We make homemade products for the walk-behind tractor with our own hands

To quickly and efficiently cultivate the soil, you need to make homemade “crow’s feet” cutters for a walk-behind tractor, which will mix the soil to a sufficient depth and break up hard clods.

A homemade rake for a walk-behind tractor is also a useful attachment. It is best to have several of these different types of rakes.

Every gardener will also need a homemade hiller for a walk-behind tractor. The hiller will allow you to form smooth and high ridges in all beds with root crops. A homemade blade for a walk-behind tractor will make it easier to remove snow and sand from the land and create good conditions for further tillage.

Selection of walk-behind tractor

When choosing a walk-behind tractor in the Neva line for a future miniature tractor, you need to take into account the following parameters: power, weight, engine type, plow parameters, price aspects.

Power . It is determined by the area of the zone where the work will be carried out. The larger it is, the more powerful the walk-behind tractor should be. The best option here is the Neva MB-23. Today it is the leader in power among all representatives of this line. Can also work on very hard soils. Creates a traction force of 180 kgf. Can unlock one of the wheels. Improves maneuverability. Engines of various powers can be installed in it. Today there is a very wide range of them. Thanks to this, each master will be able to choose the appropriate option.

Usually Neva MB-23 is presented in the following variations: 10.0 and 8.0.

Data of the first: Briggs&Stratton engine, its power is 10 l, the number of gears is 4 (2), the role of transmission is performed by a gear reducer filled with oil, suitable gasoline AI-92 and AI-95, processing parameter 86 - 127 cm, milling speed from 20 to 160 (per minute), carries out processing at a level of 20 cm. Second data: the engine is the same, only with the parameter 8 l, all other indicators are identical. Today you need to pay from 43,000 to 45,000 rubles for the Neva MB-23. The modification you purchase matters.

If you need a more modest unit, you can purchase the Neva MB-2. This is also a very productive technique, but with a less powerful engine. It has many modifications, for example “6.5 Pro” and “7.5 Pro”.

Be sure to read: Dongfeng mini tractor

They are powered by the same brand of engine. In one modification its power is 6.5 liters, in the second - 7.5 liters. Their similar characteristics: a chain reducer as a transmission, suitable gasoline AI 95 and 92, processing level 20 cm, its width - 86-127, milling speed from 20 to 160 (per minute), weight - 98 kg, number of gears 4 (2 ). Distinctive indicators: - functional volume, in the 6.5 model it is 205 cc, in the 7.5 version it reaches 215 cc, - fuel tank, its volume in the first model is 3.8 liters, in the second - 4.6 . Today the price of the Neva MB-2 is in the range of 33,000 - 45,000 rubles. Weight. The following rule applies here: the more complex the excavation work, the higher the weight of the walk-behind tractor, and the reverse principle. When choosing between a gasoline or diesel engine, base it on the factors that are more important to you. If you need a quiet device that starts quickly in cold weather, then give preference to the gasoline type. If you need a more economical device with stronger traction and stable speed, purchase the diesel version. This version also works better with difficult soils and large areas. Plow parameter. It depends on the depth of the upcoming processing. It is better to take a collapsible modification in which you can adjust the width. This way you can configure the plow for a given situation

Homemade rake for walk-behind tractor

If you wish, you can easily make a homemade rake for a walk-behind tractor. For wide-grip hay rakes, you can use regular water pipes that differ in diameter. You will need to put a special bushing on the round rod, then tap its surface, turning it slightly.

When making, a round rod is best suited. Most parts of the rake are held together by electric welding, since this method is simple, and at the same time a reliable design is obtained.

Greater design simplicity can be achieved if the rotating parts on the axes are fixed without rolling bearings.

It is better to make the hay rake for the walk-behind tractor foldable, as this will simplify their transportation.

Motorcycle dog and caracat

Anyone who has had the chance to ride an imported motorized towing vehicle will probably see in its design a lot of similarities with a conventional walk-behind tractor. Almost the same front traction unit with the engine, a similar method of transmitting torque, similar controls on the steering wheel. The only thing missing is rubber tracks, with the help of which the motorized dog will pull the sled and rider across the snowy field.

When realizing their dream of a motorized towing vehicle, avid fishermen and hunters can go in two ways: buy a ready-made snowmobile attachment or make it yourself.

Today, tracked attachments for almost all types of walk-behind tractors (Neva, Salyut, Agat, Favorit, Cascade, Forza, etc.) are produced on an industrial scale. The price of this unit is quite high (about 30 thousand rubles).

Therefore, anyone who is trying to save money and at the same time is well acquainted with the caterpillar undercarriage structure can make it and ski sleds themselves. To do this, you need to weld a strong frame on which the engine and steering wheel, chassis and driven sprockets, as well as two intermediate shafts with rubber rollers will be placed.

Speaking about what can be made from a walk-behind tractor, it is worth mentioning such an interesting homemade product as a karakat. The strength of this car is in its huge wheels, which are ordinary inner tubes, tightened with strong belts.

Sometimes truck tires are used to make ultra-low pressure tires. They are lightened by carefully cutting out part of the surface with an electric jigsaw, leaving only part of the bead and lug tread pattern.

Homemade rims are installed on the karakat from a walk-behind tractor, modifying and expanding standard car rims. You can also put a very original wheel on a lightweight walk-behind tractor. To do this, two aluminum basins are welded along the contour, the bottom is cut out to fit the size of the hub, and they are equipped with stiffening ribs and side stops for fixing the camera.

Despite its external clumsiness, the carakat based on a walk-behind tractor is surprisingly passable and stable. It not only easily overcomes swampy lowlands, but is also capable of carrying quite a significant load (up to 100 kg).

Anyone who plans to assemble an ATV using a walk-behind tractor as a base must be prepared for the fact that he will not reach super-high speed on it. But in terms of maneuverability and maneuverability, such a device is in no way inferior to a more expensive one.

The seating position in a home-made SUV remains traditional “motoblock”, and not motorcycle-like as in a “quad”. There is no need to make rims for this ATV yourself. You can use standard ones from any passenger car, designed to install wide-profile “mud” tires.

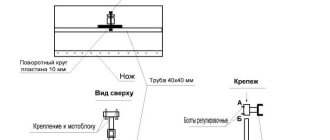

How to make a homemade blade for a walk-behind tractor

The walk-behind tractor can serve as a bulldozer for leveling soil, clearing sidewalks or roads from dirt and snow. To do this, you need to make a homemade blade on a walk-behind tractor, usually sheet metal 1-2 mm thick is used. Four steel ribs (stiffeners) from a sheet 3-4 mm thick are welded inside the blade.

Holes are drilled into them locally to fasten the blade with the rods in a strictly vertical position in relation to the front of the walk-behind tractor. It is also better to sheathe the bottom of the blade with tin so that it does not bury itself in the ground.

- 1 – dump sheet (tin);

- 2 – 4 pcs stand (stiffening ribs);

- 3 – bottom sheet of the dump (tin);

- 4 – knife; 5 – linkage mounting eye.

Walk-behind tractor: device

The thematic unit is a wheeled chassis on which an engine with a power of up to 14 hp is placed. The motor is powered by diesel or gasoline to set the chassis speed through the gearbox.

As a result, the user of the walk-behind tractor effortlessly pushes the equipment forward, holding it by the handles. The latter houses the start and speed buttons.

The chassis of the walk-behind tractor consists of two wheel axles with thick tires. In winter, it is better to equip tires with chains so that the unit does not slip on snow and ice.

But for better maneuverability on wet ground, it is recommended to replace axles with tires with metal lugs.

An alternative option is a caterpillar track. But then the question arises: “how to make tracks on a walk-behind tractor with your own hands and what materials and means to use for this?”

To make themed caterpillars, enthusiasts use:

- Conveyor belt and links cut from a profile pipe;

- Split tires from cars and other transport equipment.

Convenient homemade seeder for walk-behind tractor

Conventionally, seeders for walk-behind tractors are divided according to the number of simultaneously sown rows - from 1 to 5; vegetable seeders and precision seeders are also distinguished. Vegetable seeders are used for dotted sowing of vegetables: carrots, onions, beets. The device for feeding seeds is driven by the support-drive wheels of the sections. In addition, the rotation speed of the device is regulated by replaceable sprockets.

Precision seeding vegetable seeders have a brush sowing device. In such a device, a rotating brush stirs up a layer of seeds in a hopper so that they fall out into a hole located in its rear wall. The hole is closed by a rotary disk having holes of different diameters. By turning the disk, you can change the size of the holes and thus change the seed sowing rate.

A homemade seeder for a walk-behind tractor is usually connected to the walk-behind tractor using a universal hitch, thanks to which the walk-behind tractor can be equipped with two-row and four-row seeders.

About the device of the walk-behind tractor

Next, you will find out which walk-behind tractor is better to choose. To make it clearer what the principle of homemade walk-behind tractor manufacturing and its additional components is, you need to consider in detail the structure of the walk-behind tractor as a means of small-scale mechanization. So, this unit includes several main working units:

- The main driving force, i.e. engine.

- Transmission.

- Chassis.

- Basic controls.

Engine

The main driving force in the design of walk-behind tractors is a standard internal combustion engine. Depending on the type and brand of walk-behind tractor, for example Cayman Vario, Patriot Ural, Texas, Foreman, Crosser, Viking, Forza, the engine used may be different:

- Gasoline 4-stroke engine. This engine is used for units belonging to the light and medium class of devices.

- Diesel 4-stroke engine. Motors of this kind are used on heavy and powerful walk-behind tractors designed to work on the most difficult surface areas.

Video: The best diesel walk-behind tractor

For more information about the operation of a diesel walk-behind tractor, watch the video:

Of course, 2-stroke engines are also available, but they are used in fairly old models of walk-behind tractors, being significantly inferior to 4-stroke engines in terms of power thrust. However, most consumers get 4-stroke gasoline engines. Their device includes the following systems:

- The system responsible for supplying fuel. Consists of a fuel tank, carburetor, air filter and fuel hose.

- A lubrication system that carries out the process of lubricating those parts that rub against each other.

- A starter that spins the crankshaft.

- A cooling system that removes heat from the engine cylinder block using air flow.

- An ignition system that produces a spark at the spark plug.

- A gas distribution system that ensures the flow of the air-fuel mixture into the engine cylinder and is also responsible for the exit of exhaust gases.

The important thing is that the engine is sold with all the main operating systems, which greatly facilitates the process of making a homemade walk-behind tractor.

Transmission

The main function of the transmission is to transmit torque from the engine to the wheelbase, as well as regulate speeds and change the movement of the unit. Its design includes several working units: gearbox, clutch, gearbox and differential (not available in all models).

Transmission can be of several types:

Basically, the classic type of gear transmission is used on heavy walk-behind tractors, and it consists of bevel and cylindrical gears.

Other types of transmission are used in light and medium types of walk-behind tractors. At the same time, regardless of the type of transmission, the design contains a PTO - a power take-off shaft, which transmits torque to the working units of the unit.

As for the clutch, it can be different:

- In the form of a V-belt transmission. The essence of the process is the clutch lever, which tightens or loosens the belt, thereby transmitting or stopping the transmission of torque from the motor to the gearbox.

- Single or multi-disc dry or wet clutch.

- Conical coupling.

Most high-quality walk-behind tractors Sadko, Don, Huter, Profi, Plowman, Champion, Carver use the second type of clutch, which is the most reliable.

Chassis

The chassis includes not only the wheelbase itself, but also the frame structure to which these wheels are attached, and where the main working units of the walk-behind tractor are located.

In more modern models of walk-behind tractor, it is possible to change the distance between a pair of wheels, which allows you to adjust the track size of the walk-behind tractor.

Today, there are two types of wheels - pneumatic and metal with lugs.

Basic controls

The walk-behind tractor control is located on the handle of the unit, responsible for changing the speed and direction of movement of the device. The controls include:

- Levers, steering wheel and gear shifters.

- Clutch control.

- Engine stop lever or button.

- Gas supply, etc.

The design of the walk-behind tractor does not have a seat for a person (as in the Salyut walk-behind tractor), so the control itself is carried out by a person with his own hands.

Homemade shovel for walk-behind tractor

The walk-behind tractor often acts as a bulldozer, leveling the soil and also clearing sidewalks or roads of dirt and snow. It is equipped with a blade shovel.

You can make a homemade shovel for a walk-behind tractor without any difficulty if you have a grinder, a drill and a welding machine on your farm.

You won’t have to look for a long time for a suitable metal, since an ordinary two-hundred-liter steel barrel will be suitable for making a shovel-dump. By carefully cutting it into three parts, you will get three curved segments for a shovel. By welding two of them along the contour, you will get a blade shovel with a metal thickness of 3 mm, which is quite enough for the required rigidity of the blade blade.

How to make a mini tractor from an MTZ walk-behind tractor?

To remake walk-behind tractors of this brand, you should also take into account their design and capabilities.

MTZ units have sufficiently high power, which makes it possible to make a full-fledged mini-track tractor out of them. It will be distinguished by high cross-country ability and excellent traction with the soil, due to which the quality of soil plowing for such a machine will be many times higher than that of wheeled mini-tractors. Before you begin, be sure to study the drawings, in which you will find all the information required for the alteration.

The procedure for assembling a mini tractor is as follows:

- First, switch the walk-behind tractor to operating mode with a mower;

- After this, completely dismantle the front platform of the unit;

- Install a caterpillar drive in the front part of the mini-tractor being manufactured;

- In the niche intended for mounting the steering rod, install the adjusting rod. This element will increase the rigidity of the entire structure;

- Weld the driver's seat to the top of the frame;

- Next to the engine, arrange a platform for mounting the battery and hydraulic distributor.

This manufacturing method is suitable for converting MTZ 05, MTZ 09 and MTZ 12 walk-behind tractors into small tractors. Each of them has enough power to work with a trailer and attachments at the same time.

Making a homemade disc hiller for a walk-behind tractor

We begin to make a homemade disk hiller for a walk-behind tractor by searching for lids from steel pans that are unnecessary on the farm (preferably not enameled, but simply metal). The required diameter is approximately 40-50 cm, taking into account the fact that the depth of germination of potato roots into the ground is no more than 15-20 cm. Next, we sharpen the blades of the lids, and in our case they are already hiller discs, on a grinding machine. If the lids are flat, then they are slightly bent to one side with a hammer.

Next, in order to make a convenient hiller, you need to make a cart to which the disks that move the soil will be attached. This can be a structure made of pipes and bushings; we attach small support wheels to its lower frame.

After this, you can proceed to testing such a hiller directly in the potato plot of the garden.

Minitractor from the Neva walk-behind tractor

Converting a walk-behind tractor into a small tractor may be slightly different.

It all depends on the design features of the walk-behind tractor and its capabilities. Let's consider the principle of manufacturing a mini-tractor from Neva brand walk-behind tractors. As in the first case, before making a mini tractor, you need to study the diagrams. They detail the dimensions of the elements and the order of their installation during assembly.

The procedure for reworking will be as follows:

- The manufacture of the frame is carried out in the same way as in the first case. To create it, use pipes of different sections. Fastening of frame elements is carried out by bolts and welding;

- Next, proceed to the manufacture and installation of the chassis. To install the rear wheels, use an additional axle, which can be made from a steel pipe. Press bearings and bushings that will be equipped with the rear wheels into both ends of the latter;

- Next, the tractor from the Neva walk-behind tractor needs to be equipped with a motor. Moreover, the engine can be installed both in the front and in the rear of the frame. In the second case, the front and rear wheelbase of the mini tractor will need to be expanded;

In the end, the self-made unit will only need to be equipped with a driver’s seat, lighting devices and side lights. Due to its small size, the finished tractor will have high maneuverability, which will allow it to be used effectively in hard-to-reach places.

How to make a homemade plow for a walk-behind tractor

Is it necessary to make a plow for a walk-behind tractor if you don’t have any special metalworking skills? Yes, it's worth it. The design of this agricultural implement is quite simple and therefore anyone can correctly make a homemade plow for a walk-behind tractor.

Before you begin to implement your plan, you need to look through the previous posts on our website, where we described the manufacturing process in detail with drawings.

Professional tools are best suited for the job; they will allow you to perform all technological operations with your own hands at the required level and at the same time maintain their quality. An amateur tool is unsuitable for such work because its level of strength is insufficient to perform some of the operations.

Reviews

Oleg, Taganrog

I have been using the walk-behind tractor for several years now. I also wanted to buy an adapter for it, but I saw a homemade mini-tractor online and got excited about this idea. I thought it would be difficult to do this, but gradually, as I studied the material and delved into it, I realized that I could do everything myself. I chose a drawing, bought the necessary components and got to work. It took me about a month, but I achieved my goal. Now work on the site goes faster.

Ivan, Krasnodar

I bought a walk-behind tractor and was happy with my new “assistant”. But, I am a supporter of modernization, so I constantly improve my equipment. It was the same this time - I decided to assemble a mini-tractor. The design is simple, I found the components quickly. Now I have a new unit, and my neighbors are surprised that I was able to assemble it myself.

To create a mini tractor at home, you don’t need to turn to professionals. All you need to do is select a diagram and drawing, buy the necessary spare parts and get to work. Moreover, now you can find instructions where each step is captured in the photo.

Homemade crow's feet cutter for walk-behind tractor

This is an all-welded, non-dismountable steel cutter, which gives it significantly greater strength than conventional cultivator cutters. A homemade crow's foot cutter for a walk-behind tractor shows great efficiency and is successfully used when plowing hard soil. It can be aggregated with almost any walk-behind tractor or cultivator with a suitable axle diameter.

The “crow’s feet” cutter is very good to use when plowing the land for planting potatoes, especially if the soil is hard with large clods of earth, or when, to prevent the Colorado potato beetle, wireworms and other garden pests, you need to quickly plow the garden “in the winter.”

“Crow’s feet” are usually sold unsharpened, and many gardeners who have already tested these cutters recommend sharpening them for easier and faster plowing.

Below are drawings of a homemade crow's feet milling cutter with a diameter of 520 mm, a grip of 1250 mm, and a total number of beams of 30 pcs. 3 pcs. per section. The beam is bolted to the coils.

When plowing the soil with such a cutter, it loosens and rises to a depth of an average of 40 to 100 mm, depending on humidity.

From tractor to boat

The most common modifications from a conventional walk-behind tractor are all kinds of complex equipment and vehicles.

True, the latter can be more called homemade products based on the engine and transmission of the device. Potato planters . If there is a large area for planting potatoes, a device based on a walk-behind tractor would be ideal. It includes several elements at once. First of all, the potato planter is equipped with a small hopper for tubers.

In front of it is a plow that makes a ditch, and behind it is a hiller that fills and forms a bed. All devices must be adjustable in accordance with the planting depth and size of the beds.

Mini tractor . Most often, craftsmen construct all kinds of mini-tractors. In this case, the shift in the center of gravity of the equipment should be taken into account, since the engine is installed in the rear. Therefore, care should be taken to expand the wheelbase of the rear axle.

Currently, you can find on sale all kinds of components and assemblies for creating a tractor based on a walk-behind tractor, such as front axles, brake system, all kinds of rods and levers, pedals. But if you wish, you can make all this yourself, using suitable parts from old cars.

When using more powerful tires, such a tractor can easily turn into an all-terrain vehicle.

Boat motor . The engine from a walk-behind tractor can also be an ideal replacement for a conventional outboard motor. To do this, the necessary fastening should be made on the boat hull, and the standard engine cutter should be replaced with blades. In the right hands, a walk-behind tractor can also become the basis for creating a small buggy-type car. True, it will not be possible to drive in urban conditions - this is due to the official registration of the vehicle with the state traffic inspectorate. But it can be an excellent help in rural areas for fishing trips or hunting for mushrooms. Also, such an “SUV” is ideal for mastering driving skills for beginners.

Most often, the front axle from a “disabled” vehicle is used as the chassis for such a homemade vehicle, the rear axle is a drive axle, it can be installed from an old Zhiguli or from an Ant scooter. By the way, the size of the wheels used will depend on this. The frame shape and body design are made based on the operating conditions of this equipment. But you should not miss such a moment as the need to install seat belts and roof bars.