Every woodworking craftsman has several types of chisels in their toolkit that have their own purpose. A chisel is an indispensable tool when working with wood blanks. With its help you can make carvings of varying complexity.

Specialized stores offer the purchase of both ready-made sets of chisels and single copies of various models.

Classification

By method of use

Impact chisels

Immersion is ensured by light blows on the end part. The handles are equipped with metal rings on the back. It prevents the handle from breaking.

Hand chisels

Immersion into the tree is done by hand effort.

According to production method

- Stamped.

- Forged, having a thickened blade.

- Cutting, from less hard and dense steel.

By shape

The purpose and appearance are determined by the name:

| Name | Working part width (mm) | Handle size (mm) | Longitudinal section type | Cross-sectional shape |

| semicircular | 12 | 145X25 | smooth | ͝ |

| semicircular | 16 | 145X25 | smooth | ͝ |

| semicircular cerasic | 4 | 145X21 | smooth | ᴗ |

| eismus | 8 | 145X21 | smooth | ˅ |

| cranberry | 12 | 145X25 | spoon | ͝ |

| curved cranberry | 4 | 145X21 | spoon | ᴗ |

| cranberry-cerasic | 4 | 145X21 | spoon | ᴗ |

| semiclucarza | 12 | 145X25 | curved | ͝ |

Among classifications, national traditions can be taken as a criterion. For example, Japanese craftsmen proposed their own unique form of chisel. It is equipped with a shorter blade with a thick, long cone-shaped neck. This makes the tool comfortable, easier to hold and control while carving.

Thanks to a special recess on the back side, sharpening is more economical and faster. The combination of the shank and the conical cup makes the connection to the handle the most durable.

Thanks to two layers of the metal part (soft iron and high-strength steel), the sharpness is maintained for a long time, the blade is easily and quickly sharpened.

According to work purpose

- Plotnitsky . Allows rough processing of workpieces of different types.

- Carpentry . Used for neat, delicate work. Suitable for carving linden, spruce and poplar.

- Lathes . Cutters used for working on a lathe.

- Klukarzy . Thanks to the curved working part, they allow material to be removed from deep grooves.

- Multifunctional . Combines a nail puller and a frame lifting device. It's called "European".

- Looped . They have a special device. Used for rounding corners, preparing hinges and locks.

- Scrapers . Made from plastic. Needed for cleaning irregularities, repairing wheels, removing burrs and protrusions.

- Pocket . They have a folding blade.

- Mini chisels . Purpose: fine thread. These include rivets (miniature models with a narrow blade similar to a sharp leaf, allowing you to create a neat, high-precision design), marigolds (designed for cutting out thin elements with rounded shapes).

- Chisels . Used when knocking out unnecessary elements in the material.

- Shoals . Cutters equipped with an oblique blade for decorative work on relief. Used for sculptural carving.

- Shtiheli . They are distinguished by mushroom-shaped handles and an oblique cutter. Used for preparing grooves.

By type of longitudinal section

- Direct . The most common. The blade and blade are completely smooth.

- Curved . A special feature is the noticeable bend of the blade and blade.

- Klukarzy . They are distinguished by a sharply curved blade along the entire length. Used for punching wide pieces of wood.

- Reverse . The presence of sharpening on the other side of the blade and a notch on it allows you to create relief elements above the main surface. Such specimens are called “reverse cranberries.”

By cross section type

. The difference is the straight profile. Available in many sizes.

Flat- Angular cerasics . The cross section resembles the letter "V". Its angle is 60-90 degrees. Convenient for three-dimensional carvings, for example, images of hair.

- Radial . The cross section resembles a semicircle. Allows you to carefully and smoothly bury the tool into the wood. Used for contour carving. The working part can be sloping or flat.

- Bracketed . The smooth cutting part is equipped with sides of various sizes, placed at certain angles. Gives a narrow, even sample.

- Cerasics are round . Similar to the radius version, with a smaller thickness. Purpose – figured carving.

According to the shape of the working part

- Straight (the blade is perpendicular to the blade, used for rough processing in even stripes).

- Oblique (the beveled blade makes it easier to penetrate the wood).

Purpose of a chisel by type of work performed

- A flat chisel is used more often than other types. The blade width of a flat chisel ranges from 6 to 30 millimeters. The angle of the sharpened blade is 15-25 degrees. It is used for final processing of workpieces.

- Use a round chisel to process the workpieces and cut out simple recesses.

- A bevel chisel has a blade that is beveled at a 45-degree angle. It is used in the manufacture of longitudinal recesses and pre-processing of parts.

- The corner chisel is shaped like a Roman numeral V. Two blades folded at different angles are designed to make V-shaped recesses.

- A semicircular chisel is designed for cutting ornaments of varying complexity.

- In “clukarza” the cutting blade is round, straight or angled.

- “Caesariki” is a variant of a semicircular chisel with a narrow blade. Their main purpose is to cut narrow recesses and thin ornamental elements.

- The universal chisel has many attachments, various configurations and sizes.

Read here: Modern side cutters - a review of the best models and selection tips for beginners

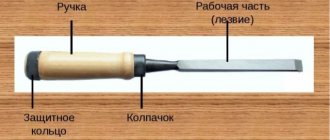

You can get acquainted with the types of tools in the photo of the chisel below.

Purpose

The large number of operations performed indicates versatility:

- sampling of recesses;

- chamfering;

- cleaning of grooves;

- thread;

- planing.

The purpose of the tool is indicated by the sharpening angle. With a large value, the cutting edge is stronger. For this reason, under conditions of rough work, the chisel is sharpened at an angle of 27-40 degrees. Chiselling is done with a chisel. This tool is gradually being replaced by electric machines. Its features: a narrow, thick blade, tapering towards the end. The power of the working part allows it to be used as a lever to remove chips from deep holes.

For work on a workbench, the cutting edge of chisels is sharpened more intensely. Its angle is 20-31 degrees. Considered optimal for maintaining strength while maintaining maximum sharpness.

For delicate work and removing small volumes of chips, scoring models with a razor-like blade are used. They have the greatest sharpness, allowing for delicate carvings. Hammer strikes are contraindicated. Only hand cleaning is possible. The length of the blade is 200-270 mm, the angle is sharpened to 15-22 degrees. They dull much faster than other types, especially when processing hard wood (oak, walnut, larch, maple).

Sharpening procedure

A sharp blade on any tool is much safer than a dull one. Such tools include a chisel. The frequency of sharpening depends on the frequency of operation of the tool, but in any case, the chisel must be sharpened at least twice a year.

Even a purchased chisel is not sharp enough to perform woodworking. Therefore, before starting work, it must be sharpened.

Used chisels develop irregularities and burrs on the chamfer, which are corrected on a grinding wheel. The damaged chamfer is held near the circle, thereby removing irregularities, chips and rust. The sharpening stone, which has three levels, allows you to achieve maximum sharpness of the chisel.

Japanese chisels and chisels

Japanese craftsmen combined the best characteristics in their instruments, which determined the particular popularity of the models and their higher price. The popularity of the models is due to their main feature - the structure of the cutting blade. The blade is made of two layers of steel, joined together by hand forging. On top there is a layer of softer metal that is easy to sharpen, and below there is a thin layer of ultra-strong high-alloy steel that ensures the sharpness of the blade.

Differences also exist in the form of the instrument. The cutter is shorter than in European and Chinese counterparts. The critical knot combines two options at once: the neck of the blade goes into the skirt and is wedged with the shank into the handle. This makes the device suitable for impact and hand use. The most popular brands: Daitei, Hattori, Shirogami, Tasai and others. The average price for one unit ranges from $70-100.

How to sharpen a chisel

Begin sharpening the chisel on the flat side. The chisel must be moved up and down along the stone. The instrument is held with both hands, making smooth and leisurely movements.

After grooves appear on the surface of the stone, sharpening should continue on a medium-grained surface and finish on a fine-grained surface. Sharpening can be considered complete when the smooth side takes on a mirror-like appearance.

Sharpening a chisel using a whetstone is a complex and painstaking procedure. It is easier to use a special sharpening device.

Rating of sets with chisels

Ready-made sets of chisels make it possible to buy tools of different widths and shapes to perform different tasks at the best price, and storage is provided with the help of a case or case. When purchasing, you need to look at the number of devices, width, blades.

Stanley DYNAGRIP 2-16-888

An excellent set for a carpenter who has to move frequently to different projects. The set is sold in a plastic case with 5 chisels of different sizes, all of which are placed in a separate place. The cutting element is protected by rubber. The tool itself is flat in appearance, with identical two-component handles.

Pros:

- A large set with a width ranging from 6-25 mm, which will allow you to perform almost any task.

- The weight of the set is 1.3 kg, which is convenient for carrying.

- Small product dimensions 30x30x5 cm.

- The suitcase has a handle and latches for easy transport and increased comfort. The tool will not fall out when carried.

- The handles have steel heels for hammering.

- The handle has a soft coating and is shaped to fit your fingers.

- The steel is alloyed and will last for many years.

Minuses:

- The high cost of the kit is around 2000 rubles.

- There is no width of 8 and 12 mm, which are often used for figure cutting.

- Weak sharpening from the manufacturer, so it needs fine-tuning before use and after purchase.

- Some elements may have broken geometry, so they are only suitable for rough manipulations.

NAREX SUPER 2009 LINE PROFI 8, 10, 16, 32 mm

Czech set of chrome-manganese steel and straight blades. Special attention should be paid to the rubber-coated handles and impact heel. The quality of the tool is excellent; the set contains the most popular chisel sizes. Consumers also like the sharp edge and long service life of the products. Disadvantages include broken geometry and lack of a case.

pros:

- Application of chrome vanadium steel.

- High quality sharpening.

- Optimal ratio of cost and quality.

- Comfortable handles.

Minuses:

- No case.

- Cutting edge with broken geometry.

Enkor 10401 1/6/36

The best choice for beginners in woodworking, due to the optimal price and 4 chisels of different widths, namely 10, 12, 16 and 20 mm. The working rod is made of alloy steel, which ensures a long service life. The blade can be additionally hardened.

Pros:

- Affordable price, starting from 400 rubles.

- Thick handle provides a tight fit in the hand.

- Light weight of the tool.

- Set includes 4 chisels.

- The blades have a rubber cap.

Minuses:

- Ugly design.

- No case.

- It is recommended to use only for soft wood; if it gets on a knot, it may quickly become dull.

- For fine work there are no 6 and 8 mm blades.

After studying all the best wood chisels, you can make the right choice for your needs. The entire article is written for informational purposes and does not force you to purchase a particular product.

Making blanks on a machine

Turning chisels are divided according to their functionality into the following groups:

- Rough processing. The chisel has 2 cutting blades located at an angle relative to each other.

- Meisel finishing treatment. Meisel is a smooth flat cutter with an angular sharpening on one side.

- Semicircular chisel for processing non-standard products.

- Cutting blade for removing excess wood when making patterns.

- Round chisel for processing round parts. Its blade can be either smooth or serrated.

- A file that processes the ends of workpieces.

- Cutter limiter that regulates the turning depth.

How to do it yourself

Making a quality tool begins with the right choice of materials. For the blade you can take:

- Metal cutter. Among other blanks, this one has sufficient rigidity and holds an edge well.

- Metal drills will become the basis for narrow mini-chisels.

- A semicircle can be easily obtained from a used punch.

- A chisel for corners can be made from any profiled tool.

- The file will also be an excellent source for a carpenter's chisel.

- Needle files become the basis for creating a thin tool.

To make a mini chisel, you can take a small piece of metal as a blank. It is more convenient to create small instruments at home.

For the handle, take a wooden beam. It is much more reliable than plastic, and it sits more confidently in the hand.

On the market you can find forged chisels for wood carving. They are made from durable carbon steel, they are resistant to wear and keep their shape and sharpness longer.

We will look at ways to create professional chisels from scrap materials.

Let's prepare the tool:

- Metal cutter;

- Pliers and forceps;

- A container of water to cool hot metal.

Chisel from a milling cutter

A do-it-yourself chisel is made very quickly using the following algorithm:

- Using a saw, we cut out the workpiece of the required length along the contour drawn in advance. Allowance should be made for a handle of the same length as the blade. In this proportion, the tool will be securely fixed in the wooden casing.

- We grind the surface of the blade, constantly dipping the metal in water to cool.

- Now we cut out a handle from wood. To do this, use a saw and a plane. The handle will consist of 2 halves, between which a metal blank will be fixed.

- In one of the halves of the handle we create a socket for the blade. To do this, we create a shallow contour according to size.

- We connect the finished parts using wood glue, clamp them in a vice and leave them for a day. For reliability, the halves can be tightened with small self-tapping screws.

In this way you can make straight or beveled mini chisels. Instead of a disk, any part made of durable steel will do.

Metal drill tool

How to make a chisel from a drill is not difficult:

- The end is flattened with an impact load or cut off;

- Give the knife the desired shape. A drill makes excellent marigolds or rivets;

- Using the given algorithm we make a handle.

Drill chisels are widely used in carpentry practice: they can be made easily and quickly, and most importantly - to the required, thinnest size and shape.

Semicircular chisels

The most common semicircular chisel for wood carving is obtained from a punch - the workpiece already has the desired shape. All that remains is to cut off the excess metal and sharpen the blade.

How to make a semicircular chisel:

- Take a punch of the required diameter.

- Use a saw to cut off the excess part of the radius.

- While the metal is warm, it can be given the desired roundness, for example, a semicircle can be slightly flattened to obtain a semi-oval.

- Sharpening the blade.

- Let's make a handle.

We use a file

A file chisel is made on a grinding wheel. This is how thick straight cutters and chisels are made. It is necessary to sharpen the file at the desired angle and insert the workpiece into the wooden handle.

If desired, you can turn a corner chisel from a square file. To do this, you need to stock up on a good abrasive for a metal wheel.

Files

A thin needle file will make an excellent tool for cutting any shape. Moreover, you can do it right in the kitchen over the gas stove.

- We take the file by the middle with pliers and heat it over gas until red hot.

- Carefully but quickly bend the hot workpiece to the desired shape and lower it into cold water to cool.

- We wipe the tool and sharpen it.

How to use the tool

When performing wood carving, the following work is carried out: drilling, sawing, cutting and gouging. To create a quality product, it is impossible to do without measuring tools.

During the work process, the need arises for auxiliary tools or devices that help fix the workpiece and limit the degree of impact.

The nature of the work determines the choice of the necessary tool. Historically, the best examples were made using hand tools, but the modern trend towards mechanization and automation of labor has not bypassed this area of activity.

Set of various cutters for wood carving

There is a whole range of machines, mini-drills (drills), hand-held milling cutters, jigsaws, grinders, etc. on sale. Certain products can be made in automatic mode using copy-milling devices (pantograph).

The main tools of the carver

Wood carving is the processing of wood to give it a special shape or create a relief on it. The following main types of such operations can be distinguished:

- The through type of processing includes sawing and slotting wood carving. The sawing type is carried out with a jigsaw or file. The slotting type consists of punching through wood using a chisel or cutters when using a wood cutting machine. A pattern appears on a wooden product, which is why this type of carving is also called openwork.

An example of a box made with slotted carvings - The flat, creased type involves creating a pattern that is in-depth in relation to the main background. The following varieties of this type are noted: contour carving, staple carving, geometric carving and on a black background. The contour subtype is made in the form of grooves of various shapes using cutters, an angular or semicircular chisel, and a knife. Bracket carving is carried out with the same type of element in the form of a bracket using a semicircular chisel.

- The relief type is typical for carved panels, and the elements in it are raised in relation to the main background. The main tool is chisels of various shapes. Particularly notable is the Kudrinskaya carving, which is distinguished by its unique curls of flower garlands.

An example of making relief wood carving - The sculptural type of carving is distinguished by the creation of three-dimensional forms in the form of wooden sculptures. The entire arsenal of instruments is used in the creation of such works. Recently, a carving pantograph has often been used for this type of creativity.

- House carving is intended for decorating wooden houses and is always popular. In its implementation, almost all types of processing considered are used. The house variety provides for significant areas and large dimensions.

Templates for house carving

In order to do such work, a wood carving tool is used, both the main type and an auxiliary one, or even a carpenter's one.

What types of knives are used?

One of the primary cutting tools used for artistic wood carving are wood carving knives of various designs and purposes. The following types of knives are distinguished:

- Cutter knife. It is considered the main tool of a carver and is used when carrying out any work. It can have different blade lengths, handles, and even have different shapes. The most important difference is that the cutting angle is 35º. Dimensions and angle of the blade of the cutter knife

- Knife-jamb. It is used in flat-relief and openwork carvings to create long straight lines, form an oval contour and process the sides of recesses. Main dimensions: cutting chamfer angle - 20º, blade bevel angle - 35-60º, blade length - 35-80 mm, blade width - 6-45 mm, handle length - 90-160 mm.

- Bogorodsky knife. Designed for sculptural carving. The length of its blade is in the range of 25-90 mm, and the width is 10-25 mm.

- Auxiliary knives are needed for certain jobs. There are knives that allow you to make curved finishing of a volumetric relief, others are designed for editing slotted threads.