Advantages of the model

Machine 1k62 represents the frontal type of equipment. Even processing of parts made of hardened metal is acceptable.

The positive aspects are not limited to the above:

- High strength of each of the parts included.

- Wide range of operating speeds.

- The versatility of the device in operation.

- Possibility to use carbide cutters.

- Vibration resistance.

1K62D — screw-cutting lathe — For identification

Good afternoon artisans! Today I came across this machine 1K62 D, Chelyabinsk, 1996 from an open storage area, they wanted to take it to scrap metal. I dissuaded him - I don’t know why. It seems like I’m not a machine operator myself - I work in metal structures (canopies, cornices, greenhouses, etc.) and I’m trying to master forging. Now the problem arose for me: to keep it for myself and restore it, give it to someone, then the price of the issue. I took it, I took it, but now I don’t know what to do with it, I just can’t watch it when I let someone need things into metal. (this is how I got a press and also a machine)

www.chipmaker.ru

Technical characteristics and passport

Starting with the basic parameters, it is recommended to pay attention to the following figures:

- The maximum weight for workpieces is as follows: weight in the centers up to 1500 kilograms, weight in the cartridge - up to 500.

- The total length of the blanks is up to 150 millimeters.

- Machining diameter: above the support up to 200 mm, above the bed 400.

The spindle supplied with the screw-cutting type of equipment has the following parameters:

- The M6 series housing is used.

- The reverse speed has a speed of 2420 rpm.

- Rotation occurs at a frequency of 12.5 to 2000 rpm.

- Direct rotation at 25 speeds.

- Up to 45 mm diameter steel bar.

- Hole with 47mm diameter.

Caliper feeds also have certain parameters:

- From 1 to 192 mm pitch of cut thread.

- 44 pieces of possible standard sizes for metric threads.

- 3.4 meters per second is the feed speed along when the movement is fast. The transverse is 1.7 meters per second.

- 49 steps for longitudinal feeds.

- 250 mm – transverse stroke of the caliper.

- The carriage stroke is 1330, 930 and 660 mm.

User manual

The main advantage is a wide range of possibilities for owners of such machines. Processing will take place without problems, both with small and large parts. Workpieces with a total weight of up to 300 kilograms are easily attached inside the cartridges.

The future subtleties of the work and the mass of the part determine which tools should be chosen and how to set the parameters. The end surfaces are processed with the following devices:

- Dies.

- Taps.

- Zenker.

- Drill.

- Sweeps.

- Incisors.

The shape of the required complexity will be acquired by the product only if the appropriate type of tool is used during processing. When the spindle is mounted on bearings, access to the processing of structures made of hardened types of metal is opened. Even the appearance of shock loads does not negatively affect the final accuracy.

Location of controls

The mechanism has the following handles responsible for control:

- For moving the slide and carriage in mechanical mode.

- To move the slide.

- Connections to the frame at the tailstock.

- Clamping the quill, moving it.

- Lead screw control.

- Rotation of the indexable cutting head and its fastening.

- Friction part clutch.

- The thread pitch and position are at normal or maximum level.

- To control the gear.

- Selecting the type of thread.

- For left-hand thread, feed.

- Indicator of thread pitch, feed.

- Spindle operating frequencies.

Each handle has several positions to ensure functional control.

Taps and switches, buttons, regulators are additional controls available to each operator.

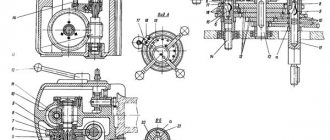

Headstock

A general passport with technical parameters will confirm that the part ensures that a certain frequency is transmitted to the spindle during rotation. The number of operations the masters perform is the same frequency that is set. The headstock is designed in such a way that it provides the following capabilities:

- Multi-start thread.

- Right-hand thread or reverse left-hand thread.

- Increased gear ratio to 8.32.

- Thread increased by 16 with a pitch 4 times larger than the standard one.

Tailstock

Guide elements move the tailstocks forward. Be sure to attach it to the frame. A certain fastening of this unit will allow you to perform certain specific works. Additional clamps are the handle eccentric along with a simple lever system. The quill is additionally secured with a handle. The rotational movements of the lever are caused by the displacement of the handle.

Characteristic is the active use of transverse displacements of the tailstocks. Flat cones should not cause problems. This makes it easy to process parts whose dimensions are small. Metric threads are made with a minimum depth.

Caliper

The main purpose is to move the cutter fixed in the tool holder. This movement is carried out along the axis of the spindle, across this part, or at a certain angle. The cross design is always characteristic of this part. In total, it has three main moving units:

- Carriage.

- Cross slides.

- Cutting slides.

These nodes sometimes have different names in various technical literature. The rotating plate is fixed at literally any angle in relation to the base. The main thing is that the caliper supply does not turn on simultaneously from several parts at once. A special locking mechanism is provided for this.

Gearbox

Certain types of threads are created thanks to the feed module. A lead screw with a fixed pitch of 12 millimeters becomes the main assistant during all kinds of manipulations. There is no need for special links, even when the current pitch needs to be increased. According to the passport, the mechanism facilitates the creation of the following types of threads:

- Pitchevaya 1-96.

- Modular – 0.5-3.

- Inch - from 2 to 34 threads.

- Metric. The minimum step is 0.5 millimeters. The maximum step limit is 12.

Subtleties of working with shaped blanks and conical parts

The technical characteristics of the 1K62D modification allow turning and cutting the required threads on conical-shaped parts, as well as shaped blanks. Processing of these blanks is carried out using two methods.

It is necessary to achieve displacement of the tailstock housing in the transverse plane. At a certain angle of location of the axis of the centers and the axis of the workpiece itself, the cutter is capable of turning conical parts. But due to the asymmetrical arrangement of the center holes relative to the installation centers, it is impossible to make a cone of an ideal shape.

Using a copying module for operation, which is fixed to the rear of the frame with brackets.

Bracket for fixing the copy module

By correctly selecting the fastening angle, it is easy to achieve the ideal cone-shaped part.

This processing method allows you to obtain a universal cone; the part will be of any acceptable length. This type of processing allows you to obtain a cone of the correct shape.

If you replace the copying cone ruler with a shaped one, the functionality of the machine expands even further. Specialists can process the shaped surfaces of step shaft blanks.

The 1K62D modification machine supports maximum load modes and impact processing of parts. A big advantage is the unpretentiousness of the choice of workpiece materials; it is easy to work even with steel, cast iron, durable parts.

Before starting the machine, it is necessary to adjust the cutters; the machine is required to perform several workpieces of minimal, medium and high complexity.

Electric scheme

For any modification of the unit, spindle movement is considered the main working movement. It is transmitted from the drive through a gearbox with a V-belt drive. The passport reports that 23 speeds are supported. But the number is actually decreasing. Some gears operate with approximately the same gear ratios and ratios.

According to kinematics, the machine consists of the following circuits:

- 3 of them are on the caliper.

- There is also a cross feed.

- Accelerated movement.

- The last chain is a screw feed.

When the thread is cut, the screw part is activated. It uses a 68 lead screw. A special nut is fixed on the apron, which also becomes an integral part of the process.

Only the working condition of the couplings will ensure cross-feed. They transmit torque to the running shaft through gear-type wheels. The energy is then transferred to the transverse caliper. If necessary, the couplings will also provide transverse movement. The movement passes through gears and is communicated to the rack and pinion. The rail is fixed motionless on the frame. As a result, the mechanism rotates. The apron and caliper move together.

The auxiliary electric drive directly provides rapid feed when the need arises. Using screw pairs, owners can easily adjust the position of the quill at the tailstock and slide.

Screw-cutting lathe 1K62D (RMC 750)

If you need to buy a screw-cutting lathe 1K62D (RMC 750), call:

in Moscow +7 (499) 372-31-73 in St. Petersburg in Minsk +375 (17) 246-40-09 in Ekaterinburg in Novosibirsk +7 (383) 284-08-84 in Chelyabinsk +7 (351) 951 -00-26 in Tyumen +7 (3452) 514-886

in Nizhny Novgorod +7 (831) 218-06-78 in Samara in Perm in Rostov-on-Don in Voronezh +7 (473) 202-33-64 in Krasnoyarsk +7;

in Abakan, Almetyevsk, Arkhangelsk,

Astrakhan, Barnaul, Belgorod, Blagoveshchensk, Bryansk, Vladivostok, Vladimir, Volgograd, Vologda, Ivanovo, Izhevsk, Irkutsk, Yoshkar-Ola, Kazan, Kaluga, Kemerovo, Kirov, Krasnodar, Krasnoyarsk, Kurgan, Kursk, Kyzyl, Lipetsk, Magadan, Magnitogorsk, Maikop, Murmansk, Naberezhnye Chelny, Nizhnekamsk, Veliky Novgorod, Novokuznetsk, Novorossiysk, Novy Urengoy, Norilsk, Omsk, Orel, Orenburg, Penza, Perm, Petrozavodsk, Pskov, Ryazan, Saransk, Saratov, Sevastopol, Simferopol, Smolensk, Syktyvkar , Tambov, Tver, Tomsk, Tula, Ulan-Ude, Ulyanovsk, Ufa, Khabarovsk, Cheboksary, Chita, Elista, Yakutsk, Yaroslavl and other cities

Toll-free number throughout Russia.

In the CIS countries - Belarus, Turkmenistan, Uzbekistan, Ukraine, Tajikistan, Moldova, Azerbaijan, Kyrgyzstan, Armenia in the cities of Bishkek, Baku, Yerevan, Minsk, Ashgabat, Chisinau, Dushanbe, Tashkent, Kiev and others for the purchase of equipment such as screw-cutting lathe 1K62D (RMC 750) call any convenient number listed on our website, or leave your contacts under the ORDER A CALL button at the top of the site - we will call you back.

stanok-kpo.ru

More about the electrical diagram

The basis of operation is a three-phase alternating current network, it is the power source for all electrical equipment. A grounding wire is required. The electrical equipment is represented by several units that are always included with the machines:

- The push-button station at the headstock is responsible for starting or turning off the drive.

- Transformer along with local lighting bulbs.

- Pump.

- Package type switches.

- The motor and electric pump are powered by a thermal relay.

A so-called magnetic starter is separately provided, which prevents the motor from starting spontaneously.

Final Thoughts

The tractor plant that produces these machines has not existed for a long time. But machines manufactured many decades ago still work due to their reliability. Some of the parts are wearing out. If necessary, they are replaced; if not, the entire machine is replaced completely. It is almost impossible to find new equipment that would belong to the 1K62 series. Therefore, various letters are added to the main marking to indicate the modification.

Analogues of this machine are also produced. Often it is enough just to tint the body to give the equipment a marketable appearance. The main thing is regular maintenance. Its volume must also be complete; any mechanic can handle the job.

Screw-cutting lathe 1K62D, 1K625D – Everything for dummies

- home

- Video library Natural science Physics

- Mathematics

- Chemistry

- Biology

- Ecology

- Social studies as a science

- Drawing

- Computer science

- Editors and compilers

- Music

- Science Physics

- Foreign languages

- Theoretical mechanics and strength of materials

- Metalworking machines

forkettle.ru