Technical characteristics of a hacksaw for wood

It was the wood hacksaw that became the ancestor for a huge number of hand tools. Over a long period of use, a simply huge number of different varieties have been produced, all of which have their own performance properties. When considering the main types of hacksaws for wood, attention should be paid to the blade, which is the working part of the tool. Among the features we note the following:

- The length of the canvas may vary significantly. In this case, too high an indicator causes greater elasticity, but this significantly complicates sawing hard wood. However, too short a length makes the cutting process difficult. Most often, models with a length of 25-30 cm are chosen for domestic use, as well as 45-50 cm for construction work, where a larger stroke is required to significantly increase productivity.

- Some experts recommend that when choosing a length, you should be guided by the following rule - the length should exceed the diameter of the workpiece by approximately 2 times. If this is not the case, then the work becomes significantly more difficult. Quite a lot of force is required to release the blade.

- In most cases, during production, the width of the product is maintained at 10-20 cm. There are also versions with a narrow blade on sale, however, GOST 26215 does not allow the use of such versions, since they are damaged even with slight force.

- When creating the main part of the tool, a variety of alloys can be used. Most often this is tool steel, which can withstand quite serious impacts. Manufacturers also use alloyed alloys, to which special substances are added, which improve performance properties.

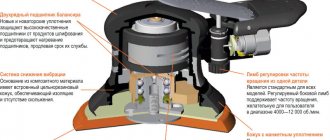

In most cases, the hardness of the material is 45 HRC. It is recommended to pay attention to the design option, which has an indicator of 55 to 60 HRC.

Such a hacksaw for wood can withstand prolonged exposure. Increased hardness can be determined by the dark coating of the teeth.

Download GOST 26215-84

Popular models

Information from sellers about which wood hacksaws sell best makes it possible to judge the most popular models. Let's look at some of them.

Stanley Jet Cut SP2-15-288

This hacksaw is equipped with a D-shaped handle, a 50 cm blade with a tooth pitch of 7 mm. A tooth with three cutting edges ensures ease and speed of sawing. The fine Swedish steel used in the production of the blade ensures high quality of the tool. The teeth are practically not subject to wear, which allows for many years of successful use. Price - within 1200–1300 rubles.

Bison Expert

The tool is popular, benefits from its reasonable cost (from 700 rubles), as well as its versatility. Triangular hardened teeth allow longitudinal and transverse cutting at a fairly high speed. The special tooth setting technology eliminates the occurrence of clamping forces, improves productivity and work efficiency. Hardened, specially set teeth, with a pitch of 5 mm, a comfortable plastic handle. Canvas length from 40 cm.

Stanley General Purpose 1-20-089

Designed for precise and accurate cutting of workpieces, this hacksaw has fine teeth (TPI=11) made using Jet Cut technology, an ergonomic handle, and a polished steel blade. A special feature is the precision provided by the fine teeth. At the same time, the operating speed is also quite high, due to the teeth with three cutting edges (sawing occurs in both forward and reverse motion). The comfortable handle provides a firm grip, excellent control and ease of use; it is attached to the blade with three screws. Length 380 mm, price - 650–700 rubles.

BAHCO Laplander 396-LAP

An excellent tool designed for sawing dry and wet wood, designed and manufactured specifically for hunters, fishermen and tourists, although it is also used by gardeners and even builders. Excellent Swedish quality, TPI=7, Sandvik XT shaped teeth, allowing sawing both along and across the grain. The canvas has a special coating applied not only to protect against corrosion, but also to reduce friction. Length when folded is 23 cm, weight is 200 g. The blade is securely fixed in both the folded and open positions. The only drawback is the price - from 1.6 to 2 thousand rubles.

Pull blocks. Purpose and device

Tightening straps for securing cargo. Transportation safety

Purpose and types of teeth

The main part of the working element of the structure is represented by teeth. Tool performance is characterized by a different number of teeth, which are also characterized by other properties. An example is TPI - the number of teeth that are designed for one inch. A narrow hacksaw for wood or a wide version is characterized by the following features:

- A large tooth allows for high labor productivity, but the resulting cut becomes rough.

- A hacksaw with a fine tooth allows you to get a high-quality cut, but the sawing task becomes much more complicated.

The most important criterion for choosing a tooth is the degree of machinability of the material. If you need to obtain high cutting accuracy, then select a tool with a TPI value of 7-9. However, a hacksaw with a TPI of 3-6 is suitable for sawing logs.

Teeth are also classified according to the degree of processing. There are knee and regular versions, the first is characterized by the fact that it can withstand quite a long impact and not become dull. However, the knee version cannot be re-sharpened due to the low degree of machinability; ordinary metal can be sharpened. Therefore, the hardened hacksaw is thrown away after wear.

Types of saws

Hand saws, according to the accepted classification, are divided into two main groups: hacksaws for working with wooden products; saws for cutting metal parts.

The rating for the use of hacksaws for wood in the household is much higher than for devices for cutting metal, so it would be rational to pay special attention to this group of cutting tools.

The main indicators of high-quality and productive work are the cutting direction. Therefore, hacksaws are divided into three main categories:

- cross saw;

- rapite saw for longitudinal cutting of wood;

- longitudinal-transverse (universal) saws.

The main difference between all these categories is the shape of the teeth that cut the wood. A crosscut hand saw has straight teeth, while a rip saw has forward-sloping teeth. Universal saws have the same inclination of the teeth, but the cutting process in different directions is carried out due to special sharpening of the cutting edge.

Types of teeth

The teeth of any hand saw serve double duty. Firstly, their main purpose is to cut wood fibers, and secondly, to remove the resulting sawdust from the cut site. It is necessary to take into account that the volume of waste is 5-7 times greater than the amount of wood from which it was formed.

That is why the distance between the teeth must be quite large so that the sawdust can be removed during the cutting process. If there is not enough space for sawdust, the hacksaw blade will become clogged and begin to slide over the waste, greatly reducing sawing performance.

Trying to space the hacksaw teeth too rarely resulted in a significant slowdown as the small number of cutting edges removed few chips. In this case, it was necessary to take into account that the thickness of the workpiece was greater than the pitch of three adjacent teeth. Otherwise, when sawing, vibrations and impacts of the hacksaw may occur, which may even cause its breakage.

Taking into account all these nuances, hacksaw manufacturers were forced to look for a middle ground that would make it possible to cut wooden workpieces efficiently and quickly. You can, of course, increase the height of the teeth and the spread of the hacksaw, but then the edges of the cut will be rough, which is only suitable for preparing firewood.

The inventors' activities were aimed at changing the shape of the hacksaw teeth. After all, when making a longitudinal cut, the tool acts on the wood along the entire width of the seam, so the teeth are made more inclined than during cross-cutting, when it is necessary to trim the fibers on the sides of the cut.

An alternative way to save the carpenter's physical effort and increase the speed of work was to create a cutting surface that saws in both directions.

Based on the type of teeth, saws are divided into three types:

- A wood hacksaw with a large tooth, which is used for rough cutting of logs and beams (cutter height 4-6 mm).

- The middle tooth is used when working with small parts (3-3.5 mm).

- Fine teeth are very effective when high-precision sawing is required and when working with small products (2-2.5 mm).

According to GOST, manual hacksaws are qualified by the number of teeth per inch of blade length. Therefore, the number behind the inscription of the international standard PPI or TPI indicates the number of incisors. The larger it is, the smaller the tooth of this hacksaw.

Today's modernized instruments are made with small gaps cut into the blade. As a result, the teeth are grouped into 6-7 pieces. These gaps are good for removing wet chips when working with raw wood.

Characteristics of hacksaws for wood

Some characteristics of a tool can only be determined at the time of use. The main parameters are the following:

- The quality of the resulting cut.

- Performance indicator.

- Tooth wear rate.

- The degree of surface protection from exposure to high humidity.

It is recommended to choose productive versions when you need to saw logs or when performing construction work. In the production of various products, a tool is used that is designed to obtain a high-quality cut. Do not forget that the working part with small teeth wears out quite quickly; it is also not suitable for sawing soft wood.

Dimensions and material of the canvas

A blade for a wood hacksaw is made using various materials, which largely determine the basic qualities. Among the features we note the following:

- Most often, tool steel is used, which, due to its composition, can withstand quite serious impacts.

- Some alloy alloys can also be used in the manufacture of hacksaw blades. By adding certain chemical elements, the degree of wear resistance increases.

- There are alloys with a high concentration of silicon and carbon, which improves performance characteristics.

When choosing, attention is paid to size. A fabric that is too long loses its rigidity and its ductility increases. A working part that is too wide also complicates the task; a working part that is too thin cannot withstand the applied load.

Handle shape

An important structural element of the tool is the handle. The handle of hand hacksaws can also be classified according to a fairly large number of characteristics. The features include the following points:

- Various materials are used in production. In most cases, the handle is plastic, since this material is lightweight and can withstand moisture. Also, metal and wood can be used in the manufacture of the handle.

- The shape is also significantly different. In some cases it is represented by a simple handle, in others by an element with a hole.

It is important that the handle is comfortable to use, otherwise prolonged sawing can create a lot of difficulties. In addition, it must be securely attached to the working part, since otherwise the applied load will damage the connection.

Types of teeth

As previously noted, the tooth can be regular or hardened. Classification is also carried out depending on the purpose of the tool:

- For longitudinal sawing. In this case, the working part resembles oblique triangles, which look like hooks. Due to this shape, it is possible to cut along the fibers. This version has sharpening on both sides, due to which mechanical processing is carried out when the blade moves in both directions.

- For cross cutting. The tooth in this case resembles the shape of an isosceles triangle, which greatly simplifies the procedure for removing material when moving the saw in both directions. It is worth considering that this design option is only suitable for working with dry material.

- Mixed sawing. In this case, the wood hacksaw has a combined working part. Due to this, when moving forward, material is removed, and during the reverse movement, the channel expands. That is why you can quickly saw even large products.

The area of application of the tool depends on the shape of the tooth. Do not forget that the hardened version can last for a long period, but due to the increased hardness of the metal, re-sharpening is practically impossible.

HANDSAWS (HACKSAWS) FOR WOOD. LET'S LOOK 'INTO THE JAW' OF THE TAME 'PREDATOR'.

Wood is a natural material based on high-strength fibers. Under compressive, tensile and bending loads, its specific strength is not inferior to many metals. It is not for nothing that until the mid-thirties wood remained one of the main structural materials in

aviation, inferior to duralumin only in manufacturability, but not in specific strength. It is not so easy to destroy the structure of wood.

HAND SAWS (HACKSAWS) are one of the main TOOLS for woodworking. And not only - they are also used for processing various artificial materials, such as chipboard, laminate, PVC. In order for a HAND SAW (HACKSAW) to work, its teeth must be set apart. DEVELOPMENT is a mechanical deviation of the teeth to the sides so that the width of the cut exceeds the width of the blade, otherwise it will “wedge.” However, a cut that is too wide is also not necessary, because it will take additional effort to create it. For example, according to the specifications of the well-known manufacturer of HANDSAWS (HACKSAWS) - the company STANLEY - with a blade thickness of 0.75 mm, the cutting width, determined by the spread of the SAW TEETH, should be 1.25 mm. As for the size of SAW TEETH, in Russia the practice of indicating it has not taken root. In the rest of the world, it is customary to indicate the pitch of the SAW TOOTH in the number of “teeth per inch” (TPI – TOOTH PER INCH) or the number of “points per inch” (PPI – POINTS PER INCH), which is recalculated from TPI using the formula PPI = TPI + 1 They are often indicated together through a fraction, for example, “7/8”. In practice, the SAW TOOTH size is used from approximately 2.5/3.5 for HANDSAWS (HACKSAWS) for rough work with raw wood and up to 14/15 for HANDSAWS (HACKSAWS) for fine work. There were practically no specialized HANDSAWS (HACKSAWS) created for working with artificial materials, but the need to process them significantly influenced the evolution of HANDSAWS (HACKSAWS) for wood. It went in several directions: improving the shapes and layout of SAW TEETH contributed to increased efficiency, and the use of modern materials and processing technologies contributed to the durability of products. The DAGGER TOOTH has the shape of an isosceles triangle and cutting edges on both sides, sharpened at an acute angle. It works when moving in any direction and is therefore the main type of SAW TOOTH in BOW SAW blades. However, due to the acute sharpening angle, it is not suitable for sawing along the fibers, since it does not destroy them, but only splits them. In this case, the SAW TEETH characteristically become jammed in the split fibers and sawing becomes significantly more difficult. The chisel-shaped tooth has the shape of an asymmetrical triangle, inclined forward in the sawing direction. Its top is sharpened across the blade, and it acts like a CHISEL. Such a SAW TOOTH cuts perfectly along the fibers, but across it clings to them, requires additional effort, in other words, it practically does not saw. AN OBLIQUE UNIVERSAL TOOTH is a cross between a DAGGER and a CHISEL TOOTH. This is an asymmetrical triangle, the front edge of which is sharpened at a relatively large angle to the blade - about 60 degrees - and therefore can also work when sawing along the grain. The sharpening angle, which is blunter than that of a DAGGER SAW TEETH, does not particularly affect the efficiency when sawing across the fibers, since, cut by the sharp tips of the SAW TEETH, they are destroyed quite well by such an edge. Using this type of SAW TOOTH, you can easily cut out, for example, a circle. TOOTH WITH A GROUNDED TOP. Sometimes for some reason it is called triangular. It is formed from a DAGGER or OBLIQUE UNIVERSAL SAW TOOTH by partially grinding off the top. Due to this, three additional cutting edges are formed, which significantly improve the properties of the SAW TOOTH and allow you to make cuts both along and across the fibers. This SAW TOOTH shape is very similar to STANLEY's JET-CUT shape. JAPANESE TOOTH. Unlike other types of SAW TEETH, which are formed on a flat blade, this SAW TEETH requires a blade that is wedge-shaped in cross-section. It is cut in a wider part of the canvas and due to this does not require wiring. This SAW TOOTH is inclined to one side and cuts only in the direction of the inclination, and the sharp cutting edge angle and the large relative height of the SAW TOOTH make it so aggressive that it can only work with very small feed forces. A HANDSAW (HACKSAW) with such a SAW TOOTH can be sawed exclusively when moving “towards you,” which is traditional for Japan. Hence the name SAW TOOTH. Until recently, the schemes for alternating SAW TEETH did not shine with variety: most used exactly the same SAW TEETH, sharpened at opposite angles with the opposite set. So the considered forms of SAW TEETH have a historical value rather than a practical one. Using, for example, a HAND SAW (HACKSAW) with a DAGGER-shaped SAW TOOTH for longitudinal sawing leads to a very obvious effect of the TOOL getting stuck in the wood, while a CHISEL-shaped tool, when trying to cut across the grain, gives the feeling of the blade jumping in your hands. What new have the leading manufacturers of HANDSAWS (HACKSAWS) come up with in this matter? JET-CUT - STANLEY sharpening uses straight DAGGER SAW TEETH with a ground top, grouped in groups of eight. In each group, six SAW TEETH are set apart in a row, but the last two are not. They provide additional cutting of fibers closer to the center of the cut and active removal of sawdust from its area. Sawing across and along the grain. XT – sharpening from SANDVIK. The basic shape of a SAW TOOTH is an oblique UNIVERSAL, inclined forward at a small angle, that is, almost DAGGER. Two such unset SAW TEETH with opposite sharpening angles are followed by the same SAW TOOTH, but with the top ground off and set apart. Today, HANDSAWS (HACKSAWS) with such sharpening are, apparently, the best in almost all indicators - efficiency, required force, cleanliness of the cut, durability. This is due to the fact that such SAW TEETH “do not do extra work” - the first ones cut the fibers, and the last one “completes the work”. Alternating groups of SAW TEETH with small and large cavities is used by manufacturers of HANDSAWS (HACKSAWS) and SAW BLADES for raw wood. An example of such a solution is the so-called WOLF TOOTH of a BOW SAW blade. The problem is that the fibers of raw wood are difficult to break down, and when sawing it, relatively large chips are formed, which do not fit into the small interdental spaces and clog the cut. Enlargement of the interdental cavity (GALTELI) allows you to cope with this. There are several options for such a grouping of SAW TEETH, in particular, the so-called KREMLIN TOOTH, which is obtained manually on domestic HANDSAWS (HACKSAWS) by removing every third SAW TEETH and sawing out a cavity in its place. The optimal size of the SAW TOOTH in terms of efficiency is determined by the amount of pressure on the blade and the amplitude of movement of the HAND SAW (HACKSAW). For modern SAW TEETH (XT, JET-CUT, UNIVERSAL OBLIQUE), the force and range that an average man can develop over a long period of time corresponds to a “7/8” pitch. This is exactly the size of the SAW TOOTH, most often found on modern HANDSAWS (HACKSAWS) from leading manufacturers. The durability of the SAW TEETH is also determined by its shape and the quality of sharpening. It is equally important to maintain the equality of height and sharpness of all SAW TEETH. Otherwise, the sharper and taller ones have an increased load, and they quickly become dull. For this reason, for example, factory machine sharpening is several times higher in durability than subsequent manual sharpenings of the same blade. The most resistant sharpening is the XT type - sharpening from SANDVIK, since it is optimized for the distribution of load between cutting edges for various purposes. The configuration of the SAW TEETH and the various techniques for alternating them appear to be important. But first of all, the quality of a HAND SAW (HACKSAW) is determined by the quality of the steel used for its manufacture. It is subject to quite stringent requirements: high strength and elasticity, ability to accept sharpening, durability of the cutting edge. Good metal does not crumble, does not bend under the action of a sharpening TOOL, the mark is not lost, and the blade takes its original shape after inevitable deformations during use. The technology for forming SAW TEETH is the second most important factor affecting the quality of a HANDSAW (HACKSAW). The best way is to cut the SAW TEETH with a grinding wheel on a CNC machine. In its more advanced version, a wide – the width of the SAW TOOTH profile – profiled circle cuts SAW TEETH on a package of several dozen blades in two passes. Additional hardening and tempering of the SAW TEETH is carried out using the method of induction heating with air cooling. Then the setting is formed by bending the SAW TEETH on a special production line. Cutting out SAW TEETH requires significantly lower equipment costs and for this reason is used in numerous domestic enterprises that produce HANDSAWS (HASSAWS), (alas, as a rule, with little success). The main disadvantage of this technology is that it does not solve the sharpening issue at all. As a result, domestic HANDSAWS (HACKSAWS) are not sharpened by the manufacturer at all and are suitable for use only after sharpening and setting, which require special TOOLS and high qualifications. The use of steel with high elasticity for the HANDSAW (HACKSAW) blade and the use of a SAW TOOTH no larger than “7/8” make it unnecessary to set the SAW TEETH throughout the entire service life of the HANDSAW (HACKSAW). When sharpening on CNC machines, the required sharpening angles and, most importantly, the height of the SAW TEETH are maintained with very high precision, so the efficiency of the HAND SAW (HACKSAW) is maximum. Subsequent manual sharpening cannot provide such accuracy, and after it the efficiency reaches, at best, 70 - 80% of the initial one, and when sharpening is performed by a person who does not have the proper experience, it is much lower. The most efficient types of SAW TEETH, for example, BAHCO XT and STANLEY JET-CUT, could hardly be sharpened by hand - the planes on which the tops of the SAW TEETH are ground are too shallow. In most European countries, the cost of labor time required to manually sharpen a HAND SAW (HACKSAW) far exceeds the retail cost of a new TOOL. In Russia now the situation is largely similar - often a “used” HAND SAW (HACKSAW) is simply thrown away. But just recently this was impossible to imagine!!! Additional hardening of the SAW TOOTH to high hardness increases its durability by 5 - 6 times compared to factory sharpening of the same quality and at the same time makes it impossible to sharpen a dull HAND SAW (HACKSAW) with a simple file. A hardened SAW TOOTH can only be slightly corrected using a diamond file. But you cannot use any kind of abrasive wheels, including diamond ones - inevitable heating will lead to uneven tempering of the SAW TOOTH and immediate destruction of the cutting edge when working with such a “restored” TOOL. Now let’s look directly at the main types of HANDSAWS (HACKSAWS) themselves...

Hamlet Vartushtyanyan

You can get answers to your questions by writing a letter to

Reproduction of materials is prohibited.

Website: https://eletos.ru/

| Reader rating: (4 votes) |

Rules of operation and care

Only with proper use and timely care can the tool last for a long period. Among the features we note the following:

- It is recommended to work with the tool taking into account the material it is intended for.

- You cannot work with materials that are characterized by high hardness of the surface layer.

- After each work, the surface must be cleaned of chips.

- It is recommended to store the hacksaw only in conditions of low humidity and normal temperature.

At the time of cutting, you need to apply medium force, and also make sure that the working part does not jam. Otherwise, there is a risk of damage to the structure.

Some parts of the hacksaw will eventually lose their performance characteristics. If the tool is not used for its intended purpose, it will not last for a long period.

What types of hand saws are used for what purposes?

- The classic hacksaw is the most common of all. It has a long and wide canvas. If the blade is too long, the hacksaw may tilt to the side when cutting. Great care must be taken to avoid deviation of the cutting line from the initial marking. This hacksaw is suitable for working with timber, boards, chipboard and so on.

- Hacksaw with back. This saw model has a rigid rib attachment, which minimizes the vibration frequency of the blade. This hacksaw also has smaller teeth and a higher TPI coefficient. They are designed for cutting plywood, chipboard with a coating layer and sawing profile strips.

- Finish saws have an adjustable handle. They are needed for cutting grooves, grooves and straight and profile planks.

- A circular hacksaw, or a hacksaw with a narrow blade. It is also used for cutting grooves, as well as for cutting out parts with rounded areas and large holes.

- A bow saw is well suited for cutting knots and rough parts of material, as well as for cutting out parts from plywood and wood. This hacksaw is distinguished by a thin blade fixed on both sides in a frame. It is worth noting that you need to work with it extremely carefully due to its increased fragility.

- The award has two handles. The appearance of such a saw is in many ways similar to a plane. It is used for cutting tenons and grooves, deepening holes and slots in materials of any hardness.

- Garden saw with curved blade. Most often, for greater convenience, they are made folding. This saw is well suited for garden work. The saw blade is made of chrome steel. Widely spaced teeth with an inclination in the direction of the handle will allow you to conveniently cut down twigs and branches, placing emphasis on yourself while cutting.

- A two-handed saw has the highest productivity. It has two wooden handles. For greater efficiency, cutting with such a saw requires two people. A two-handed saw is often used for sawing large logs and trees.

- A hand or pocket chain saw is a small piece of chain with two handles on the ends. This saw is convenient for both one and two people to work with. The log or branch is wrapped around a chain and cut is made using the handles. A manual chainsaw, like a folding one, is well suited for gardening.

Photo gallery: types of hand saws

This classic hacksaw can be easily sharpened

This hacksaw has hardened teeth and increased wear resistance

A hacksaw with a back or butt minimizes vibration of the blade during operation

A hacksaw with a narrow blade is well suited for cutting holes and grooves

This saw has an adjustable handle, which allows you to work at the desired angle.

A bow saw is well suited for cutting parts from plywood.

This type of hacksaw is similar to a plane and is used for cutting tenons and slots.

Two-handed saw suitable for cutting large logs

Garden saws with curved blades are well suited for cutting down knots and small tree branches.

The hand chain saw is compact and well suited for sawing logs while camping and branches in the garden.

Thus, having carefully studied all the nuances regarding hand saws, everyone will be able to choose the most suitable option for themselves. Choosing the right tool will provide you with high-quality and enjoyable work.

Types of instruments

There are various types of hacksaws. The most widespread are the following:

- A hacksaw for longitudinal sawing is characterized by a certain tooth shape.

- The transverse hacksaw has become very widespread, as it is intended for dividing the workpiece into several parts.

On sale there is a small hacksaw or with a large tooth, as well as a bow saw. A carpenter's saw, the design and purpose of which can be different, is an integral attribute of various shops specializing in the sale of tools. A hand saw is found in the home workshop, as well as in various workshops where wood processing is carried out.

For curved sawing

The bow saw has become quite widespread. This is due to the fact that it has a small tape, due to which it is possible to process along a curved line. Among the features we note:

- Small sizes. This point determines that processing can be carried out in a wide variety of conditions.

- It is possible to replace the blade when it wears out.

At the same time, the teeth are small in size, which ensures high quality cuts.

Blade steel

It is not recommended to buy a hacksaw made from steel with a hardness below HRc45. Such a tool is only suitable for sawing pine boards no more than 20 mm thick, and even then there will be chips and burrs on the cutting line. It is better if the hardness of the steel is equal to HRc50 or exceeds this indicator. Good professional tools are equipped with combined blades for hacksaws - the hardness of the base is HRc45, and the cutting edge is HRc55 - 60. But you need to remember that sharpening such a saw at home is impossible, only in a specialized workshop.

When choosing a hacksaw in a store, it is very easy to recognize the combined blades - the cutting part is darker in color than the rest of the blade. The tool passport must indicate the steel grade and its hardness. If there is no such information, then assume that the hacksaw is made of mild steel and can be sharpened with a regular file. But before you sharpen your hacksaw, find out what tool is used for sharpening, how to hold it and in what sequence to work.

Japanese hacksaws

There are quite a large number of different Japanese wood hacksaws on sale. Their key features are as follows:

- Relatively low cost.

- In production, steel is used that can withstand long-term mechanical stress.

There are a wide variety of Japanese hacksaws; the choice is made depending on the tasks assigned at the time of processing the material. Recently, most purchases are made through an online store.

Choice depending on design and details

The target contingent can meet more than a hundred models of wood saws as part of the thematic selection.

The difference between the models is noticeable in the following ways:

- Teeth – size and shape;

- Dimensions of the working surface;

- The composition of the canvas (in particular, we are talking about the grade of steel);

- Handle shape.

Although a hacksaw does not have many elements for working with wood, changing at least one of them significantly affects the operation of the entire tool.

For example, by changing the thickness of the handle, the latter will fit well in a large or small palm.

Tool selection criteria

The question of how to choose a hacksaw for wood has become quite widespread. The main criteria are the following:

- Type of material.

- Sizes.

- Shape of teeth.

- The shape and type of material of the handle.

- Purpose.

Choosing a hand saw for wood is quite difficult due to the wide range. You can cut wood easily only if you have the appropriate experience.

In conclusion, the information above indicates the need for a wood saw. It is used when carrying out construction work, procuring materials for heating a house, and performing work on the manufacture of various products. That is why the tool should be in the assortment of every master.

Selection depending on the type of operation

It is clear that a hacksaw for wood is designed for sawing wood and analogue materials. But the technique of this sawing is different.

Hence the saws with different purposes:

- Swing model – welcomes longitudinal cutting;

- The transverse option comes in handy when the workpiece needs to be sawed across its grain;

- Tenon design - allows you to cut recesses;

- Circular Saw – Can create holes.

If even photos of hacksaws for wood do not really help you decide on the right option, you should focus on the classics, which allow you to change attachments.