How to calculate the volume of a septic tank?

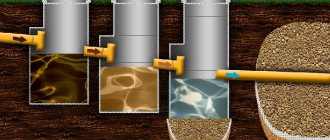

A number of rings installed on top of each other form wells, which in turn serve as a septic tank - a local wastewater treatment system. In this case, the first well is mandatory, since it performs the purification function, the rest filter the resulting wastewater. The number of such sections may vary.

To calculate the volume of concrete rings for a septic tank, use the formula:

V = n * Q * 3/1000, where:

- V—volume (measured in m3);

- n is the number of people who live in the house;

- Q - water consumption per user (per day);

- 3 - the number of days required for wastewater treatment (according to SNiP).

This is a very simplified option, but thanks to it you can calculate and calculate the volume of a septic tank for a private home. But you should understand that the result is approximate, since the initial data uses the calculation of the average value of water consumption per person living at home. It is equal to 300-350 liters. But before using the indicator, it is worth conducting additional research.

Technology for manufacturing sewerage from reinforced concrete rings

Before creating a sewer system in a private house with your own hands, you need to carefully study the entire process, calculate and take everything into account.

The main stages of creating a sewer system from reinforced concrete rings:

- Calculation of the required chamber volumes, selection of suitable ring diameters, design of the features of their placement, selection of a septic tank layout (one/two/three-chamber).

- Determining the installation location, taking into account all the rules and regulations - treatment facilities cannot be located wherever you want, the choice of location is clearly regulated.

- Digging a pit of suitable size and depth.

- Installation of reinforced concrete rings, if you plan to fill the bottom with concrete, perform this stage.

- Pipeline supply to the tanks through which wastewater will flow.

- Thorough sealing and waterproofing of all joints and seams.

- Backfilling of soil, installation of a hatch on the upper tank (for ease of maintenance during operation).

Calculation of the required volume of chambers

To understand what volume of chambers would be the optimal choice, first determine the approximate volume of waste that will flow into the tank. The chamber should easily accommodate the volume of wastewater for 3 days. On average, one person uses about 150 liters of water per day, the norm for one person in 3 days is 450 liters. This value is multiplied by the number of people who will permanently live in the house (4, for example) - 1.8 cubic meters.

You can add 10% for the arrival of guests (1.98 m3). It turns out that for a family of 4 people you will need a chamber with a volume of 2 cubic meters (that is, 2000 liters).

Choosing a septic tank location

The location is chosen very carefully - when a septic tank is created from concrete rings, the design necessarily takes into account the location of other objects, distance from certain structures, etc.

Where the sewerage system may be located:

- At a distance of more than 5 meters from private houses.

- At least 50 meters to water intake wells.

- At higher elevations - so that precipitation and melt water do not enter the reservoir.

- The pipeline is laid at a certain angle, without bends or turns, so that the drains move freely.

- If you plan to clean the septic tank using a sewer truck, you need to place it where there is convenient access.

- It is irrational to place the system very far from home - the costs of materials and installation increase.

Digging a pit for a sewerage system

The pit is dug manually using bayonet shovels or using earth-moving equipment. If digging is done manually, then at least two people are involved - one (two, three) digs, and the second carries out the soil with a bucket. Then the pit is filled with a layer of sand up to 50 centimeters thick, compacted, and concreted (if a ready-made concrete slab is not used as the bottom).

Installation of reinforced concrete rings

A sewer well made of concrete elements can be different. Depending on the design and volume, the weight of products may vary, but usually reaches a ton or more. Therefore, special equipment is used for installation - a truck crane.

You can try to install the system without a truck crane, for which the rings are rolled to the installation site, dug to the required length, and the bottom is concreted. But this option is very labor-intensive and does not guarantee high quality of the system.

A truck crane or manipulator allows you to install a septic tank quickly and easily; special hinges are provided for installation, which greatly facilitate installation. The rings are simply placed one on top of the other. If there are locks, the rings are not strengthened; otherwise, they are connected with metal brackets or plates.

It is better to drill rings with a high-power hammer drill and special drills. Make two holes on opposite sides of the joint, then fasten the plate with bolts on the nuts, tightening them well.

Next, the sewerage system is sealed using concrete or waterproof plaster (“Aquabarrier”). You can mix concrete yourself from two buckets of sand and one bucket of cement, mixed and mixed with a small volume of water. The joints inside and outside the well are coated with concrete.

Drainage system design

Installation of the system is relatively easy. The main thing is to do everything according to the rules and follow the technology step by step.

The main stages of arranging a wastewater disposal system:

- Creating a sewerage diagram: determining the location, indicating a point on the plan, drawing a curved line from the house to it, measuring the distance.

- Purchase of plastic pipes with a diameter of 10 centimeters of the required length, tees (for forks), corrugations (used to connect a bathtub, washbasin, shower) for the sewerage system, riser and special plumbing sealant.

- Digging a trench along the line from the house to the sewer at an angle so that the end of the pipe falls in the middle of the far ring.

- Methods for removing the sewer riser: through the foundation (breaking through it) or from under the house (digging a deep trench). The first option is faster and simpler.

- Connecting a tee to the end of the riser with a slope of 45 degrees, laying a plastic pipe into the well, connecting all turns with tees.

Pipe installation and seam sealing

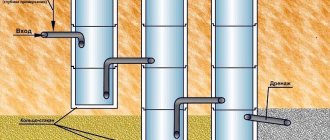

Concrete rings are punched with a hammer drill and holes are made for the pipe. The pipes are inserted 10-15 centimeters into the tank and connect separately located wells. The drain hole for another well is made on a hill, not reaching 30 centimeters to the top of the products. The seams are sealed, the trench from the house to the tank is buried.

Regulatory Requirements and Regulations

It is necessary to understand that the disposal and disposal of wastewater is clearly regulated by the regulatory documentation of the Russian Federation, non-compliance with which leads to negative consequences both for the ecosystem and for the liability of those responsible. Therefore, when calculating a septic tank for the needs of a household, they rely on a number of standards and rules, in particular:

- SNiP 2.04.03-85 “Sewerage. External networks and structures”, regulating sanitary protection zones around small treatment facilities, as well as adjusting the active volumes of installations.

- SNiP 2.04.01-85 “Internal water supply and sewerage” or their updated version SP30.13330.2012, for determining wastewater flow rates.

- A manual for the design of engineering systems MDS 40-2.200, which provides the main regulatory calculations for the calculation of septic tanks and their auxiliary structures (drainage wells, filtration fields, etc.).

What is required to calculate the volume of a septic tank?

When thinking about installing local treatment facilities, it is necessary to decide on the design. Preference should be given to one of two modern devices - a septic tank (methane tank) or an SBR reactor (aeration tank). Most owners prefer to install digesters - equipment in which the processes of biodegradation (biocenosis) and mechanical clarification take place in an oxygen-depleted environment (anaerobic). Such equipment, being quite effective, remains affordable for the majority of owners of small private farms.

First of all, it is necessary to understand that digesters are large-sized structures, the biocenosis in which occurs without forced activation (overflow, pumping, mixing), in contrast to SBR reactors, which are 6-7 times smaller with the same productivity. However, the natural processes of mechanical purification due to sedimentation (sediment formation) and flotation with fermentation gases, as well as microbiological decomposition of waste organic matter, also require the creation of certain conditions - the effectiveness of their work directly depends on the ratio of load indicators to the volume of the installation, temperature and time parameters .

Calculation of the volume of a septic tank for a private house can be carried out using a single-chamber or multi-chamber scheme. So, if the daily filling of an anaerobic installation does not exceed 1 m 3, then for a full-fledged biocenosis, a single mono-capacity is quite sufficient. For large quantities of discharges, two-, less often three-chamber arrangements or modular tanks mounted in series are adopted. Two-chamber septic tanks are divided into active zones of equal size, however, division is allowed in which the first compartment occupies up to 0.75 of the total volume.

Naturally, the key importance when designing an installation is its dimensions, or rather the working (active) volume of the septic tank, which is calculated:

- as the volume of daily wastewater inflows multiplied by the number of days required for the processes of anaerobic decomposition and sedimentation to occur;

- as the total volume of all active parts of cameras or modules;

- taking into account the height of the distance from the bottom of the container (compartment) to the cut of the spout pipe from the installation;

- with deduction of the height of the layer of sedimentary accumulations (-20%). When removing sediment regularly (at least 2 times a year), its amount is not taken into account.

When calculating local treatment facilities for your site, you should rely on the fact that a septic tank, followed by soil post-treatment, is recommended when wastewater flows up to 3-5 m 3 /day. If the recycling volumes are planned to be higher, then preference should be given to SBR reactors or hybrid structures (digester + aeration tank).

Let's look at how to calculate the volume of a septic tank for a home using simple tabular and formula calculations.

Calculation of volume through wastewater inflow

The primary determined initial indicator is the quantitative flow (cubic capacity, displacement) of household wastewater into the treatment plant. It can be found using the average statistical data on water consumption by one person (Table 1), knowing the number of regular users of the building’s utility networks, and also taking into account the period of anaerobic reactions.

Based on the range of indicators from Table 1, a lower value should be taken if an autonomous sewer system is being designed for a cottage development for individual use, and a larger value if for a blocked building or several houses with a common drainage system.

Table 1. Calculation of water consumption per person

| Groups of water consumption objects (residential buildings) | Water consumption standards per day per person, q, l/day. |

| Non-gasified, equipped with water supply, sewerage and baths | 90-120 |

| Gasified, equipped with water supply, sewerage and baths | 115-150 |

| With water supply, sewerage, equipped with bathtubs and solid fuel hot water boilers | 140-180 |

| With water supply, sewerage, equipped with bathtubs and gas hot water boilers | 170-190 |

| With installed flow-through high-speed hot water boilers for several water collection points | 190-250 |

Using the data in Table 1, we find the required size of the septic tank through its active volume (Vak, l or m 3):

where D is the time (days) that wastewater must be in the installation for biocenosis processes to occur. Based on the recommendations of SNiP 2.04.03-85, when unloading sediments annually, the minimum D is taken:

- 3, if the flow into the reactor is up to 5 m 3 /day;

- 5, if the flow into the reactor is more than 5 m 3 /day;

q – daily water consumption (l/day) per person from Table 1;

r – number of resident, permanent users (persons).

The data in Table 1 is average, but convenient to use when designing small and medium-sized public sewer systems. If the task is to derive more accurate figures for the receipt of household wastewater, taking into account the individual characteristics of individual developers, then it is possible to recalculate the number and time of use of water consumption points. To do this, take as a basis the data of SNiP 2.04.01-85 or SP30.13330.2012, which provide the second and hourly water consumption of plumbing fixtures (Table 2).

Clarifying the flow into the sewerage plant based on data from water collection points can significantly change the requirements for the capacity of the anaerobic reactor, both up and down.

Table 2. Calculation of water consumption for plumbing equipment

Then the active volume of the septic tank:

Where q1, q2,…, qn – specific costs of plumbing fixtures;

t1, t2,…, tn – estimated average daily operating time of household water points.

Recommendations for choosing and determining the size of a septic tank based on the calculated volume

Having determined the filling volumes of the treatment station, we adjust the dimensions of the septic tank taking into account safety factors and geometric parameters of the structure.

Capacity adjustment

If we plan to clean the container less than twice a year, then add a reserve (+20%) for sediment:

If necessary, you will need a reserve volume (+20%) if you plan to receive guests often and for a long time. Then the final formula for calculating the active total volume of all chambers or modules (from the bottom to the lower edges of the outlet pipes):

The volumetric characteristics of a treatment plant that is planned to be operated seasonally can, on the contrary, be reduced by 20%.

Accounting for geometric parameters

When selecting working tanks of a given capacity, it should be taken into account that the specific geometric dimensions of the septic tank may have functional significance. So, if there is a clear predominance of height over dimensions in plan, then the lower part of the container is excluded from the process (volume necrosis), since through ducts are created between the inlet and outlet pipes. Consequently, wastewater does not have time to settle, partially flowing into the next chamber, which negatively affects the final result of cleaning at the outlet of the equipment. On the other hand, shallow tanks that are too elongated have a small headroom for settling and sediment accumulation.

Taking into account the indicated properties of the liquid medium, the active zone, even in the smallest sewer installation, is recommended with a minimum depth of 1.3 m with a surface area of 1.8 m 2.

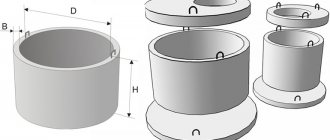

Calculation and sizes of rings

The table shows typical sizes of reinforced concrete rings and the estimated quantity for the required volume of wastewater per day for two, four and six people.

| Ring sizes (DIAMETERxHEIGHTxMASS) | volume, m3 | Number of required rings, taking into account the starting and revision rings | ||

| 2 people, 1.6 m3/day. | 4 people, 4 m3/day. | 6 people, 10 m3/day. | ||

| 1000x1000 | 0,78 | 7 | 16 | — |

| 1500x900 | 1,6 | 3 | 8 | — |

| 2000x900 | 3,14 | 2 | 4 | 10 |

| 2500x1200 | 5,9 | — | 2 | 6 |

| 3000*990 | 7 | — | — | 5 |

Practical recommendations for calculating and choosing a septic tank

Having decided on the required displacement of the total active zone of a septic tank for a country house, you can begin the practical selection of the tank(s) for it. It must be a sealed vessel or several mounted in series.

Today, many types of containers are offered, from both factory and home-made production. However, the material of their manufacture does not directly affect the processes of biocenosis, while the form factor is of decisive importance.

Let's consider how to calculate a septic tank made of concrete rings and the no less popular ready-made factory-made “Tank” installation.

How to calculate the total volume of a prefabricated septic tank made of reinforced concrete rings

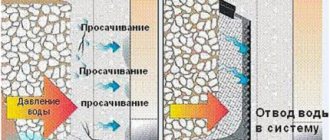

Reinforced concrete sewerage structures are distinguished by their reliability and practically unlimited service life. The problem that previously accompanied them - insufficient tightness - is now solved by modern means of waterproofing. Therefore, the use of ready-made reinforced concrete rings for wastewater treatment equipment is found in the vast majority of cases in the manufacture of anaerobic concrete tanks for small farms.

We start calculating the volume of a septic tank from concrete rings with the already described theoretical calculations for determining its active volume (formulas 1 and 2), as well as the active volume with reserves (formulas 3 and 4).

We select rings based on the MDS 40-2.200 manual, which recommends placing the bottoms of the tanks at least 3 m from the ground surface. This is due to the technical capabilities of pumping out sludge using sewerage machines. Therefore, with a ring height of 890 mm, there can be no more than three of them in one well.

In order to bring all the data together when calculating a septic tank made of concrete rings, you can rely on tabular indicators (Table 3), and also use the formula for the volume of a cylinder.

Where r and d are the internal diameters of the ring, respectively;

h is the height of the ring.

Let’s say that the active volume of the working chambers, taking into account the sediment Voc (formula 3), is 3 m 3 . We use a two-chamber scheme, which in practice is convenient to implement from standard rings of equal diameters. For self-assembly, it is easier to order reinforced concrete products with internal dimensions of Ø 1000 mm, since they can, with appropriate skill, be installed manually. Let’s take just this option as an example.

Next, Table 3 will help you calculate the volume of a septic tank made of concrete rings. From it we find, using formula 5, that the internal volume of one ring with a height of 890 mm is equal to 0.785 m 3. Not to be confused with the tabular volume, it shows the amount of concrete in the walls of the product. Therefore, to ensure the displacement Voc, we need K (pcs.) rings:

that is, 2 pcs. for the first camera and 2 pcs. to the second.

We take into account that the height of the air volume above the liquid level (dry volume) cannot be less than 500 mm (clause 3.35, MDS 40-2.200). Therefore, we will need to add another ring with a height of 590 mm above each of the chambers.

Table 3. Dimensions of concrete rings

At this point, the calculation of the volume of a septic tank made of concrete rings can be considered completed, however, to bring the structure to its logical integrity, it is still necessary to select slabs for the bottom floors of wells and covers with mandatory inspection hatches.

Calculation of the “Tank” septic tank for a country house

Purchasing a ready-made, factory-produced structure greatly simplifies the production of an autonomous sewage system. One of these popular designs in the Russian Federation is the Tank anaerobic station. If you decide to choose similar products, then calculating a septic tank for your home will also be simplified. Many official sellers provide a range of models from which you can order a treatment plant that can process any amount of wastewater from your household. For example, the “Tank 1” model has a maximum productivity of up to 0.6 m 3 /day, which is sufficient to serve from 1 to 3 residents.

Therefore, in the calculations of a factory septic tank for a private house, the main points will be:

- determination of wastewater volumes using formulas 1 and 2 without taking into account the coefficient D, that is, only for one day;

- selection of the area where installation will be carried out. The equipment turns out to be quite cumbersome, especially models for large volumes of wastewater, consisting of several separate modules.

Septic tank installation technology

There is nothing difficult in making a reliable and durable septic tank from rings. When designing several compartments, a linear construction principle is used, in which all concrete columns from rings are lined up along one line.

The receiving compartment and the following tanks are placed in close proximity to each other, and the filter column is located at a slight distance from them.

Step #1 – measurements and design

One of the prerequisites for effective wastewater treatment is to create conditions for it to remain inside the walls of the septic tank for at least three days. Therefore, the dimensions of the chambers are determined using the total three-day volume of wastewater as a basis.

According to standards, the daily volume of water consumption per household, subject to the use of household appliances, is about 200 liters.

So for a family of two or three people, the minimum volume of a treatment plant should be about two cubic meters. A family of 5-6 households will require a more spacious structure with a volume of 3-4 cubic meters.

When calculating, only the volume of the septic tank compartments is taken into account; since the filter well is not one of these, it is not taken into account (+)

But when determining the volume of the structure, it is worth making a small reserve. After all, if guests arrive, there is a risk of “overfilling” the norm. And eliminating the consequences is a rather complex and at the same time expensive procedure.

The table below will help you determine what size rings you will need and in what quantity.

Marking and dimensions of manufactured reinforced concrete rings indicating the outer/inner diameter, weight and volume

When choosing rings, keep in mind that the actual volume of the column must be clearly higher than the calculated one. This is due to the fact that as the drains fill, they rise only to the level of the overflow holes and never reach the top edge. Therefore, the calculated volume of liquid must be placed up to the level of these pipes.

Step #2 – preparing the necessary materials

When choosing rings for a septic tank, it is advisable to buy products with locks. The presence of locks not only simplifies the installation process, but also prevents their displacement under the influence of frost heaving. When purchasing products, you need to pay attention to the evenness of the seats and carefully inspect the integrity of the locks.

In addition to the rings themselves, materials and construction tools will also be required:

- sewer pipes;

- fine crushed stone;

- river sand;

- polyurethane foam;

- cement mortar;

- waterproofing compounds;

- rolled thermal insulation materials;

- building level;

- ladder;

- perforator;

- wide brush;

- container for mixing the solution.

To create overflows between wells, you will need asbestos-cement or polypropylene pipes marked “for external sewerage.”

Polypropylene pipes are famous for their strength and elasticity; their operating temperature is about 65°C

The diameter of asbestos-cement or polymer pipes used for overflow should be 110-120 mm.

Step #3 – digging a pit and arranging the bottom

It is better to carry out excavation work after the onset of the first frost or in the hottest months. During this period, the lowest groundwater level is observed.

The pit can be dug manually, by hiring a team of “diggers”, or by using the services of an excavator. If we take into account the costs of carrying out excavation work, then the costs of a team of diggers will be comparable to the amounts that will be spent on calling out special equipment.

The dimensions of the finished pit should exceed the dimensions of the installed rings by 50-80 cm. This will simplify the installation process and allow for external waterproofing of the joints of the structure.

When calculating the pit depth, three values are summed up: the height of the monolithic or filtration bed (20-30 cm) + the height of the rings (indicated in the table) + the height of the slab (15 cm).

It is better to immediately remove a large amount of soil removed from the pit from the site, using the same machine that delivered the rings

The pit for installing the treatment plant should be two-tiered: its second tank should be buried 50 cm lower than the first. Alternatively, dig your own hole for each tank.

To connect sewer pipes, trenches are dug, laying them below the freezing depth of the soil. The width and depth of the trenches are selected based on the dimensions of the rings used for the construction of the tanks. Most often they are made 50 cm wide with a depth of 1.2-1.5 m.

The bottom of the dug trenches should be located at a slope of 2-3 cm, distributed per linear meter. It is better to calculate in advance the difference between the extreme points, multiplying the distance between them by the slope value stated by the standards.

Compliance with this condition will ensure gravity flow of the liquid. The leveled and compacted bottom of the trenches is covered with sand, forming a layer 10 cm thick.

The bottom of the pit is carefully compacted again. For concreting, standard cement mortar prepared in a 3:1 ratio is used.

If you plan to install a lower ring equipped with a bottom, you don’t have to construct a concrete screed. In this case, you can limit yourself to crushed stone filling, forming a layer 20 cm thick.

The bedding created after compaction must have a flat horizontal surface, free of differences

It is necessary to achieve an effect in which the pillow sags as much as possible. To thoroughly compact the embankment and achieve maximum density, tamping is alternated with filling the fill with water.

Step #4 – installing rings and sealing seams

The construction of a septic tank begins with the installation of its closed part - the lower ring, equipped with a bottom. It is set exactly so that the walls are positioned strictly vertically. Compliance with this condition will ensure the strength and stability of the structure.

When using a ring without a bottom as a base, the bottom of the pit must first be concreted. To do this, pour a concrete screed 30 cm thick. The dimensions of the created concrete screed should be 20 cm larger than the diameter of the immersed ring.

An option for pouring the base for a three-chamber septic tank, the tanks of which are arranged not in a straight line, but in the form of a triangle

It can take up to two weeks for the concrete to harden. As soon as it acquires the necessary strength, install the first ring. Laying the rings without outside help is almost impossible. This work is performed with two or three assistants.

To protect the structure from leakage and reduce the harmful effects of groundwater on concrete, the joints between the base and the lower edge of the ring are thoroughly coated with waterproof cement mortar.

Ideal for waterproofing materials:

- bitumen mastic;

- deep penetration impregnation.

As an impregnation for treating concrete rings, it is good to use cement-based compositions such as “Penetron” or “Aquacement”.

When sealing joints, liquid glass is often added to cement mixtures, which increases the resistance of the joints to excess moisture.

Toxic compounds must not be used for internal processing. During operation, they can destroy bacteria that are responsible for the decomposition of bio-inclusions.

All subsequent ones are installed on the first ring one by one. To create a more durable fixation, metal brackets are installed on the outside of the structure. The “entry” points of the staples are concreted and covered with a layer of insulation.

Immerse the rings into the tank using a tap. The resulting joints between the elements are also carefully sealed. The voids between the outer walls of the tank and the pit are filled with a mixture of soil removed when digging the pit and sand.

The “pockets” should be filled evenly, alternating compacting the soil composition with filling with water.

Such a layer will perform a dual function: drain rain and groundwater, and also serve as a shock absorber

The upper part of the structure, located above the soil freezing level, should be insulated. In severe frosts, there is a high probability that an ice plug will form inside the tank. And this significantly reduces the speed and efficiency of cleaning.

It is convenient to use as a heat insulator:

- pieces of expanded polystyrene;

- finished shell products.

At the top of the columns, necks with holes for sewer hatches are installed. They are equipped with concrete or cast iron covers.

The second compartment of the purifier is equipped with a ventilation pipe. It should rise 70-80 cm above the ground surface.

Image gallery

Photo from

Finishing concrete ring

Method for narrowing the neck of a septic tank

Sealing the butt seams of the well

Installation of ventilation pipes

Step #5 - installation of overflow pipes

The location of the overflow pipes is determined by the level of the pipe leading from the house. Since the overflow septic tank device is designed to ensure the movement of liquid by gravity, the highest point of the sewer pipe must be located below the freezing level of the soil.

The overflow on the opposite wall of the tank should be approximately 15-20 cm below the supply point.

The overflow between the second tank and the filtration column can be done at the same level, or the same 5 cm can be maintained

To connect the sewer pipe, a hole of the appropriate size is made in the wall of the ring using a perforator. The easiest way to fix the pipe in concrete is with polyurethane foam. It will retain moisture and act as a damper pad.

The entrance of the pipe to the tank wall is carefully sealed. The inlet pipes coming from the house, as well as the overflow pipes between the chambers, are equipped with tees.

The main purpose of the tee is to direct wastewater downward in order to improve its processing and prevent crust erosion

Tees at the ends of the outlet and inlet pipelines will provide unobstructed access for clearing blockages.

To increase the resistance of pipes to the most severe frosts, it is advisable to apply a layer of insulation to them and cover the top with a protective casing.

Practical application of calculations

The presented method for calculating the volume of a small treatment plant allows you to design a fully functional septic tank on your own or make preparatory estimates for the purchase of a ready-made installation. The method is obviously simple, as well as sufficiently accurate to meet the needs of domestic consumption.

At the same time, it is up to you to decide which method of waste disposal you prefer. On the one hand, a septic tank designed to be assembled from concrete rings will require additional installation efforts and time spent on its construction. However, its relatively low cost will allow you to create wells with a good performance margin. On the other hand, ready-made factory containers guarantee simplified installation and accelerated commissioning of the structure, but for this you will have to pay a significantly larger amount of money than for concrete rings.

How to calculate the volume of a septic tank

I have a house in the village. I decided to make a sewage treatment plant. I studied the issue for a long time. I searched for information on the Internet and read articles on this topic. The design of the septic tank was calculated using the following algorithm:

- 1-3 people live in the house in the fall and spring, on short visits, on weekends.

- In the summer, 4-5 people live permanently + guests come.

- For a short time, there are up to ten or twelve people.

Therefore, I decided to make a treatment plant with a reserve and for growth if there is an addition to the family. On average, I calculated the volume of the septic tank if it is used by 8 people. It turned out: 8x3x200 liters = 4800 liters. Round up to 5 cubes.

The user calculated the cubic capacity of the septic tank as follows: per day, 1 person consumes 200 liters of water, and the total volume of the septic tank is calculated taking into account a three-fold reserve, for example, in case of a volley discharge. Total – 600 liters per person.

According to dvs5, the cost of ready-made septic tanks of the volume he needed did not fit into the planned budget at all . Therefore, he decided to make a septic tank himself from concrete rings, because... The groundwater level is low – 6 m.

The user divided the construction of a septic tank into sequential steps:

- At a depth of 0.6 m, he laid the outlet from the house into the septic tank - a “red” sewer pipe with a diameter of 110 mm.

- The top of the pipe was insulated by dvs5 with extruded polystyrene foam 5 cm thick.

- Dvs5 chose a place for the septic tank at a distance of 15 m from the house and 25 m from the water supply well.

- To calculate the area of the filtration field, dvs5 did a soil water absorption test.

To do this, he dug a hole.

After the soil-vegetative layer came loam. At a depth of 1400 mm sand began to appear. The user spilled the sample in a jar of water. There was some clay in the sand. Having deepened the hole to 1500 mm, dvs5 poured water into it.

After soil absorption tests, the result was 150 liters per day per 1 sq. m or 0.15 m/day. The sand is dusty and clayey. Permissible design load – 35-55 l/day per 1 sq. m. The following coefficients were used for calculation:

- +15% – more than 2 meters from the lower level of the filtration field to the groundwater level;

- +15% – seasonal accommodation.

The user took the average value of water absorption: 45+30% (reserve) = 58 l/day per 1 sq. m. Next, 1600 l/day was divided by 58 = 27.6 sq. m.

The result is a figure for filter wells (coefficient 1), but how many wells will be required for this area? dvs5 did this:

- For pipes - coefficient 0.5 (the user took the average): 27.6/0.5= 55 sq. m.

- For tunnels - coefficient 1.5:27.6/1.5=18.4 sq. m.

I chose the tunnels based on the price-area principle. I bought the cheapest ones. Total 8 pcs. After the tunnels I will install an inspection well. I used tongue-and-groove concrete rings. 2 pcs. with bottom. Two through. Two with a cover with adjustment hatches. The septic tank diagram is below.

Filtration field diagram.

About private sewerage schemes

Sewage wells made of concrete rings vary in volume, configuration, and design. A specific scheme is chosen based on a variety of conditions and factors (terrain of the site, number of residents, soil properties, etc.). Typically, a single-chamber septic tank is chosen for houses with sparse occupancy, while a two-chamber septic tank is suitable for constant use by a small family.

A two-chamber septic tank requires the presence of two tanks: usually each is made of a bottom, 3 rings, and a hatch is installed in the upper ring. The most difficult stages of work here are creating input/output, ventilation systems, organizing heat/waterproofing, maintaining the required slope of pipes, etc.

Main details and components of a well made of reinforced concrete pipes:

- Reinforced concrete rings with a diameter of more than 1 meter in the required sizes and quantities

- Insulated cover made of concrete, wood, metal

- Rings for outlet neck

- Pipe for ventilation

- Concrete slab for pit

- Reinforced concrete ring with bottom

- Sand and crushed stone pillow

- Inlet, outlet for pipes and drainage

- Waterproofing and sealant for treating walls inside and outside

For proper wastewater treatment, only settling and the work of bacteria is not enough - filtration fields are often made where water leaves the reservoir. Further, the wastewater can be used for irrigation and technical needs.

When it comes to a two-chamber septic tank, there is no need to complete construction of fields or filtration wells - septic tanks themselves cope with small volumes of water (in the second tank the wastewater is further purified).

In a two-chamber septic tank, the first tank is built from 2-3 rings; dirty water enters here and settles for a short time. Solid large sediments remain at the bottom, light wastewater goes into the second chamber, where it is cleaned again and removed from the site. Often special microorganisms are added to the second tank, which accelerate decomposition and processing.

Types of septic tanks by type of wastewater treatment:

- Cumulative - a regular sealed cesspool made with waterproof walls and bottom. The sewer truck cleans the pit as often as necessary.

- Anaerobic - most often these are two-chamber septic tanks, where anaerobic bacteria work, purifying wastewater by 65-75%. Water is further purified in filtration wells, fields with anaerobic bacteria or trenches.

- Aerobic, biological treatment station - wastewater is also accumulated here and partially processed by anaerobic bacteria. The waters are clarified without oxygen, and then they are further purified with forced air injection. The wastewater is 98% purified and can be discharged into the ground.

Learn how to make your own sewer system in your dacha

First you need to decide whether people will live at the dacha permanently or seasonally. Then they calculate the total volume of wastewater that is expected to accumulate over 3 days. In accordance with the calculations, rings of the required volume (height and diameter) are selected that are suitable in size for all the necessary elements for the well. Next, a diagram is drawn up, a trench is dug, cameras and pipelines are installed, everything is sealed and insulated. The soil is backfilled and the system can be used.

Drawing up a diagram

The sewerage layout plan must include all the necessary points and elements.

What does a septic tank scheme include:

- Location of the first, second tanks, filtration fields, taking into account the requirements of SNiP and standards.

- Calculations of tank volumes, installation features, calculation of the required number of parts and elements.

- Determining the units of special equipment required to perform the work.

Calculation of the cost of hiring equipment and purchasing materials

The cost of renting equipment and materials directly depends on what kind of septic tank is planned to be installed, what the volumes are, and the features of the system. For excavation work, bulldozers, excavators, and dump trucks are usually rented. Installation of concrete rings is carried out using a truck crane.

Prices vary greatly in the regions, so everything can be accurately calculated only after companies provide price lists. But on average, digging a pit and removing soil from a site costs from 350 rubles per cubic meter. If they dig 3 holes of 1.5 m3 in volume, then excavation work will cost 1,600 rubles.

Cost of materials:

- Concrete ring with a volume of 0.6 m3 - from 4,500 rubles, 3 pieces cost 13,500 rubles (this is for one chamber of three rings).

- Cement - you will need about 2 bags of 200 rubles each (400 rubles).

- Sand – 100 kilograms is enough (120 rubles for material and up to 500 rubles delivery).

- Pipes of the required diameter and length, connecting elements, waterproofing and sealants - all this can vary greatly in characteristics, which is why prices vary widely.

Sewage wells made of concrete for a septic tank are the best choice, thanks to which it will be possible to create a high-quality and durable, reliable and durable wastewater drainage system.

Calculation of the cost of building a septic tank from concrete rings on a turnkey basis

A septic tank made of concrete rings is a reliable, durable and relatively inexpensive autonomous sewage system for a country house. Despite the apparent simplicity of the design, such a scheme, especially in the recommended three-chamber version, provides a high degree of purification of any domestic sewage, after which the water can be drained into the ground by drainage without any damage to the environment.

Such a scheme is allowed for implementation if groundwater is located at the construction site at a depth of at least 3–4 meters.

When choosing a septic tank design, you first need to determine its minimum volume. The online calculator below will help with this.

The calculator algorithm takes into account the average normal water consumption of one person. Plus, some consumption features have been added that affect consumption, which can be checked off in the proposed list.

Calculator for calculating the minimum required volume of a septic tank

Having determined the required volume, according to the proposed table, you should select from the proposed options a suitable septic tank layout. If possible, it is still recommended to give preference to three-chamber schemes, as they provide the maximum degree of purification.

An alternative to a septic tank made from rings

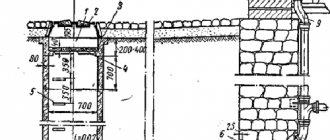

Cast concrete septic tank

It’s not difficult to build a septic tank with your own hands – the diagram of which is given below.

Scheme of a monolithic septic tank

To do this, it will be necessary to purchase concrete rings, concrete mortar, high-strength plastic, steel and brick. The septic tank must be equipped with a hatch made of durable materials.

After all materials have been purchased, the following steps are performed:

- Trenches for pipes and main frames are dug.

- Then the pipes are installed, after which the formwork is carried out.

- Next, concreting is carried out, evenly from top to bottom.

Pro tip: In order for the concrete to dry evenly and not too quickly, it must be systematically watered and covered with film.

- While the concrete hardens, a finishing well is installed; for this, brickwork can be used for discharge.

- After the concrete has completely dried, it is necessary to cover the upper part of the septic tank compartments with a roof, in which there should be space for an inspection pipe, as well as for inspection hatches.

The disadvantage of installing a septic tank with your own hands is the inability to provide it with all the necessary filters. The only thing that can be done is to ensure that the waste is broken down at a rapid pace. To achieve this, you need to add a set of certain enzymatic bacteria, which can be freely purchased on the market, into one of the compartments.

For more information about this, see “Installation of a monolithic concrete septic tank.”