What is alternating current

This type of current represents the organized oscillatory movement of charged particles. The cause of the phenomenon is electrical voltage varying according to a sinusoidal law. The electric current is related to it by a direct relationship: I=U/R. So it is constantly changing in the same way.

Current and voltage of this type are characterized by the following parameters:

- Instant value. This is the current i and voltage u at the current time.

- Maximum value. This is the largest deviation from the zero value (Imax and Umax).

- Amplitude. This is the difference between the largest deviations.

- Frequency. This is the number of oscillations per unit time (f). For mains current, the figure is 50 Hz (cycles per second).

- Period. This is the duration of one oscillation cycle in seconds (T). The value is related to frequency: T=1/f.

The fact that current and voltage are constantly changing makes calculations very difficult. To simplify them, the so-called effective value. This is a direct current (voltage) equivalent to a given alternating current, i.e. causing the release of the same amount of heat in a linear conductor.

For example, the current value is the voltage of 220 V in a household outlet. In fact, the voltage in it constantly changes according to a sinusoidal law from +311 to -311 V.

What is direct current

Direct current is the ordered movement of charged particles that meets 2 conditions:

- the direction does not change;

- the amperage varies so smoothly that the inductive properties of the circuit do not manifest themselves at all.

One pole of the DC voltage source is negative (-), the other is positive (+). It is generally accepted that the current moves in the direction from “+” to “-”. But in metals, where free particles are negatively charged electrons, they move the other way around - from “-” to “+”.

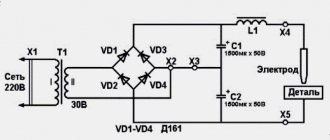

Direct electric current for welding is obtained by rectifying alternating current. They use a circuit of diodes (valves) - semiconductor devices that transmit electricity in only one direction. To smooth out ripples, the diode bridge is supplemented with a capacitive filter.

DC welding machine (diagram).

Features of application

The work of electric current in conductors consists of 2 phenomena:

- Heat release. Its amount is proportional to the square of the current: Q=(I^2)*R, where R is the resistance of the conductor.

- Creation of a magnetic field. Its intensity increases if the conductor is wound into a coil.

Welding is based on the first phenomenon. When an electric current moves through an air gap, an arc discharge is formed, characterized by a high temperature. It causes the metal to melt, as a result of which the edges of the workpieces merge together.

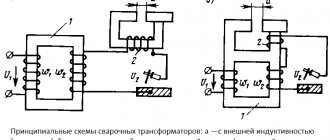

The ability of electric current to create a magnetic field is used to reduce voltage using a transformer. It consists of 2 unconnected coils. The primary is connected to the network, and the electric current flowing in it through an alternating magnetic field induces an emf in the secondary. The voltage reduction factor depends on the ratio of the number of turns in the coils.

We recommend reading: How to weld a car with your own hands

Effect of welding current on welding

According to the formula Q=I²xR, heat input in the electric welding process depends on the current strength. The higher its value, the deeper the metal melts.

It is necessary to select the optimal value, otherwise the following defects arise:

- If the current is too low, there is a lack of penetration.

- If it is too high, there is a burn through of the metal, an extensive weld pool, and deformation of the workpieces.

In both cases, the seam becomes less durable.

Factors influencing the choice of indicators

The welding current value is selected according to 2 criteria:

- Electrode diameter. The thicker the consumable, the higher the amperage.

- Coating material. For example, rutile electrodes are used to cook at a lower electric current than basic electrodes.

The diameter of the consumable is selected depending on the thickness of the workpieces.

Table of the influence of welding current on various indicators.

What is alternating current in welding

Is it good or bad, which current is better? Variable or constant? No one will give you a definite answer.

To begin with, it is better to understand the features of processes with alternating current, they are as follows:

- The behavior of the arc leaves much to be desired: with alternating voltage it is the most unstable.

- The welding seam is not of the highest quality due to deviation from the axis of the welding arc.

- If the arc goes out, its combustion can only be resumed when the voltage increases.

- The metal is splattered to a large extent.

Despite all these complexities, the equipment required for AC welding is simple and inexpensive. These are, first of all, transformers - devices that are still very popular among welding masters.

It would seem that electrodes for alternating current should gradually lose their relevance: after all, many rectifiers have appeared on the market - inexpensive and with small dimensions convenient for use. However, these consumables are still in demand in many industries and handicraft workshops.

Most of the brands are universal, which is also extremely suitable for older generation domestic welders.

If you look at it, the best consumables for “change” have and show very serious production advantages. First of all, this concerns the resulting electric arc: its durability and easy ignition. Another feature of such electrodes is the low level of metal spattering during welding.

Welding transformer

To carry out welding using a transformer, the following mandatory structural elements are required:

- Windings primary and secondary. The primary is made of a special insulated wire; there is no insulation on the secondary winding.

- Magnetic wire.

- Screw for controlling the position of two windings and changing the distance between them.

- Protective housing for the entire unit.

- Screw handle, running nut.

- Fan and other elements depending on the transformer model.

Despite the fact that many welding professionals regard transformers as equipment of the “outgoing generation,” they are presented on the market in the form of a wide range of models of very different values and for wallets of any thickness.

Transformers differ according to the following criteria:

- dimensions and weight;

- output current strength;

- output voltage level at idle;

- volume of electricity consumed;

Welding generator

The generator design includes the required structural elements:

- The most important part - the converter consists of an electric generating element with an alternating voltage motor. They provide changes in current indicators.

- Drive internal combustion engine.

- Indicator for monitoring and recording current strength.

- Mode switches.

- Special circuit breaker.

- Regulators for current and arc behavior.

- Terminals for connecting cables and 230V outlets.

These types of generators are available in two versions:

- Collector generators.

- Valve generators.

The main advantages of a gas generator in comparison with other welding machines are:

- Compact and therefore highly mobile.

- Convenience, relative cheapness, noiselessness.

- Wide functionality and high reliability.

- Quite high technical characteristics.

Selecting current for welding materials

The recommended range is given on the packaging with consumables. The exact value is determined experimentally.

Electrode 4 mm

These consumables are used to cook workpieces 4-6 mm thick. Set the electric current strength within 120-200 A.

Electrode 3 mm

Consumables with this thickness are used to connect parts to a wall of 3-4 mm. The optimal welding current values are in the range of 80-160 A.

Electrode 2 mm

Thin consumables are used to cook steel 2-3 mm thick. Choose an amperage between 40 and 80 A.

AC and DC Welding Equipment

Welding work is carried out using the following equipment:

- Transformers. The simplest, cheapest and most reliable devices. They produce alternating voltage at the output.

- Rectifiers. They differ from the previous ones by the presence of a diode or thyristor bridge that converts alternating current into direct current. Compared to the previous version, they are larger in size and weight, more complex in design and more expensive.

- Inverters. They produce a constant electric current at the output. They are compact in size.

The inverter converts the mains current in the following order:

- Straightens.

- Converts to high frequency AC (60-80 kHz). This function is performed by a special electronic unit with fast-switching transistors, controlled by a microcircuit.

- Using a converter, it lowers the voltage to the operating value.

- Straightens again.

Increasing the frequency of the electric current can significantly reduce the size and weight of the transformer. As a result, the cost of the device and losses in it are reduced.

Equipping the inverter with electronics provides additional benefits in the form of the following functions:

- Hot start. Facilitates arc ignition by briefly increasing voltage.

- Anti-sticking. Voltage relief in situations where the consumable has touched the workpiece for a long time (often observed during ignition).

- Arc force. It consists of a short-term increase in the strength of the electric current in cases where there is a risk of arc extinction. Most often this occurs when the electrode and the workpiece are short-circuited by a drop of molten metal.

- Stabilization. Provides preservation of welding mode parameters under conditions of input voltage fluctuations.

Inverters are more expensive than other types, but the ease of operation and high quality of the seam justifies the price difference.

There are devices for the following types of electric welding:

- Refractory consumable in a protective gas environment. Use a torch with a tungsten or graphite electrode and a nozzle for injecting argon. Filler material in the form of wire is fed into the welding zone. The device can be operated without gas supply. Then a hollow wire filled with flux is used as a filler material. When burned, it turns into gas.

- Consumable electrode. Such consumables are equipped with their own flux in the form of a coating (coating). In addition to protective components, it contains easily ionized arcs that improve combustion.

Devices for welding with consumable consumables are equipped with an electrode holder.

According to their purpose, devices are divided into types:

- For manual welding - argon and consumable electrode.

- Semi-automatic devices. Designed for welding with a refractory consumable, the filler material is supplied mechanically.

- Automatic machines. Work is carried out without human intervention in accordance with user-specified settings. The unit is equipped with a refractory electrode.

We recommend reading: What to do if your eyes hurt from welding

DC Electrode Rating

Differences in welding with different current polarities.

Types of electrodes used for DC welding:

- UONI - 13/55 - famous electrodes of their kind for direct current, applicable for steel alloys - with low doses of alloying elements and with the addition of carbon. They have significant advantages: the welding seam is very plastic and tough for mechanical stress, very durable. Almost no impurities and gases are formed. The arc is easily ignited. A wire of parameters Sv-08 or Sv-08A is placed in the rod.

- UONI - 13/45 are also used for joining workpieces made of carbon and low-alloy steels. The seam is not inclined to form cracks - neither hot nor cold. It is very ductile and tough, with ideal tightness, which makes it a suitable option for welding containers that will subsequently be subject to high pressure. Seams made with these electrodes do not age much longer.

- OZL – 6 are distinguished by their narrow focus: they are used in working with heat-resistant steels. Pores and cracks do not form in the seams, they are not subject to further corrosion and have the same heat resistance as the base metal. Suitable for metals with different structures.

- OZS-12 are intended for steel alloys with a low proportion of alloying additives and carbon. It is possible to work in any spatial position and is tolerant of surfaces with rust. The weld is formed with excellent characteristics: strength and durability. Stable arc. There are no releases of toxic substances during operation.

- TsL - 11 are also highly specialized electrodes, which are intended for steel alloys with additions of chromium and nickel, as well as corrosion-resistant steels. Welded seams are resistant to corrosion. The metal hardly spatters, the arc is stable, and the slag in the form of a crust is easily separated.

- ANO - 21, despite the fact that they are also intended for carbon and low-alloy steel alloys, like previous brands of electrodes, these consumables are extremely popular among craftsmen of various levels of professional training. Their features are a fine-scale structure of the weld metal, excellent arc ignition, softness, slight metal spattering, and so on.

- LB – 52U are distinguished by the high productivity of the welding process with their help. The arc is stable, the metal hardly spatters, work is possible in any position in space, and almost no cracks form in the seam.

- MR - 3 typical universal electrodes, which are rightfully present in both lists - for both alternating and direct current. Pores and hot cracks practically do not form in the weld, the arc is powerful and stable, there is little spattering of metal, and easy separation of slag in the form of a crust.

- OZCH – 2 are intended for welding cast iron. Despite their seemingly narrow functional focus, they have solid advantages in the form of versatility, ease of use, an excellent arc with excellent characteristics, ductility of the weld without cracks, and a well-separated crust with slag at the end of the process.

What are DC and AC electrodes

An electrode is a piece of metal wire designed to supply electricity to a workpiece. Products are divided into 2 types:

- melting;

- refractory.

Products of the first type are equipped with coating. It performs the following functions:

- Forms a protective gas.

- Serves as a source of alloying elements.

- Supports arc combustion due to easily ionized elements. For electric current to flow, free charge carriers are needed. The presence of other ions in the gap between the consumable and the workpiece, in addition to electrons, stabilizes the process.

Consumable electrodes are divided into types:

- universal – work on any type of electricity;

- for welding at constant voltage.

Refractory electrodes are also universal.

Welding electrodes.

How welding current for electrodes affects welding

When carrying out the welding process, it is necessary to select the correct current value. It is this parameter that largely influences the quality of the weld.

Low welding current

can lead to unstable arc combustion, the appearance of unwelded areas, the welding process will be constantly interrupted and, as a result, the welder will receive a poor-quality connection.

A value that is too high will result in overheating or burnout in the welding zone, as well as intense spattering.

In general, the choice of voltage indicators is influenced by several factors :

- brand and diameter of welding materials;

- spatial position of the rod during welding;

- voltage polarity (see the peculiarities of constant and alternating welding);

- seam size ;

- method ;

- type and thickness of metals being welded.

Differences between DC and AC electrodes

Based on the type of coating, consumables are divided into types:

- Sour.

- Cellulose.

- Rutile.

- Basic (calcium fluoride).

The first 3 types are universal, the fourth is intended for welding only at constant voltage. Basic and rutile electrodes are the most common.

The peculiarity of welding with alternating current is that the arc burns less stable. It is extremely sensitive to the number of free charge carriers. The main type of coating contains fluorine, which acts as a deionizing element. It makes it difficult to burn an arc, so such consumables do not work well at alternating voltage.

The advantage of calcium fluoride coating is the absence of organics, which eliminates the saturation of the metal with hydrogen and provides it with good protection against oxidation. As a result, the seam is strong and flexible.

It is also necessary to pay attention to the characteristics of the welding machine. To start an arc on alternating current, some electrodes require an increased open circuit voltage - 70 or 90 V versus the standard 50. This is especially necessary when re-igniting when the consumable is covered with slag. Most transformers have an open circuit voltage of 50 V. There are models with an additional output that generates an open circuit voltage of 70 (V). They cost more. For an inverter, this figure is 89-93 (V).

When choosing electrodes, you should consider the type of welding machine.

Advantages and disadvantages of electrodes for alternating current

Speaking about the advantages, we should also mention the excellent protective properties of such electrodes: they protect the weld pool well from the negative effects of the atmosphere. Also, when working with a transformer, you do not need to use a rectifier.

But despite this, AC welding electrodes have their drawbacks. They are inferior to materials for constant tension in the quality of the resulting seam, contribute to the active spattering of metal and poorly absorb energy from mechanical loads, which is why they are less durable.

Electrode brands for AC and DC current

You can cook using alternating current with the following consumables:

- OZS-4, OZS-6, OZS-12 (rutile). Designed for welding carbon steels.

- MP-3. Designed for joining low carbon steels. Recommended for beginner welders. Provide high quality connections even when the workpieces contain dirt, rust and moisture. The MP-3S variety is intended for high-carbon and low-alloy steels.

- ANO-4, ANO-6, ANO-21. The first grade is created for low-carbon steels, the middle one for carbon steels, the third for high-carbon and low-alloy steels.

- W.P. Tungsten consumables.

- WL-15 and WL-20. Alloyed tungsten consumables.

We recommend reading Features of flux-cored wire welding

The following electrodes are used to cook only with constant electric current:

- UONI-13/55. They are considered the best for the manufacture of critical structures made of carbon steel. When the arc extinguishes, the molten coating immediately solidifies at the end of the electrode, so it must be cleaned to re-ignite.

- OZL-8. Designed for steels alloyed with chromium and nickel. Used in the manufacture of units experiencing high loads; create a durable, oxidation-resistant seam. It is necessary to ensure smooth cooling of the metal, otherwise it may crack.

- Kobelco LB-52U (Japan). Designed for the manufacture of critical structures from low-carbon steel. They are often used when it is not possible to perform double-sided scalding, for example when installing pipelines. They are sensitive to the humidity of the coating, therefore they require preliminary calcination at a temperature of 300°C.

- ESAB OK 61.30 (Sweden). Electrode for stainless steel.

Flaws

- Electrodes for AC welding are inferior in connection quality;

- They exhibit high metal spattering and uneven seam formation;

- They have relatively low impact strength.

Physico-chemical composition

DC and AC electrodes may have significant differences in their composition if they are intended for different types of metal, but for the same ones they can be very similar. There are often small differences of tenths of a percent.

| Item name | Content in composition, % |

| Carbon | 0,08 |

| Silicon | 0,3 |

| Manganese | 0,4 |

| Phosphorus | 0,025 |

| Sulfur | 0,03 |

Specifications

These characteristics are the main ones that guide specialists when choosing. They are determined by the composition, coating and other parameters of the surfacing material. After all, to make the right choice, you need to know what the temporary tensile strength of the electrodes is, and so on. Using the example of the technical characteristics of the OK-46 electrode, you can find out the basic data that this type has.

| Relative extension, % | 28 |

| Impact strength, J/cm squared | 140 |

| Test temperature, degrees Celsius | +20 |

| Tensile strength, N\mm squared | 510 |

| Maximum bend angle of the weld, degrees | 150 |

| Relative yield of deposited metal, % | 96 |

| Weight of electrodes for 1 kg of seam, kg | 1,7 |

Stamps

Many of the brands that are designed for alternating current are also well suited for working with direct current, both with direct and reverse polarity. It is for this reason that their choice may seem wider, and some repetitions with materials for other types of current will also be noticeable. The following brands are very common:

- ANO-4;

- ANO-6;

- ANO-21;

- MP-3;

- OZS-4;

- OZS-6;

- OZS-12.

Designation and marking

In the marking, the type of electricity is indicated by the last digit. But taking into account the fact that there is a selection here not only in variants with alternating or direct current, but many brands of electrodes for welding with alternating current can also be used with direct current, there may be several numbers:

- 1 – for any polarity of direct current and at alternating current with a frequency of 50 V;

- 2 – direct polarity of direct and alternating at 50 V;

- 3 – reverse polarity of DC and AC at 50 V;

- 4 – for any polarity of direct current and at alternating current with a frequency of 70 V;

- 5 – direct polarity of direct and alternating at 70 V;

- 6 – reverse polarity of DC and AC at 70 V;

- 7 – for any polarity of direct current and at alternating current with a frequency of 90 V;

- 8 – direct polarity of direct and alternating at 90 V;

- 9 – reverse polarity of DC and AC at 90 V;

Choice

The first thing to do when choosing is to pay attention to the metal with which you will be working. The base metal and the one that goes into the electrode rod should be as similar as possible. More detailed details can already be found in the specific brand, what it is intended for. The next important point is the diameter. It is also important here that the thickness of the workpiece matches the consumable material being used. It is also worth paying attention to what frequency the device should have. The materials are suitable for three standards: 50, 70 and 90 V. If your machine cannot support what it is designed for, then it is better to choose a different brand of electrodes, as there will be too many technical problems that will degrade the quality of the seam.

“Important! You should not take materials with “0” in the marking, since it is only used for permanent use.”

Difference between AC and DC welding

AC transformers have the following advantages:

- low cost;

- simple design;

- high efficiency;

- reliability;

- great resource.

Flaws:

- Poor seam quality. It turns out wide and uneven due to arc fluctuations.

- Large metal losses due to strong splashing.

- Poor arcing.

- Ability to weld only carbon steel.

AC welding is used in the following situations:

- There are low quality requirements.

- A large input of heat is required, for example in the construction of ships.

Direct current devices are more complex and more expensive. They are characterized by relatively large power losses, but provide high connection quality and arc stability. In addition to carbon steel, they can be used to weld stainless steel, as well as non-ferrous metals (using appropriate electrodes).

In DC welding, there are 2 connection methods:

- With straight polarity. The negative pole (cathode) is connected to the electrode, the positive pole (anode) is connected to the workpiece.

- With reverse polarity. The anode is connected to the consumable, the cathode to the workpiece.

Difference in currents.

AC Electrode Rating

Types of electrodes for welding with alternating and direct current.

The type of current is indicated in all markings of consumables - this is always the last digit. The main thing is to remember that if the last place in the marking is 0, then the electrode is not suitable for welding with alternating current.

- OZS – 12 with rutile coating. The most common type of electrodes for welding with alternating current, which is used on almost all Russian-made machines. Excellent welding of carbon steel parts, suitable for connections of critical structures. Significant advantages of these electrodes are the ability to work in any position in space, the absence of pores in the seam, a stable arc, and a completely acceptable dose of toxic gases released during the welding process.

- MP – 3 are designed for welding low-carbon steels. The advantages are similar: excellent arc stability, acceptable metal spatter. The slag crust comes off very easily. With these consumables you can cook even rusty, damp and poorly cleaned workpieces.

- ANO – 4 are also used for carbon steels. Excellent arc that ignites quickly and easily. You can cook wet and rusty products. There are no pores or cracks during seam formation. Easy separation of slag crust. There is virtually no metal spattering.

- MP-3C are distinguished by their high versatility: they are suitable for both low-alloy and carbon steels. The arc is ignited easily and instantly, the seam is protected from slag and oxides due to the rutile coating. The seams are smooth and durable, they can withstand significant loads. You can work with them in any position in space.

- ANO – 6 are used for connecting parts made of low-carbon steels. They are not afraid of rust, scale and dirt. The arc is stable and easily ignited, the seam is formed correctly.

- OZS – 4 for carbon steels, can be welded in any spatial position. The arc ignites easily. You can weld metal workpieces with edges of medium and large thickness at high temperatures. Attention! Doesn't like dirt on the surfaces being welded - they stop working.

- ANO – 21 are also intended for steels with carbon additives and low-alloy alloys. They are very easy to handle, can be worked in any position, and are also used in conjunction with an inverter and a semi-automatic transformer. The metal hardly splashes during operation, and the slag in the form of a crust is easily separated. An arc with excellent qualities - stable and soft.

- OZS – 6 are intended for carbon steels. They are characterized by a high throughput speed, which gives high labor productivity with a welding seam of excellent quality. Capable of welding oxidized surfaces.

Welding current designations for electrodes

The marking of consumables is in the form of a fraction. The last digit in the denominator indicates the type of current. “0” stands for “DC only with reverse polarity.” Other numbers mean that the consumable is universal, i.e. can cook with any type of current. At the same time, the polarity is encrypted for constant, and for alternating - the minimum required value of the no-load voltage.

The data is summarized in the table:

| Recommended DC polarity | Open circuit potential difference of alternating current source, V | Designation |

| Reverse | – | |

| Any | 50±5 | 1 |

| Straight | 2 | |

| Reverse | 3 | |

| Any | 70±10 | 4 |

| Straight | 5 | |

| Reverse | 6 | |

| Any | 90±5 | 7 |

| Straight | 8 | |

| Reverse | 9 |

Thus, the number “5” in the marking means that the electrode can be used to cook:

- Direct current of straight polarity.

- Variable if the no-load voltage of the source is at least 70 V.

Additional Information

When welding with direct current, an uneven distribution of thermal energy is observed between the workpiece and the electrode:

- For consumables that melt. The anode spot is colder than the cathode spot. Therefore, to connect thin-walled workpieces, direct polarity is used (so as not to burn them), for thick-walled ones, reverse polarity is used (for deeper penetration).

- For refractory consumables. The anode spot, on the contrary, is hotter than the cathode spot.

Welding with a refractory electrode is carried out only with straight polarity, regardless of the thickness of the workpieces. When connected in reverse, when the discharge hits the consumable, it quickly becomes clogged.