Main types of tools

Specialists in the field know very well what devices and mechanisms can be useful in various works with wood. It is quite difficult for a beginner to understand the huge assortment. In order to create your own universal arsenal, allowing you to perform any operation, you need to get acquainted with the classification of tools, their types and features.

These products include professional and household products, universal and specific ones. In the woodworking tools category, you can choose:

- mechanical hand products;

- electrical devices;

- machine equipment.

Most owners who prefer to do their own repairs and construction have simple hand tools. The use of various electrical devices, networked and mobile, simplifies the process and allows complex operations to be performed conveniently and efficiently.

Electric woodworking tools make the process much easier

Machines designed for wood processing are installed not only in specialized enterprises. The equipment range also includes household options that have compact dimensions and are easy to operate.

Fraser

As the name suggests, it is needed for milling, namely chamfering, cutting quarters and cutting grooves and splines.

What to pay attention to

All the tools collected here are most often suitable not only for woodworking operations, but also for working with other materials: plastic, metal, plywood. You just need to choose the right consumable.

Hand tools for the DIYer

In the range of power tools for woodworking there are many universal devices that are used in a wide variety of jobs. Every craftsman should have them in stock. The presence of this tool makes it possible to perform a lot of tasks around the house and on the site. A practical owner should have:

- hacksaw saw;

- axe;

- chisel;

- hammer;

- plane;

- rotation

Hand tools for wood

These are the carpenter’s main assistants, without whom it is impossible to do construction and repairs. A hacksaw is a tool consisting of a plastic or wooden handle and a metal blade with teeth. Saws are produced in a wide range, differing in size and size of teeth. The tool is designed to divide a whole part into elements and eliminate excess. For small operations, a special jigsaw with a thin blade is used. Cleavers and axes are used for splitting, chopping, and trimming.

Jigsaw with thin blade for small operations

A metal chisel, consisting of a working part and a handle, is useful in chamfering, forming recesses, etc. When working with this tool, a special hammer is used, which is called a mallet. A plane will help make the surface smooth and give the board the ideal geometry. If you need to use it regularly, it is worth purchasing a power tool for woodworking. There are several types of devices of this type: tongue and groove jointers, jointers, etc. To form holes in wooden materials, a brace is used that works with various types of drills.

A plane will help make the surface even.

In his work, the master will also need special materials for processing, allowing him to create a perfectly flat, smooth surface. In such operations, sandpaper is used. You need to stock up on material with different sizes of abrasives in order to perform rough and finishing work.

Sandpaper for finishing work

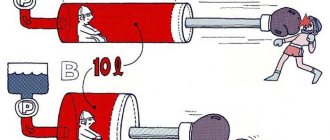

Belt sander

This type of sander is used for rough grinding. Used for rough surfaces or for removing paint, it allows you to remove a fairly thick layer of wood. After the belt sanding, it is necessary to treat the surface with an orbital or eccentric sander for more precise processing.

What you need to know when choosing

- Sanding is a tedious and tedious process, often in an awkward position. A more powerful device will reduce the pain a little;

- But don’t overdo it: unskilled hands can easily make dents in the wood, which will take a lot of time to fix;

Electric tool for woodworking

Qualified specialists and many home craftsmen prefer to acquire electrical equipment that allows them to quickly and efficiently perform various types of work. This woodworking tool is offered in a wide range. The most popular devices include electrical ones:

- planers;

- drills;

- chain saws, circular saws;

- screwdrivers;

- grinding machines, etc.

An electric planer greatly simplifies the process of giving ideal properties to a wooden surface. Using a drill, holes of the required size are created. You can also use this device for installing fasteners and mixing solutions.

An electric planer greatly simplifies the process.

Electric grinders are very popular among professionals and amateurs. Production uses belt models designed for large volumes of work. In everyday life and repairs, vibration and planetary tools are used for sanding wood.

A chain saw or circular saw is an indispensable piece of equipment for a craftsman who has to carry out large volumes of woodworking. Modern multifunctional models perform a range of operations.

A circular saw for wood is an indispensable tool

A home craftsman, a specialist who manufactures complex structures, will find a milling device useful. Mechanical and electrical woodworking tools allow you to create shaped elements, stairs and window frames, and furniture.

Not only hand jigsaws are used in creating small elements, in work that requires special precision. You can also purchase an electric wood carving tool.

An electric jigsaw will perform work that requires special precision.

The advantages of electrical appliances include the speed of operations and the absence of the need to expend a lot of effort. For stationary work, it is advisable to purchase models that operate from the network. Mobile devices with rechargeable batteries allow you to perform operations anywhere.

Wood cutting tools

The set of carpentry tools for cutting wood includes:

- saws and hacksaws;

- jigsaws;

- knives, cutters, scalpels;

- woodworking machinery.

Saws and hacksaws

Application of saws:

- longitudinal and transverse cutting - classic hacksaws;

- cutting holes - circular saws;

- production of connecting tenons - tenon saws.

Saws are distinguished by design:

- two-handed, used for sawing large logs;

- one-handed – hacksaws;

- bow - with stretched fabric;

- rewards - short saws.

Hacksaws for longitudinal cutting have teeth inclined forward, for transverse cutting - symmetrical teeth. Saws with large teeth (4 - 6 mm) are used for sawing logs and bars, with medium teeth (3 - 3.5 mm) - for cutting medium-sized parts, with small teeth (2 - 2.5 mm) - for precision manufacturing of small parts .

According to the international classification in the marking PPX or EPX, the number X indicates the number of teeth per inch. The fewer teeth, the larger they are. For cutting raw wood, hacksaws are used, the teeth of which are arranged in groups of 5–7 pieces. The spaces between the groups are needed to remove sticky raw sawdust.

Jigsaws

A jigsaw is a type of bow saw with a narrow blade and a large distance between it and the frame. The frame has a U or U-shape. The jigsaw is used for curved cuts. It ensures high quality cuts and precision manufacturing of parts.

Woodworking machinery

When sawing wood use:

- circular saws for longitudinal and transverse cutting;

- machines for cutting bars;

- jigsaws.

Additional accessories

In addition to the main tool, additional devices are also used when working with wood. The home handyman will find it useful:

- workbench with a vice;

- pliers and pincers;

- clamps;

- rulers and tape measure;

- carpenter's pencils;

- corner and protractor;

- plumb line

The workbench guarantees ease of use

The presence of a workbench guarantees ease of use. This design is used to perform a large number of operations. It is equipped with drawers; various small items are stored in them, which should always be at hand for the master. Using pliers or pliers, you can easily remove hardware and quickly dismantle it. Clamps of different configurations are useful for fixing elements.

Healthy! Starter set of cabinetmaker's hand tools. Review

Arsenal Masters review: hand tools for cabinetmakers. * This photo review was created for informational purposes and is not a product. You can print this page yourself and for free.

Recently, the hobby of making handmade wood products on your own has become increasingly attractive. A wide range of materials, including expensive and exotic ones, have become more accessible. And in light of the revival of carpentry, interest in a good tool that pleases the hands and soul is gaining popularity. Therefore, in this review we will only talk about hand tools: no battery-powered, electric or pneumatic ones - in a word, nothing noisy, ringing, or rumbling.

What the Masters advise:

- When working with expensive wood, it is recommended to use initially high-quality tools. Here, like nowhere else: the stingy pays twice.

- If you're on a limited budget, it's best to buy everything you need as needed.

- There is a minimum set, which you still can’t do without.

Let's look at the necessary tools in terms of their use in the main operations that lie ahead of you. Quick navigation down the page: 1. Measuring and marking the product 2. Fixing and basing parts and workpieces 3. Giving the required shape to workpieces: sawing or cutting, planing and scraping, chiseling and drilling

- Hand saws

- Planes (planes) + starting sets of planes

- Chisels

4. Product assembly 5. Storage and care Plus we will offer

- Several options for carpentry tool sets

So, hand tools must ensure the performance of the above operations, let's consider them:

1. MEASURING MARKING TOOLS:

Rulers:

Rulers (we measure distances) 12-15 cm, 30-50 cm.

Malki and squares:

Small pieces and squares (we measure and check the angles).

Reismus:

Thicknessers - with their help we transfer straight parallel lines relative to the end surface. Extremely convenient for marking spikes. There are needle and knife thicknessers. The first ones are marked with one or more needles. And knife ones - with knives made by analogy with a primer knife or disk ones, as in the photo below. Marking is done not the old fashioned way - with a needle, but with a ring knife. It gives stable, even markings, “without moving” along the waves.

Marking knives and/or jamb knives:

A Marking Knife (for example, a Hattori Arrow-shaped Marking Knife or a Lee Valley Marking Knife) (or) a Jamb Knife (for example, a Japanese Dick Folding Jamb Knife or a Narex Profi Professional Knife) is useful for marking. Awl

:

We recommend an inexpensive German WERA awl:

Tape measures :

For example, HEYCO measuring tape 5 m or STABILA BM tape

Pencils:

T, 2T - better than Koh-I-Noor.

View in the catalog with prices All measuring instruments

2. VICE, CLAMPS, CLAMPS AND OTHER FASTENERS .

Vices, clamps, clamps and other fasteners.

Initially, a set of F-shaped clamps with a grip size of 20, 30, 60 is sufficient. The best working surface for basing is a carpentry workbench with a vice.

3. SAWS, PLANES (PLANES) AND CHISELS (CHISLES).

Shaping is done through the operations of sawing, planing and chiselling. And here you can’t do without saws, planes (planes) and chisels (chisels)

Hand saws

Hand saws:

Backed - having a hard backing that covers the upper part of the blade to give it rigidity and stability during sawing. These saws are also called tenons, since they can be used to make high-quality tenons for the tenon-groove connection. Popular: Veritas

and Garlick

It is better to take Japanese saws due to higher productivity and better surface quality of the workpiece after cutting. Due to the three-sided sharpening of the tooth (and not two-sided as on ordinary European saws), the cutting of such saws is pulling. That is, you apply force at the moment when the saw moves towards itself. Therefore, less effort is wasted, and it cuts faster and cleaner. The Japanese axing saw - Dozuki - is more efficient and has a better price-quality ratio.

Select the size of the saw to suit your taste. Naturally, the larger size of 240 mm will provide more possibilities. But if you work with small forms, then 180 mm will be enough for you. Bladeless - these also include ordinary European hacksaws (pictured below left) and Japanese ones (bottom right). They are designed for longitudinal and cross cutting depending on the tooth pitch. As a universal one, you should take 14-16 tpi.

Planes (planes) + starting sets of planes

Planes (planes): In light of the application and selection of the optimal set, it would not be a sin to once again recall the types and functionality of planes.

Sherhebel - Used for initial rough planing of boards and workpieces. The Scherhebel knife extends beyond the plane of the sole up to 3 mm. Its blade has an oval cutting edge, removes thick chips and leaves deep hollows on the processed surface.

Planer (plane No. 7) - designed for precise processing of large planes, for leveling (plane) edges. The knife of the jointer is equipped with a chip breaker, and the block exceeds the length of the plane by 2 - 3 times.

Semi-jointer, also known as No. 6, has the same functionality as the jointer, but only in smaller sizes:

For basic planing, a double plane is used. He is also No. 4 with a chipbreaker. Best choice price/quality Dictum). The most popular is Veritas.

The planer is a werewolf. He is a butcher - his knife is turned upside down with the chamfer facing up. Therefore, it has a large rake angle and is used for finishing planing.

Zenzubel - necessary for selecting and cleaning quarters, folds, grooves, and sharpening perpendicular surfaces. Here you can also choose the best option for you.

There is also molding, folding, tongue and groove, and shavings that plan the profile. But this is no longer a starting level, but a more advanced one. We will talk about it in another article.

And there were still Cycles or staples, representing a steel plate, the edges of which were carefully polished, and the sides meet at right angles; used to smooth the surface of wood after planing, since planes and sizing always leave behind more or less noticeable depressions that should be eliminated when finishing the wood.

Planer starter kits

If we consider all planes from a starting point of view, then the options for a set of planes for a carpenter to start are as follows: Veritas set of 3 planes:

Prefabricated set of 5 planes. You can choose from only Veritas or Dictum planes (more economical), as well as a mixed set of planes from different manufacturers, including Lie-Nelsen. In the photo from left to right: a chisel, a cross-cut plane, a double plane No. 4, a semi-jointer (No. 6), a wooden jointer.

The following can be used as a sawblade: Dick 235 / 19 mm / 18 g Di 703339 or Veritas 178 / 17mm A2 05P41.01 or Lie-Nielsen 197/19 mm LN 1-042 chisel plane. plane: Miter plane 160 / 44 mm 20 degrees Dick or Miter plane Veritas Block Standard Plane 160 mm / 41 mm / 25° A2 05P22.30 or Miter plane Lie-Nielsen N9 1/2 SA 158/34.9 mm LN 1- 9-1-2 The rest of the planes are from the range of the same manufacturers. General note: it is preferable to buy metal planes, sherhebel, semi-jointer, jointer, chisel and end plane. Wood Planes - Planes are more difficult to set up. Need experience. They wear out the pad faster. They cannot be stored in rooms where there are changes in temperature and humidity. In short, they are more demanding in terms of care and storage. But if you “agree” with them, then they will also delight you for many years.

Chisels

Chisels. For the first time, two chisels with straight blades 4-6 and 15-20 mm wide are sufficient. But if the possibilities allow it is better to have a set: 6, 8,10,12, 20, 32, 40, 45mm Suitable like Japanese Hattori

as well as European Narex. The latter are the best choice in terms of price-quality ratio.

4. TOOLS FOR ASSEMBLY OF THE PRODUCT.

There are an extraordinary variety of types of connections. You can find out more about them and the necessary tools for them in our review of “Arsenal-Master Super Connections”. It presents both classic and non-standard options. But what you definitely need as a minimum for assembly is: Hammer

Kiyanka

Plus: good glue for permanent joints, of which there are plenty in carpentry.

5. STORAGE AND CARE OF HAND TOOLS:

A true Master takes care of his instrument. Therefore, it won’t hurt: Oil for caring for metal and wooden surfaces Camellia

Sharpening device The most popular is the Veritas Sharpening System II sharpener.

Sharpening stones will help keep your tool always sharp and ready for work. It is better to use water stones to start. Grit used: 1000 grit - required (King or New Cerax 1000/3000) separately 3000 or 4000 grit optional. To store tools at hand and safe, it is better to use a drawer, box, shelves, cabinets, etc.) If you choose from our assortment, Festool Systainers have proven themselves to be excellent.

OPTIONS FOR JOINERY TOOL SETS

And in conclusion, several options for sets of carpentry tools from an extreme minimum to a full set: 1. Set of 5 tools: thickness planer, carpenter's square, hammer, plane No. 4 and end plane:

2 set: 12 tools that are necessary for any carpenter according to the magazine “Finewoodworking”: hand jigsaw, scraper, surface planer, plane No. 4, square, chalkboard, marking knife, backing saw, shavings, chisel, end plane, chisel. 3 set: carpenter's square, hammer, clevis saw, regular clevis saw, chisel, planer, thicknesser, shavings, tenon saw, hand drill, template for tenons.

4 kit: this kit is expanded with templates and stops for making tenons and uses both European and Japanese saws.

Set 5: the dream of many! If you want exactly this, then we will help you not only form it, but also complete it with a tool box (custom order).

We recommend a ready-made carpentry set of professional tools for any work PINIE (Czech Republic) PREMIUMPLUS art. Case1PDPFW Also "Arsenal Master" offers

- Starter set of cabinetmaker's hand tools N4 for making OPTIMUM joints

- Starter set of cabinetmaker's hand tools N4-1 for making joints MINIMUM

View: Carpenter's Starter Set No. 3 Carpenter's Starter Set N5 All presented sets can be selected in our store. Each item can be selected from at least 2 different manufacturers. We will be happy to help you create your unique carpentry tool kit so that you can enjoy it for many years.

We recommend that you look at the entire range of tools in the Catalog and what we offer to equip the Workshop

We work with our souls!

Team "Arsenal Masters RU" All Useful photo reviews "Arsenal Masters":

Some recommendations for choosing a tool

You can wisely choose the necessary woodworking tools from a large assortment without spending extra money. Experienced professionals give several recommendations:

- When choosing a hand tool, special attention must be paid to the quality and reliability of the working part. When working with it you have to use force. Durable, well-sharpened products will allow you to spend less effort and time.

- Any tool should be convenient. Handles, configurations, dimensions of equipment and devices are selected taking into account personal characteristics. Comfortable models will eliminate inconvenience, fatigue, and ensure safety.

- Home craftsmen who rarely use woodworking tools should, if necessary, give preference to manual types. This will significantly save the cost of purchasing equipment. If such work is performed regularly, it is better to purchase electric analogues.

For regular work, purchase an electric woodworking tool.

You don't have to have every type of tool in your arsenal. You can limit yourself to several types of universal devices if working with wood is not a professional activity or a favorite hobby.

Electric circular saw

It is also called a circular saw, or a circular saw in common parlance. The main task of an electric saw is straight cutting of wood. For example, if you want to “dissolve” the board lengthwise into two parts.

By installing the required blade, the required depth of cut is achieved. And modifying the saw with a plunge-cut mechanism will allow you to start cutting not from the edge of the product, but from the middle. It will also provide for tilting the saw blade.

An electric saw cannot cope with figured cuts, but it can boast of power and speed.

What you need to know when choosing

- For large volumes of work, choose a model with more power: it will save a lot of time;

- Pay attention to the maximum depth of cut specification;

- Additional features such as speed control, soft start and overheating protection will make work more comfortable;

- Select the most suitable saw blade for processing wood of a certain hardness.

Wood carving assistants

The skill of wood carving has been highly valued at all times. Exquisite figured elements decorate the facades of houses, furniture items, and household utensils. The advent of CNC machines that perform this operation at a high level has not made hand carving less popular. It remains one of the most popular hobbies for creative people. Special tools for wood cutting allow anyone to master this skill.

Wood carving remains one of the most popular activities for creative people

There are several types of this art. The flat carving technique is used to create silhouettes with shallow contours. In the relief method, the decor protrudes above the recessed background. For geometric patterns, the technique of deepening lines is used. When performing openwork carving, gaps are cut out. Using this art, you can create three-dimensional images in 3D format.

A carving specialist uses a large number of different tools. They are selected depending on the type of work. The master’s arsenal includes universal products that are used in many operations with wood. These include hacksaws, chisels, and milling cutters. There is also a specific tool:

- knives;

- engravers;

- incisors.

Woodworking tools are selected depending on the type of work

Wood sawing tools

You can cut wood or materials made from it using several types of tools:

All of them are manual and electric. The hacksaw is ideal for garden work; it is used to saw not too thick branches, boards, and blanks for carpentry.

When constantly sawing wood at home, it is simply necessary to have a circular saw (circular saw). It cannot make shaped cuts, but it cuts through boards, plywood, and some types of plastic as quickly as possible.

If you need to cut down trees or prepare firewood, then in this case you use chain saws. There are also hand saws for logging, which require two people to work with.

Use a jigsaw to cut out shapes of arbitrary shape. It is suitable for cutting out blank models, artistic panels, various crafts, furniture parts, and kitchen appliances.

Carving knives

Knives help the master create skillful carvings. There are many types of this hand tool. The most popular options include:

- Tatyanka;

- Bogorodsky;

- jamb.

Wood knives for creating intricate carvings

The Tatyanka knife has a long handle. When working, the beveled blade is located 2 centimeters from the master’s hand, which allows you to create small elements. Bogorodsk knives are available in several models; they can be used for rough and fine carving. This tool has a semicircular handle, and the blades are partially sharpened, similar to a penknife. The structure of the jamb is identical to that of a professional shoemaker's tool. Its blade is beveled at an angle of 45°, sharpening is one-sided.

Bogorodsk knives for fine carving

During operation, wood cutting tools become dull and require regular sharpening. The craftsman must have special devices on hand to maintain the necessary sharpness of the blade. For this we use:

- bars with surfaces of different grain sizes;

- fabric skins of several numbers;

- leather belts and special grinding paste.

Wood cutting tools need regular sharpening

Planing tools

Carpentry tools and planing devices include planes, jointers and cycles.

The plane consists of the following parts:

- pads (housings),

- knife - cutting tool;

- wedge for fixing the knife in the block.

There are the following types of planes:

- Sherhebel for primary wood processing. The blade has a rounded shape and removes a three-millimeter layer of wood in the form of a gutter in one go. Knife width – 30 – 35 mm, cutting angle – 45o. Dimensions of the pads – (205 – 240) x (50 – 65) x (40 – 50) mm.

- Planer with a single blade for leveling wooden surfaces. A straight knife with a width of 40 - 50 mm removes 0.5 mm of chips in one pass. The dimensions of the block correspond to the dimensions of the Scherhebel.

- Planer with double blade for finishing surfaces. The cleanliness of the surface treatment is achieved by supporting the wood fibers with a chipbreaker, a small (0.3 mm) layer of removed wood. The dimensions of the knife and block correspond to the characteristics of a plane with a single knife.

Planers are used for planing long parts. They differ from planes in the width of the knife (60 - 65 mm) and the size of the block (650 x 70 x 75 - 80 mm). For planing concave and convex surfaces, as well as making grooves, planes with shaped knives and different configurations of the sole of the block are used - humpbacks, kalevki, zenzubels, folding gobels, tongue and groove, etc.

Cycles are used for planing wooden floors. They are knives attached to handles at a certain angle.

Chisels in wood carving

An important working tool is a chisel. These devices also have several types. Masters use devices:

- straight,

- reverse,

- corner,

- curved,

- cranberries.

Chisels differ in profile shapes and create a groove of the desired configuration. When working with the tool, a mallet is used. The sharp working part allows you to do without force load. There is a modern assortment of electric chisels that can be powered by mains or battery.

Chisels differ in profile shapes

When choosing tools, you must be guided by their purpose:

- jigsaws and chisels are used in making sculptures;

- wooden posts and balusters are decorated with a hacksaw or router;

- An engraver and chisels will help you make ornaments on trim, planks, and furniture.

Axes and splitting axes

From time immemorial, carpentry work has been performed with axes. They trimmed logs, made windows, doors, and built log houses with their help. Axes and cleavers are needed to split logs into firewood. An ax of a certain type is a military weapon.

Note! Splitting tools differ in size, shape of the metal part and handle, which is made of wood or fiberglass.

Today, electric splitters (wood splitters) are produced, which can quickly split logs of a certain length and diameter. Their cost is two orders of magnitude higher than ordinary high-quality axes.

Engravers making carvings

A popular carver's tool is the engraver. It is an excellent replacement for a traditional cutter and performs complex operations faster and better. There are several types of such devices. The work can be used:

- hand engraver with a set of working attachments;

- flexible shaft;

- laser device.

Hand engraver performs complex operations efficiently

Hand engravers can be installed on a screwdriver or drill, sharpening machine. This set is a convenient electric tool for making ornaments, openwork, figured or applied carvings.

Flexible shafts are equipped with chucks for fixing on a standard drill. The working tool can be a drill, a milling cutter, or a bur. It is advisable to have a sharpening machine that will allow you to regularly adjust the equipment and ensure the sharpness of the working blades.

The sharpening machine will ensure the sharpness of working blades

In industries where mass production of carved wooden elements is established, laser machines are used. Now such devices can be purchased for household use. The equipment operates under the guidance of a computer program, eliminating inaccuracy and defects. There are models that run on battery power or mains power. These devices include not only attachments of various types, but also tools for sanding wood. Multifunctionality turns the machine into an ideal assistant for the master.

Laser machine for home use

Drilling tools

Hand drills, rotary hammers, and augers are necessary for drilling holes. It is much easier to carry out woodworking with an electric drill. It will require special attachments.

There are a large number of types of nozzles, including countersink, center (perk), spiral, screw. A drill can be used to drill holes for bolts, tenons and other types of connections. By selecting a nozzle of the desired shape, you can expand the range of work performed.

Woodburning

Not only carving can perfectly decorate wood objects. Burning allows you to create an original panel and interesting decor. This type of creativity is accessible to everyone. Modern tools for wood burning have a high degree of safety; school-age children can use them.

Electric burners are offered in a wide range. The design of all devices is similar; they operate from a network with a voltage of 220V. The working tool is a metal needle. When current is applied, it heats up and burns through the wooden surface. There are models on the market with solid and wire working tools. Instruments with hard pens have several disadvantages:

- during prolonged use, the handle overheats;

- it is difficult to create small parts;

- do not allow decorating on hard wood;

- risk of burnout during long-term use.

Electric burners are offered in a wide range

Burners with a wire needle do not have such inconveniences. These devices:

- heat up quickly;

- can be used on any type of wooden surface;

- provide the opportunity to apply drawings of any complexity.

The disadvantages of the devices include higher cost, expensive repairs in case of breakdown, and the need for frequent replacement of burnt-out needles.

In specialized stores there are ready-made sets that contain burning boards with a design. You can realize your own creative idea, use boards, wood boards, plywood, and bars for this. The material must be well dried and well polished. Beginners mastering wood burning tools should not start by creating complex compositions.

Ready-made set for wood burning

Electric hacksaw

Also known as a reciprocating saw, and colloquially called an alligator saw

According to the principle of operation, it completely repeats the classic hand hacksaw, only the reciprocating movement is provided by electrical energy, and not by your hand.

Unlike a circular saw, a reciprocating saw is messier, slower and rougher, but it is safer to work with. However, the alligator also has advantages: the depth of cut, which is limited only by the length of the saw blade (and they are replaceable, so you can always find consumables for any task in the store), and the ability to work in hard-to-reach places.

What you need to know when choosing

- The blade speed adjustment parameter will allow you to select the optimal mode based on the hardness of the wood;

- The higher the power, the faster you will complete the task;

- The longer the blade, the thicker the board you can reach.

As the name suggests, it is needed for milling, namely chamfering, cutting quarters and cutting grooves and splines.

What to pay attention to

All the tools collected here are most often suitable not only for woodworking operations, but also for working with other materials: plastic, metal, plywood. You just need to choose the right consumable.

Fruit tree grafting tool

Special devices are needed not only for construction, repair and creativity. A gardener needs a tool for grafting fruit trees, allowing him to competently carry out this difficult operation.

The work uses a knife that has a specific design. This can be a copulating device equipped with a straight, long wedge. If grafting is carried out using a kidney, a budding instrument is used. A clean cut allows you to create a blade with a sharp point at the end.

Special knife for grafting a fruit tree

To sharpen a special tool for grafting fruit trees you will need:

- coarse block;

- fine-grained whetstone;

- leather belt and special paste.

When choosing a knife, make sure that it has a comfortable handle shape and is equipped with a durable, reliable blade.

Surface grinder

It is also called vibration.

Used for finishing wood after the belt has been passed over it. Also used for polishing.

What you need to know when choosing

- The “motion amplitude” parameter is responsible for the speed of work, but if it is large, the result of the work will lose its beauty;

- The ability to regulate the oscillation frequency will allow you to select the desired mode for any type of surface;