a real owner do without a chainsaw? This is nonsense! Many small and not so small tasks will stop without this tool: cutting branches, pruning bushes, small carpentry repairs, etc. What can I say, you yourself know better how much you need a chainsaw.

And the popular chainsaw Partner is named so for a reason - it helps in the household just as well as a partner. And if this chainsaw breaks, it’s very difficult without it. Fortunately, you can try to repair the Partner chainsaw yourself. Let's see in what cases this is possible.

Why it won’t start and what to do

There may be several reasons why a chainsaw starts poorly or does not start. To install them, you need to diagnose the device. Possible causes of problematic startup:

- there is no spark at the spark plug;

- poor condition of the air and fuel filter;

- poor fuel supply and exhaust channel performance;

- The breather, which is located on top of the tank, does not function well.

Often carbon deposits appear on the electrodes of the spark plug and the tool does not start. Therefore, first check the spark plug. If the reason is not hidden in it, then the remaining elements are examined.

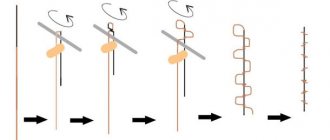

- To test the ignition spark, you need to remove the spark plug. To do this, remove the tip located on the high-voltage wire, take out the spark plug and put the tip back on. The spark plug is applied to the cylinder and the starter is started. The engine ignition unit is working properly if the electrodes produce a spark when turned on. When there is no spark, you need to use a feeler gauge to adjust the distance between the electrodes or clean the entire part. For the chain saw to start, the distance between the electrodes must be from 0.2 to 0.5 mm.

- To check the fuel supply, you need to fill the tank with a fuel mixture. The system pipe is disconnected from the carburetor and pumped up. Fuel flows in spurts when the system is working properly. If the supply is weak, clean the channel through which the fuel or filter is supplied. When gasoline leaks appear under the tank cap, this means that the tank is full and can affect engine performance.

- The fuel filter is checked by disconnecting it from the carburetor. The gasoline supply channel is disconnected and fuel is pumped. If there is no pressure in the pipe, then drain the fuel from the tank and pull out the filter cartridge. It is cleaned or replaced with a new one.

- The breather valve (valve), located on the fuel tank cap, is designed to equalize the air pressure, which allows gasoline to flow freely into the carburetor. Sometimes it becomes dirty, air does not flow inside and a vacuum is created, which does not allow the chainsaw to start. The hose through which fuel is supplied is disconnected from the carburetor and then checked. Fuel should flow out of the disconnected hose. If this does not happen, then clean it with a simple needle or a stream of air under high pressure.

Partner 350 chainsaw device

The Partner model in the 350th configuration stands out for its excellent selection of components and high build quality. The basis of garden tools is a 2-stroke, 1-cylinder internal combustion engine, running on a mixture of AI-92 gasoline and motor oil. The piston group of the engine is forged and coated with a chrome alloy to extend the working life of the internal combustion engine. The factory engine includes a proprietary CCS filter, which is distinguished by its ability to capture the smallest foreign particles, preventing them from entering the fuel.

Partner chainsaw differs from its analogues in its simplified starting, which was achieved thanks to a modified starter with a self-cleaning drum, a professional fuel pump and durable electronic ignition. To pre-pump the used fuel into the cylinder, the model is equipped with a primer.

For the safety of the operator while operating a running chainsaw, the Partner company has equipped the garden tool with a high-quality inertia brake, which is instantly activated when the saw set hits a nail or any other foreign object.

The working parts of the Partner are a metal bar and a chain. Their tension is carried out using two keys, without the need to remove the protective cover of the plastic case.

One of the main advantages of the Partner 350 chainsaw is the convenient location of the controls necessary for operation. The throttle lever, combination switch and factory starter cable are located at the rear of the tool, making it much easier to operate in tight spaces.

Checking the breather and cleaning it.

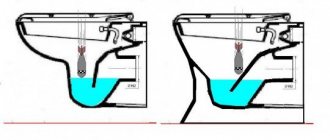

The breather is another element, due to improper operation of which the chainsaw may not start or stall during the sawing process. This element is located on the fuel tank cap in the area of the air hole. This is a kind of valve that does not allow gasoline to leak out and equalizes the air pressure necessary for the free flow of fuel into the carburetor.

If the breather is dirty, the running chainsaw stalls, and when started, it refuses to start. The whole point is that air stops flowing through the hole. As a result, negative pressure (vacuum) is created inside the fuel tank, preventing the flow of gasoline to the carburetor.

Identifying the problem is quite simple. Disconnect the fuel supply hose from the carburetor and see what happens to the gasoline. If it flows freely in a good stream, then everything is in order with the breather. If it is absent or it flows weakly and intermittently, then the cause is identified - the breather is clogged with dirt. The problem can be solved by cleaning the air hole with a regular needle or a powerful jet of compressed air.

When the engine refuses to work, but there is a spark at the spark plug and fuel is flowing, you should check the ignition.

Checking it is not at all difficult: unscrew the spark plug, adjust the gap between the contacts, connect it to the wire and press it against the cylinder body. After this, watch for a spark to appear.

We determine the availability of fuel and its supply.

First, you need to make sure that there is a fuel mixture in the tank of the chainsaw that does not want to start, and that it is properly supplied to the carburetor. With a full tank, check how the mixture is supplied through the gas line. We disconnect the fuel system pipe from the carburetor and try to pump it up. In case of complete order, when pumping, gasoline will be supplied jerkily in accordance with the standards set by the manufacturer. Weak fuel supply or its absence can result from:

- The fuel supply channel is clogged;

- Fuel filter clogged with debris.

Often the cause of poor starting of a chainsaw can be a too full tank. In this case, you should pay attention to the presence of smudges under the saw housing cover. If they are present, then look at the connection of the gasoline supply pipe to the carburetor. Most often, it is squeezed out by pressure when screwing on the tank cap, which is tucked right under the neck, which prevents the engine from starting.

The quality of the fuel mixture can also be one of the reasons why the chainsaw does not start. If, after completing the work, you do not drain the remaining gasoline and leave the tool for long-term storage (more than 2 weeks), then the processes of resin formation and polymerization of the components will begin to occur inside the tank. What can cause carbon deposits to appear on the piston, rings and cylinder liner. Therefore, always prepare the mixture in only the required quantity before work.

If it starts and stalls

When a chainsaw starts and stalls, it is due to the carburetor or other parts. Causes of malfunction:

- Fuel is not getting to the engine well. This occurs due to a clogged breather.

- There is not enough fuel in the tank. By tilting the tool sideways, the remaining fuel flows into one place. Because of this, the saw stops working.

- Fuel is of poor quality.

- The spark plug insulator overheats when poor contact is made between the wire cap and the spark plugs. The contact between them becomes worse due to carbon deposits or mechanical shear.

- Spark plugs are faulty.

- Fuel does not flow well to the carburetor through the fuel filter or pump. As soon as the tool starts to increase speed, it immediately stalls.

- If the air filter is dirty, the engine cannot withstand high loads and stops.

- Insufficient or no lubrication in the chain.

Stalls when you press the gas

If the chainsaw stalls when you press the gas, then you need to inspect the gasoline and air filters, as well as the fuel pump.

- During operation, the air filter becomes severely clogged, and when you press the gas, the tool stops working. The filter is dismantled, cleaned or washed with warm water, dried thoroughly and only then installed back. Then disconnect the fuel hose screwed to the carburetor. Gasoline should flow out through it. The hose is cleaned or replaced with a new one if the liquid does not leak out. The filter is working properly and you don’t need to check it if the gasoline flows well.

- The chainsaw stalls - the gasoline pump may have worn out. If gasoline flows through the walls of the pump, it means that the device has stalled because of it. This part is replaced with another.

In order for the chainsaw to start, you need to accurately determine the cause of its malfunction, and then try to fix it yourself. If the problem is not found or you cannot fix it yourself, then it is better to seek help from specialists.

Chainsaw Partner 350 repair instructions. Chainsaw Partner 350: faults and their elimination

One of the main features of this saw, its users note durability of operation with a minimum number of failures. And yet they happen. To determine why the saw stopped working, you need to perform basic diagnostics.

If the saw does not start, then:

- there is no spark on the spark plug;

- fuel is not supplied;

- no air coming in.

First you should check for the presence of a spark: by unscrewing the spark plug, connecting it to the high-voltage wire and placing it on the cylinder, pull the starter. If there is a spark, then clean and adjust the gap on the spark plug (0.5 - 0.65 mm). If it is not there, then you need to change: either the flywheel or the coil (magneto). In addition, the spark plug itself may fail or the high-voltage wire may break.

The next step is to check the fuel supply. To do this, you need to disconnect the supply hose from the carburetor and check its presence. Absence may indicate that the fuel filter or delivery system is clogged. The carburetor itself may also become clogged.

If you do not have experience in repairing and cleaning it, entrust this work to specialists.

If the air supply deteriorates, the saw should start, but it will not work well. Remove and wash the air filter. Put it back in place only after it has completely dried.

If the saw starts well, idles and stalls when gas is supplied, the muffler is most likely clogged. Remove, disassemble, wash, put back and continue working.

You can also easily change the saw bar and chain, carburetor, starter, oil pump, ignition and clutch with your own hands.

And you will be able to replace a broken starter cable after watching this video:

We recommend entrusting more complex chainsaw repairs related to replacing the cylinder-piston group or crankshaft to specialists, although if you are familiar with two-stroke engines, then this work will not be difficult for you, and spare parts for Partner chainsaws are not in short supply in Russia.

To enlarge a picture, click on its thumbnail.

We advise you to regularly monitor the serviceability of the safety group: brake and chain catcher. Remember that the saw should be thoroughly cleaned of small chips. It can not only clog technological holes in the oil pump and other places, but also interfere with the operation of the brake.

Operating Instructions for Partner 350

In this manual you will find not only a detailed description of the saw, but also basic techniques for working with the tool. We would like to draw your attention to the fact that this chainsaw can run on AI95 or AI92 gasoline with the addition of oil for two-stroke engines in a ratio of 1:50.

Chainsaws Partner 351 – carburetor adjustment

Before you start setting up the carburetor of the Partner saw with your own hands, you will need to clean all the mechanisms of the tool from dirt and carbon deposits. The best way to do this is to use a compressor with a blow gun or a can of compressed air.

The Partner 351 chainsaw is equipped with three adjustment bolts located under the holes in the upper left part of the body. If you are adjusting the carburetor of a model for the first time, it is better to remove the cover. If the owner of the tool already has experience in independently adjusting the unit, then the standard housing cover can be left in place.

The left bolt is responsible for adjusting the amount of fuel supplied to the carburetor. The right bolt, accordingly, adjusts the quality of the air-fuel mixture. For convenience during adjustment, the manufacturer designates the adjusting bolts with the Latin letters H and L, where the letter L marks the quantity bolt, and the letter H marks the quality bolt. The third basic adjustment bolt is designed to adjust the position of the throttle valve when the engine is idling.

If for some reason there are no markings on the body cover of the Partner 351 saw, then you need to independently determine which bolt is responsible for the position of the throttle. To do this, you will need to remove the cover and examine the bolts. The one on which the spring is installed will be the bolt responsible for adjusting the position of the damper.

Before adjusting the carburetor, all adjusting bolts must be set to the fully tightened position. After this, they will need to be loosened by exactly a fifth of a full turn. Subsequent adjustment of the Partner 351 carburetor is performed in the following order:

- First you need to start the saw motor and let it idle for a few minutes. During this time, the engine should warm up;

- After heating the cylinder, you will need to turn the bolt marked L in the clockwise direction. As soon as the engine starts to operate at maximum speed, the bolt must be turned 1/4 in the opposite direction. In this position of screw L, the chainsaw should operate stably at idle speed. If the engine runs intermittently, its operation can be corrected by turning the T bolt in different directions;

- Then you need to start turning screw H until the saw motor reaches maximum speed. Once they are reached, the bolt will need to be turned 1/4 turn in the opposite direction;

- If, when the engine is running at maximum speed, the Partner 351 chainsaw chain begins to rotate on the bar, then its movement must be stopped by turning screw T.

To more accurately adjust the maximum speed of the saw motor, it is best to use a tachometer when adjusting the carburetor. Without it, you can only determine the operation of the engine by ear.

How to change the throttle cable on a chainsaw Partner. Repair of Partner P351XT chainsaw. Episode 1 Disassembly

If the saw does not start, then:

- there is no spark on the spark plug;

- no fuel;

- no air comes.

First, check for spark: unscrew the spark plug, attach it to the high voltage wire and slide it onto the cylinder, pull the starter. If there is a spark, clean and adjust the gap on the spark plug (0.5 - 0.65 mm). If this is not the case, you need to change: either the flywheel or the coil (magnet). In addition, the spark plug itself or the high-voltage wire may break.

The next step is to check the fuel supply. To do this, disconnect the supply hose from the carburetor and check its presence. Absence may indicate that the fuel filter or delivery system is clogged. And the carburetor may also be clogged.

If you do not have experience in repair and cleaning, entrust this work to specialists.

If the air supply deteriorates, the saw should start, but it will not work properly. Remove and wash the air filter. Place it back only after it is completely dry.

If the saw works well, it works at idle and stalls when gas is supplied. The muffler is probably blocked. Take-off, dismantling, washing, installation and operation.

Easily with your hands you can also change the saw blade and chain, carburetor, starter, oil pump, ignition and clutch.

Troubleshooting Tips

Fuel transfusion and filling of a chainsaw spark plug can be one-time and accidental. For example, “over-pumping” with a pump cap (primer): the engine does not start immediately, the operator presses his finger on the cap again and again, tries to start it, then pumps it up again.

In this case, the reason is not at all in the carburetor. You need to unscrew the spark plug and ventilate the combustion chamber by pulling the starter cord several times, as when starting. The candle is wiped, dried on the flame of a gas burner or burner, or another one is used. They check the spark, put the spark plug in place. They try to start it first without choke.

If it does not start after 3-4 jerks, press the pump cap 2-3 times. They try again. That is, after an overflow, it is better not to pump up the fuel first, but to pump it up incrementally. Until the engine starts.

Candles sometimes require their own maintenance and care.

- Inside, around the insulator, there should absolutely be no soot or dirt.

- The contact between the electrode and the plate from the spark plug body is cleaned with “zero” sandpaper. Carefully, without rounding the end of the electrode.

- You need to know the recommended spark plug gap indicated in the instructions for each chainsaw model (from 0.5 to 0.65 mm or more).

- To accurately adjust the spark plug gap, special feelers are used - a fan-shaped set of plates of different calibrated thicknesses, which fold into a handle like a folding knife. Sold in auto tool and spare parts stores.

- When working in winter, it is better to store the chainsaw at low temperatures. When taken out of the heat and into the cold, a sharp temperature change can cause condensation to form everywhere, including in the ignition system, and this is harmful.

One of the reasons for the lack of spark in a chainsaw is described in the following video, where they also talk about how to fix the breakdown:

Modern chainsaw ignition systems are quite compact and reliable. You just need to protect them from direct moisture, shock, and exposure to extreme temperatures. And then there will be no problems with the lack of spark during startup. Also, 1-2 spare spark plugs that are known to work will not be superfluous.

Every year the technology becomes more perfect and smarter, more complex in design and easier to operate. Manufacturers of chain saws cannot help but keep up with the times: special vibration suppression systems, easy starting, automatic chain lubrication, tool-free chain tensioning... But no matter what additional functions the model is endowed with, it is not immune from malfunctions. For a chainsaw of any price range, the vast majority of breakdowns can be avoided with proper care and use of the equipment.

Chainsaw Partner 350 Starts and stalls. Related Posts

Why does the chainsaw stall when you press the gas?

Hello! If you find yourself on this page, then, most likely, your chainsaw stalls when you press the gas, and you want to find out why this is happening and what to do about it. Anyway, I’ll try to help you in this dilemma by examining the most common causes of such chaos, as well as ways to eliminate them.

To begin with, I’ll immediately write for novice users that many chainsaws require warming up the engine at idle for about one minute before use. Why does a chainsaw start and stall - reasons and reasons. Now the chainsaw has stalled and will not start, or the chainsaw has stalled and stalled. Until the engine is warmed up, the saw may stall when gas is added.

So, if a heated chainsaw can idle, but stalls under load, then this means that:

- the carburetor is incorrectly configured or clogged - the most common case;

- it does not have enough air, the consumption of which increases sharply with increasing speed - this means that the air filter is dirty (an extremely rare case, because the filter becomes dirty evenly, which is why the user first notices a loss of power);

- it lacks fuel, the consumption of which also increases with increasing speed - this means that the fuel filter is dirty (also an uncommon occurrence);

- Well, the worst case is if there is excessive friction between the piston and the cylinder wall due to a lack of oil in the fuel mixture - after such work with a chainsaw, you will most likely end up having to repair the piston group, because clogs form on the piston and cylinder walls, preventing saw operation.

Let's look at these cases separately.

Review of saw Partner 350

This is what we will look at in more detail.

Specifications:

- power 1.52 kW;

- working volume 36 cm3;

- idle speed 3000 rpm;

- maximum recommended rotation speed 13,000 rpm;

- saw bar length 40 cm;

- chain pitch 3/8".

It is possible to use saw bars 45 cm long, but for this length the saw is still rather weak.

The saw is equipped with a hand chain brake, an easy start system, a primer for pumping fuel, a carburetor air damper regulator, has chrome-plated cylinder walls and a cyclotron air preparation system. It is assembled quite well and, inferior in class to its more famous classmates from Husqvarna and Shtil, surpasses in its consumer characteristics almost all other chainsaws in the household segment.

Read also: Testing a transistor with a multimeter on the board

Chainsaw Partner 350 does not start. How the mechanism works

In fact, all tools, both foreign (Husqvarna, Makita, Shtil, Partner 350), and Chinese chainsaws, and Russian (Druzhba, Ural), are designed identically. Chainsaw partner 350 does not start. Therefore, finding the reason why the device does not start and stalls will not be particularly difficult.

There are four elements where difficulties may arise:

- The fuel for which the carburetor is responsible;

- Lubrication;

- The air that comes in;

- A spark, the quality of which depends on the ignition unit.

They all depend on each other and interact with each other. If any element does not work correctly, the saw stops working.

Let's start with the fact that all tools start up differently - hot and cold. Two commonly used mechanisms are responsible for this process.

Be sure to look at what is written in the user manual. It states that when turning it on, you need to make sure that the emergency stop brake is engaged. But starting a saw with a brake is much more difficult, so sometimes it’s better not to turn on the brake.

As you can find out from the instructions, inside the body there is a fuel tank and an engine, and outside there is a saw part (bar with chain), a handle and a starter.

First you need to figure out exactly how the tool won’t start. For example, the saw starts up, but immediately stalls, or loses power and cutting quality.

Perhaps interruptions in operation occur due to problems in the engine. Stihl chainsaw won't start: how to start it. But I would not recommend disassembling it right away. The chainsaw does not start: reasons and methods. Your chainsaw won't start? That the chainsaw won't start. (Husqvarna). It is better to look for the problem from the simplest option.

Video

The main reasons why the chainsaw does not start in the video. The video will be useful for those who quickly want to start a saw; the author gives practical advice.

If a situation arises when the chainsaw does not start, it is important to correctly diagnose it and determine the direction in which to look for the fault. You should not use a tool that does not idle, as this indicates that there is air leaking into the engine and can lead to serious problems. If you don’t have enough experience in repairing chainsaws, it’s better to contact a specialist who will save your time and nerves.

Read also: Fasteners for hanging shelves

Home page » Chainsaw Partner 350 Doesn’t Start Reasons

Assembling the Partner 350 chainsaw. Characteristics of the Partner 350 chainsaw

This model is in considerable demand among consumers, but most often it is bought by summer residents for work on their plots.

The saw is used not only for preparing firewood, but also in construction. In general, Partner 350 chainsaws are distinguished by their compact size. They are equipped with a fairly powerful engine. Their main advantages are easy starting and reliable operation. performed by a high-quality electronic ignition system and fuel pump.

This chainsaw is completely safe to use. It has a built-in protective system that automatically triggers the inertial brake for the chain. In the same mode, its lubrication is carried out.

There will be no problems starting the Partner chainsaw even in winter, since it has a fuel primer. The starter drum is equipped with an impeller that helps clear dirt. In addition, the manufacturers have equipped the tool with the CCS system. This design traps residual particles and is also used when using the air filter for a long time.

To increase the service life of the chainsaw, the developers made chrome-plated walls on the piston group cylinder. This model also has an ergonomically shaped handle and an anti-vibration system.

Chainsaw Partner 350: characteristics and features

The Partner 350 chain saw belongs to the class of household or amateur hand-held gasoline saws. Amateur - does not mean a “club of interests” for chain saw lovers, but denotes the power and capabilities of the unit. This saw is one of the best in its class and is optimal for short-term work in the garden, on a summer cottage, etc.

With its help, you will trim bushes, prepare brushwood for the barbecue and wood for repairs, and cut down a small tree. All this is possible due to the following technical parameters:

- Weight: 4.7 kg

- Two-stroke engine power - 1.8 hp. (1300 W)

- Engine capacity: 34 cc.

- Electronic ignition system.

- The capacity of the oil tank is 0.2 l, the fuel tank is 0.4 l.

- Chain pitch: 3/8 inch.

- The maximum chain length is 41 cm, the optimal length is 35 cm.

- Primer for starting a cold engine.

The advantages of the Partner 350 chainsaw are its compact size and convenient operation. It has a built-in safety system: the double inertia brake is activated automatically as soon as an emergency situation occurs. potentially dangerous for the saw operator.

Despite this, the price of Partner chainsaws is relatively low. Spare parts are also available. In Western countries, this brand is very popular due to its win-win combination of price and quality. But even Swedish quality sometimes fails.

Chainsaw repair Partner p340s

Question: I decided to work with a Partner 340 s chainsaw. About 20 days, 7-8 hours a day.

The frosts were severe. There are no complaints about the winding and the engine, but the chain lubrication has disappeared. What to do?

Answer: It is very likely that if the oil was thick, the oil pump drive was torn off.

It’s as if there should be a weak point in the drive just in case - either a worm, or a gear on the plunger, but it’s not good to make it weak to such an extent.

You need to remove the clutch, remove the pump and look. Or to the service.

Question: On the 3rd day of operation, the transmission mechanism failed, i.e. the motor is running, but the chain does not spin as at idle. What's the problem? Did some gear fly off?

Saw Partner p340s, sawed wood. I took off the box and there was a drum under which the sprocket was hanging. Maybe marriage? I twist the chain by hand, the sprocket rotates, the inside is not movable, the drum itself is also not movable.

In the assembled and wound up state and the brake is raised, the chain does not rotate either at low gas or at full throttle, there is no clutch.

Answer: This means the sprocket has become unsoldered from the drum. Surely it’s a manufacturing defect, only the leading sprocket is classified as consumable by the manufacturers, many even clearly indicate this in the saw’s passport.

Question: This is a problem with the Partner p340s chainsaw - I press the gas and it happens that there is a failure, as if there is not enough mixture, but the tank is full.

The mixture was made 40:1, oil 2t, power active partner, pink, gasoline 92nd. The saw is new.

I saw the board at low speeds and it might stall. And oil also leaks from the chain when it just sits unwound.

Answer: The carburetor is most likely not adjusted.

Question: The Partner 340 S chainsaw is in use. It has stopped starting completely. In use for a little over 2 years.

At first it began to start intermittently, but it started every time. Now you can’t start it at all - the best you can do is pull the handle, start the engine for a couple of seconds and immediately stall, after which it won’t start.

Preparing for launch

Before starting the chainsaw for the first time, you should check the condition of the saw set and the quality of the tension of the bolts on the body. After this, prepare the fuel mixture in the proportion specified by the manufacturer and pour it correctly into the tool tank. You cannot start work without making sure that the device is in full working order - this can lead to breakdown of expensive elements and serious injuries.

Preparing the fuel mixture

For normal operation of the chainsaw, it is recommended to take gasoline with an octane number of at least 90. The best option is AI-92 grade; the use of lower quality fuel can cause engine knocking and a decrease in its productivity.

Figure 2 – Filling with fuel mixture

Two-stroke engine oil is required for both break-in and continuous operation. It is better to purchase brands designed for specific chainsaw models. The proportions for preparing the fuel mixture for each saw are indicated in the operating instructions; on average, it is recommended to mix at a rate of 1:33. For old domestic chainsaws, the mixture is prepared in a ratio of 1:15.

Important ! Leaded fuel is used to refuel chainsaws with engines without a catalyst. Its presence can be identified by the green cap of the gas tank; for models with a catalyst, unleaded gasoline must be filled.

Refueling

It is recommended to prepare the dressing mixture in a metal container. First, pour the required amount of oil, and then dilute it with gasoline and bring until smooth. Carefully pour the prepared mixture into the chainsaw tank, being careful not to stain the body, and screw the cap tightly. The finished mixture can be stored for no more than 30 days, after which the oxidation process starts. At the same time as refueling, it is recommended to check the oil tank for chain lubrication and top it up if necessary.

Finding reasons why a chainsaw won't start

Amateur and professional chainsaws are complex devices. The motor life of their two-stroke engines, components and assemblies has its limitations. For this reason, quite reliable and expensive tools, along with cheap Chinese units, periodically fail and refuse to start. The situation when a chainsaw does not start or stalls is not very pleasant and sometimes confuses the user. How to identify and eliminate the malfunction, restoring the functionality of the tool.

Identifying and eliminating obvious chainsaw faults.

To determine the reason why the chainsaw does not start or stalls when starting, it is necessary to troubleshoot the tool. The essence of the procedure is a sequential inspection of the condition and operation of the main working elements of the saw engine. At this stage we check:

- Presence of a spark on the spark plug;

- Fuel supply;

- Filter status;

- Operation of the breather built into the fuel cap of the stalling unit;

- Functioning of the exhaust channel.

Checking the spark on the spark plug and eliminating the causes.

The first step in finding the reasons why a gasoline saw does not start is to check the spark on the spark plug. There are many factors that influence the operation of this element. However, the main ones at the initial stage of tool troubleshooting are:

- Incorrect carburetor adjustment;

- The presence of more than the required amount of oil in gasoline;

- Air filter clogged.

All of them contribute to the formation of carbon deposits on the spark plug electrodes. In 50 cases out of 100, saws do not start when cold due to the lack of a spark due to carbon deposits on the electrodes and their corrosion. The result is either a decrease in the gap or an increase in it.

Checking the spark plug of a non-working chainsaw

Checking for spark is quite simple. To do this you will need:

- Remove the tip of the high-voltage wire;

- Unscrew the spark plug;

- Put the tip back on;

- Place the candle skirt against the cylinder;

- Start with the starter.

If at the moment the chainsaw engine starts, a good spark is observed between the electrodes, then everything is in order with the ignition unit. If it is not there, then it is worth cleaning the element itself and checking the electrode gap. If necessary, use a special probe to adjust the distance between the contacts.

For spark plugs from different manufacturers, the distance between the electrodes may vary. For some it may be equal to 0.5 mm. Others have 0.2 mm. Therefore, carefully study the manufacturer's recommendations.

There may be no spark at the spark plug for other reasons. The main malfunctions that affect poor starting of the chainsaw and unstable operation of the internal combustion engine at idle, which can cause the tool to stall, include the following:

- Overfilling of the spark plug channel with fuel;

- Lack of contact between the high-voltage cradle and the tip of the spark plug;

- Failure of the ignition unit.

How to start a cold chainsaw if the spark plug channel is constantly flooded with gasoline? You can fix the problem while starting the tool using the following algorithm:

- Unscrew the spark plug with a special wrench;

- Wipe it with a clean and dry cloth;

- Dry for 20...30 minutes;

- Remove carbon deposits with a file and adjust the gap between the electrodes;

- Drain the remaining fuel from the spark plug channel and dry it;

- Collect everything and try to start the mechanism.

As a rule, these measures are quite enough to start the chainsaw and get the job done. However, this extreme measure does not eliminate the main reason why the engine does not start or stalls - improper operation of the carburetor, which needs fine adjustment.

If there is no spark due to poor contact of the high-voltage cradle with the tip of the spark plug, it is necessary to check the connection. The test can be carried out using a regular tester. If a defect is detected and corrected, the chainsaw should start without any problems.

Chainsaw won't start when hot

In cases where the chainsaw does not start when hot, you need to conduct a visual inspection of all the main components of the chainsaw. The inspection should start with the spark plug. Check the spark, inspect the surface of the spark plug electrode, these actions will help determine the direction in which to look for the problem.

Malfunctions in the ignition system

If, upon inspection of the spark plug, it is found that it is wet and sparking does not occur at the contacts, this means that the problem should be looked for in the ignition system, inspect the coil, and check the gap between the flywheel and the coil contacts. You can also check how tightly the cap of the high-voltage wire sits on the spark plug, and the spark plug itself. Try replacing it with a new one.

Problems in the fuel system

If upon inspection it is discovered that there is a spark, but the spark plug is dry, then there is a problem in the fuel system. Checking it should start with the fuel filter. Next, you need to inspect the fuel hose and its attachment to the carburetor, pay attention to fuel leaks from the carburetor and the presence of gasoline in the air filter housing. It is advisable to start removing the carburetor only if a visual inspection does not allow you to determine the cause of the breakdown.

Read also: Electrical engineer where to study

A characteristic sign of a problem in the fuel system is an excessive amount of fuel in the engine cylinder. Typically, signs of this include an excessively wet spark plug and the presence of a spark at the plug contacts. In this situation, it is necessary to turn the chainsaw over so that the spark plug hole is directed towards the bottom. If gasoline flows from the cylinder, then the reason that the chainsaw does not start is fuel overflow into the engine.

It “fills” with fuel, sometimes due to incorrect carburetor adjustment or malfunction.

You can familiarize yourself with the process of adjusting the carburetor using the example of the Champion 254 saw by watching the video instructions.