During construction, finishing or working with wood, there is often a need to make various recesses in materials. Everyone knows that round holes can be easily drilled using a drill with a drill bit or a hole saw. But with square, rectangular or complex-shaped recesses the situation is different. And here a chisel comes to the aid of the master; we will tell you what it is in this article.

So, why you need a chisel became partly clear already from the introduction, but let us repeat: this tool is necessary for making recesses of various shapes in a variety of materials.

What materials are we talking about? Yes, about almost anyone. With this impact device you can process wooden products, make niches or grooves in brick, concrete, stone. A wedge-shaped SDS chisel with a chipper is capable of splitting rock or concrete during the dismantling process. A device in the form of a roller cutter is used for drilling holes in durable rocks.

Each listed task corresponds to devices of a certain shape. That is, it is useless to approach materials made of natural or artificial stone with a tool for processing wood and vice versa. But despite the different shape and appearance of the instruments, they are all united by a common principle of action - impact-splitting or impact-cutting.

What is this chisel?

Any construction chisel is a device that receives strong blows from a hammer, perforator or chipper with its rear part, and transmits it through a strong metal body to the contact zone of the device with the rock. At the same time, the working leading edge of the punch is always sharpened, which allows you to concentrate maximum energy on the minimum contact patch. Due to this, the material being processed cannot withstand and is cut through or split. So, blow by blow, the sharpened device penetrates deeper into the surface.

Making a dovetail notch with a wood chisel

In order for the device to withstand the colossal loads that occur at the point of contact of its working edge with the workpiece, only high-strength tool steels of certain types are used for its manufacture. Alloy grades are established by GOST standards. The standards also impose strength requirements on handle materials for manual operation.

In everyday life, we most often find chisels for woodworking (carpentry and carpentry), as well as chisel attachments for rotary hammers and jackhammers for processing stone, brick, and concrete. We will explain these types in more detail.

Description of the tool

When considering what a chisel is, you should pay attention to the fact that such a tool is represented by a steel bar, which can have a square or rectangular cross-section. In many ways, the working surface resembles a chisel. Among the features we note the following points:

- On the reverse side of the metal bar there is a handle, which is often made using plastic or wood. The most commonly used wood is oak or beech; both types of wood are characterized by increased mechanical strength.

- The top is usually made flat. At the same time, there is a bronze or metal ring around the circle, which reduces the likelihood of a crack appearing under mechanical stress.

- The purpose of the chisel is to cut the material with transverse blows. Due to this, the fibers are cut.

- At the time of operation, the blows are made with a hammer. In this case, it is recommended to use a mallet, since when using a regular hammer there is a possibility of defects quickly appearing.

- Typically, when using a chisel, certain depressions are created in the surface of the solid wood.

Design features determine that the tool can take fairly strong blows. It is worth considering the rapid dulling of the cutting part due to the transfer of high force to the edge. Therefore, application and periodic maintenance involve sharpening the surface, which requires special equipment.

Working with the tool

[rek_custom2]

- Drilling produces cylindrical holes, through or not, which are used for installing tenons or connecting elements of fittings into them.

- To install elements of a quadrangular section, a flat chisel is used. This tool helps to hollow out a cylindrical hole into a rectangle or square shape.

- Working with a chisel is a physically difficult process, and chiselling is done along or across the wood fiber.

- The tip of the chisel is set on the marking and then the master begins to hit the handle of the tool with a hammer.

- When working with large parts, the master can sit on the element being processed.

- Nests are hollowed out in large layers to avoid the formation of crooked walls that do not correspond to the size.

- They don’t make a through hole; the craftsman walks to the middle of the intended distance, then turns the block over and chisels on the other side. This way, the bottom layer of the processed material does not crumble and spoil the product.

History and characteristics of the instrument

At the time of excavations of ancient cities and settlements, the remains of wooden utensils were obtained, which were characterized by quite high quality and beauty. This indicates that various tools were used during the work, including a chisel. The chisel tool is a simple product, the purpose of which is to gouge out various holes and sockets, as well as surface roughing. The key feature is the one-sided sharpening of the cutting edge.

As previously noted, a wood chisel has a rectangular working part. However, recently, tools with a semicircular blade have become widespread.

Its purpose is to obtain grooves of various shapes, as well as to clean corners. There is also a U-shaped version, which has recently been used to obtain recesses intended for door hinges. By using a special tool, the quality of the resulting excavation is significantly improved.

The product in question is a hand-held tool. The carpentry chisel GOST 1185-80 is equipped with a special handle, which significantly simplifies the process of processing the material. In the manufacture of this element, various materials can be used, in most cases wood with increased density.

Download GOST 1185-80

Device and principle of operation

The design of the tool is quite simple - a metal rod with a sharpened edge at one end and a wooden handle at the other. There are standards for carpentry tools - GOST 1185-80 defines a chisel as a percussion-type hand tool.

The design, despite its simplicity, has its own characteristics, and the parts have their own names. The metal blade is called the blade, the wooden part is called the handle.

The tool is used to chisel holes in the longitudinal and transverse direction of wood fibers. When working with a hammer or mallet, blows are struck on the handle. To prevent the handle from cracking, a metal ring can be installed in its upper part.

In operation, the chisel is used as follows:

- The place that needs to be hollowed out is marked on the workpiece;

- Place the sharp edge of the blade on a line perpendicular to the direction of the fibers and make a notch with a light blow of the mallet;

- In a similar way, notches are made along the entire perimeter of the recess;

- After the notch has been made along the entire perimeter, 3-4 mm of wood is removed from the hole;

- The next step is to remove a layer of 2-3 mm;

- After this, a notch is made again around the perimeter;

- The operation is then repeated until the desired excavation depth is achieved.

Shank Types

For carpentry and carpentry type tools, the use of two types of shanks is allowed. For carpentry, a shank in the form of a pointed peak is more often used. The carpenter's style can use both a peaked shank and a bowl shank.

These types of shanks are used depending on the purpose - the bowl is made for 18-25 mm rods, which are used in carpentry and can withstand heavy loads.

Lance, used for small rods. These types of shanks, in addition to rigid fixation in the handle array, are additionally fixed with a metal cap on the blade side. When using a chisel with this type of handle, you should not use a hammer; it is better to use a wooden mallet or mallet.

Material

The state standard also defines the type of material used to make the rod. To make the blade, 12 grades of steel are used; for the wooden handle, the material used must be made of hard wood.

Dimensions and weight

Standards such as dimensions and weight are also defined for the tool. Carpentry chisels are designed for finishing work and are smaller in size. So, with a blade width of 6 mm, the maximum weight should be 180 grams. The largest weight of a carpentry chisel with a rod width of 20 mm is 370 grams.

The carpenter's tool is more powerful and, accordingly, heavier - with a blade width of 16 mm, the weight should be no more than 430 grams, and for the largest one with a width of 25 mm, the weight should be 630 grams.

The carpentry tool also has a large length - the total length with the handle is 345 mm. The length of the canvas is 150-157 mm. The joiner's is smaller - its total length is 315 mm, of which the working rod is 165 mm long. The total length of the handle is 185 mm, and the working part is 110 mm. The shape of the handle is complex - in cut it is 40 by 36 mm.

Types of chisel

There is a chisel for metal processing in the assortment of almost any man who is used to doing household work with his own hands. There are also options for various sets for working with wood. Depending on the area of application, the following versions are distinguished:

- The carpenter's chisel has become very widespread. It is used in large construction, for example, when constructing a roof or other floors. When designating, a combination of mi and tse can be used. In most cases, the length of the product is at least 300 mm. People living in country houses often purchase a carpenter's chisel, since it is universal in use in a wide variety of cases.

- Carpentry is used when carrying out work related to the manufacture of various products. Characterized by a working width of about 15 mm. The scope of application is in the manufacture of furniture or window frames; the handle is attached by a shank that rests on a special collar. This design option is suitable for performing work in an apartment, since it is easier to use and allows you to achieve high accuracy.

In most cases, hand tools have a working part, in the manufacture of which tool steel is used. It is characterized by increased resistance to mechanical stress. The tenon chisel is also used for a wide variety of work.

Drill bits - designs and types. Purpose, classification, scope.

Blade bits , depending on the design and equipment with a hard alloy, are intended for drilling soft and medium-hard rocks, as well as soft rocks with interlayers of medium, low-abrasive rocks, as well as for drilling out cement plugs, metal parts of the bottom of casing columns and expanding the wellbore. According to the industry standard OST 26-02-1282-75, the following blade bits are produced:

two-blade 2L with diameters from 76.0 to 165.1 mm with conventional (flow-through) washing;

three-blade AF with diameters from 120.6 to 469.9 mm with conventional and jet-monitor washing; three-bladed abrasive-cutting action ZIR with diameters from 190.5 to 269.9 mm with conventional and hydromonitor washing; six-blade abrasive-cutting action 6IR with diameters from 76.0 to 269.9 mm with conventional and hydromonitor washing; peaked U with diameters from 98.4 to 444.5 mm with conventional flushing. The following types of bladed bits are produced (except for type P bits): M - for soft rocks; MS - for soft rocks with interlayers of medium hardness; MSZ - for soft abrasive rocks with medium-hard interlayers; C - for rocks of medium hardness. P-type blade bits are produced in two types: C - for drilling out cement plugs and metal parts of the bottom of casing columns; P - for expanding the wellbore. In six-blade 6IR bits, three blades have a normal height, and three have a shortened height (the blades alternate in height). Flushing is carried out through three channels located between the blades.

Blade bits are not used when drilling with hydraulic downhole motors and electric drills, since drilling requires high torque. Roller bits. For drilling oil and gas wells, roller bits with conical rollers are mainly used. Roller bits are designed for continuous drilling of oil, gas and geological exploration wells, as well as wells for various purposes in the mining industry, in construction with bottom hole cleaning with liquid or air. Roller bits have the following advantages over blade bits.

1. The contact area of roller bits with the bottom is much smaller than that of bladed bits, but the length of their working edges is longer, which significantly increases the efficiency of rock destruction.

2. The bit rollers roll along the face, in contrast to the blades of the bladed bit, sliding along it, as a result of which the wear rate of the cutter teeth is significantly less than the wear rate of the bladed bit blades.

3. Due to the rolling of the roller cutters along the face, the torque consumed by the bit is relatively small, so the risk of jamming the roller bit is minimized.

In accordance with GOST 20692-75, roller-cone bits are manufactured in three types: single-cone - I, double-cone - II and tricone - III. Tricone bits are most widely used. According to the location and design of the flushing or blowing channels, bits are manufactured: with central flushing - C; with lateral hydromonitor flushing - G; with central blowing - P; with side blowing - PG. Hydraulic jet bits, as a rule, are produced with replaceable nozzles, when a socket is bored in the lower part of the flushing channel of the bit to install replaceable nozzles made of wear-resistant material. In this case, it is possible to install nozzles of any required exit diameter into the bit. Roller bearings are made: on rolling bearings - B; on one plain bearing (the rest are rolling bearings) - N; on one plain bearing sealed with O-rings and lubricant reservoirs - NU; on two or more plain bearings with sealing - AU. These bits are manufactured in accordance with the technical specifications TU 26-02-874-80. For example, bit III-215.9SZ-GAU-R6 means: III - tricone; 215.9—bit diameter, mm; SZ - type of bit (in this case, for drilling abrasive rocks of medium hardness); G — type of flushing (in this case, side jet flushing); AU—type of support (in this case, sealed, oil-filled, having two radial plain bearings); R—the bit is manufactured using imported technology; 6—assembly serial number. Theoretically, for every rock there should be a bit capable of breaking it down most effectively. However, it is impossible to have as many types of bits in service as there are varieties of rocks with different physical and mechanical properties. In practice, bits are used that provide good performance in a certain group of rocks. In domestic drilling practice, the following types of tricone bits are currently used. In addition to tricone bits, double- and single-cone bits are used in drilling practice. Double-cone bits are designed for drilling soft and tough rocks with interlayers of medium-hard rocks. A distinctive feature of these bits compared to tricone bits of the same diameter is the increase in the size of the rollers and more favorable conditions for the location of flushing holes. Double-cone bits are a non-separable structure consisting of two sections (paws) welded together, on the axles of which rollers with teeth rotating freely on supports are mounted to destroy rocks. Double-cone bits are hydraulic jet bits with two side channels into which replaceable nozzles are installed that direct jets of drilling fluid to the peripheral part of the bottom of the well. Single-cone bits (used for drilling hard rocks located at great depths. They consist mainly of one paw, on the axle of which a spherical cutter rotates freely on ball bearings, into the body of which carbide cylindrical teeth (pins) with a hemispherical or prismatic working surface are pressed. Diamond bits for continuous destruction of the bottom ... Diamond bits are designed for drilling vertical and directional wells when passing through sandstones, dolomites, limestones and other rocks, in which the effectiveness of using roller bits is sharply reduced. The correct use of diamond bits ensures: 1) high cruising drilling speeds ; 2) reducing the number of hoisting operations; 3) cost savings; 4) reduction of curvature when drilling vertical wells. Diamond bits, like blade bits, do not have independently moving parts. They consist of a shaped diamond-bearing head (matrix), made of powdered carbide material, and a steel body with an attached locking thread. Diamond bits are manufactured with diameters of 91.4–391.3 mm in two modifications:

1) single-layer with the placement of diamond grains in the surface layer of the matrix according to certain patterns (types - radial DR, stepped DT, and stepped with spherical protrusions DC);

2) impregnated (impregnated is a diamond bit in which, during manufacturing, bulk diamonds are mixed with the matrix material - the charge, thereby ensuring uniform saturation of the matrix with diamonds) with an approximately uniform distribution of small diamond grains in the volume of the matrix material (type - with spherical DI protrusions). Diamond bits during turbine drilling, compared to rotary drilling, give a higher mechanical speed with the same penetration per bit. Drilling with diamond bits can continue without interruption for up to 200-250 hours. Diamond bits are not allowed to drill in frequently interspersed fractured, cavernous rocks composed of various fossils and other strong abrasive rocks. Before drilling with diamond bits begins, the wellbore is calibrated and the bottom of the well is cleared of metal. As the well deepens, a large amount of metal debris accumulates at the bottom as a result of teeth chipping and support elements of roller bits falling out. Part of the metal located at the bottom is crushed during the drilling process and carried by the drilling fluid to the surface, the other part ends up in the cavities and walls of the well; this metal can get back to the bottom during the drilling process. Metal at the bottom leads to catastrophic chipping of diamonds. Cleaning the bottom of deep wells from metal objects and large rock fragments can be achieved by using shaft cleaning methods developed by VNIIBT.

1. Before running the diamond bit, the last two or three trips with the roller bit must be carried out while simultaneously cleaning the well from metal and large cuttings using a downhole slurry trap installed above the bit in rotary drilling and above the turbodrill in turbine drilling.

2. If additional well cleaning and bore calibration is necessary, a special trip of the downhole slurry trap should be made.

When turbine drilling with a diamond bit, for more intensive removal of drilled rock from the bottom-hole zone, a reflector cover is installed on the shaft of the turbodrill, which changes the direction of the jet emerging from the nipple of the turbodrill and thereby contributes to better removal of drilled rock. When drilling elastic-brittle and elastic-plastic rocks with diamond drilling, volumetric destruction occurs by shear and shear. Therefore, one of the conditions when selecting rational parameters for drilling bits is to ensure fatigue and volumetric destruction of the rock at the bottom. The main criteria in this case should be the permissible load on the diamonds and the critical peripheral speed, determined accordingly by the strength of the diamonds, the existing standards for flushing the face and the hardness of the rocks. The use of diamond bits and drilling heads in drilling is permitted only in cases where their diameter is less than the diameter of the wellbore. Below is the minimum difference between these diameters.

Diameter of diamond bits and drilling heads, mm 91.4—227.0 242.1—391.3

Minimum borehole diameter difference

and drilling tools, mm 1.6 2.4

A diamond bit is considered completely worn out with a total loss of 40% of diamonds.

The successful use of diamond bits has led to the creation of a number of carbide bit designs that provide a similar principle of rock destruction. The Ukrainian Research Design and Technology Institute of Synthetic Superhard Materials and Tools based on superhard material Slavutich created ISM type bits for drilling oil and gas wells. The production and use of ISM bits reinforced with inserts from Slavutich began in 1967. During this time, more than 150 standard sizes of bits and other rock-cutting drilling tools reinforced with Slavutich material with a diameter of 91.4-391.3 mm were created. Recently, the so-called Stratapax (trademark) blade-type bits, manufactured (USA), equipped with varying numbers of two-layer Stratapax diamond-carbide cutters (plates), have become widespread abroad. Stratapax cylindrical cutters have a diameter of 13.3 mm and a height of 3.5 mm. The thickness of the diamond layer is 0.6–0.8 mm. The thickness of high-quality carbide is 3.0-2.7 mm. The cutter has the high strength of carbide and the wear resistance of diamond. Stratapax cutters are soldered to carbide substrates in the shape of cylinders or holders in the shape of teeth. Large sizes of Stratapax incisors. allow the protrusion of the Stratapax cutters above the bit body to be up to 12-15 mm. This creates good conditions for removing cuttings from the rock destruction zone and eliminates contact between the casing and the face. The bits manufactured by various companies differ in the method of fastening the Stratapax cutters, the design of the flushing systems, the configuration and material of the bodies. Matrix type bits have increased resistance to mud erosion compared to bits whose bodies are made of steel. Chisels with diamond-carbide inserts are a highly effective tool for drilling soft and medium-hard rocks, during the destruction of which the cutters retain sharp edges for a long time. When rotary drilling, bits of this type provide an increase in the mechanical rate of penetration by 2 times compared to roller bits, penetration per bit by 3-7 times with an axial load 2-2.5 times less and with a comparable torque.

9. Chisels for special purposes. Core drilling equipment (core receiving devices) and drilling heads for them.

All core drilling equipment, regardless of design, consists of the following main parts:

1) a drill head to destroy the rock around the core being drilled; 2) outer casing; 3) internal core pipe for storing and removing core; 4) core holder (core grabber). According to the principle of application, core drilling equipment is divided into projectiles (core receiving devices) with a non-removable (permanent) core pipe and into projectiles with a removable soil carrier. When working with core drilling equipment with a removable soil carrier, the core is removed with a special catcher on a rope, and the drilling head is raised after it has been completely worked out. The process of lifting a loaded soil carrier and lowering a new one proceeds as follows. When lowering, the catcher grabs the soil carrier by the head connected to the core pipe. After the soil carrier is captured by the catcher, it is lifted using a winch installed on the surface. After lifting the soil carrier with the core, an empty soil carrier is dropped into the drill pipes, which, having reached the projectile, sits with its head on the support. Drilling continues. Recently, core drilling equipment with a removable base carrier has been almost universally used. By type, drill heads are divided into blade, roller and diamond. In core drilling equipment of all types, the core is formed by a drill head, and a core holder is used to tear off and hold the core. The importance of the core holder in ensuring good core recovery is very high. There are a large number of different designs of core holders. One or another design is used depending on the drilling conditions, physical and mechanical properties of the rocks being drilled, etc. The receiver of the selected core is a core pipe, ending at the top with a valve through which the flushing fluid exits the core pipe. Three- and four-blade paddle drill heads are designed for drilling with core bits in the same formations as continuous demolition paddle bits, and their designs and materials are also similar. In our country, roller-cone drill heads are used for core drilling. They can be one-, three-, four- or six-cone. Diamond drilling heads are similar in design and availability of diamonds per unit area to diamond bits for continuous destruction of the face. With the rotary drilling method, the most widely used core drills are “Nedra”. VNIIBT has developed projectiles of this series in the following sizes: 203/100, 164/80, 138/67 and 122/52 mm (the numbers in the numerator indicate the diameter of the projectile body, in the denominator - the nominal diameter of the drill head core receiver). For difficult drilling conditions, core drills of the “Silur” series are designed in sizes: 146/80 and 114/52 mm. The shells of this series have the same core-receiving part as the shells of the Nedra series (core catcher, core-receiving pipe, adjusting screw), but the body has a reduced diameter. For drilling in difficult-to-extract rocks, core tools of the “Cambrian” series are used. These tools allow you to select cores of a larger diameter compared to the core tools of the Nedra and Silur series and work with special drilling heads. Cambrian core shells are available in sizes: 172/100 and 122/67 mm. Core shells "Nedra", "Silur" and "Cambria" have non-removable core receivers. To ensure a high percentage of core removal in turbine drilling, special turbodrills for core drilling have been created, in which the turbodrill, core receiver and drilling head are a single complex, adapted to work in high-speed mode. Working with a core drilling rig has a number of specific features. Before lowering into the well, the projectile must be assembled on the surface and carefully inspected. Drill heads of any type should be lowered into the well, if possible, without expanding the wellbore; In this case, you should monitor the weight indicator. If tightening of the drill string is detected, this interval is explored. When lowering the tool into the well, not reaching the bottom by 10-12 m, the mud pumps are turned on; during rotary drilling, the drill string is rotated while simultaneously feeding it smoothly to the bottom; when drilling with turbines, the turbo drill is turned on and reaching the bottom with a smooth feed. A core drilling rig is used to drill without breaking away from the bottom, while the drill head is fed evenly to the bottom. The penetration per trip is determined by the wear resistance of the drill head, and for core barrels with fixed core receivers it should not exceed the useful length of the core receiver pipe. Before separating the core from the bottom or before building up during rotary drilling, it is necessary to rotate the tool until the axial load on the drill head is removed. The separation of the core from the bottom must be carried out with continuous washing and slow lifting of the tool. To guarantee separation and retention of the core, lifting and lowering to the bottom without rotation (with an axial load 20-30 kN higher than the drilling load) should be carried out two or three times. Upon completion of drilling with core sampling, it is recommended to reduce to a minimum the time for equalizing the parameters of the drilling fluid before lifting the tool. To better preserve the core when lifting the tool, sudden impacts from the drill pipes should be avoided. It is prohibited to unscrew drill pipes with a rotor. The operating mode of core drilling rigs is set based on the standard sizes of bits, drilling depth, the nature of the rocks being traversed and the drilling method.

Extenders . They are used to expand the diameter of the well when drilling solid and core drilling bits, as well as to center the drilling tool during the drilling process. The most common are tricone reamers. They consist of a housing in which three pairs of slightly tapered rollers are mounted on the axes. The cones are located around the circle at an angle of 120° to each other. Tricone reamers are available in diameters of 243, 269, 295, 346, 394 and 445 mm. In addition to tricone reamers, four- and six-blade reamers, single-cone pilot reamers and over-bit pin reamers are available. Milling bits. Designed for drilling wells in low-abrasive rocks and for drilling out cement bridges and metal in the well. Milling carbide spiral bits are produced as DFTS. The design feature of these bits is the arrangement of carbide plates in a spiral. The working part of the bit is spherical. The face is washed through channels and a central channel connected by bends to the space between the spiral belts. The design allows for the replacement of worn spirals with new ones. When drilling with DFTS-type bits, a core with a diameter of 3-5 mm is formed at the bottom in the center, which is then destroyed by hard alloy plates fixed in the wall of the central channel and carried out through two open side channels beyond the spirals. Bits for the reactive turbine drilling method (RTB ). When working with RTB units, serial tricone bits and DRB bits, specially designed for RTB, are used. A characteristic feature of the armament of cutter bits of the DRB type for RTB is the presence of milled teeth or carbide teeth only on the peripheral rims. VNIIBT has developed six-cone bits for RTB: DRB12K and DRB13K. For DRB type bits, the most expensive part is the body, which is advisable to use repeatedly. Therefore, these chisels have replaceable welded feet. Insert bits for turbine and rotary drilling without lifting the drill string to change the bit. The essence of the drilling method without lifting the drill string to change the used bit is that the new bit is lowered and the used bit is raised (using a rope and a special tool - an overshot or reverse circulation) inside the drill string. For turbine drilling, a special design of a turbodrill with a plug-in rotor, to which a plug-in bit is attached, has been developed and produced. The insert bit consists of two main components: the bit mechanism and the cutting roller sets.

Difference from a chisel

A chisel and a chisel have almost similar properties, but there are also serious differences. The difference between a chisel and a chisel is the following points:

- In the type of work performed. Chisels are used exclusively for making small indentations, as well as creating chamfers. A chisel is required when it is necessary to remove a large layer of material. That is why both versions are found in the master's set.

- By method of application. The chisel is designed to work without applying a shock load, with the exception of a small number of cases. The design of the chisel handle, on the contrary, allows for striking with a mallet.

- Constructive features. They consist of a thicker rod, as well as the presence of a special o-ring on the top of the handle, which eliminates the possibility of cracks and other defects.

There are simply a huge number of different instruments on sale. Craftsmen quite often choose ready-made sets; a chisel and a chisel are very common.

Terms of use

To ensure that the application does not lead to injury, and the resulting surface is of appropriate quality, the rules of the work being carried out should be considered. When considering what a chisel is used for, we note that it is required in the case of removing a large amount of material from the surface. Let's call the basic rules the following:

- At the time of work, the workpiece must be firmly fixed. Otherwise, there is a possibility of serious defects occurring.

- The first stage involves cutting the wood fibers, after which the chips are reduced in one pass. By applying dimensions, you can significantly increase the accuracy of the resulting recesses and holes.

- Due to the periodic deepening of the blade into the material under the influence of an impact load from the mallet, the required cutting depth is ensured. It is quite difficult to control this parameter.

At the time of striking, you need to ensure that the tool fits tightly to the surface. Otherwise, there is a possibility of it slipping, causing injury. When considering what kind of work a chisel is used for, it should be taken into account that this tool is not universal in all cases. An example is the production of round holes, which are most easily formed by using a drill.

How to choose a chisel?

When choosing a bit for any task, you should focus on three main criteria:

- Purpose. For rough work, for example, when building a wooden frame, processing floor joists, you should choose a carpentry tool of a suitable width, and the wider, the greater the amount of material that can be removed in one pass. Delicate work requires narrow carpentry models with a cutting part of a suitable shape. In construction and dismantling work, attachments for a jackhammer or hammer drill are used.

- Material. The bit must withstand shock loads, and this especially applies to its cutting part. Although carbon steel is used in production, it varies in its characteristics. The cutting edge should not crumble, and this is the main parameter when choosing a tool.

- Cost and manufacturer. The previous point completely depends on it. You should not expect good performance from a cheap tool made by an unknown company. On the other hand, the cost of high-quality models is often unreasonably high due to the resonant brand. The optimal option, as always, is somewhere in the middle.

Security measures

As previously noted, one must be very careful when applying significant force to a surface. The main safety recommendations include the following:

- When performing work related to chiselling, you need to ensure that the equipment used is in proper condition.

- Due to high-quality sharpening of the cutting edge, it is possible to obtain a more accurate and high-quality surface.

- To eliminate the possibility of making mistakes during work and getting injured, you should pay attention to the condition of the handle and striking part. Even minor damage to the grip ring can cause the handle to crack.

- Before starting work, care should be taken to ensure that the handle does not have significant defects. Chips and cracks can cause the tool to slip.

Do not forget that the chisel is a tool with a narrow focus. That is why it is undesirable to use it for other purposes.

What features do chisels have?

All versions of the tool in question are designed for hollowing out metal, brick, concrete, wood or other material. The working part is made in a square or rectangular form.

It is worth considering the fact that the handle can be removable or non-removable. For the removable version, you can purchase a variety of attachments. In addition, there is a tool that acts as an attachment for a hammer drill. The peculiarity lies in the special shape of the shank, which ensures reliable fastening. The scope of application is very wide - construction, repairs, production sites. When using a hammer drill with a nozzle of this type, you can significantly increase productivity, since the electric motor significantly simplifies the task. Often, a hammer drill with a chisel attachment is used to break off tiles or create grooves; the shape of the working part can differ significantly.

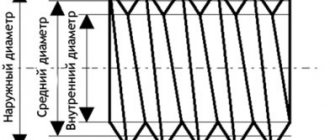

Roller bits

Used as a crushing and shearing tool. A design feature of the cutter is the arrangement of the pressed-in number of carbide pins. Used for mechanical destruction of soft and hard rock during drilling. The bits are classified into 1÷4 and 6 roller cone. Their type is determined by the location of both the cutters and the configuration of the teeth. As the drill rod begins to rotate, the pins of the cutters roll along the bottom of the face, crushing and chipping the rock. The teeth are made, more often, of carbide metal (tungsten carbide), with thermal exposure of the main quickly deteriorating parts. The drilling principle is based on the destruction of rocks, usually with a three-cone tool, with a central flushing hole. The penetration depth varies up to 500 meters, with a rotation speed of no more than 250 rpm.

What features do chisels have?

A chisel can be used to perform carpentry work and produce wood carvings. It is very similar to the previous type of instrument, but has its own characteristics. Among the features we note the following:

- Can be used for shaped selection of grooves and grooves.

- The shape of the working part may differ significantly; the choice is made depending on the task at hand.

- The blade width, as a rule, varies in the range from 5 to 40 mm.

- The main feature is that the handle is intended only to hold the tool and guide it. This is due to the lack of a ring at the end of the handle.

A chisel is designed to remove small amounts of material from a surface. In this case, figured cutting is possible.

GOST

- GOST 1185-80 – for joinery and carpentry products.

- GOST 26474-85 – for diamond drilling heads and bits (types and sizes).

- GOST 20692-2003 – for roller-cone options (types and sizes)

Marking

According to GOST, a drill bit must be marked, which consistently indicates its type, diameter in millimeters, type of tool (by rock type), type of flushing/purging, type of support bearing, modification of the plant and serial number of the factory model.

Moreover, some characteristics have specific letter abbreviations and digital designations.

Marking of bit type:

- I – single-cone;

- II – double-cone;

- III – tricone.

Designation of the type of flushing or purging (location of channels):

- C – with central flushing;

- G – with hydromonitor side-type flushing;

- CG – with combined flushing;

- P – with central blowing;

- SG – with side blowing type.

Based on the type of support bearing, the following product categories are distinguished:

- B – on bearings with rolling elements, as well as with one/several thrust plain bearings, or without the latter.

- VU - on bearings with rolling elements, with several or one thrust sliding bearing, as well as with sealing of the support.

- H – radial sliding bearing, several, or one thrust sliding bearing, and the remaining bearings are sliding bearings.

- NU – the previous option, but with sealing of the support.

- A – at least two radial plain bearings, at least one thrust plain bearing.

- AU – the previous version, but with sealing of the support.

Depending on the type of rock for which the bit is designed, one of the following letter designations is located in the corresponding part of the marking:

- M – soft rock, tool with steel teeth.

- MZ is a soft abrasive rock with carbide teeth.

- MS – soft rock and interlayers of medium hardness, with steel teeth.

- MSZ – abrasive soft rock and medium-hard interlayers, with carbide teeth.

- C – steel teeth, for medium-hard rock.

- SZ – carbide teeth, for medium-hard abrasive rock.

- ST – steel teeth, for medium-hard rock with hard interlayers.

- T – steel teeth, for hard rock.

- TZ – carbide teeth, for abrasive hard rock.

- TK – carbide and steel teeth, for hard rock with strong interlayers.

- TKZ – carbide teeth, for abrasive hard rock with strong layers.

- K – carbide teeth, for hard rock.

- OK – carbide teeth, for very strong rocks.

NOTE:

The data listed above is taken from GOST 20692-2003.

Differences between chisels, chisels and chisels

Also, do not forget that a chisel is often used to cut material. This tool is characterized by the following features:

- The working part is a continuation of the handle, which is often metal. In the production of chisels, casting technology is often used, which increases the resistance of the product to impact loads.

- The cutting edge is sharpened on both sides. Due to this, upon impact, the product is positioned perpendicular to the surface being processed.

- The main purpose is to chop the material, and not to remove it layer by layer.

- The chisel has a handle, which is often made using wood.

The difference between a chisel is that the tool is suitable for removing material from the surface in layers. In addition, when considering the difference between a chisel and a chisel, we note that the second tool is designed for more precise work, obtaining high-quality products and surface carvings.

In conclusion, we note that there are simply a huge number of different chisel options on sale. If work is carried out rarely, then it is recommended to give preference to kits that may also be in the budget category. Experienced craftsmen select tools individually in accordance with their own needs. High-quality designs are obtained by using tool steel, which can withstand significant mechanical stress. The cutting edge is periodically sharpened, which ensures a long service life.

Drill bits

Another common type of equipment with a wide range of capabilities. Flat, blades, peaks, channel - this is not a complete list of forms of hammer drill bits working in conjunction with electric and pneumatic impact machines.

Running bits for rotary hammers and demolition hammers with different shank options

Hammer bits are noticeably different from their manual counterparts:

- The handle is missing. Instead, there is a universal shank for the SDS chuck;

- Thicker blade that can withstand strong and frequent mechanical shocks from electric or pneumatic tools;

- A more blunt sharpening angle so that the cutting edge remains sharp longer and withstands impacts on a durable work surface.

But still, the main difference is the materials for which SDS hammer drill bits are used . Such nozzles are excellent for making niches, recesses, grooves and grooves in walls made of natural and artificial stone.

Making grooves using a hammer drill with a chisel

All this makes the perforated chisel look not like a chisel, but like a chisel. In stores, by the way, impact attachments for rotary hammers are often sold under the name chisel.

Powerful peaks are capable of splitting stone and concrete and are often used during dismantling work. With the help of shovels, brickwork can be easily dismantled or old plaster can be removed.

U-shaped channel bits (also called channel chisels) are useful for cutting grooves for electrical wiring.

This is what the working edge of a U-shaped channel bit for a rotary hammer looks like

Working with hammer drill bits usually does not cause problems. You just need to choose the appropriate size of the blade or lance and the corresponding power of the hammer drill. During the chiselling process, it is important to ensure that the equipment is not pinched between layers of splitting material. Otherwise, it may be difficult to remove it.

Due to serious vibrations, the work process must be interrupted periodically to give the hands a rest. When chiseling for a long time, use construction earmuffs to protect your hearing.

It is noteworthy that despite the wide range of tool manufacturers, the shanks of all products are the same and differ only in size: SDS, SDS-plus (SDS+), SDS-max, SDS-hex. Therefore, in order to buy a suitable attachment, you only need to know the size of the cartridge of your hammer drill or chipper.

Perforating bit attachments rarely break and are mainly due to improper operation (usually when trying to break out a broken part of the material with great force). But how quickly the cutting edge becomes dull depends solely on the quality of the steel and the activity of use. In any case, a dull product can always be sharpened.

Also, with active use, over time, the end part of the shank wears out (flattens), which absorbs impacts from the bump stop piston.