The rotating spindle head of the machines is equipped with a mechanism for manual axial movement of the spindle sleeve, which allows processing of holes whose axis is located at an angle of up to ±45° to the working surface of the table. The drive power and high rigidity of the machines allow the use of cutters made of high-speed steel, as well as tools equipped with plates made of hard and super-hard synthetic materials.

The 6P13 vertical milling machine differs from the similar 6P12 machine in the installed power of the main movement and feed motors, the dimensions of the working surface of the table and the amount of table movement.

Design features:

- mechanized tool fastening in the spindle;

- proportional feed deceleration mechanism;

- a device for periodically adjusting the size of the gap in the longitudinal feed screw pair;

- safety clutch protecting the feed drive from overloads;

- braking of the horizontal spindle when stopping using an electromagnetic clutch;

- protection device against flying chips.

- various automatic work cycles;

- wide range of spindle speeds and table feeds;

- high drive power;

- high rigidity;

- reliability and durability.

Technological features:

Purpose and scope of vertical milling unit

6р13 machines are capable of processing parts along complex trajectories. The technical parameters of the equipment allow milling horizontal-vertical and inclined surfaces.

The equipment is equipped with a vertical quill spindle. Capable of processing workpieces made of steel, cast iron, non-ferrous, as well as difficult-to-process metals. To work on this unit, mainly face and end mills are used.

The machine has the ability to process:

- vertical planes;

- horizontal;

- inclined surfaces;

- grooves;

- corners;

- framework;

- curved surfaces.

The machine has a copying device specifically for curved surfaces. The scope of application of the machine is single and serial production.

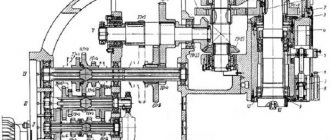

Device

The version in question is no longer mass-produced. However, finding spare parts is not difficult. Most modern analogues have similar units and components that are interchangeable.

Main parts of the machine:

- The frame is in the form of a bed.

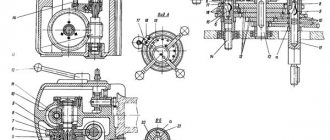

- Rotary type head.

- Speed box.

- Feeding block.

- Switching unit.

- Console part.

- Mobile table with slide.

- Electrical components and mechanisms.

The layout of the unit is also made in a standard style. On the frame there is a support with a slide that serves to move the table vertically. A headstock with a speed unit and electrical equipment is mounted on it. The headstock is aggregated with a spindle equipped with a device for rotating the cutting tip with an angle of no more than 45 degrees. The spindle is in a static state during the working process. The table is located directly above the head, equipped with feed units, electronic and mechanical controls, and slides for forward and lateral movement.

Specifications

The main parameters are similar to the previous model of this series 6р12. The main characteristics include:

- distance from the spindle axis to the working surface – 30-500 mm;

- to the axis of the spindle guide – 4 cm;

- manual movement along – 10 cm;

- across – 32 cm;

- vertically – 42 cm;

- mechanical movement along – 1 meter;

- across – 30 cm;

- vertically – 40 cm.

The maximum weight of a part that can be processed on this machine is up to 300 kg. The spindle rotates at a frequency of up to 1600 rpm.

Manufacturer

The equipment is manufactured at the Gorky Milling Machine Plant. It began operations in 1931. Engaged in the production of universal milling machines of various models, equipped with a universal digital display (UNC) and having numerical control - CNC machines.

Provides a machine passport, including the necessary technical documentation.

general description

Unlike most other similar machines, 6р13 equipment has the ability to travel along a curved path. For this, a copier is used, and a special electrical sensor is used to prepare and describe the trajectory. Based on this machine, several modifications have been created that are equipped with numerical control.

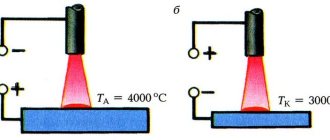

The rotating head is equipped with a special mechanism for manual, axial movement of the spindle sleeve, with the help of which holes with an inclination angle of 45° are processed. The machine has enough power to use high-speed metal cutters when working.

Machine operation

The 6P13 milling machine operates according to the classical scheme, in which the main working movement is the rotation of the cutter, and the auxiliary movement is the feeding of the table with the workpiece or part fixed on it. The operating mode in machines of the old design is calculated manually and set using adjusting handles and levers. In more modern modifications, adjustment and control of the milling process is carried out by CNC, and it becomes possible to work according to a template thanks to a copying device.

Manual control

It is carried out using the main and backup flywheels for longitudinal and transverse movement of the table, a handle for manual vertical movement, and a spindle sleeve extension flywheel. After switching the corresponding toggle switch, it becomes possible to work in an automated mode, where a choice of several preset feeds is available. A number of control mechanisms make changes to the direction of rotation of the spindle, its angle of inclination, rotation speed, lighting and cooling modes. The general start of the machine and the spindle start are carried out separately; emergency stop buttons are duplicated in convenient places.

The 6P13 is characterized by relative ease of operation, is not too demanding on the milling operator’s qualifications and is intuitive for an experienced worker. These qualities, coupled with reliability and high quality of processing of materials, determined the need for a machine in various sectors of the national economy.

The most effective use of the machine is in small engineering firms and car repair enterprises.

Location of components

Basic structural mechanisms 6р13:

- bed;

- swivel head;

- gearbox;

- gearbox;

- switch box;

- console;

- work surface with slide;

- electrical equipment.

The basic unit of the machine is a cast frame on which all parts and components of the mechanism are fixed. The gearbox transmits 18 possible speeds to the spindle head. The number of spindle revolutions changes due to the movement of three blocks with a gear structure along the splined shafts. The rotating head is fixed in a standard ring groove and is attached to it with 4 bolts.

Description of the mechanism

As mentioned above, the machine is equipped with software that allows:

- carry out diagnostics and ensure performance;

- install new and remove existing programs and even edit their data if necessary;

- configure the chain of required functionality commands;

- fully control the operating process of the unit;

The software allows you to control the functioning of the entire work process, from the start of finishing work to completion. Using the software, the operator receives information about all errors and breakdowns, other system parameters, basic information regarding the operation, as well as additional information. You can view information about installed software and, if necessary, install new software or change functionality.

This software is only part of the entire electrical equipment of a vertical milling machine. Its operation is provided by a three-phase electrical network with a voltage of 380 volts. The control elements are equipped with a protection mechanism. Operation can also be ensured with the help of special machine converters and even stabilizers. This protects the device from damage due to electrical voltage surges.

The control station is started by the introductory automatic machine. Its operation is controlled by handles and built-in levers located on the outside of the equipment.

The device operates normally at voltages:

- 110 volts - main operating circuits;

- 55 volts - the circuit that controls the stop of the router;

- 48 volts - motor;

- 24 volts - main lighting;

- 380 volts is a power circuit that has three phases.

The feedback operates using a generator, and the speed - a tachogenerator built into the electric motor.

Location of controls

The main control elements of the equipment in question:

- various clamps: spindle, slide, console, located on the frame and on the guides;

- buttons for start, spindle impulse, stop, feed switching;

- switches for automatic or manual control;

- head rotation mechanism;

- mechanism for operating in automatic mode;

- flywheels for extending the sleeve and for moving the machine.

Kinematic diagram

The spindle of the 6P13 milling machine is driven by an electric motor using a stepped seven-shaft gearbox located in the upper part of the machine. It also performs the functions of adjusting the rotation speed. The table is driven through a complex multi-shaft mechanism from a low-power electric motor, or manually using mechanical control devices. The location of these and some other elements is indicated on the kinematic diagram of the machine.

Types of milling units

There are several main types of cantilever milling machines:

- Horizontal units are characterized by a spindle positioned horizontally.

- The spindle does not change its location relative to the desktop during operation.

- The vertical variety of such machines is distinguished by the corresponding position of the spindle.

- There are universal cantilever milling machines. Their important difference is the ability to arbitrarily rotate the desktop.

Universal cantilever milling machine

There are widely universal cantilever milling machines. They have an additional spindle head that can be easily positioned at different angles relative to the main spindle head.

Horizontal and vertical machine types are the most common options. Another feature by which machines are classified is related to the size of the working surface, which is provided for its operation.

The designation consists of four characters. The first number indicates that we are talking about milling machines, the second indicates the generation to which the equipment belongs (in this case it is P).

1 – characterizes the subtype – vertical milling machine. The last number indicates the size of the desktop. The 6P13 machine is designed for a size of 400 by 1.6 thousand mm.

Purchase terms

To find out more information and buy a vertical milling machine 6P13 (6T13), you can contact us by phone +7 (4852) 66-40-25 , through the order form on the website or by email This email address is being protected from spambots. You must have JavaScript enabled to view. The price depends on the configuration and design. We provide a 12 month warranty on new machines. Under an additional agreement, we carry out transportation and commissioning work at the customer’s premises.

Peculiarities

Detailed technical characteristics of 6P13.

- The main movement drive has a power of 11 kW, the feed drive has a power of 3 kW.

- The maximum parameters of the processed parts are weight - 630 kilograms.

- Dimensional characteristics - 2.57 thousand mm in length, 2.252 thousand mm in width, 2.43 thousand mm in height.

- There are 22 table feeds. Longitudinal and transverse are in the range from 12.5 to 1.6 thousand millimeters per minute.

- The vertical feed speed often varies between 4.1 and 530 millimeters per minute.

- The rotation angle of the spindle head is possible up to 45 degrees.

- The distance from the end of the spindle to the table can be easily changed from 30 to 500 millimeters. The spindle axis is 46 cm away from the frame.

- The table position can change within the following limits: longitudinal by 1 thousand mm, transverse - 400 mm, vertical - 300 mm.

- One division of the dial corresponds to a movement of 0.06 millimeters. This applies to movements in length and width, relative to vertical marks.

- Weight is 4.3 thousand kg.

Application

This unit has a vertical spindle; the part is capable of performing cross-shaped movements in the horizontal plane. The equipment is often used for processing products made of various metals: cast iron, non-ferrous metals, steel and difficult-to-cut metals. Face mills or end mills can be used.

End mills

Available to work with a wide range of machined surfaces. These can be not only horizontal planes, but also inclined and curved ones. It is easy to process corners, grooves, frames. A special copier is provided, it is used for precise processing of complex surfaces. Manipulation avoids chips and defects.

The equipment has high power and is characterized by high rigidity. These qualities allow processing with a high-speed steel cutter. It is allowed to use a tool equipped with plates made of hard synthetic materials.

This machine can be used for both serial and individual production. The design includes a rotating spindle head, which can be easily installed at different angles to the main spindle.

There is manual control of horizontal movement. This method makes it possible to process holes that are located at an angle of no more than 45 degrees from the main axis of the spindle.

Brand

The 6P13 unit is an improvement of the previous 6P12 model. The description of the differences is as follows:

- Its main drive and feed motors are more powerful.

- The desktop in this model is larger in size compared to the previous model.

- The amount of table movement in 6P13 is greater.

- Increased set of spindle rotation numbers.

- Increased main engine power.

The model name consists of four characters, each of which has its own meaning.