What are welded mesh and how are they produced?

Welded mesh is a high-quality metal structure of specified geometric dimensions. Welded mesh is made using a special technology from steel rods perpendicularly connected to each other by spot contact welding. This technology ensures maximum reliability of fixation of all elements, guaranteeing strength and durability, as well as the ability of the welded mesh to withstand various harsh conditions.

Certain types of steel are used to make welded wire mesh. Most often, low-carbon steel or stainless steel is used in production, since these types of steel make the welded mesh resistant to water and corrosion. Steel is used because it is cheap and easy to bend and cut.

Welded mesh production technology + Video on how to make it

Making mesh from small diameter wire

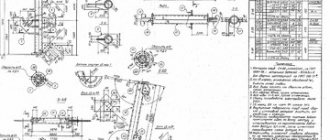

For the production of welded mesh, machines are used that ensure strong welding of wire sections located at right angles to each other. The intersection points are tightly soldered by spot welding.

Subject to proper setup and quality maintenance, modern machines provide maximum productivity, precise mesh cell geometry, material savings, minimum failures and good profitability by optimizing energy consumption.

On the market you can find several modifications of equipment for the production of welded mesh. Accordingly, it will not be difficult to select units of the required power. The RL 2000 is considered one of the most popular models among manufacturers.

These machines show the best results when working together with SPO-70 broaching mills. The devices are equipped with the option of stepless electromagnetic speed control. Welding is provided by three-phase electron. The cost of the kit will be about 350 thousand rubles, and a 380 V electrical network will be required to provide it.

The raw material for the production of welding mesh is stainless, galvanized or carbon steel wire with a cross-section of 1.2-4.7 mm. At the same time, the size of the cells is dictated by consumer demand, but technologically they can be of any size.

The high productivity of the units makes it possible to carry out one-time deliveries of large volumes of products of various ranges. Loss of production capacity occurs during wire threading and material replacement processes. Today, equipment manufacturing companies are actively developing automatic raw material supply systems. The most promising lines are those with two unwinders and two wire feed channels. In other words, if the wire feed stops on one channel, the machine will automatically switch to the second. As a result, downtime is reduced. At the same time, it is still possible to program the length of the web within a range of up to 80 m, and the welding speed will be up to 100 rows per minute.

Making a mesh from a metal rod

The algorithm for producing welded mesh from steel rod is quite simple, so even a non-mechanized line will be sufficient for the production of small volumes. However, if an enterprise wants to expand its range with a product that is widely in demand among consumers, it makes sense to purchase automatic equipment. The level of automation is dictated by the diameter of the feedstock (metal rod): the smaller it is, the easier it is to mechanize the process.

To make a mesh from large-diameter reinforcement, the rods are cut into measured sections and placed in the trays of a welding machine - for longitudinal and transverse rods. Then the longitudinal rods are laid out at a given distance from each other, and the second tray, moving along them, ensures that the transverse ones are laid out. Depending on the equipment model, moving parts may vary.

When the rods touch at the place of their intersection, they are mutually fixed using a special apparatus, and then soldered using contact welding.

At the same time, the quality of the mesh - the final product - directly depends on the characteristics of the raw materials. Thus, the presence of bends, rust and other defects is fraught with poor “adhesion” of welding and, as a result, defects.

Application options for welded mesh

Welded mesh has a huge range of applications. Despite their lightness and flexibility, welded mesh has a robust design and is durable. This means that welded wire mesh systems are ideal for applications where installation with less flexible wire systems may be difficult, and where meeting the highest standards of durability is paramount. Ready-made welded mesh is much more convenient to use than bar reinforcement, which requires a bundle, which saves time and money when carrying out work. You can use welded mesh when:

- Carrying out plastering work.

- Screeding of floors, ceilings, foundations. When welded mesh is used in this way, it prevents cracking, shedding, and helps maintain the geometric integrity of the building element/structure.

- Installation of brick and block masonry. Reinforcement with welded mesh can significantly increase the strength of the structure, resistance to loads and various adverse effects.

- Road construction to strengthen foundations.

- Laying sidewalks and paths.

- Installation of fencing, fencing.

- Use in agriculture. Welded mesh can be used in the manufacture of cages and pens.

Advantages of using welded mesh

- High strength. Welded mesh is resistant to deformation, stretching, and tearing. Due to the increased diameter of the steel rod, it is able to withstand significant loads while maintaining the specified cell geometry. The strength of the welded mesh is affected by the steel core and its thickness. The strength of welded mesh is proportional to the diameter of the wire and inversely proportional to the mesh size - large cells make the mesh “weak”.

- Resistance to various weather factors and temperature changes. These characteristics make it possible to use welded mesh outside buildings (on the street), inside wet, unheated rooms.

- Moisture resistance. The galvanized coating protects the masonry mesh from corrosion.

- Compatibility and excellent adhesion with any mortar mixtures, including concrete. Reliable adhesion ensures the durability of the reinforced structure, the absence of peeling and destruction.

- Compliance with sanitary standards, environmental friendliness.

Welded mesh coating options

Welded mesh differs in cell sizes, wire diameter and metal processing method. In other words, the choice of welded mesh for different tasks is carried out based on the type of surface treatment and cell size. The presence of a protective coating extends the service life of the welded mesh and allows long-term use in open spaces.

- Non-galvanized welded mesh is a simple and cheap option and is used where aesthetics are not required. For example, when pouring a floor, in masonry, when equipping entrances. But when used in conditions exposed to atmospheric precipitation, non-galvanized mesh requires painting, otherwise it will rust and lose its characteristics over time.

- On the contrary, welded galvanized mesh is protected from corrosion, durable, and has a high degree of aesthetics, which is why it is often used in the construction of fences. Stainless steel is considered durable, aesthetically pleasing and reliable, even when used in damp conditions. Buying welded mesh of this type will be more expensive, but you are guaranteed to get quality and durability.

Welded stainless steel mesh is produced using special production technologies:

- galvanic galvanizing is the process of applying a protective layer up to 20 microns by electrochemical action on the workpiece.

Hot-dip galvanizing is a complex technological process that allows you to achieve protection of 60 microns. This technology provides a high degree of corrosion protection even in the event of mechanical damage.

For additional protection, the mesh is not only galvanized, but also covered with an additional layer of polymer protection, which is done after welding. This not only adds aesthetics, but also extends service life, increasing the degree of corrosion protection. Welded mesh with a polymer coating is not afraid of a chemically active environment. Using this material, you can equip a fence made of welded mesh, as well as partitions in warehouses and enterprises. The production process involves dipping the mesh into a polymer solution, which creates a layer on its surface of about 0.5 m.

Product Specifications

Technical features are determined by what the welded mesh is made of. For its manufacture it is used:

- wire profile periodic material;

- wire material with a trapezoidal cross-section;

- wire with a T-shaped section;

- round shaped wire.

Welded mesh standards allow different directions of working reinforcements.

In addition, the grid can be:

- reinforcement;

- masonry

Different brands of products differ in the following parameters:

- wire diameter;

- map areas;

- cell size.

Depending on the wire manufacturing technology, the mesh can be:

- galvanized;

- non-galvanized;

- with polymer coating.

The finished product is not exposed to temperature fluctuations and climatic conditions; it is practically not subject to deformation. The polymer-coated grille has water-repellent properties and is therefore not subject to corrosion. It is stronger and more durable.

Types of welded mesh

The production of welded mesh involves several options for the production of finished products. It is possible to purchase welded mesh in the following formats.

Welded mesh in roll

Welded mesh in a roll has maximum flexibility, which allows it to be rolled into rolls due to the smaller wire diameter. Due to the fact that welded mesh in rolls allows for quick installation and also meets many requirements and construction standards, this material is often used for the construction of fences.

You can view the welded mesh in rolls available for sale or compare them here.

Welded mesh in cards

With this option, the welded mesh is made in a rectangular shape. The diameter of the wire used here is larger, so the rigidity is higher.

The grid in maps is often used at various stages of construction:

When pouring the floor. In order to prepare rough and finishing bases in the form of a floor screed, reinforcement is necessary; this is where welded mesh is used, which is an inexpensive and durable material. When laying building blocks and bricks. We are talking about building houses. Here it is customary to reinforce every fourth row using 8 mm reinforcement or masonry mesh, which is selected according to the thickness of the block. It is easier to work with masonry mesh, the wire diameter of which is 1.6-1.8 mm, since it is equally suitable for both glue and cement mortar. During road construction. The use of welded mesh allows you to increase the strength of concrete and paths on the territory of private houses.

You can view the welded mesh available for sale in maps or compare them here.

Masonry nets

Reinforced mesh for masonry walls or masonry mesh is used in construction as a reinforcing element when creating reinforced concrete structures, erecting walls, pouring floors and foundations to strengthen the structure. The use of masonry mesh allows you to increase the strength of the wall without increasing its thickness. The reinforced mesh with high tensile strength can be bent without damage, and also has anti-corrosion properties and a long service life.

You can view existing masonry nets for sale or compare them here.

Expanded metal mesh TsPVS

All-metal expanded metal mesh (TSPVS) is a metal sheet, evenly cut and stretched into diamond-shaped, staggered cells. Cold-rolled sheet metal with a zinc coating is used for the manufacture of CPVA. TsPVS mesh is a relatively new material on the market, but has already established itself as a cheaper analogue of chain-link mesh and welded wire mesh. The TsPVS mesh is easy to cut, has a lower specific gravity, and is visually aesthetic. TsPVS meshes are used for:

- Reinforcement when performing plastering work.

- Reinforcement when laying tiles, stone and similar building materials.

- Reinforcement during facade work and application of thermal insulation coatings.

- Fencing garden plots, making cages for pets.

- Production of screens for heating radiators and ventilation grilles.

- Manufacture of fencing for electromechanical devices, thermal insulation of pipes.

- Guards for bins, trailers, conveyors, etc.

- Cutting off concrete at the stage of roof installation.

- In interior design.

The special shape of the TsPVS mesh gives it rigidity, and the absence of welds eliminates the presence of vulnerable areas in which the process of structural destruction begins. Due to its shape, moisture and foreign contaminants do not accumulate in the mesh fabric, which eliminates the appearance of pockets of corrosion.

You can view the commercially available CPVA meshes or compare them here.

Welded mesh with PVC coating

PVC coated welded mesh with plastic coating is made of high quality galvanized iron wire. A smooth plastic coating is attached to the anti-corrosion coating using strong adhesive, which increases the service life of the wire. Welded mesh with PVC coating is used for fencing residential and public buildings, such as gardens, parks, and other buildings. You can buy PVC-coated welded mesh in the form of rolls and panels, as well as in various colors.

Welded wire mesh. Benefits and Applications

Content

Welded wire mesh. Benefits and Applications. This is an excellent reinforcing component for concrete structures. Welded wire mesh consists of intertwined wires that are welded together at regular intervals with equal spacing, thus forming a barrier. Used in arrays of small and large projects. Strengthens the integrity of concrete structures.

Welded wire mesh. Benefits and Applications

Welded Wire Mesh Welded wire mesh

is a metal screen made of mild steel wire or stainless steel wire. It is available in various sizes and shapes (https://ukazs.rf). Welded wire mesh can be customized into different shapes. Metal can be coated with special coatings that improve the resistance of surfaces to chemicals and other aggressive substances.

Welded wire mesh serves as a strong anchor for the concrete. Concrete becomes brittle and crumbles over time, but wire mesh greatly extends its life. They are ideal for temporary or permanent partitions. Depending on the application, welded wire mesh is created in different types and styles. Depending on the welding process and the different types of materials used in the structure, these wires can be divided into categories. They can also be customized according to your needs and requirements.

Advantages of welded mesh

Welded wire mesh is made from high quality low carbon iron wire by a fully automatic computer controlled welding machine. It has several advantages

- Increase site efficiency and productivity by reducing dependence on on-site labor

- The likelihood of the bars bending incorrectly is reduced because the bending machines bend the mat as one unit

- Provides precise reinforcement size where needed through variable bar size and spacing

- Welded wire mesh can be placed relatively quickly compared to placing individual rods and tying them down. This leads to a reduction in slab casting cycle time

- Reducing construction costs by increasing construction speed

- Designers can use thinner bars at shorter spacings, allowing for efficient stress transfer to the concrete with much smaller crack widths, resulting in better surface finishes

- Welded wire mesh can be produced from rolls instead of standard length rods, minimizing wastage

- Welded wire mesh requires less storage space on site

- Factory cutting and bending eliminates the need for on-site rebar

- Factory production is inherently safer compared to flexible fittings on site

- Easy unloading and installation at the workplace.

Welded wire mesh. Application

Welded wire mesh. Application

- Construction

Reinforcing welded mesh is widely used for reinforcing concrete structures. In this case, a welded reinforcing mesh is placed inside the poured concrete forms (the foundation slab of the frame is poured under the slab), which serves to increase the strength of the concrete structures being formed.

- Making frames

Reinforcing road surfaces or parking lots in this way with welded reinforcement mesh is called road reinforcement mesh.

- Manufacturing of various fences

- Used as masonry mesh

- As a coal mine support grid to support the roadway of a coal mine.

Welded wire mesh. Benefits and Applications

New innovations and advancements are emerging in welding technology. Remote welding machines can increase productivity and reduce downtime. On-site repairs and alterations are in high demand, and manufacturers providing these services are known for their ability to adapt to changing market needs.

There are various types of welded wire mesh, each of which can be used according to the needs and requirements.

Types of Welded Wire Mesh

Types of Welded Wire Mesh

PVC Welded Wire Mesh

This type of mesh is coated with fine PVC powder to resist corrosion. The plastic coating protects the base metal and also adds color to the finished product. These types of mesh provide good corrosion resistance and quality that is not usually found in conventional wire mesh.

Wire mesh panels made from welded PVC have

- excellent qualities

- strength

- durability.

PVC coated and sprayed welded wire mesh is resistant to

- corrosion

- aging

- sunlight

- weather conditions.

It can be used in

- agriculture

- construction

- transportation and mining of minerals to protect structures

- safe separation

- keeping poultry and livestock

- decorations

- etc.

Galvanized Welded Mesh

Galvanized Welded Mesh

Galvanizing can occur either before or after the fabrication of wire mesh in either woven or welded form. After welding or weaving is completed, the mesh is immersed in a bath of molten zinc. The zinc bonds to the surface of the wire, thoroughly sealing it and protecting it from rust and corrosion. This can be done using electroplating, which uses electricity to bond the zinc to the underlying metal wire, or hot-dip, which involves immersing the product in a galvanizing tank full of molten zinc at a temperature of around 450 C.

One of the main advantages of galvanized wire mesh is that it offers a wide range of hole sizes and wire diameters. It is used on wire mesh for various applications of the finished product. From landscaping a fence to a heavy industrial area

Welded Stainless Steel Mesh

This type of mesh is created by welding stainless steel together at intersection points to form a uniform steel barrier. It provides users with strength and durability. The welded stainless steel wire mesh has a uniform appearance. This is one of the most popular forms of wire mesh. It can be cut into smaller sizes such as rectangles, squares or disks.

Stainless steel mesh filters are widely used because they never react with liquids and hence this increases their durability and performance.

It is widely used in

- transport

- agricultural

- mining

- horticultural

- entertaining

- other service areas.

Welded wire fencing

This type of mesh wire is available in rolls or panels that are used for fencing. Available with or without galvanized coating. The version without galvanization has a lower cost.

They are easy to install. Rolls are custom made to specifications and require little or no cutting. Can usually be installed by one or two qualified personnel.

Wire fencing rolls are ideal for jobs that require larger linear footage. Covering them may require work crews and professional installers.

There are also additional materials such as posts, rings, pliers and everything else you need to install the fence. The panels are pre-designed in specified shapes and sizes to suit the structure in which they are used. It can be easily disassembled and reused.

Welded wire fencing cannot be cut to traditional standards as it is a thick steel fence that requires torches and labor to penetrate.

Welded wire fencing is one of the most durable fence designs on the market because it is made of steel. And the actual posts that support it are set into the ground at the same depth as the cement supports.

It is used in

- residential

- commercial

- agricultural and industrial premises.

Welded steel gratings

Welded steel gratings are made from automatically resistance welded steel. The support rods and cross members are resistance welded under high temperatures and pressure to form a permanent connection. This technology can not only ensure the welded steel grating has a strong structure, but also can maintain a smooth and even surface that is easy and free to walk on.

Welded steel grating can be made from a variety of materials such as carbon steel rods, aluminum steel rods and stainless steel rods.

Welded steel bar grating is the most popular of all grating types due to its strength, cost-effectiveness to manufacture and ease of installation.

It's used

- at most industrial enterprises

- in commercial buildings

Widely used as

- pedestrian paths

- platforms

- protective barriers

- drain covers

- ventilation grilles.

The welded steel grating has

- anti-slip surface

- corrosion resistant

- good drainage function

- high strength

- bearing capacity.

Welded wire mesh for slab reinforcement

Fabric reinforced to the plate increases tensile strength compared to steel, which is extremely tensile. Welded wire mesh is a prefabricated reinforcement consisting of a number of parallel longitudinal wires with a precise distance between them, welded to the transverse wires at the required distance.

Wire welding is carried out by contact welding with solid-state electronic control, and all distances are controlled by an automatic mechanism of high reliability.

Mechanical connections, established through cross-wire welds, are responsible for transferring stresses from concrete to steel and vice versa. It can be used in tile and ferrocement works.

Tags: fittingsconsumerWelded wire mesh

Welded mesh sizes

The overall dimensions of the welded mesh depend on the type of product selected. For example, the most popular welded mesh widths in cards are 0.25m, 0.5m, 1m, 1.5m and 2m. The length of the masonry mesh is usually 2m or 3m.

A roll of welded mesh is usually 50m long and 1m or 1.5m wide.

CPVA mesh is packaged in rolls 4m, 8m or 10m long. The roll width is 1.25m.

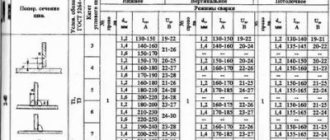

Regardless of the type, the following welded mesh cell sizes (mm) are distinguished: 15x6, 25x10, 25x25, 50x20, 50x25, 50x50, 100x100, 150x150, 200x200. The diameter of the welded mesh wire also varies and has values of 0.5, 1, 1.6, 3 or 4 millimeters.

Economic calculation. During single shift work.

Data on the cost of raw materials and cards were taken from the website of OJSC Metalservice - mc.ru as of March 3, 2011

| Name | Map | Material price per kg | Specific gravity of material | Actual weight | Basic expenses | Market price of the product | Revenue per product | Income per shift | Income per month |

| Welded steel mesh 50*3 | 500* 2000 | 29 | 0,0385 | 1,309 | 37,96 | 72 | 34,039 | RUR 40,846.80 | RUB 898,629.60 |

| Welded steel mesh 50*3 galvanized | 500* 2000 | 39,49 | 0,0385 | 1,309 | 51,69 | 116 | 64,30 | RUB 77,169.11 | RUB 1,697,720.38 |

| Welded steel mesh 50*4 | 500* 2000 | 26,79 | 0,089 | 3,026 | 81,06 | 114 | 32,93 | RUR 39,520.15 | RUB 869,443.34 |

| Welded steel mesh 100*3 | 2000* 3000 | 29 | 0,0385 | 3,927 | 113,88 | 222 | 108,11 | RUB 37,840.95 | RUB 832,500.90 |

| Welded steel mesh 100*4 | 2000* 3000 | 26,79 | 0,089 | 9,078 | 243,19 | 354 | 110,80 | RUB 38,780.13 | RUB 853,162.93 |

IMPORTANT:

Our equipment is capable of smoothly working with wire with a diameter of 2.5 mm, which can significantly reduce costs and increase profits.

We are always ready to answer all your questions! tel: (toll-free); +7(4822) 60-55-60 Email:

Where to buy welded mesh in Voronezh at wholesale prices

To perform certain construction work, you will need the appropriate types and sizes of welded mesh. When purchasing welded mesh, you must consider:

- Intended use of welded mesh.

- Effective permanent and temporary loads.

- Dimensions.

- Regulatory requirements for the placement of welded mesh.

Depending on the purpose and overall dimensions, as well as the cell size of the welded mesh, the price varies significantly. You can choose a suitable welded mesh at low wholesale retail prices in the EVERYTHING IN THE HOUSE online store. We guarantee low prices for welded mesh, and our offers contain cheap prices for welded mesh.

You can also clarify the possibility of reducing the price of welded mesh by contacting the manager by phone or ordering a call back. Delivery options for welded mesh can be selected during the ordering process or interaction with the manager.

Direct link to compare the characteristics of different types of welded mesh here.