sewage system is not used for two weeks, the bacteria may die.

Advantages and disadvantages

The advantages of a biofilter for a septic tank include:

- simplicity of design;

- small sizes;

- efficiency of purification of clarified water;

- ease of operation;

- autonomous operation of the device without energy consumption;

- complete absence of unpleasant odors.

But there are also disadvantages.

- The biofilter increases the cost of the septic tank.

- In anaerobic models, bacteria will need to be added periodically.

- They work effectively only with constant operation of the sewer system.

- You will have to make sure that wastewater saturated with chlorine, which immediately kills all microorganisms, is not discharged into the sewer.

To summarize all of the above, it should be noted that biofilters for septic tanks are devices that allow you to avoid constructing large filtration fields, spending a lot of time and money on this. These are compact tanks that effectively purify wastewater to near-perfect purity.

How to make a biofilter?

If a conventional septic tank is installed on the site, then to improve the quality of its operation, you can additionally install a biofilter. You can purchase a structure that is ready for installation. This option is good because you can very quickly upgrade an already finished septic tank.

However, ready-made biofilters are not cheap, so many owners decide to make this part of the treatment plant themselves. The work on manufacturing a biological filter goes like this:

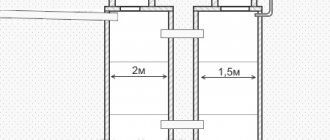

- A pit for a biological filter is being prepared next to the septic tank;

- If a ready-made plastic container is used, it must not only be lowered into the pit, but also secured to a reinforced concrete slab laid on the bottom. To create a container for installing a biofilter, you can use other options, for example, making a well from concrete rings or making a monolithic structure. In the latter case, you must first build the formwork and fill it with mortar. Filling is done in layers with compaction of each layer;

- The prepared pit is filled to two-thirds of its volume with backfill - expanded clay or other suitable material;

- The pit is backfilled. If the well body is plastic, then backfilling is done not with soil, but with a mixture prepared from dry sand and cement (ratio 5 to 1);

- A ceiling is installed on the well, and a ventilation system must be provided;

- The well cover must be insulated. The easiest way to use polystyrene foam for these purposes;

- The biofilter should be discharged into a storage well or ditch.

A biofilter is a device that allows you to improve the quality of wastewater treatment. Installing a biological filter avoids the need to install filtration fields.

Device

Now let's move on to a more practical plane. How exactly are filter structures constructed? We are interested in their design and the possibility of constructing them with our own hands.

Well

An idea of how a filter well works is given by its simplest implementation - a barrel without a bottom, buried below ground level.

Another budget solution is a well made from old tires.

All wastewater entering it is absorbed into the ground; however, there are two problems here.

- The absorption area is limited by the bottom area.

- The soil inside the barrel will gradually silt up with an inevitable drop in productivity.

To overcome these limitations, the basic design is slightly modified.

- The walls of the well are made perforated. There are a lot of ways to get perforation: using special concrete rings with drainage holes, brickwork with gaps in each row, etc.

- Drainage is poured under the base of the well and around the outside walls - the same crushed stone. What is this instruction related to? The absorbent area increases significantly - water through the layer of crushed stone reaches the surface of the entire pit, and not just the area limited by the walls. Moreover, as the water level in the well increases, its productivity increases, since wastewater begins to filter through the walls.

- The silt settles not at the bottom, but on the surface of the bedding. Even when a significant amount of silt falls out, gaps remain between the stones, through which water continues to flow to the absorbent surface.

Filter field

How is a filtration field for a septic tank constructed?

- On the empty part of the site (if it is located on a slope - downward from the house), several ditches or a shallow pit are torn off. Depth is usually from 50 centimeters to a meter. Calculation of the filtration field for a septic tank is based on the type of soil and its absorption capacity: for sand it is approximately 70-90 liters of water per day, for sandy loam soils - 30-50, for loams - up to 25.

For clay soils, a sand and gravel filter can be used to discharge purified water into a ditch or reservoir.

Useful: sometimes a simpler calculation scheme is used. For each person permanently living in the house, 6-8 linear meters of drainage pipe are laid in the ground.

- The ditches or pit are filled with crushed stone to a depth of approximately 10 centimeters; A drainage pipe or the notorious infiltrators are laid on the bedding.

- Then the filtration field is filled with crushed stone so that it is at least 10 cm above the surface of the drainage devices. Of course, the pipes are laid with a slope (about 1 cm per linear meter).

- The crushed stone is covered with soil on top, on which garden plants can be planted.

Mechanical filter

In general, most of the factory-produced septic tanks-stations for deep biological treatment are equipped with filters. However, the price of a ready-made solution is much higher than the cost of building it yourself.

What solutions can be used for high-quality treatment of settled wastewater?

- The maximum degree of purification from biological contaminants can be achieved by placing a buffer container filled with... ordinary bottle brushes in the wastewater path. Bacterial cultures multiply in large numbers on their bristles, which devour food and feces retained by the bristles.

The photo shows a homemade biological purification filter made from a barrel and dishcloths. An air compressor aerates the wastewater to activate aerobic bacteria.

- An even simpler scheme is to install a tee and a vertical pipe buried in the ground, plugged from below, on the path of the drainage to the drainage. The outlet of the tee, directed towards the drainage, is blocked by several layers of ordinary polymer mosquito net. All contaminants larger than the mesh size remain in the lower part of the pipe.