How to make a hole in metal without a drill - Metalworker's Guide

Metal processing is carried out not only in industrial conditions.

When performing repair work on a car, manufacturing structures on a personal plot, or carrying out home renovations, it is necessary to drill holes in the metal. At home, a hand drill is most often used. This versatile tool requires some skill in working with hard work. You can purchase or make your own machine for drilling holes in metal, but this is not a cheap pleasure.

The technology of drilling holes in metal is to remove a thin layer of material due to the simultaneous translational and rotational movement of the drill.

The main condition for high-quality and safe (for the tool) processing is keeping the chuck axis in a fixed position. Using a machine is easy to maintain straightness, which is not the case when working with hand tools.

If you are not confident in the steadiness of your hands (this is a normal situation for an ordinary person), mechanical assistants (jigs) are required for drilling at right angles.

If you are making a hole in a thin steel plate, straightness does not matter.

Devices for drilling perpendicular holes

There are several types of guides for hand-held electric drills. Power-driven tools are not suitable for working with metal, especially when it comes to precision.

- Drilling jig. It is made in the form of a housing that is easy to hold, inside which there are guide bushings for drills of various diameters.

- Guide for drill (manual). Supporting device in which the instrument is fixed by the neck

- Drill stand (semi-stationary). In fact, it is an inexpensive alternative to a drilling machine.

The material of the bushings is harder than the tool, so the holes do not wear out. By installing the jig exactly above the center of the intended hole, you don’t have to worry that the drill will “lead” away from the given direction.

This device is especially useful when drilling perpendicular holes in pipes of small diameter, when the tip tends to slip off the cylindrical surface.

The sole is placed on the workpiece, held by the handle with the second hand. The drill moves strictly vertically, preventing distortions and drifts of the drill.

The design can have a corner holder for small-diameter pipes, which makes the device more versatile.

With a rotating mechanism, you also get a device for drilling holes at an angle.

True, it will not be possible to drill metal in this way; lateral loads will quickly break the drill.

Popular: What is an anchor and what is it for?

The carriage with the tool attached (at the same neck) moves along the rod using a lever. The workpiece is held firmly on the sole using a vice or clamp. The quality of drilling is very high, but the cost of the device is considerable. Although, compared to a drilling machine, it is inexpensive.

You can make a device for holding the drill at a right angle yourself. It is enough to drill holes of various diameters in a block of durable material, for example, textolite or ebonite.

Just don’t count on lateral support - it’s more of a “device” for visual control. If the drill deviates laterally, it will quickly break the guide hole in the jig.

The next problem is drilling deep holes

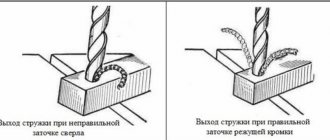

Technologically, it would be correct to use a lathe. Moreover, when processing cylindrical parts (for example, a gun barrel), the workpiece rotates, but the drill remains stationary. Cooling and forced removal of chips from the hole are required.

For this purpose, deep hole drills have special grooves on the surface, or the drill is periodically removed from the workpiece to clear chips.

At home, be sure to use drill guides. Craftsmen recommend not drilling holes with a depth of more than 2/3 of the length of the drill. You can use ordinary water for cooling; the drill is periodically removed from the hole to clear chips and cool.

The use of special long drills requires special technology.

As soon as the cutting part, together with the retracting edges, disappears into the hole, the chips will clog the grooves and block rotation. Therefore, at the last stage, removing the drill and cleaning the chips is performed more often.

Drilling large diameter holes in metal

Drilling large holes in metal with a bimetallic crown - video

This procedure is even more complicated than deep drilling. Drilling large holes is done either with a crown (for small thicknesses) or with a regular drill in several stages.

- A crown for metal is practically no different from a similar device for concrete or drywall. The difference is in the material of the cutting surface and the sharpening of the teeth. A guide drill is located in the center, which prevents the crown from “leaving the route.” The work is carried out at low speeds with forced cooling. The hole diameter is actually unlimited, it all depends on the torque of your drill.

- Drilling in several stages. If the workpiece is significantly thick, you should stock up on a set of drills with a difference in diameter of 25%. Starting with the thinnest, we gradually move to the next sizes, up to the final diameter. It is important to maintain the position of the center of rotation of the drill chuck, so you cannot do without a guide.

- Using cone drills. This tool is a set of sequential drills of different diameters on a common axis. If you are processing thin steel plates, it will be more convenient to use a conical step drill.

When do you need a special tool for drilling wood?

The question of how and what is the best way to drill a hole in a product made of chipboard, MDF, plywood or solid natural wood is relevant not only for carpentry specialists and those who professionally make furniture, but also for home craftsmen who prefer many jobs around the house do it yourself. The choice of drills for wood in such cases is made depending on what type of holes need to be drilled:

- blind, without an exit from the opposite side of the product (intended for mounting hinges on interior doors or on doors that are equipped with furniture structures);

- through (threaded connection elements (bolts and studs) are placed in them; without such holes it is impossible to install door handles and locks).

The main purpose of feather drills is to quickly make through holes of small depth. When drilling blind holes, be aware of the protruding tip of the drill bit.

For woodworking, you can purchase an expensive tool (such as a disk cutter). However, its use is not justified in all cases. For most situations where wood needs to be drilled, a tool that is easier to use and significantly less expensive will do the job. These are, for example, feather drills, which, despite their affordable cost, are highly efficient in use. A wood drill bit can be used in combination with either an electric drill or a regular screwdriver.

How to make a hole in metal without a drill? — Machine tools, welding, metalworking

Metal processing is carried out not only in industrial conditions. When performing repair work on a car, manufacturing structures on a personal plot, or carrying out home renovations, it is necessary to drill holes in the metal. At home, a hand drill is most often used.

This versatile tool requires some skill in working with hard work. You can purchase or make your own machine for drilling holes in metal, but this is not a cheap pleasure.

The technology of drilling holes in metal is to remove a thin layer of material due to the simultaneous translational and rotational movement of the drill.

The main condition for high-quality and safe (for the tool) processing is keeping the chuck axis in a fixed position. Using a machine is easy to maintain straightness, which is not the case when working with hand tools.

If you are not confident in the steadiness of your hands (this is a normal situation for an ordinary person), mechanical assistants (jigs) are required for drilling at right angles.

If you are making a hole in a thin steel plate, straightness does not matter.

How to make a large diameter hole in metal

Any design, whether in your home or in production, involves working with metal.

Often, during the operation of this material, the question may arise: how to cut a circle in metal?

It deserves attention, since the labor intensity of the work process and the quality of its result directly depend on the choice of the right tool and technology.

Methods for cutting a circle from thin metal

Metal circles

Metal can be thin or thick and durable, so a variety of tools are used to cut it.

The choice of materials and cutting technology also depends on what diameter the circle is needed and how even it should be.

Using a jigsaw

If you need a perfectly even circle, you can use an electric jigsaw to cut it out.

The work is carried out in several stages:

- First, the thickness of the metal is determined and the appropriate saw blade for the electric jigsaw is selected.

- Before cutting a circle in metal with a jigsaw, the outline of the circle that will be cut is drawn on the working plane.

- Using a drill and a drill (with a diameter of eight to ten millimeters), a hole is cut out from which work will begin.

- A jigsaw saw blade is placed in the resulting gap and cutting continues according to the intended drawing.

Cutting using this tool does not take much time and effort. Moreover, using a jigsaw you can get a circle with perfect edges. But this tool is used only for working with metal of minimal or medium thickness (for example, 2 - 3 mm).

Useful drilling techniques

To make even holes without damaging the equipment or material, you can use several techniques:

- Place a washer with coolant on the surface of the workpiece. This will ensure that the drill is evenly lubricated during the drilling process.

- If you need to make a hole with a drill in a vertical surface, you will need a ball made of paraffin. It is fixed opposite the drill.

- When working on a machine and power tools, you need to set the speed to low. At high speeds, even the cooling mixture will not help.

Conventional equipment is not a suitable option for the work. Metal burrs that appear after creating the hole must be removed with sandpaper.

To drill through stainless steel, you need to choose the right equipment. To do this, you need to understand the labeling and consult with the seller. A separate stage is the process of drilling at home. To do this, you need to practice with unnecessary workpieces and learn how to use coolant. Advice from the experts will help you avoid mistakes.

What and how to drill stainless steel.

How to make a hole in metal without a drill? — Metals, equipment, instructions

How to drill a concrete wall with a regular drill and not a hammer drill?

How to drill through a concrete wall with a regular drill? - this was probably the question that the craftsmen asked when they had to hang shelves, cornices, etc.

Concrete is a strong material and therefore can be drilled extremely poorly. How to make a hole in a wall without a drill. How to drill through a concrete wall. Hole in. Even how to drill a wall in a panel house may seem like an impossible task.

Although, if you know certain secrets, this common rumor will greatly simplify the process for you.

Choosing a tool

What is needed, the first question that a home craftsman should ask himself is not how to drill through a concrete wall with reinforcement, but with what. The main assistant here will be a hammer drill, because it is intended for stone and not concrete.

Despite this, even powerful drills cannot cope with a wall more than twelve cm wide. How to drill a hole in metal.

Although if we are talking about foam concrete, a drill is preferable, since a hammer drill will simply break it.

The quality of the drill also determines whether it will be possible to drill a hole in a concrete wall.

One of the best options is to use drills designed specifically for impact drills. Their working part is essentially a plate made of strong metal. With the help of these drills, the question of how to drill through a thin concrete wall is resolved.

There are also ring drills that have a diamond coating. How to make the right hole correctly, make a hole without a drill or hammer drill. I make holes without a drill and a deep hole in how to make it.

They are very strong, they are used in special drilling rigs, so they do not cost enough. Therefore, using them to solve the problem of how to drill a hole in a concrete wall at home is no less impractical.

Application of crowns

Often you need to get a large diameter hole in the wall for an outlet. How to drill through a load-bearing wall and then? Then crowns are used, which have metal soldering around their circumference.

Crowns come in different sizes, but the most popular are the 68-centimeter ones, which are designed for sockets at this time. How to make a hole in the turns of a drill, the third method involves doing without.

How to make a hole in glass, a hole in glass without a drill. When working with these parts, you need to turn off the impact mode of the hammer drill.

There are such bits also for drills. How to drill a hole in wood without a drill. Alas, they have a coating of a different nature - from a tungsten-cabrid alloy. They are convenient to use, since it is quite possible to drill a hole in a concrete wall with a drill without simultaneously making a hole in a tile. Such crowns are used only with powerful drills.

How to make a hole without a drill with your own hands at home

Our client has some healthy advice here:. Treatment of pain in.

Drills are an additional device for drilling into a concrete wall. How to drill a hole in a concrete wall with a hammer drill. How to drill a hole in a brick wall -. Their diameter is varied. Experienced craftsmen advise making selections based on the diameter of the dowels.

Drilling concrete with a hammer drill

What will you need, how to drill a hole

in a concrete slab using a hammer drill? The procedure is simple:

- the drill switches to impact mode, then drilling begins; the tool must be held strictly at a right angle;

- after a couple of weeks, the drill is moistened with water, this will help avoid overheating;

- If you succeed in drilling a reinforced concrete wall, the drill must be removed without turning off the device itself;

- To clean the resulting hole from dust, a drill is inserted into it several times.

Can't drill into a wall? Did the hammer drill hit something hard? This means you need to try making a hole somewhere else.

We make do with a drill

How to drill into a concrete wall

without a hammer drill?

The issue of using a conventional drill when working with concrete remains unresolved. So is it possible to drill through a concrete wall ? It’s up to you to decide for yourself.

The tool may break. In addition, the procedure will take more than just time. Drilling a hole in concrete with a drill is an option if you use a special tool - a punch. It is simple to operate: place the sharp end at the place where the hole will be located, hit it several times with a hammer, and then, of course, start drilling.

In this case, it is important to prevent the instruments from overheating.

When the drill hits an insurmountable obstacle, you need to use the punch again until the desired goal is achieved. to drill correctly

concrete wall using

a drill

. Although it takes more than just time and does not require a lot of effort, if you don’t have a hammer drill, use it too.

Diamond drilling

This is the next way to easily drill through a concrete wall. However, only professionals who have special equipment use it (a high-power electric motor is not like that).

How to drill a frame wall? This will not cause any difficulties, because diamond drilling allows you to obtain holes of large diameter and depth, and without dust that irritates the eyes. At the same time, water is supplied directly to the drill, which causes it to cool.

You need to drill several holes, but you don’t have a drill at hand, how can you make a hole without the help of a special tool. How to make a hole without a drill how to make a lathe from a drill for.

Ultimately, the resulting holes have a neat design, and the appearance of cracks is completely eliminated.

How to drill into tiles without cracking? See here. How to drill through a concrete wall. Hole in concrete with a hammer drill. What is a jig for drilling holes? Find out further.

Expanding the hole with a feather drill

Please note that the example is shown on wood. In fact, widening a hole using feather drills is a completely ignoble task, and only for the reason that the feather drill will have nothing to grab onto. But there is a very simple way to carefully enlarge the hole. It also happens that a hole was made, for example, with a No. 20 pen, but then something was changed in the project, and the hole should be made larger, up to 2.5 cm in diameter, and in such a way that the center is not displaced. The whole problem is that a drill of a similar diameter cannot be inserted into a drill, and to expand with a feather drill, it must be rested against something so that the center is not displaced.

Look at the photo - there is a hole, it was made with a pen drill with a diameter of 2 cm, and then you need to rest the tip of a pen with a diameter of 2.5 cm. But this cannot be done, and therefore the tip will dangle along the sides of the hole, and then you will not be able to center the drill itself . If the pen does not have support from below, but its tip has nothing to rest against, but if so, we suggest resting the edges of the pen drill. In this case, you will need to drill a hole with the first No. 20, and then widen it with a No. 25 pen. Take the other pieces of wood and drill a hole with a #25 feather. Next, we place the board over the small hole by 2 cm and center it. This can be done even by eye.

See what it will look like. As you can see, the larger diameter feather bit will then hold the sides of the wide hole and the feather can be drilled through the center of the smaller diameter hole. Next, drill, while holding both boards together (or better yet, secure all the boards with clamps, and then the drilling will be much more accurate). The feather will begin to rest against the sides of the wide hole, and it will not move to the sides. In fact, there is nothing difficult, but sometimes this method helps a lot. In order to fully understand the process, we suggest you watch the video.

How to drill hardened steel at home

To improve the basic characteristics of the metal, it is often hardened. This technology involves increasing the hardness of the product due to strong heating of the metal and its rapid cooling.

In some cases, after heat treatment it is necessary to perform drilling. By increasing this characteristic, drilling hardened metal becomes more difficult.

Let's take a closer look at all the features of drilling hardened steel.

How to drill through hardened steel

Drilling a hole in hardened steel

The widespread question of how to drill through hardened steel can be associated with the fact that when using conventional technology, the tool quickly becomes dull and becomes unusable. That is why you need to pay attention to the features of drilling hardened alloy. Among the features of the technology, we note the following points:

- It is necessary to properly prepare the hardened workpiece.

- In some cases, a special tool is required.

- Coolant is being used.

If necessary, you can make a drill for hardened steel with your own hands, which requires certain equipment and skills. However, in most cases, a purchased version is used, since it will cope better with the task when cutting hardened steel.

Hardened steel drilling process

Nuances when drilling

The technology in question has a fairly large number of features that need to be taken into account. Drilling of hardened metal is carried out taking into account the following points:

- Before carrying out work, pay attention to the hardness of the surface. This parameter is used to select the most suitable drill. Hardness can be determined using a variety of technologies.

- During drilling, a large amount of heat is generated. This is why rapid wear of the cutting edge occurs. In this regard, in many cases, cooling liquid is supplied to the cutting zone.

- When cutting difficult-to-cut material, it is necessary to sharpen the cutting edge from time to time. For this, a conventional sharpening machine or a special tool is used. Only diamond-coated wheels are suitable as an abrasive.

Steel Drilling Tool

There are a variety of methods for cutting hardened steel. Some of them significantly simplify the processing. Only by taking into account all the nuances can the quality of the resulting hole be improved.

Useful drilling techniques

A variety of technologies can be used to work with hardened steel. The most common technologies are characterized by the following features:

- Surface treatment with acid. This technology is characterized by long-term use, since it takes quite a lot of time to reduce the surface hardness. Sulfuric, perchloric or other acid can be used for etching. The procedure involves creating a lip that will contain the substance used in the cutting zone. After prolonged exposure, the metal becomes softer, and it will be possible to drill using the conventional version.

- You can use a welding machine to achieve your goal. When exposed to high temperatures, the metal becomes softer, which greatly simplifies the procedure.

- Most often, a special drill is used. There are versions on sale that can be used for processing hardened steel. In their manufacture, metal with increased resistance to wear and high temperatures is used. However, the complexity of manufacturing and some other points determine that the cost of a special tool is quite high.

In addition, to achieve this goal, a punch is often purchased. It can be used to make a small hole, which will simplify further drilling.

Use of lubricants

When drilling through hardened steel, serious friction occurs. That is why it is recommended to purchase and use various lubricants. Among the features of this processing method, we note the following points:

- First, the drilling area is processed. A small amount of lubricant is applied to the surface where the hole will be located.

- Oil is added to the cutting edge. To process hardened steel, a small amount of the substance is required, but it must be added from time to time, since it scatters when the tool rotates.

- During work, it is recommended to take breaks to cool the cutting surface and the surface being processed.

Lubricating steel with special oil

Special oil not only simplifies drilling, but also increases the service life of the tool used.

This is because oil can reduce the temperature of the cutting edge.

Twist drills, which are represented by a vertical rod with two grooves, have become quite widespread. Due to the specific arrangement of the grooves, a cutting edge is formed. Among the features of the choice, we note the following points:

- The pobedite drill bit has become quite widespread. It can be used to work with various hardened alloys. However, a surface with too high hardness cannot be processed with such a tool.

- The choice is also made based on diameter. It is worth considering that it is quite difficult to obtain a large diameter hole. The larger diameter version is much more expensive due to the use of a large amount of material in its manufacture.

- Attention is also paid to the sharpening angle, the purpose of the product and the type of material used in manufacturing. For example, cobalt versions are characterized by higher resistance to high temperatures.

- It is recommended to pay attention to products exclusively from well-known manufacturers. This is due to the fact that Chinese versions are manufactured using low-quality materials. However, such an offer is much cheaper and can be used for short-term or one-time work.

- When choosing a drill, you can be guided by the markings. It can be used to determine which materials were used in production. The diameter of the hole that can be obtained when using the tool is also indicated.

Drill for hardened steel

In a specialized store you can find almost everything you need to carry out the work. However, the fairly high cost of the product and some other factors determine that some decide to make a drill themselves from scrap materials. Similar work can be done if you have the required tools.

If necessary, a drill can be made from hardened steel. Among the main recommendations for carrying out such work, we note:

- Rods are selected that are made from tungsten and cobalt alloys. People call this metal victorious. Compared to a conventional drill, this version is characterized by increased wear resistance.

- To process the workpiece, you need to secure it in a small vice. Otherwise, the work will be quite difficult.

- To sharpen such a surface, a diamond stone is required. The usual one will not withstand long-term work.

- The end surface is sharpened to create a surface that resembles a flat-head screwdriver. The cutting edges are then sharpened to produce a sharp tip.

In order to reduce the degree of surface machinability, oil is added. This ensures long-term processing due to reduced friction and lower temperature.

Homemade drill bits

In conclusion, we note that processing of hardened steel should be carried out exclusively with the use of special tools. The work requires a drilling machine, since a manual one will not allow you to get the required hole.

, please select a piece of text and press Ctrl+Enter.

What you need to know about drilling holes in metal

You can secure a metal sheet or part using a variety of fasteners. However, you need to make holes for them. Drilling holes in metal requires a person to use special tools. To carry out the work without difficulty, you need to be able to choose equipment and work with workpieces of different sizes.

Drilling holes in metal

Equipment types

Drilling begins with preparing tools for work. You can make holes using a screwdriver, drill or a special drilling machine.

To make a hole, you need to select the appropriate equipment. For metal workpieces, you need to choose specialized equipment that is suitable specifically for this material. This is due to the fact that equipment for wood, concrete or ceramic tiles have different sharpening and shape. Tooling for metal products is marked with the letters HSS.

The working part of the tool is coated with titanium nitride coating, which increases their strength and wear resistance. For hard steels, a different tooling is used, which is designated P18. The strength of the tool increases when cobalt is added to its composition. An example of marking is P6M5K5.

To drill alloy steel, drills with a tip made of carbide are used. With their help, you can drill any metal workpieces, however, due to the high price, this is not cost-effective.

When the hole is made, you can select a drill for the thread. Its diameter will depend on the previously used equipment. To make holes of different diameters in thin metal sheets, you can use cone drills.

Is it possible to drill with a drill in concrete?

Situations often arise when it is difficult to find a tool for drilling metal products at a construction site, but there is equipment for working with concrete. You cannot make holes of large diameter or in thick metal sheets with concrete drills. Otherwise, you may break the equipment or damage the surface being processed.

How to drill with a step drill?

On sale you can find stepped structures for creating holes in metal of various diameters. Several drills of different diameters are fixed on one axis. They are designed to create holes of various sizes in thin sheet metal. When working, do not rush or put too much pressure on the drill handle.

Is it possible to drill with a Pobedit drill?

Any master of finishing work will tell you that drilling metal with Pobedit equipment is unacceptable. Pobedite drills are designed for hard and, at the same time, brittle materials. These include natural stone, brick, concrete. When it hits metal, the drill will hit the surface and damage it, but there will be no hole.

How to drill large diameter holes?

Drilling large holes in metal requires the use of appropriate equipment. You can do the work in several ways:

- Crown for metal surfaces. It is a circle of the required diameter with sharpened edges. There is a drill in the center that pierces the metal. Next, at low engine speeds, the bit makes a hole of the selected diameter. During work, it is necessary to use forced cooling of the sharp edges of the crown and the surface being treated.

- Multi-stage operation. This implies the use of several metal drills of different diameters. Work begins with equipment of the smallest diameter and increases as drilling progresses.

- Cone-shaped equipment (stepped). Designed for working with thin sheet metal.

Builders recommend using crowns. However, when working with them, it is necessary not to increase the speed and ensure that all the teeth running around the circumference are intact.

How to avoid dulling a tool?

The tool becomes dull because it overheats during use. To maintain sharpness, drilling should be done at low speed. There is no need to press the power button all the way down. When drilling thick workpieces, you need to use coolants or pastes.

If there is no cooling lubricant, machine oil can be used instead. Coolant keeps the tool from overheating and reduces friction.

How to drill metal correctly?

When you turn on the tool, the drill may slide to the side, which makes it difficult to make a hole in the selected location. You can cope with this problem using a core.

It is a metal cylinder with a sharp point at one end. It is necessary to attach the sharp end to the marking and hit the back side of the core with a hammer.

There will be a notch on the metal through which a hole is drilled. DISASSEMBLY 3. Drilling metal

Drilling thick workpieces

Not many novice craftsmen know how to drill a hole in thick metal. Deep drilling is more difficult than usual. In production, it is carried out using lathes. In them, the workpiece is fixed in a movable spindle, which rotates it.

If it is not possible to use industrial equipment, you can drill a deep hole using a drill. To do this, you need to purchase special guides for power tools. Additionally, it is necessary to use machine oil for cooling. During operation, you need to stop periodically to clean out the chips and allow it to cool.

How to drill with a drill?

Drilling metal with a drill requires following some recommendations:

- To make a hole you will need an electric drill, a core punch, a hammer, machine oil and safety glasses.

- Initially make markings.

- Wear safety glasses.

- When the pressure on the drill is low, you need to select the low speed position and start working.

- Don’t forget to water the area being treated with coolant.

If you follow the technology and use high-quality tools, you can make holes of different diameters and depths. To drill straight holes or accurately select the depth, you can use a device called a “depth stop.” It is attached to an electric drill and adjusted to the desired depth.

How to drill with a screwdriver?

You can drill metal workpieces not only using industrial equipment or an electric drill, but also using a cordless screwdriver. This power tool is low power. Because of this, it is suitable for drilling holes of small diameter and depth.

Drilling is performed using industrial equipment and power tools. It is important to choose the right equipment and take into account the depth and diameter of the hole. To ensure that your equipment lasts longer, you should use coolant. You need to drill perpendicularly to avoid damage to the workpiece or tool.

Hassle-free drilling

During work, you can use a small section nozzle, as well as a used grinding wheel for an angle grinder. It is important to remember that it should have a smaller diameter than the hole being created.

Read also: What is coolant in production

Before carrying out work, a circle for the hole is marked on the workpiece, and the second circle will be smaller than the first by a distance equal to the diameter of the drill used. After this, 2 holes are marked in opposite places of the circle. It is necessary to retreat 3 mm from them and mark the places for drilling. Thus, drilling occurs along the entire drawn circle. If additional work is necessary, some areas will have to be processed with a chisel. This will create jagged edges that will then need to be filed down. It is important to ensure that during work the circumference does not increase, i.e. do not expand the planned diameter.

Cone drill

The described types of drills are made from tool steel. The shanks of such products can be hexagonal or cylindrical. The cutting edge removes all burrs, so the edge is smooth. The end of the drill head has a sharpened point that allows pre-drilling of the material.

Using these products you can:

- create cuts with a diameter of up to 30 mm;

- forget about jagged edges;

- carry out boring of various diameters without changing the nozzle.

Thanks to step drills, you can create cuts of various diameters in sheet steel up to 4 mm thick. Unlike a simple cone drill, when using such products, the drilled diameter is fixed.

The disadvantages include:

- the need to use tools with low speeds and high torque;

- sensitivity even to small distortions.

Despite these disadvantages, this attachment allows you to conveniently work with metal plates, quickly drilling circles of the required diameter.

Metal crown

Metal processing is a complex process, so such work is usually carried out using specialized equipment. To carry out work at home, you can use core drills.

Such products allow you to make the edges round and centered. In this case, a standard drill is used for drilling. The products consist of several parts:

- crown;

- centering attachment;

- product shank;

- screws that are necessary for fastening.

When using a core drill, the speed of work increases up to 10 times. Another advantage is the ability to accurately drill in the range from 1.2 to 15 cm.

In this case, there is no need to perform alignment during drilling. It is also worth noting that such drills have higher wear resistance compared to twist drills.

Before starting work, a centering drill is installed in the center of the circle, after which drilling is carried out. After this, the drill is retracted and the work is carried out with a crown.

How to make a hole in metal without a drill

How to drill concrete

wall with a regular drill and hammer drill?

How to drill through a concrete wall with a regular drill? - this is the question that the craftsmen probably asked when they had to hang shelves, cornices and so on.

Concrete is a strong material and therefore can be drilled very poorly. Even how to drill a wall in a panel house seems an unsolvable problem.

Although, if you know certain secrets, this process will be significantly simplified for you.

How to make a hole in a concrete wall without a hammer drill and a hammer TEST!

If you need to attach a baguette in your house, but you don’t have a jack drill

, then the hole can

be made

using a conventional

The eyes are afraid. hands do || How to “drill” a hole in concrete WITHOUT A PERFORATOR

The eyes are afraid. hands do || How to drill a hole in concrete WITHOUT

PERFORATOR My drill does not have a single drill

There are also such bits for drills. But they have a coating of a different nature - from a tungsten-cabrid alloy. They are convenient to use, since you can drill a hole

in a concrete wall and at the same time making a hole in the tiles is quite possible for her. Such crowns are used only with powerful drills.

Drills are another tool for drilling into a concrete wall. Their diameter is varied. In the vast majority of cases, when installing hidden electrical wiring, there is no way to do without such a dirty and noisy procedure as gating. Experienced craftsmen advise making a selection based on the diameter of the dowels.

Do-it-yourself restoration of parts holes

Restoring holes with your own hands can be done using the surfacing method:

- Prepare the spare part. The unit that needs to be repaired or restored must be cleaned of rust or dirt.

- Boring the hole is done on a lathe or milling machine using cutters and milling cutters. Clean the surface.

- Carry out surfacing of the alloy build-up by arc welding. Apply the suture wider, with a “margin”.

- Grind the resulting weld seam. Cut a thread in the element with a tap or drill a hole for the axle or hub.

- Clean off all unnecessary “growths” and rudiments. The part can be used for its functional purpose.

The process of restoring gaps using surfacing is much more economical than purchasing new components. It is used both for repairing very large mechanisms (cranes, graders, conveyor systems) in production, and for restoring elements for cars and household appliances independently, or with the help of specialists. Our company is ready to provide you with metalworking services of any complexity.