Polystyrene foam is an inexpensive material from which craftsmen make a wide variety of products. It is very popular not only because of its low cost, but also because of its ease of processing. Not everyone knows that foam plastic does not have to be cut with a regular knife. In this case, it will crumble very much and it will be simply impossible to make an even cut.

But this material melts very well, and at a relatively low temperature. That is why the most convenient way to work with polystyrene foam is to cut it using special cutters that rely on high temperature. But cutting foam plastic with your own hands is also possible in other ways, which we will definitely consider.

What is polystyrene foam and what is it used for?

Foam Sheets

Foam is a white material that consists almost entirely of air. It is used for packaging equipment, food, as a heat-insulating and sound-proofing material, as a basis for the manufacture of household items, logos and many other things. One of the main advantages of polystyrene foam is its low cost . Many people buy it in order to make some product from this material and sell it profitably. But even for an ordinary person, polystyrene foam will be very useful, because you can make a lot of things for your home from it. The main thing is to be able to work with the material correctly, as well as choose it for specific purposes.

What material to choose for cutting

Before we start working with the material, we need to find out what kind of foam there is, what type of foam is best used for cutting at home.

Polystyrene unpressed

This is the most common and familiar polystyrene foam, which is familiar to us from technology packaging. The material consists of many small white balls that are tightly connected to each other, but can become separated from mechanical stress. It is very widespread and is most often used in the manufacture of products at home.

Polystyrene pressed

This is a similar type of foam, which is simply additionally pressed. Because of this, it has a much denser structure, it is more difficult to crumble, but such material also costs much more than its non-pressed counterpart. Due to the high price, pressed polystyrene foam is not widely used, but for some products it can definitely be used, since its structure is quite smooth.

Polystyrene extruded foam

Polyvinyl chloride foam

The rarest and most unused type of this material, which has one interesting property - the ability to extinguish on its own when ignited. It does not emit hazardous substances, but if it does catch fire, the smoke from it is very dangerous and can pose a health hazard.

Prices for foam plastic

Styrofoam

Metal plate cutter

There is another way to convert a soldering iron into a foam cutter. To modify the tool, you simply need to replace the tip with a copper plate. Steel will also work, but it takes longer to heat up and is more difficult to sharpen. However, with proper sharpening, a steel plate can cut any synthetic material, including polystyrene.

One side of the plate must be carefully sharpened. Sharpening can be done on both sides. It is necessary that the sharpening angle is not too large. The cutting of the material is carried out not only by the blade, but also by the blade of the plate. Such a cutter has one drawback - you will have to experimentally find the optimal heating temperature for the knife.

How to cut foam without special equipment

The first common question is what to do if you need to cut foam, but building a special cutter is too difficult, expensive and useless. There is a way out, even several.

Methods for cutting foam plastic

Wood hacksaw

The large teeth of the hacksaw allow it to grab onto the foam granules and cut it quite effectively. To implement this method, you do not need to modify anything yourself; you just need to purchase or take a ready-made hacksaw for wood. In the same way, cutting can be done using a jigsaw; in this case, it will be important to choose the right file for it.

Wood saw

But this method is not widely used, since when using it, the foam will crumble in any case, and it will not be possible to achieve a perfectly even cut. Also, if you use the tool carelessly, the plate may crack and all the work will go down the drain. Therefore, the following methods are almost always used to cut such capricious material.

Tools for cutting foam plastic of different densities ↑

Tools for cutting foam sheets differ from each other both in functionality and in the complexity of working with them.

Most popular hand tools:

- a sharp knife for foam plastic (painting knife, stationery knife or shoe knife);

- thermal knife in the form of an attachment for a soldering iron, operating on 220V;

- jigsaw or string;

- a hacksaw for metal (sometimes even used for wood, but with fine teeth).

The most common painting knife

Most builders don’t even think about how to cut polystyrene foam at home - this is the most common painting knife, which is also called a construction knife or stationery knife. The main requirement for such a tool is a solid, sharp blade, which can always be replaced, and in some cases, simply shortened - the main thing is that its length is sufficient for the thickness of the panel. A similar tool with a shortened blade (used for drywall) does not work well here.

Professional innovative thermal knife

Such products, as in the top photo, were declared by the Patent Department quite recently - only in April 2010, but, despite their “youth,” they very quickly gained popularity in the market. The main obvious advantage of such a cutting tool is that after cutting PSB of any density, there is practically no debris left in the form of granules.

This device is ready for use immediately after removal from the original packaging, and it takes literally 1-2 seconds to heat up. The handle here is made of lingofol (something like wood, but with higher mechanical strength), and the cutter is made of stainless steel and ceramic. This combination provides a fairly long service life if the breakdown is not done intentionally.

String for cutting PSB

In the top image, there is another option for cutting foam plastic so as not to crumble - this is a homemade unit made from a charger and a string from a piece of nichrome. You can, of course, use unregulated current sources, for example, a battery or a charger for a cordless drill (screwdriver), but here, of course, the design will lose quality.

In addition to the power source and nichrome, you will need some kind of frame - you can even use a small coffee table. Fans of figure cutting will appreciate this device.

You can use a hacksaw for metal

It is not always possible to cut polystyrene foam at home with a paint knife or other devices described above due to their absence; for this you can use a hacksaw or a separate blade. Only in this case should you be prepared for the appearance of debris in the form of granules, since PSB consists of them. The teeth, even small ones, will destroy the structure, but if the cutting is done for insulation, then this does not matter from a technological point of view.

CNC Laser Cutting Machine

Of course, you can use not only a string or a knife to cut foam, but also more modern devices with numerical control. If you do this on an industrial scale, then CNC machines, which are controlled by a computer, are precisely suitable for such purposes. The advantage of such equipment is that an entire workshop of such units can be controlled by just one person from the operator’s cabin.

It is almost impossible to make such a car by hand.

There are different machines, or more precisely, their software is specified in different ways and in different volumes. That is, older models (they are still being produced, but not in the same quantity) have integrated software, and you cannot change it in the usual way, and in later developments you can independently add certain programs for making three-dimensional figures with the most bizarre and complex shapes.

3D foam processing

Various unique shapes made using this method can be used:

- in the metallurgical industry for casting certain alloys;

- for tuning in the automotive industry;

- in industrial construction for the manufacture of formwork, sleeves for insulating pipelines, as well as for pouring any architectural forms;

- theater stage decoration;

- advertising logos, inscriptions and so on.

Sleeves for insulation of external and underground pipelines

This tool for cutting foam is the most accurate of all of the above, since computer programs, unlike the human eye, do not produce errors. Consequently, you get a minimum amount of waste thanks to the ideal calculation of the area and volume of the figure in relation to the workpiece. There are special programs that, with a little help from the operator, can develop any configurations and transfer them to the machine.

Cutting material using a hot tool

To cut a sheet of foam plastic, you can use the most ordinary knife, if you first prepare it for this procedure:

- You need to make sure that the length of the knife is greater than the thickness of the sheet that will need to be cut.

- Next, you need to mark the lines on the sheet along which it will need to be cut.

- The next step is to heat the knife using a gas stove or a special gas burner. Carefully draw a hot knife along the intended line; the foam will begin to melt and cut clearly along the line.

It is important to consider that it is not possible to achieve a perfectly even cut using this method, and it is also only suitable for cutting small pieces of material. The fact is that even slightly shaking hands will not allow you to achieve a straight line, and a constantly cooling knife will not allow you to make a neat and long cut.

But if your goal is to cut off a small piece, then a hot knife will allow you to do this very quickly and without wasting extra money and time. Please note that after cutting, the knife should never be used in the kitchen or at home, as the foam contains toxic substances.

Knife

A simple soldering iron cutter

If you need to make quite a lot of foam blanks, but don’t want to make an overly complex cutter, then you can use its simple analogue, which works on the basis of a regular soldering iron.

It is important to choose a soldering iron that is not too powerful, since its temperature is excessive for normal sheet cutting. If the power is too high, the foam will smoke a lot, smoke, and be difficult to cut.

The next step will be to select and install a nozzle on the tip of the soldering iron, since the standard tip is in no way intended for these purposes. We need to find or make our own long and flat tip, which will look like a small knife blade, but less sharp. Copper wire folded several times is good for making such an item. Another option is to simply take out the tip of the soldering iron and shape it into the desired shape.

Next, the tip is tightly fixed to the tip of the soldering iron and you can start cutting.

The soldering iron is inserted into a socket, heats up and cuts the foam using a similar principle to a hot knife. The main advantage of this method is that there is no need to constantly heat the knife; cutting can continue continuously.

Soldering iron cutter

Thermal methods for cutting foam plastic

Cutting material using a thermal cutter is also a fairly popular method. The instrument itself has the appearance of a nichrome thread, which is laid on a frame in the shape of a frame. When an electric current passes through the nichrome wire, the metal surface heats up and the foam begins to melt. There are several types of cutter designs. The simplest option takes the form of a nichrome string stretched over ceramic insulators, which are attached to the edges of a frame made of wood or metal.

Using this tool, you can cut not only foam boards, but also wooden slats, plastic pipes, as well as any material that melts or decomposes at temperatures up to 270°C. If you need to cut sheets with a significant length of cut, then it is much more comfortable to use the machine, which looks like a thread stretched in a vertical position on a textolite stand.

Special cutter for cutting foam plastic

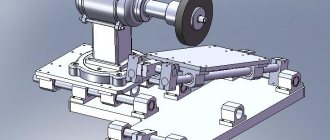

If you want to make foam products on a regular basis, and so that they turn out really smooth and good, then you will have to make a special cutting machine that will allow you to do all this.

Prices for a special cutter for foam plastic

Foam cutter

On the Internet you can find many variants of this design, which differ in size and appearance, but they have the same essence. We will analyze one of the most popular and simple designs, which has proven itself well.

Table 1. Main methods of cutting foam:

| Cutting methods | Advantages | Flaws |

| Wood saw | Simplicity and accessibility | Can't get a perfect cut |

| With a hot knife | Availability | The knife cools down quickly |

| Soldering iron cutter | Will not cool down, so you can make long cuts | It takes time to create |

| Homemade machine | Allows you to make perfectly straight cuts | Complexity |

Specialized machines and their prices

Manufactured machines are supplied to mass production. There are modifications with six cutting elements, which allows you to quickly cut a large volume of foam in one pass. Laser machines perform work for architectural purposes and are capable of cutting various shapes and thicknesses of materials.

Specialized foam cutting machine

The machines have excellent characteristics, can have the functions of simultaneous processing of many elements, and have high productivity. The price of the devices is high; you need to know exactly for what purpose the cutter is used.

FRP 01

The simple design allows you to modify the device to suit various shapes and sizes of foam blanks. Devices for cutting various types of foam allow you to carry out a number of actions. The ability to cut linear parts, shaped elements, insulation boards and signs has been implemented.

Cutting is performed by the machine by connecting to the CNC. The cutting program is supplied complete and has various settings. The price of such a device starts from 110 thousand rubles; it is important to check the functionality and reliability of the design before purchasing.

SRP "Contour"

There are modifications of machines for the production of elements of various shapes. The machine for cutting polystyrene foam is operated manually, has a simple design, and rich functionality. Power consumption is not high, the components are collapsible, which allows you not to worry about transportation.

The cost of equipment starts from 40 thousand rubles. The main difference between market models and hand-made ones is the safety and reliability tests of the parts.

Step-by-step instructions for making a cutter

First we need to decide on the tools and materials that we will need to create the cutter. The list of required materials includes:

- A sheet of chipboard or other dense base, approximately 600 by 400 millimeters . The size can be changed, it will depend on the size of the sheets you are going to work with.

- A flat wooden strip, about a meter long.

- Material for legs: 4 caps from plastic bottles, a piece of lath or other material.

- Nichrome wire, approximately 0.4 mm . You need about half a meter, but it is better to buy with a reserve.

- Tension spring. It is for tension, not compression. Such a spring cannot be found everywhere.

- 10-15 screws.

- Wires, crocodiles for fastening them.

- Computer power supplies and cable for it.

Now let's move on to the tools that we will need to manufacture and assemble the structure. These include:

- Drill or screwdriver;

- Jigsaw or hacksaw for wood;

- Screwdriver;

- Pliers;

- Drill for screw diameter.

Prices for popular drill models

Drill

Stages of creation

- Cutting part. To do this you will need nichrome wire, approximately a spiral with a diameter of 0.6 mm. It can be taken from old electric stoves or other heating electrical appliances. The length of such a wire should be 14 cm (its resistance will be 2 ohms).

- Transformer application. For everything to be correct, the first step is to calculate the voltage and current for heating the cutting part. This can be done using the formula - Ohm's law I=U/R. Thus, you can determine the power of the power transformer.

- Making a cutter. The base can be made of any metal, but its length must be at least 11 cm. Next, an insulator - a PCB plate - must be attached to the end. Now fasten the contact groups along the edges of the plate; they can be removed from the electrical outlet. It is into these contacts that it will be possible to attach spirals of different shapes.

- How does the cutter work? After the cutter is plugged in, the wire will heat up and become slightly reddish in color. This is exactly what matters, since a heated cutter will make it possible to easily and quickly cut the foam, which will not peel off.

It is important to know: having received such a device, in just three minutes you can cut the required shape from a sheet of foam plastic.

Be sure to follow all safety rules so as not to injure yourself and others. After all, the power of the cutter is enough to damage any part of the body during operation. And connecting to electricity further increases the risk of injury.

Video - How to make a foam cutting machine with your own hands

Where to get nichrome wire

Rolls of nichrome wire

Nichrome wire is an integral part of the cutter, but not everyone knows what it is, and most importantly, where to get it. Nichrome wire differs from ordinary wire in its strength and very high melting point. That is why it is most convenient to use to create a foam cutter.

This wire is used in irons, boilers and some other heating devices. In addition, it can be bought in electronics stores and markets.

Prices for nichrome wire

Nichrome wire

Power supply, its connection and configuration

Our cutter will operate from a regular computer power supply, which almost everyone has, but if you don’t have one, you can buy it at any computer store; it’s inexpensive.

The power cord must be plugged into a power outlet and the device turned on. But the power supply will not turn on due to the nature of its operation. In order for it to turn on you need:

- Find the largest connector that is designed for the motherboard.

- Prepare a small piece of regular wire or find a hairpin.

- Find the green wire there, there will be only one.

- Now, using a hairpin, you need to connect the green wire with one of the black wires, and it doesn’t matter which one.

After these simple manipulations, the power supply will work.

Computer power supply

All that remains is to somehow obtain the voltage we need using a power supply. To do this, you need to find a Molex connector, which is a connector with four holes, to which wires of different colors go.

In the holes with the yellow and black wires, you need to connect the wiring wires, which will power the entire cutter. With this all manipulations with the power supply are completed, you can move on to building the cutter itself.

Selecting wire length

Before you start making the foam cutting machine itself, you need to calculate the length of nichrome wire, which will be sufficient for normal cutting of the material. To do this you need:

- Take a long strip and screw it on both sides.

- It is necessary to attach a tension spring to one of the screws, which we will also use in the future.

- Pull the nichrome wire to the maximum possible length. One end of it will be connected through a spring.

- Now you need to connect one wire from the power supply to the very end of the wire that does not have a spring.

- There is no need to secure the second wire tightly; we will move it. Depending on the position of the wire, the temperature of the wire will increase. The closer the two ends are, the hotter it is. Thus, you need to find a position at which the wire temperature will be sufficient to cut the foam. Please note that if the wires are placed too close, the foam will burn, which will negatively affect the final quality of the product.

Next, you need to measure the distance between the wires and remember it. This is exactly how much wire will be used to cut the foam.

Now the entire structure needs to be disassembled and the manufacture of the main part of the cutter can begin.

Selecting wire length

Base

The first thing you need to do is take a board for the base and screw 4 legs prepared in advance to it. The easiest way to do this is to take 4 caps from plastic bottles and secure them to the back of the board using regular screws. It is important that the screws do not come out from the back of the board. This can happen if the fastener is too long.

Next, you need to find the flattest side of the base and attach there the structure to which the wire will be screwed.

Chipboard for cutter base

Wire holder

The wire fastener in our design consists of two twisted pieces of lath that are tightly attached to the base. It is important to assemble everything so that an angle of 90 degrees is formed and nothing wobbles.

The first step is to fasten the two slats together. The length of the first should be equal to the length of the wire that is suitable for cutting. The length of the second staff will express the distance from the edge of the cutter to the wire. It must be selected based on the size of the workpiece you are going to process.

Now the resulting angle of slats needs to be screwed to the base using corners. It is important to do this in such a way that the structure does not wobble.

Now you need to drill a through hole in the base where the fishing line will go. To do this, you need to screw a screw to the center of the rail and tie a thread to it. When the thread goes down, you need to put a point in the place with which it comes into contact. This is where you need to drill.

On the back side of the base, next to the hole, you need to screw a small screw. It should be as close to the hole as possible.

Wire installation

Wire fastening

Now you need to start attaching the wire. The first step is to secure the spring to the screw located on the rail. A nichrome wire is wound to the end of the spring, and the spring needs to be stretched by about half.

The other end of the wire must be tightly wound around the screw, which was screwed onto the back side of the base. The wire should be well tensioned, and the spring should not be in its original position. Nichrome wire can be quite uneven due to the fact that it very readily takes the shape that it is given. To make it as even as possible, you need to stretch it and move a piece of wood along it until it visually becomes smooth. It is unlikely that you will be able to make the wire perfect, but minor irregularities will not greatly interfere with cutting.

The last step will be setting up the cutter. The fact is that the screwed rail does not create a right angle with the base of the cutter. To fix this, you need to take a square and apply it to the rail. Now, using a screwdriver or screwdriver, you need to turn the screw a little until an even angle is formed.

This completes the process of creating a homemade foam cutter. All that remains is to connect the power.

Wire tension through a spring

Power connection

In order for the cutter to start working, it must be connected to power from the block that we made in the previous steps. For ease of fastening, you can buy special crocodile clips that will help secure the wire in a couple of movements. If there are no crocodiles, then the wire can simply be tied in the right places.

Classification of machines

The design features of the units do not differ from each other. In each of them, cutting occurs due to a hot wire fixed in a certain position. Some of the modifications have up to six adjustable strings, this allows for more massive work. Machines for cutting foam plastic can be equipped with a rotary table with a permanently fixed cutting element.

Foam cutting machine options

The devices are divided into several categories:

- equipment with software control, allowing you to cut out figures of increased complexity;

- portable cutting elements;

- transverse or horizontal types of cutting.

The most complex machines in design allow you to work on several planes of a product at once. The performance of foam cutting machines is designed for industrial purposes; some models can process over 10 meters in one go.

Video: Do-it-yourself foam cutting machine

The first end of the wire needs to be connected to the back of the base, to the screw that we screwed there. The second end must be placed on the nichrome wire itself, under the spring. If you lower the wire a little, the temperature will increase and the cutter will be more powerful.

If you need a full-fledged power regulator, here are brief instructions on how to make one:

- You need to take a piece of nichrome wire that is left and wind it around a regular ballpoint pen so that you get something similar to a spring.

- You need to bend the hooks at the ends of the spring.

- Now, in a random place on the cutter frame, you need to screw in two screws at a distance approximately equal to the length of the resulting spring. The wire must be secured to these screws.

- Next, you need to connect the end of the spring to the beginning of the nichrome wire of the cutter itself.

- The first wire from the power supply must be connected to the same screw that is located under the base, and the second wire must be secured to one of the turns of wire. Depending on the chosen turn, the resistance in the circuit will change, and therefore the power of our device.

Power regulator

Foam cutting process

In order to cut foam plastic, you need:

- Turn on the power supply.

- Make high-quality markings on the foam sheet so that you can see where the cut line should be.

- Take a metal ruler and apply it to the cut line. Without a ruler it will be very difficult to cut.

- Cutting complex geometric shapes on such a machine is also possible, but for this you definitely need to practice on simple products.

Guide board

To make it easier to cut simple products and shapes, you can screw any flat board to the base of the cutter and use it as a guide. To do this you need:

- Find a flat board and place it on the base of the foam cutter.

- Drill a through hole at one end of the board. At the other end you need to make a slot in which the screw should move freely.

- Now all that remains is to set the desired size and screw both screws to the cutter itself. Thus, the board will serve as a guide against which the workpiece must be pressed. With its help you can cut products with a perfectly smooth edge.

Material cutting process

Why difficulties arise

Polystyrene foam is a material that consists of granules compressed under certain conditions. Although the granules are sintered together, they do not fuse, which makes the granules easy to separate. This structure creates difficulties in the process of cutting the material. If anyone has had to deal with cutting foam plastic, it is easy to notice that sheets of high density are cut easier and for this you can use a well-sharpened tool with a thin tip. You can cut using power tools. Moreover, the higher the speed of the blade and the smaller the tooth, the faster and easier the cut.

In industrial conditions, foam cutting is carried out by other methods, one of which is hydroforming. A thin stream of water is applied to the block under high pressure, making it easy to cut and leaving virtually no waste. Another method is to use nichrome thread. It has a high resistance, so when electricity is passed through it, the temperature rises to a certain value, which causes the foam to melt. Industrial machines have several threads installed at once, which perform cuts in several planes.