Sealant for sewer pipes or also called plumbing sealant - this material is important for the joints of both plastic and cast iron elements of the sewer system. Let's look at what types exist and their features.

Sewerage refers to non-pressure pipeline systems, since all wastewater and organic matter in them move by gravity. However, the tightness of connections or other sections of pipelines is no less important, since the state of the internal atmosphere of residential or public premises depends on it. If cracks, cracks or other violations of the density of the pipes appear, they are replaced. However, sometimes there is no time or reason to undertake serious repairs. Often the simpler approach is to use sewer pipe sealant, which allows you to seal the cracks and fix the problem in a faster and easier way. Let's take a closer look at this issue.

When is sealing of sewer pipes required?

Often the sewer riser or outlet parts of a cast iron pipe receive serious damage. An inspection shows that a piece of the cemented patch is falling off, and the pipe itself may fail. In this case, the master decides to use sealant for cast iron sewer pipes or PVC plastic pipes. During the work, the recommendations specified in SNiPs and technical regulations, pipe wear, hydraulic effects and the possibility of leaks are taken into account.

Sealant for sewer pipes must be selected taking into account the fact that this external sewer has a significant diameter and a large length.

Sealing PVC sewer pipes is necessary to prevent sewage from entering the apartment and eliminating unpleasant odors in residential areas.

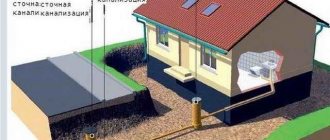

Scheme for sealing a pipe joint

Solving the problem of sealing joints must be taken quite seriously.

Having identified the cause of the malfunction that is interfering with the operation of the cast iron pipe, the owner can carry out the entire cycle of necessary work to eliminate it.

The causes of pipe leaks are varied:

- defect in the material used to install the sewer;

- improper laying of cast iron sections;

- the presence of cracks and holes in the riser.

Repair of external sewerage system

How to repair sewer pipes if they are located under an asphalt road? In this case, a trenchless repair method is used using polymer pipes. The advantages of polyethylene pipes (high strength, light weight, long service life) allow them to be used for such repairs.

Types of trenchless repair:

Types of sealants

Sealing of sewer pipes can be done with the following materials:

- reinforced aluminum adhesive tapes;

- silicone sealants;

- mastics from various manufacturers;

- polymer cement solutions;

- sanitary winding;

- epoxy resin;

- technical sulfur.

To choose the right sealant for sewer pipes, you need to know the material from which the drain is made. Silicone compounds and reinforced tapes are suitable for lightweight plastic pipes PVC, PEX, HDPE, etc. If you have to work with metal (steel or cast iron), you need to use something serious. It is also important to consider for what work the solution is purchased.

The joints of PVC plastic pipes are sealed with lightweight silicone, which is unlikely to cope with an emergency leaking sewer. It is also important to follow the instructions. It describes the optimal conditions under which sewer pipes should be sealed. For example, let's take the optimal conditions for curing silicone sealant (this is room temperature, at which it dries for about 4 minutes). When working in cold weather, the hardening time is significantly longer.

There is a need to purchase another type of sealant - frost-resistant silicone. We'll talk about the nuances of using different materials below.

Tips for choosing

It is quite difficult to independently calculate the appropriate diameter for external sewerage in certain conditions, but there are general recommendations that will help solve the problem.

- A 5-centimeter diameter is quite enough for a shower, drainage from a sink and similar elements.

- From the toilet, drains are discharged into 11-centimeter structures.

- To equip a full-fledged bathroom in apartments and private houses, the minimum size is also 11 cm. If the house is multi-story, then craftsmen often choose vertical systems with a diameter of up to 15 cm. If they are made in accordance with GOST 51613 2000.

- 20 centimeters should be equal to the cross-section of the pipeline, if we are talking about a pipeline in a horizontal plane, which collects and discharges wastewater from the entire house.

- The branch through which drains flow from plumbing fixtures to the pipe vertically should not be smaller than the riser.

Video

PVC plumbing pipes with pressure

They are relevant for systems in which pumps are responsible for forced circulation of liquid. This creates artificial pressure, and then the flow becomes continuous.

The installation of pumps will be especially relevant where there are many apartments and large premises.

The wall of a pipe with a size of 50 mm increases in thickness, otherwise they will not be able to withstand the increased load. The use of multilayer products is allowed. And here the characteristics are regulated by GOST 51613 2000.

Non-pressure type of PVC pipes

They are most often used in modern sewer systems. Their design is standard. They are not recommended for use in systems with artificially created pressure.

It is possible to install pressure pipes along the entire length of the external sewer system, but this solution is too expensive. Similar non-pressure materials are 25 percent cheaper than pressure materials.

Watch the video

About corrugated varieties

They have the most unusual appearance. The walls look like an accordion. This allows installation even in places where access is difficult.

The structure has an inner and outer layer. A smoother material is used to make the inside so that blockages do not appear inside. The outer layer is standard PVC.

How to connect plastic pipes to cast iron?

A regular rubber adapter will suffice if you need to connect a system that has a socket. Plastic external adapters are needed where there is no socket.

When using rubber cuffs, replacement is carried out as follows.

- We clean the 250 mm bell from plaque and dirt if they appear on the surface.

- Apply a layer of sealant to the outer surface of the socket. After which the part is inserted.

- A plastic pipe for the sewer system is connected to a cuff.

Plastic connecting elements require a slightly different procedure.

- We level the edge of the pipeline by 250 mm using a grinder if part of it bursts during operation.

- We put a 250 mm rubber cuff on the structure. Its surface is pre-coated with a composition for high-quality sealing.

- A plastic adapter is placed on top.

Video

https://youtube.com/watch?v=39fa3je7waI

What other adapters are there for plastic products?

The range of plastic external adapters on the modern market is quite wide. They are less reliable than metal ones, but they are more affordable. And their installation can be easily done with your own hands.

250 mm adapters are produced from polyvinyl chloride and polyethylene, which are mounted in systems with rubber cuffs.

Strong fixation is created due to the elastic ring inside; no additional tools are needed for installation.

PVC fittings for adhesive mounting are also not able to withstand high pressure. Although they are more reliable than the previous version.

Video

250 mm polypropylene adapters are produced, for installation of which welding is used. Form permanent connections. To work, you need to use special soldering irons complete with nozzles. They are made in the same size as the diameter of the pipeline.

Finally, some manufacturers produce 250 mm designs in which plastic elements are inserts, and the product itself is metal or made of composite.

These are also quite popular plumbing pipes and PVC adapters for sewerage.

Self-adhesive tapes and their properties

The structure of the sealing tape

This type of sealing can be used both to seal and protect joints, and to strengthen sealing plugs, fittings, taps, corners and elbows. The main advantage of the tape is its ease of use. It is wrapped in several layers around the pipe on the desired section of the sewer. This ensures reliable and long-term operation of the system, protection against corrosion and the effects of currents, and waterproofing of joints. Depending on the composition, adhesive tape can be used both on cast iron sewer pipes and on plastic, such as PVC or PE (HDPE) pipes.

The tape must be applied to a dry surface. Before winding, the pipe is cleaned of dirt and liquid and degreased. Next, we wrap the problem area with an overlap so that the previous round overlaps the new one by half the width. We keep the tape under tension and do not create folds.

As for the choice of insulating material, special anti-corrosion tape coatings should be used. They are used to seal joints between pipes, seal coupling units, tie-ins, and bends related to the sewer system.

What is a sealing tape that insulates a sewer pipe? The product is based on a bitumen-rubber mixture and a protective film.

The peculiarity of the material is that it has a high degree of strength, is used to work with various compositions, and does not collapse for a long time.

You can avoid the unpleasant consequences of a leaking sewer riser by sealing the joints with a silicone compound. For work, 2 types of materials are used:

- acid insulation;

- neutral sealant.

Repairing defects using a neutral compound will cost the owner much more than working with acidic insulation.

The use of silicone is economically beneficial, since the material has significant adhesion.

As for the use of other sealing compounds, here you can choose the following types:

- bitumen mastic;

- cement mortar;

- asbestos cement composition.

Step-by-step work execution

Damage to a cast iron product on a straight section is fraught with severe leakage. It is recommended to eliminate a leak in a sewer pipe only after cleaning the element to bare metal using:

- A rubberized clamp (factory or homemade). A piece of fabric impregnated with varnish or epoxy glue. Patches made of fabric, covered with a rubber strip and tied with wire to the pipe.

Before eliminating a sewer pipe leak, you will need to dismantle:

- Trimming the pipe unit with a grinder to the joint. Cleaning the socket from packing, cement, glue. Creating a stop for the lever using a grinder on the remaining part of the pipe. Installing an adapter coupling in the socket. Installing a new pipe in the adapter coupling and fixing it.

If a pipe is leaking due to a fistula, then the system must be repaired using a small wooden chopper or lead cone. The sewer pipe is wrapped with rubber or a bandage; impregnate with epoxy or use a clamp. If the system has not been cleaned, then the hole is sealed with sanitary silicone. It can be used to seal the joint between the pipe and the wedge.

It will take 2-3 hours for the joint to dry. To speed up this process, you can use a hairdryer. Before hammering, the chopik is wrapped with polyethylene from a regular bag. For tight installation, it is processed with a plane. The material of the chop can be not only wooden, but also plastic.

A rubber gasket is put on such a plug. For reliability, it is glued to the gasket with sanitary silicone. The current element of the sewer system can be sealed with gum arabic - liquid glass or office silicate glue. It is also used to process the pipe joint.

Silicone sealant

Sealing of joints is carried out using silicone adhesives made in accordance with TU 6-15-1822-95, GOST 6-02-4-53-96.

All plumbers have a weakness for this type of sealant. Meanwhile, silicone compounds have good sealing ability, allow you to seal seams and cracks in plastic and cast iron pipes, dry quickly and are easily removed from the surface.

There are two types of silicone compounds.

- The first type, neutral , allows you to work with any surface and does not come into contact with water and other substances. Features a higher price tag.

- The second sealant, acidic , is used only for PVC pipes and other plastics. Although it is a cheap substitute, it destroys metal and cement-containing materials. In the presence of water, it breaks off acetic acid, which can damage the inside of pipes. Therefore, for cast iron and steel pipes we choose only neutral sealant.

Silicone insulating material is a rubber-based composition consisting of a filler, a hardener and a catalyst. The vulcanization temperature of the material ranges from +60 to +200˚С.

Stages of sealing cast iron pipes with sealant

Silicone sealant for repairing PVC pipes in the sewerage system has a density of 2.0 g/cm³, dries at a temperature of +20˚C in 150 minutes. The tensile strength characteristics are even more varied, ranging from 16 to 20 kgf/cm² and depending on the grade of material.

The peculiarity of the sealant is that the vulcanizer has high adhesion to steel, copper, aluminum, silicate glue, and concrete. Silicone sealant is resistant to adverse weather conditions, solvents, synthetic and mineral oils.

When repairing a pipe, there is no pollution of the environment with toxic substances, since silicone materials belong to class 4 of low-hazard products. The sealant is used for gluing and sealing joints and connectors when repairing sewer pipes.

Sequence of insulation work ↑

Sealing the pipeline using self-adhesive tape is carried out in the following order:

- The surface of the pipe is thoroughly cleaned of various contaminants (grease, dirt, dust, etc.), and then dried.

- The end of the tape is freed from the protective film and attached to the pipe in close proximity to the element being insulated.

- The tape is wound in a spiral with a 50% overlap to provide two layers of insulation.

Advice. To prevent wrinkles from appearing, winding the tape should be done with slight tension.

Sealing a sewer pipe with self-adhesive tape

Technical sulfur

Sealing an old cast iron drain can be very difficult. Technical sulfur was often used to repair cast iron pipes. But to apply it, it was necessary to heat the composition to a plastic state. A special vessel was used (bath for heating sulfur).

The material is pre-melted in an electric furnace at a temperature of 130-135˚C, and then poured into the socket. Unfortunately, the repair may be of poor quality if it was not possible to fill it at once.

Observing special precautions will help you avoid unpleasant consequences when working with sulfur, since the sealant easily spills, and careless handling leads to a chemical burn.

In addition to the high temperature and risk of fire, there was another risk factor during such work - toxic gas was released during combustion. Therefore, I had to work in a respirator. Nowadays, pipes can be sealed in safer ways, so technical sulfur is practically not used.

Plumbing sealant and sealants

Assembly adhesive is widely used in construction during assembly, installation and repair work. The main advantage is the ability to glue materials of different structures, for example, concrete and plastic, wood and metal, etc.

Many manufacturers add various additives to their products that enhance certain properties. This can be particularly strong fixation, frost resistance, rapid hardening, transparency, etc. Thus, each user will be able to choose a mounting adhesive that best suits his needs.

Gaskets for adapters and plugs are consumable items used when installing central heating batteries. Serve to seal connections and protect the system from leakage. They are rings of different diameters made of elastic material. Paronite gaskets

made from asbestos rubber mass.

They are cheap and durable. If they fail, they can be easily replaced with new ones. The material for silicone gaskets

is medical silicone. Unlike products made from paronite, such gaskets retain their properties when exposed to chemicals and high temperatures and do not lose elasticity over time. They are installed in a special groove in the radiator, so the connection looks very aesthetically pleasing and neat.

Polyurethane foam is a widely used sealant. This liquid mixture of chemicals expands and hardens when exposed to air, becoming rigid polyurethane foam. Able to fill cracks, joints, seams and other hard-to-reach holes. It is used when installing windows, doors, heat and sound insulation and other construction work. Supplied in cylinders up to 1 liter. There are the following types of polyurethane foam.

One-component is a standard sealant that expands under pressure from the container in which it is supplied. Two-component polyurethane foam has a complex composition, and some components must be prepared in advance. The cylinder is inserted into the construction gun.

By area of use

Household foam is intended for simple and minor construction work and can expand up to 40 liters in volume. Usually one-component. Professional foam is used in large construction and renovation, expands up to 80 liters.

Summer foam can withstand temperatures from +5 to +35 ºС, winter - from -25 ºС, all-season foam - from -10 to +30 ºС.

An important characteristic of all compositions is fire resistance. On the packages you can find the following markings: B1 - resistance to open fire, B2 - ability to self-extinguish, B3 - heat and moisture resistance. This foam is water-resistant, so it is suitable for use in the bathroom and swimming pool.

Sealant guns are the most convenient and economical way to apply it.

A tube with sealant is placed in the device; under the pressure of the piston, the contents are fed through the tip into the work area. The piston can be driven by turning a screw or pulling the trigger.

Frame models are designed for sealants in a cartridge, and cylindrical models contain sealant without packaging; the gun body plays the role of a tube.

The spray foam gun is used during repairs, construction, insulation and sealing.

The device provides the most accurate application and economical consumption of material. It is very easy to use: the can is placed in the barrel, when you press the dispenser trigger, foam is released through the tip.

You can use the gun with one hand and perform auxiliary work with the other.

Epoxy resin (glue)

PVC sewerage equipment that is significantly worn out, with numerous damages, is repaired using epoxy resin. The material is necessary to eliminate leaks when repairing PVC pipes.

Through cracks discovered after inspection of the equipment are sealed using a two-component adhesive composition. The mixture is prepared immediately before use, following the manufacturer's recommendations.

Fragile types of sewerage (cast iron, ceramics) can also be sealed using epoxy resin. Such pipes require a stronger and more reliable connection, which epoxy glue does well.

Fixing a leak is quite easy if you use epoxy resin . The composition is used in combination with a hardener, and the ratio of components to form the working mixture is 1:2 or 1:1.

To seal seams and emergency areas, epoxy resin is mixed with a hardener and applied to the break site. The mass dries quickly, serves for a long time and reliably, and is resistant to aggressive acids and alkalis.

The polymerization reaction proceeds much faster when the temperature increases by 10˚ C. The sealing of the resulting cracks is quite strong, since the epoxy composition has minimal shrinkage, high resistance to adverse factors, and stable physical and mechanical characteristics.

Epoxy adhesive is obtained by mixing resin and hardener in a ratio of 1:10, and distilled water is used to form a composition with water-borne resin.

Epoxy resin is a common material for connecting PVC sewer pipes. The joint is sealed by pouring resin into the gap, and to obtain a lasting result it can be used in hot and cold conditions.

Expert recommendations and possible difficulties

When installing and repairing a sewer system, professional plumbers recommend:

- Rigidly fix the structures during installation using clamps.

- Do not increase the pipe slope above 15%. If the angle is steeper, the water will not have time to wash away the waste deposited on the walls.

- Seal cracks in a cast iron pipe using a bandage soaked in cement mortar and a clamp.

- If the system does not provide an angle of inclination for free drainage, use special blowers for sewage.

- Regularly inspect drainage lines.

Assembling the sewer system in compliance with the standards, sealing critical joints and careful operation will help the structure last a long time.

Cement

Sealing the joint with cement

When sealing a cast iron socket, Portland cement can be used. This substance dries quickly and provides reliable protection against leaks and accidents. For sealing, a high-quality grade of Portland cement is used. When working with Portland cement, it is necessary to apply the mixture over the joint.

A plumber's wrap is applied to the end of the pipe, and resin strands can be used for thick channels. The end is inserted into the socket, compacted and filled with Portland cement. This design will last for many years.

True, when dismantling it, your followers will have a lot of difficulties. But that is another story.

How to choose a sealant for sewer pipelines

It is necessary to build on the type and structure of the engineering communications themselves. Polymer sealants are ideal for treating joints in an apartment, office, or cottage because they:

- are inexpensive;

- available to a wide range of consumers;

- presented in a wide range;

- easy to use;

- do not require special training.

For large volumes of work, it is recommended to combine materials with each other. Alternatively: sealing tape + mastic/epoxy resin/sealant.

An important factor is the material used to make the pipes. You need to make sure that the chosen product has good adhesion to metal, cast iron, polypropylene and PVC products, since the quality of the seam and its durability depend on this.

In some cases, other means of sealing drain lines are also suitable:

- rope soaked in resin - for cast iron/ceramic drains;

- technical sulfur - for sealing small joints;

- sealing cuffs - made of rubber and suitable for various types of pipelines.

Ribbon

One of the most popular sewer sealants is tape. The most commonly used is self-adhesive tape. It can be either regular or foil. Using tape has many advantages:

- Does not deform during operation. Correctly applied tape will last a long time and there will be no bubbles underneath it.

- Non-conductivity of electricity. Quite often, the cause of corrosion is electric current; the tape will perfectly reduce conductivity and protect the pipe.

- Resistance to external influences. The tape is highly resistant to various substances and factors, so you can rest assured about the sewage system.

- Mechanical strength. The chance that a joint treated with tape will begin to diverge is very low.

The tape is multi-layered and its basis is a bitumen-polymer material, which allows it to be absolutely waterproof. Depending on the temperature to which the connection will be exposed, there are several main types:

- Summer ribbon. Perfect for hot water pipelines, as it can withstand temperatures up to plus 300 degrees Celsius...

- Winter ribbon. This tape can be used at temperatures from -2000 to +1000 C.

- Heat resistant tape. This is a special tape that can withstand liquid temperatures up to plus 1500 degrees Celsius. In this case, the difference in ambient temperatures is allowed within the range from -100 to +2000 C.

There is no need to use heat-resistant tape at home. Both summer and winter ribbon are perfect; if the pipe is located outside the room, it is better to choose the winter option.

The service life of such a tape is about 30 years. Due to its high technical performance and affordable cost, the sealant is quite popular. Before applying the tape, attention must be paid to surface preparation. They need to be thoroughly cleaned and degreased. If the tape is applied correctly, you will get two layers of protection, this can be achieved by applying the tape in wide overlaps.

Polymeric

Polymer sealants are the usual polyurethane or silicone sealants. They are used quite often in plumbing. The big advantage is its versatility - it can be used for sealing and gluing various structures and elements. The best option would be to choose the composition of the silicone sealant, taking into account the specifics of the structures for which it will be used.

The composition most often includes special rubber, which is characterized by high elasticity and good adhesion. Another undoubted advantage is that its use does not require careful preparation of surfaces.

There are two main types, based on the composition of the hardener:

- Neutral. The composition excludes acids, this allows it not to destroy the pipe, and expands its scope of use. The downside is the high cost.

- Acidic. Unlike neutral ones, it contains acids, which is why it can enter into a chemical reaction with the surface. It combines low cost and good quality well, but cannot be used for all surfaces.

Polymer sealants are excellent for metal and plastic pipes. After hardening, they form a strong rubber-like compound. High elasticity helps to bear loads and not crack.

Most often, sealant is sold in a tube for a gun (special tool). It should be applied around the entire circumference. It is required not to leave empty areas, but to fill the entire joint. After application, you can remove the residue with a special spatula.

Technical sulfur

Sulfur is a hard and at the same time fragile material. To obtain elasticity, you must not overheat the pipe, and you can also add ground kaolin. The material is made from recycled petroleum products.

Sulfur is often used for sewer joints. A huge plus is the extremely low cost compared to analogues.

Divided into two main types:

- Powder.

- Lumpy.

If you buy lump sulfur, it must be crushed before use. Sulfur is heated to a temperature of 130-1500C and poured into the bell space. After cooling, an excellent water-resistant mass is obtained. The disadvantage of this sealant is low elasticity.

Portland cement

Portland cement is indispensable for many jobs. It is also successfully used in sealing. It includes:

- Clinker.

- Gypsum.

- Calcium silicate.

The presence of such components allows us to obtain a sealant with good properties: frost resistance, high strength and water resistance. Special additives are added to the cement mixture and mixed until a thick solution is obtained. Due to its properties, it is successfully used as a sealant when installing sewers.

Epoxy resin

Epoxy resin is a versatile adhesive that is used in sealing sewer pipes. In order to obtain the desired composition, you will need to mix the glue and hardener. The proportions depend on the brand and are indicated in the instructions. When preparing the mixture, be careful; the wrong proportion can ruin the entire composition.

Bitumen mastic

The sockets of a cast iron pipe are quite often filled with a special bitumen material. This is a liquid sealant; according to the type of application it is divided into two categories:

- Cold mastics.

- Hot mastics.

At home, it is better to use cold bitumen mastic (cold welding), as it is easier and safer to work with. Unfortunately, its high cost will be its big disadvantage. This type of sealant is widely used in the installation of stormwater routes and cable drains.

Jute and hemp rope

The use of ropes as a sealant has been used for many years. Today they are noticeably inferior to modern types of sealing substances, however, low cost and ease of use remain a significant advantage.

For many generations, this sealant has justified its costs, but today it is inferior to its analogues in all respects.