Wood is a material that can be easily processed with various tools. One of their types may be a drill. You have to use a drill quite often when processing material.

The holes that need to be drilled can be of different diameters, as well as blind or through.

For small sizes, a metal tool is usually used, but for larger diameters, a specialized large-diameter wood drill is used.

There are several types:

- spiral;

- twisted or single-stranded;

- "ballerina";

- ring (crown);

- cylindrical Forstner;

- feather

There are, but are rarely used, drills for cutting conical tenons, cork drills, etc., etc. Let's look at some of them.

What is a feather drill?

The drill has the form of a rod, at one end of which there is a working part, and at the other - a hexagonal tip. The cutting blade has the appearance of a “feather”, having a central tip and two incisors extending from it.

All feather drills can be divided into single-sided and double-sided, designed to work in one and two directions, respectively. The cutting angle of the cutter of a single-sided pen is 75-90°, and that of a double-sided pen is 120-135°.

A wood drill bit has several advantages. Undoubtedly, the main one is cost. In terms of price-effectiveness ratio, it has no equal. Compared to a Fostner drill, the feather bit is much cheaper and has a wider range of working diameters.

The length of the drill is 15 cm. Using an additional extension, the depth of the drilled hole can be increased by 3 cm. The drill is ideal for creating small holes with a diameter of up to 60 mm.

In addition, the simple shape of the pen allows you to sharpen it yourself with a file or on a machine. As practice shows, they can even drill tin and thin sheet metal. Thanks to the hexagonal tip, the likelihood of the drill turning in the chuck is completely eliminated.

Advantages and disadvantages of a feather drill

The main disadvantage is the inability to drill holes with diameters larger than 60 mm

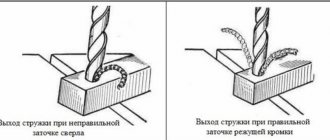

. During the drilling process, the material is destroyed only by the sharpened cutters of the end part of the nozzle. At this time, the rounded sides of the feather rub against the edges of the hole, leaving small hairs of wood on them and giving the surface a slight roughness. This spoils the view a little.

The negative aspects include the fact that a feather drill for wood loses its cutting properties relatively quickly.

| Name | Advantages | Flaws |

| Spiral | · Smooth surface of the edges of the hole; · Great depth. | · The largest drill has a relatively small diameter; Through holes only |

| Forstner drill | · Smooth walls; · Possibility of drilling holes of large diameters; · Long service life. | · High price; · Short shank, which does not allow deep penetration into the wood |

| Feather | · Low price; · Large number of diameters from 5 to 60 mm; · Possibility of using an extension that allows you to increase the depth of drill passage by 30 mm; · Can be sharpened by yourself. | · Rough edges of the hole. |

Basic information

What exactly makes the feather-shaped drill stand out from other samples designed for drilling wood surfaces? Let's figure it out.

Comparison with other models

Photo of a twist drill for working with wood

As we have already noted, consumables for drills that are designed to work with wood can have different shapes.

Let's take a quick look at all the possible options:

| Name | pros | Minuses |

| Spiral | · Smooth edges of the hole; · Large passage depth. | · Relatively small limit of possible diameter; Through holes only |

| Forstner drill | · Smooth edges; · Creation of blind holes; · Possibility of creating passages of large diameters; · Durability. | · Quite a high price; · Short shank, which does not allow deep penetration into the wood. |

| Feather | · Low cost; · Wide range of possible diameters from 5 to 76 mm; · Possibility of extending the drill by 30 cm using a special attachment; · Easy to use with your own hands; · Possibility of sharpening. | · Not very clean hole edges. |

Forstner drill

Tip: to create holes whose diameter exceeds 60 mm, it is recommended to use special “crowns” with a sawtooth edge. With a feather drill of this size, the edges of the cut may be too torn.

Sample of a crown for working with wood

Buying expensive tools for one-time use is not cost-effective. But the feather model is quite universal and the most affordable, which makes it convenient for every owner to have in their toolkit.

Steel drill bit for wood 40 mm

Advice: due to their low cost, it is advantageous to buy feather drills as a set. Then you will always be ready to drill a hole of almost any size needed.

Various sizes of wood drill bits in one set

Design Features

Compared to the more expensive models discussed above, the structure of a feather drill looks elementary:

- The working part is a flat blade with a sharp protrusion in the center, from the tip of which a sharp edge begins, leading to one of the edges of a kind of feather and sloping to the right. The thickness and width of the cutting element of the drill have the following ratio:

| Width (diameter), mm | Thickness, mm |

| 5-10 | 1,-2 |

| 10-20 | 2-4 |

| 20 or more | 6-8 |

Cutting edge of a feather drill

- The tail part is shaped like a hexagon, which is suitable for drills, screwdrivers, as well as all kinds of magnetic adapters and extension cords.

Hexagon shank

There are no such complex fragments in the form of a spiral or a drill, which simplifies even the moral approach to using a feather drill.

Features of choice

Point drill 23 mm, treated with hot steam

When buying a drill, of course, you want to get a high-quality sample, and for this you should pay attention to a number of external signs:

- Correct form. Linear dimensions must be symmetrical.

- Sharpness of incisors. The sharpening must be of a factory nature.

- No defects. The presence of visible flaws indicates the “handicraft” method of manufacturing the drill, which does not speak in favor of its quality.

- Color. The shade of steel can say a lot about the processing carried out on it:

| Color | Features of the production process |

| Steel gray | There was no processing at all |

| Black | Treatment with heated steam was carried out, due to which the strength of the metal increases |

| Golden | A special treatment was carried out using internal pressure material removal |

| Bright gold | Indicates the presence of a titanium nitride layer on the tool, which significantly enhances its strength characteristics and service life |

Drill bit for wood coated with a layer of titanium nitride

Exploitation

Instructions for using feather drills are as follows:

- We apply markings on the wooden surface that we plan to drill.

- To perform the work, it is better to take a drill with a power regulator. With a feather tool, it is best to operate at 200-500 rpm, and the larger the diameter of the drill hole, the lower the operating speed of the device is set. That is, for example, a 60 mm wood drill bit will work better at lower speeds.

- If you need to drill to a greater depth, then insert a special adapter into the chuck. If the length of a simple drill is quite enough to complete the task you have planned, then we immediately fix its shank in the drill head.

Installed “feather” in the drill chuck

- We bring the tool strictly perpendicular to the place where we want to drill a circle, and press the sharp tip to its center.

- Let's start drilling. As you deepen, you can increase the number of revolutions made.

Start of drilling according to the applied markings

- As the chips accumulate, we stop, remove the drill and clear the opening of debris.

Released chips must be removed manually

- We reach the desired mark, after which we finish the work.

Finished hole made using a pen tool

Sharpening

Grinder

With other models the situation is more complicated, but sharpening the “feathers” at home is quite easy. To do this, you will need a sharpening machine with a diamond wheel, or even just a quality rule.

Next we do this:

- We take a new feather drill as a sample.

- Based on his example, we derive the incisors of the dull one.

- We pay special attention to not knocking off the center.

If the deformation of the blade is already too great, then you should not try to restore it, it is better to buy a new one, especially since feather drills are inexpensive.

Feather drills for wood. Dimensions

You can purchase drills either individually or in a set. Often craftsmen buy a whole set at once. It usually includes pen nozzles of the following diameters: 10, 12, 16, 18, 20, 25 - these are the most common sizes that cope with their tasks quite easily.

You can buy a wood drill bit individually or to order in absolutely any size up to 60 mm. It is not advisable to produce and use feather bits with a diameter of more than 60 mm - due to the large area covered, the cutters destroy wood with great difficulty.

Application area

The tool is used when working with all types of wood, as well as its derivatives (MDF, chipboard, plywood). It is equally widely used for repairs, in the manufacture of furniture, doors, window frames, and in other areas of industrial production. There are two main types of drilling in which it is used:

- For non-through holes of small diameter. For example, the production of fastening sockets for door jambs, furniture production.

- For through holes. For example, sockets for installing studs and other fasteners.

Important! Spade wood drill bits are recommended for shallow drilling. You also need to remember about the thin tip. It goes deeper into the wood than the main head.

Terms of use

It is necessary to operate the drill taking into account the following nuances:

- before starting drilling, it is necessary to mark the place where the hole will be drilled and make a small indentation with a core;

- For work, it is best to use a drill with a speed controller. The operating speed of the drill directly depends on the diameter of the pen used - the larger the drill, the lower the frequency the shaft should rotate. Working at high speeds will lead to rapid wear of the cutters or breakage of the drill itself;

- if the pen nozzle is intended to be used for drilling deep holes, then you must immediately purchase an extension cord. It has a special lock that is clamped with a 3 mm hex key, thereby allowing the drill and extension to work as a single unit;

- In order to correctly outline the hole, at the very initial stage it is necessary to rotate the shaft as slowly as possible. It is important to set the drill perpendicular to the surface on which the hole is planned, and press the tip with little force;

- the pen is designed so that the sawdust of the wood being drilled does not come out and remains in the hole. Therefore, it is necessary to periodically stop work and blow out chips from the groove.

What to look for when purchasing?

A very large number of companies and firms are engaged in the production of feather drills. In order not to be disappointed in the instrument, when purchasing you need to pay attention to the following points:

- shape - the feather must have symmetry;

- the cutters must be perfectly smooth, which may indicate factory manufacturing conditions;

- the presence of chips and irregularities only indicates that the instrument was made in artisanal conditions, which does not add any advantages to the quality;

- color.

The last external sign is worth paying special attention to. The color of the drill can indicate how well the metal was processed.

Features of choosing a drill for wood

When it becomes necessary to choose the right drill, the first thing you need to pay attention to is the color. So, for example, each shade of the product is responsible for the type of final processing, which shows the life of the drill and its strength.

- The worst option can be considered gray products, which are not processed in any way and their performance parameters are quite low.

- The color can be golden, which indicates titanium coating and a fairly long service life.

- Black drills treated with steam during creation are no worse in performance.

In addition, it is worth carefully visually examining the object. If there are visible signs of deformation on it, then it is better not to use such a product. It is important to choose a drill without a single scratch or crack; its surface should be perfectly flat and smooth.

Types of wood drills

Sharpening

Of all the existing drills, the feather drill for wood can be considered the easiest to maintain. Sharpening it at home is very simple, just have a flat file or sharpening machine on hand.

To sharpen, you need to take a new nib as a sample. You need to draw the cutters along it, while checking the shape with the sample. Particular attention should be paid to the tip. It must be turned as centrally as possible - even a slight displacement relative to the axis of the drill will greatly complicate the work due to the different lengths of the cutters.

If the working part of the drill is severely deformed, it is not worth spending effort on restoring it - it is better to buy a new one, since their cost is low.

To drill holes in products made of wood, you can use tools of various types, differing in design, material of manufacture and geometric parameters. One of these tools is a feather drill for wood, the design features and technical characteristics of which are worth dwelling on in more detail.

Correct sharpening of the drill

Before you start directly sharpening an expensive and high-quality drill, you should try your skills on old, used products. Thus, if the result is negative, the old drill can always be used as a consumable. When your hand is full, you can switch to a new drill without fear.

For the most correct sharpening of a wood drill, its geometric parameters should be observed. This means that it is important to maintain the factory sharpening angle. Sometimes the result can be just like this – perfectly sharpened for a hammer drill. The drill itself can be processed either manually or using an electric sharpener.

Device for sharpening drills at home

Manual sharpening

When sharpening by hand, a mild steel file is used. Moreover, it is worth starting the processing process with a tool with a wide notch pitch, processing both the cutting edge and the back side. After this, you can bring the drill to perfect condition using a file with a fine notch.

Sharpening with an electric sharpener

When sharpening a drill occurs in an “automatic” mode using an electric sharpener, it is very important to have cold water nearby (in a container or running water), since it is necessary to constantly cool the rod. This will keep the product from overheating and damage.

Homemade drill sharpening machine

If you don’t have a sharpening machine at hand, you can easily make one yourself.

- It is necessary to firmly install the grinder in a comfortable position. A stationary frame with a motor speed of up to 1500 rpm (with a power of 200 W) is also suitable.

- The basis for a homemade machine may well be thick plywood or a wooden beam.

- For more correct sharpening, it is necessary to eliminate any vibration of the engine and create conditions for a smooth transition to different speeds. To achieve this result, you can use an abrasive wheel.

Step-by-step instructions for sharpening a drill

The result of the above actions is a certain scheme of actions:

- Guide the drill to the edge of the grinding machine disk.

- Mandatory adherence to the factory sharpening angle of 95 degrees.

- To improve the quality of sharpening, the drill should be secured in a washer, the rear edges of which should be tucked a couple of millimeters.

- Once sharpening is completed, it is worth continuing work at lower speeds.

- After this, you can cool the sharpened product and test it for functionality.

When sharpening a drill, it is important to understand that a person must have very good eyesight. Therefore, for better results, you need to organize high-quality lighting of the work place. If the rules are strictly followed, a sharpened drill will last a very long time and will always be a “savior” during repair or construction work.

The Lewis drill is designed to produce deep, small-diameter holes in wood of various species with any degree of humidity. The screw-shaped cutting edge of the drill begins with a sharp tip, with the help of which preliminary centering of the future hole is performed. And the spiral itself removes chips from the working area.

When do you need a special tool for drilling wood?

The question of how and what is the best way to drill a hole in a product made of chipboard, MDF, plywood or solid natural wood is relevant not only for carpentry specialists and those who professionally make furniture, but also for home craftsmen who prefer many jobs around the house do it yourself. The choice of drills for wood in such cases is made depending on what type of holes need to be drilled:

- blind, without an exit from the opposite side of the product (intended for mounting hinges on interior doors or on doors that are equipped with furniture structures);

- through (threaded connection elements (bolts and studs) are placed in them; without such holes it is impossible to install door handles and locks).

For woodworking, you can purchase an expensive tool (such as a disk cutter). However, its use is not justified in all cases. For most situations where wood needs to be drilled, a tool that is easier to use and significantly less expensive will do the job. These are, for example, feather drills, which, despite their affordable cost, are highly efficient in use. A wood drill bit can be used in combination with either an electric drill or a regular screwdriver.

Main characteristics

When using pen drills for wood, it is advisable to know how they differ from other types of cutting tools and what advantages they have.

Comparison with other types of instruments

Like metal drills, tools designed for woodworking are available in various designs and, accordingly, differ from each other in characteristics and functionality. When choosing such tools, you should have an idea of the advantages and disadvantages they have.

Feather drills, as can be seen from the table presented, have a number of advantages when compared with other types of tools. Meanwhile, a pen-type tool is not recommended for making large-diameter holes (more than 60 mm), since their edges may turn out torn. For such purposes, it is better to use core drills, which are made in the shape of a metal cup with cutting teeth located on its end part.

Due to the low cost of feather drills for wood, any home craftsman can purchase a set of them. Having such a set in your home workshop makes it easy and quick to select a tool for drilling holes of different diameters.

Design Features

The tip drill has a very simple design, the elements of which are the working and tail parts.

The working part is a flat blade, in the center of which there is a sharp protrusion used to center the hole being made. On the working part of the pen drills there are two cutting blades located on either side of the central protrusion. Each of these blades starts from the tip of the central protrusion and reaches one of the edges of the working part. The tilt of sharpening the blades of feather drills for wood, if you look at their working part in cross section, is done to the right. When making drills of this type, manufacturers adhere to certain ratios between the thickness and width of the cutting part.

The tail part is made in the shape of a hexagon. This cross-sectional shape allows not only to securely fix the tool in the chucks of drills and screwdrivers, but also to use magnetic adapters and extensions for these purposes.

The simplicity of the design, which distinguishes drills related to pen drills, the absence of spiral grooves, ribbons and other complex elements, are not indicators of the low efficiency of this tool.

Recommendations for selection

When choosing a pen drill intended for woodworking, you should pay attention to several parameters:

- correctness of shape (wood drill feathers located on the right and left sides of the central protrusion must be symmetrical and identical in their linear dimensions);

- degree of sharpness of the cutting part (sharpening of new pen drills must be carried out in the factory and meet standard requirements);

- absence of visible defects (if the surface of a new drill contains visible defects of various types, this is a clear indicator of the low quality of such a product, most likely produced in artisanal conditions);

- color (by the color of the metal you can determine the types of additional processing to which the finished product has been subjected).

Design features

The uniqueness and efficiency of feather drills lies in their design simplicity. They consist of two parts:

- The working part is the main part of the tool that comes into contact with the wood being processed. The shape resembles a shovel with a sharp tip. He is responsible for the exact position of the blade and cuts out the main part of the wood. On the sides of the working surface there are blades and cutting edges. If you look at the longitudinal section, they are sharpened to the right side.

Feather drills for wood are made according to strictly verified patterns. The proportional ratio of the width and thickness of the working part is strictly observed:

| Width (diameter) | Thickness |

| Up to 1 cm | Up to 2 mm |

| Up to 2 cm | Up to 4 mm |

| Over 2 cm | Up to 8mm |

- tail - a steel rod in the shape of a hexagon. The multi-faceted configuration allows you to securely attach it to the drill chuck, as well as use adapters to increase the working depth.

Operating rules

To increase the efficiency of using pen drills for wood and extend their service life, when performing processing, you must adhere to the following recommendations.

- Markings must be applied to those areas of the product where future holes will be located.

- For equipment that will be used in conjunction with a pen drill, it is better to choose a drill with a power regulator.

- Drilling wood using feather drills is performed at a low rotation speed (200–500 rpm). The specific value of the drill rotation speed depends on the diameter of the hole being made: the larger it is, the slower the tool should rotate.

- When the length of the pen drill is not enough to make a deep hole, special adapters are needed that are installed in the chuck of the equipment used. Otherwise, such an adapter is not required.

- Before starting drilling, the tool is brought to the surface to be processed strictly at an angle of 90°, while its sharp protrusion should be located exactly in the center of the future hole.

- Drilling should begin at low speeds, and as the drill deepens into the wood, the rotation speed can be increased.

- Chips that accumulate in the hole being created must be periodically removed from it. As soon as you notice that too many chips have accumulated, you need to stop drilling, remove the drill from the hole and remove the processing waste.

- As soon as the tool is immersed in the hole being created to the required depth, the drilling process can be stopped.

Features of operation

- Before starting work, the drilling area is carefully marked and clear boundaries are drawn. If there are many of them, then the depth of each is indicated.

- It is recommended to use a drill with variable speed control. This will make the job easier.

- The drill rotation range does not exceed 600 rpm. The golden rule is that the larger the hole diameter, the lower the head rotation speed and vice versa.

- An adapter is used to increase the drilling depth. One end of it is inserted into the cartridge, and the other into the tail section.

- The angle between the drill and the wooden surface is always 900. Otherwise, the tip may break and the workpiece may deteriorate.

- The main thing in work is the smooth increase in speed.

- Wood shavings are removed periodically.

Every craftsman should have feather drills for wood. They are easy to use. They are durable, productive, and easy to sharpen. The low price allows you to have several models of different sizes in stock.

How to sharpen feather drills

Unlike other types of drilling tools, pen drills designed for woodworking are quite easy to sharpen. To perform this procedure, you can use a sharpening machine equipped with a diamond wheel. If such equipment is not at your disposal, a quality rule will do. The sharpening procedure itself is as follows.

- If the craftsman has a set of feather drills, a new, unused tool is taken from it, which will act as a sample.

- Focusing on the geometric parameters of the sample, sharpen the cutting part of the dull drill.

- When sharpening a pen drill for woodworking, you should be very careful not to accidentally damage its central protrusion.

It makes no sense to sharpen feather drills in cases where their cutting part is sharpened too much. Given their low cost, it is easier to replace heavily worn-out products with new ones than to try to return them to working condition.

Drilling wood is one of the most common tasks in repair and construction, but it’s not always possible to purchase a high-quality wood drill. Therefore, it is very important to know how to choose a good tool and be able to sharpen a dull product!

Modern drills are often sold with a set of different drills, however, basically, they are always the same type of product, just of different lengths and diameters. So you have to independently select the types of wood drills that suit all your tasks. Of course, such a set should include a twist drill for wood; products are presented in a wide range - from 3 to 52 mm in diameter! A good tool of this kind should have an edge that will prevent it from slipping off the surface.

Products with a diameter of 10 mm or more must have a hexagonal shank so as not to rotate during operation. It is also important to know what number of revolutions during drilling should correspond to a particular tool diameter. For example, if you are dealing with small products up to 14 mm, you should set no more than 1700-1800 rpm for soft wood and half as much when drilling hard wood. When working with tools with a diameter of 16 to 25 mm, on hard rocks you should stick to 500 revolutions; the speed can be increased three times when drilling soft rocks.

The larger the diameter, the lower the speed - by observing this ratio, you will extend the service life of the product for a long time! When choosing tools, pay attention to the color of the metal - if it is a regular gray color, then such a product has not been subjected to any additional processing, and accordingly it will not last long. The black color indicates treatment with very hot steam, and the yellow color is inherent in products that are treated with titanium nitride, which increases the service life significantly.

Long wood drills are very dependent on their diameter. You will not find thin and at the same time long products - the thinner the tool, the shorter, otherwise it may break even with light pressure. So, a ten-millimeter drill can be up to 45 cm long, while a twelve-millimeter drill can be up to 60! Of course, it is absolutely not necessary to buy such long ones, unless you are dealing with drilling holes in thick beams.

Of course, you must maintain a healthy relationship between the capabilities of the drill itself and the dimensions of the drill, because a product with a length of 45 cm and a diameter of 52 mm will weigh almost 3 kilograms! An ordinary household drill will barely turn it even when idle! Experienced builders even use low-speed drill-mixers when working with such “giants”!

However, there is a compromise between the ability to drill large diameter holes and the weight of the drill! Products of this type are called feather ones, since drilling occurs due to a “feather” of the required diameter at the end of a long rod. On the market you will find tools from 10 to 55 mm. True, this compromise option also has significant disadvantages compared to the same spiral ones - they do not have a chip outlet, which greatly complicates the process of working with deep holes. Most often, these are used for drilling not very thick boards, as well as fiberboard and chipboard, so they are produced up to 15-20 cm long. However, there are also extensions with which you can make holes up to 40 cm deep!

Typically, these tools have a hex shank to ensure a firmer fit in the chuck. This option is perfect for holes for door locks. But you can work with them even with not very powerful tools, and they are much cheaper in price than spiral ones - sometimes the difference is 5-10 times! Recommended rotation speed when drilling for hard wood with tools up to 25 mm is 1500 rpm, if drills of a larger diameter are reduced to 1000. Soft wood can be drilled at 1500-2000 rpm.

Forstner drills are especially popular among furniture makers because they can be used to drill a blind hole with a flat, even and smooth bottom. That is why such drills are often called plug drills, although in fact this definition does not quite suit them, because there are special products of a different design just for drilling plugs.

The diameter of the products is presented in the range from 10 to 50 mm. Quite often the cutting edges are made of hard alloys, which significantly increases the service life of the product. As a rule, such drills are up to 10 cm in length, although with the help of extensions this parameter can be tripled. In operation, recommended speeds for soft wood range from 2500 rpm to 1000 rpm for large diameters, while hard wood is recommended to be drilled at fairly low speeds. For example, for tools with a diameter of 15 mm, it is recommended to set no more than 500 rpm.

The external resemblance to a crown gave rise to another name for such products - crowns. Their most important advantage is the ability to make holes of large diameters that cannot be made even with the largest twist or feather drills. The crowns look like a ring with teeth and are usually sold in sets, like attachments on one base, inside of which there is a centering drill. Of course, you can’t make very deep holes like this - ordinary models are capable of cutting through material up to 22 mm, professional ones - up to 64 mm. In addition, such tools are effective when working with plastic and drywall.

It would not hurt to note another unusual type - thermite drills, or, as they are called in professional language, milling drills. Due to their characteristic appearance, such products cannot be confused with anything else - they have a monolithic tip, like a conventional twist drill, and a core with many cutting edges. With the help of such tools, not only drilling is performed, but also milling - first we drill, and then we go in the right direction. You can work with milling products on both wood and plastic. Their diameter does not exceed 12 mm.

The Lewis drill is designed to produce deep, small-diameter holes in wood of various species with any degree of humidity. The screw-shaped cutting edge of the drill begins with a sharp tip, with the help of which preliminary centering of the future hole is performed. And the spiral itself removes chips from the working area.

Types of wood drills

Typically, high-quality drills are used by experienced craftsmen who require various types of products in their work to create holes in wood. These could be holes, for example, for tenons, bolts or dowels. Moreover, the drilling process itself can be very diverse in quality, which will lead to thoughts about how to properly sharpen the drill after use and whether it will have to be sharpened at all.

The most common types of drills today include: screw, spiral, feather, center, ring and Forstner drills.

Screw

If you need to drill wood across the grain without once again asking yourself the question of how to properly sharpen a drill for wood, then a screw drill with a fine thread at the end will come in handy. They can reach up to 50 millimeters in diameter. A special screw shape will help remove chips from the work site in a timely manner and thus not overheat the rod. Depending on the required hole depth, you can purchase drills longer than a centimeter, with a minimum size of 400 millimeters.

Screw drills for wood

Spiral

A spiral product can immediately be distinguished by a perfectly polished milled spiral with an edge that prevents any movement of the rod to the side during operation. It is thanks to the spiral shape that they can easily drill holes in veneer structures. The diameter of the corresponding drills reaches 52 millimeters, and the smallest can be found at 3 millimeters. In order to accurately target the intended drilling location, the tail of the product is equipped with a conical shape, which gives a lot of convenience.

If, when purchasing, the choice fell on twist drills, then you should always remember the relationship between the diameter of the product and the maximum number of revolutions that it can produce. Otherwise, the service life of the product will be sharply reduced. If you need to process hard wooden surfaces, it is better to set a maximum of 900 rpm with a drill diameter of 14 millimeters or less. But for soft wood, you can set the drilling tool to 1800 rpm.

Twist drill bit set for wood

Feathers

The most common type of drill is the feather drill. It is this that makes you think about how to sharpen a feather drill for wood, and is most often used in repair and construction work. It is the most convenient and has various options in diameter.

It has only one important drawback: this shape of the drill does not facilitate chip removal and the drilling process becomes significantly more complicated, especially when a hole with a large depth is needed. That is why experts recommend using this type of drill when working with wood boards or thick boards, where the drilling process will occur as efficiently as possible.

A special type of tip for a feather drill or a similar product with an extension can correct the situation. This extension has a hexagonal shape and can be used for other types of drills. In this case, the diameter of the final hole can reach up to 52 millimeters.

Feather drills for wood

Center and ring

But center drills are useful for creating perfectly smooth through holes in a wooden surface. Typically, such products take the form of a 50 mm (minimum 12 mm) rod with a cutting edge at the bottom, reaching a length of up to 150 mm. Of course, it will not be possible to make deep enough holes. For this purpose, ring drills are suitable, which look similar to a crown or a ring with teeth. They are usually sold as a whole set in the form of attachments with a centering drill and a single base.

Forstner drills

When it comes to repairing or creating furniture, and not about thoughts with the question of how to sharpen a feather drill for wood, then you can immediately safely go for Forstner drills, which are best suited for this task. They allow you to drill completely blind holes with a perfectly flat bottom. In this case, the diameter of the product reaches from 10 to 50 millimeters. The drill itself is coated with a specialized alloy, which serves as protection and increases service life.

Forstner wood drill bit

Design

The Lewis drill is included in the basic tool kit of a professional carpenter, being lightweight, it does not load the motor of an electric drill, and allows you to make blind and through holes in hard-to-reach places: corners of beams, places where wooden parts are overlapped, etc.

The twist drill consists of the following sections:

- A shank that has a hexagonal profile and is designed to fix the drill in the chuck of a drill or drilling machine.

- The main working part, which is a spiral tape of a constant cross-section and a relatively small angle of inclination. For the Lewis spiral, it is selected in such a way as to ensure reliable removal of chips from the drilling zone.

- Centering, ending with a tip with a conical thread, which allows reducing the axial load during the operation. For a tool of relatively low rigidity (and a twist drill is just that), high axial loads become the main cause of failure.

Due to the complexity of the Lewis drill profile along its length, such equipment is almost never manufactured in a welded version. The material is high-speed steel grades 10Р6М5, Р6М3 and the like, according to GOST 19265-74.

A special feature of the Lewis spiral is its single-thread nature, which provides the drill with the ability to spontaneously retract into the cavity of the resulting hole. At the same time, the direction of the drill improves, and as the hole deepens, the edge is trimmed to obtain a smooth generatrix.

How does a Lewis drill work?

At the initial moment of drilling, a conical tip is pressed into the material, which is driven deeper during rotation. Then the main, spiral part of the drill rests on it. Unlike other designs of wood drills, the tool in question initially has only one working edge, and then drilling occurs with a spiral cutting part. By increasing the total length of the cutting edge, this helps to reduce the total axial force on the drill, but increases the risk of jamming and “driving” of the drill from the center.

The first problem is solved as follows. Firstly, it is preferable to install a Lewis drill on low-speed, more powerful drills. Secondly, such spiral-like drills are inappropriate to use for making holes in hardwood, since the resulting chips contribute to jamming the waste in a rather long groove. Typically, the number of revolutions is chosen inversely proportional to the diameter of the resulting hole.

To solve the second problem, a twist drill can be used as a reamer, and the preliminary pass, with the exception of particularly deep holes, can be performed using a regular drill. From operating experience it is known that direct production of holes using a Lewis drill is advisable for diameters not exceeding 15...30 mm. In other cases, feather drills are used, and twist drills are used only on the last pass, when it is necessary to increase the smoothness of the side walls.

The moisture content of the wood does not matter when using such a drill, nor does the direction of the wood grain.

Features of use

Among the advantages of Lewis drills it should be noted:

- Smooth increase in work load as the tool deepens into the material.

- High quality of the inner surface of the hole, since the burrs formed during drilling are completely cut off by the side cutting edge and are immediately removed outward by the auger generatrix of the drill.

- The wide helical flute ensures reliable removal of chips, regardless of their quantity.

- The hexagonal tip on the shank ensures reliable retention of the drill in the chuck.

High quality and productivity, especially noticeable when producing holes of significant depth, do not cancel out some of the limitations of twist drills:

- When a Lewis drill jams, which is possible when working with hard wood, it stops almost instantly and is accompanied by a sharp kickback. This could result in injury to the worker.

- Since the cutting forces during such drilling are high, the quality of the material is decisive for the durability of the auger drill. Therefore, it is worth purchasing tools from well-known manufacturers who indicate the steel grade (the grade is usually not indicated on Chinese-made drills).

- A twist drill has increased fragility, since during hardening it is usually calcined over the entire cross-section. With relatively low rigidity, this can cause destruction of the working part.

- The cost of Lewis drills is higher than regular ones, with the same diameters of the resulting holes.

- Low-power drills (less than 1000 W) may not be able to turn a drill of this design when started. It is also important that the drill has a reverse function.

How to sharpen a Lewis drill?

With a sharp increase in load during drilling, as well as deterioration in the quality of the resulting hole, Lewis drills must be sharpened. It is performed in the following sequence:

- When single-plane sharpening, the back angle of the drill is given a value of 28...32º using a file, and they try to maintain this value along the entire length of the screw part. When using a grinding wheel, the drill must not be moved. This sharpening is used for small diameter twist drills;

- When conical sharpening, which should be performed for drills with a diameter of more than 6...8 mm, the tool is placed at the side of the grinding tool. Hold the tip with your right hand, and the screw part of the drill with your left hand, and as close as possible to the cone. By rocking the tool at an angle of approximately 45º and pressing it against the end, they try to recreate the previous value of the taper when moving from the threaded part to the screw part;

- If it was not possible to maintain the required parameters, the Lewis drill can be sharpened. For this purpose, the rake angle is reduced and the width of the cutting band is increased. True, the drill cannot be used with the same efficiency for drilling viscous wood with high humidity;

- At the final stage, the drill is fine-tuned, which consists of removing all identified marks and nicks, after which the conical thread on the tip is restored.

Working with Lewis drills must be done with some experience, since this tool design is very sensitive to the torques that load the drill.

- Advantages and disadvantages

- Dimensions

- Operating rules

- Selection rules

The wood spindle drill is very popular among carpentry craftsmen due to its high performance, in which it is unlikely to be compared with standard twist drills for a similar purpose. Drilling pens do an excellent job of forming holes with a diameter of 5 to 60 mm, not only when working on wood, but also when processing other materials (chipboard ,

MDF

, plastic, drywall, etc.).

As for the cleanliness of the cut, it is not ideal here, so perka is in most cases used to perform rough processes. Feather drills have an elongated rod body with a cutting tip and a hex shank.

A carpentry device with a central point and a pair of incisors branching off from it received its name due to the special shape of the working part, made in the form of a feather. Spade drills come in both single-sided and double-sided, and cut in one or two directions, respectively. A sample with a one-sided cutter has a cutting angle of 75-90°, while for a double-sided drill this parameter is 120-135°.

Advantages and disadvantages

One of the main advantages of feather drills is their affordable price.

If we compare them with cylinder drills, then the pen models have a large range of working areas, while the cost of such samples is several times less. The length of the tool is 15 cm, but the hole can be deepened by 30 mm by using a special extension.

The wood tip drill has a simple configuration, thanks to which it can be sharpened without any problems both on professional equipment and manually, and you do not need a special expensive sharpener, but a regular file will be enough. In practice, craftsmen use such drills quite widely, drilling with them not only wooden material, but also thin sheet metal. The hexagonal shank of the product allows you to tightly fix the drill in the power tool chuck, completely eliminating its rotation.

Along with the advantages, feather drills also have disadvantages, and first of all this concerns the limitation of the cutting diameter, since the maximum groove diameter here will be no more than 60 mm. The drilling process in this case is carried out exclusively with pointed end cutters, while the rounded sides of the tool, when in contact with the edges of the groove, leave small wood fibers on them. Because of this feature, the surface of the hole becomes rough and takes on a not very neat appearance. Another disadvantage of the perka drill is that the tool quickly becomes dull and requires re-sharpening.

Advantages and disadvantages of the drill

The advantages of feather drills include the following:

- Low cost.

- Possibility of using one holder to hold plates of different sizes.

- Simplicity and ease of changing cutting plates.

- The ability to sharpen part of the drill several times for cutting (if we are talking about a one-piece design of the tool).

- No distortions.

- The ability to drill holes with a large diameter to a depth that will be 2 times greater than the diameter of the drill you choose.

But the main disadvantages are that there is no way to remove chips during the operation, and there is a possibility of displacement, but with experience working with such a drill, specialists will be able to drill holes with the required degree of accuracy. To do this, during the operation, the hole should be cleared of chips somewhat more often, which causes the work process to stop.

Dimensions

Depending on the nature of the work, craftsmen purchase individual copies or a complete set of feathers, which usually includes the most popular nozzles of the following diameters: 25 mm, 35 mm, 40 mm, 50 mm and 60 mm. It is these diameters of joinery that will allow you to cope with standard tasks when forming various holes. If you need to cut a groove with a diameter of more than 60 mm, it is better not to purchase feather drills, as they will not be able to cover a large area of the material and the drilling will not be correct.

Operating rules

To ensure that the drill bit does not become deformed during operation and that the work is completed correctly, it is necessary to follow the basic rules for its use. Before starting drilling, craftsmen recommend marking the place where the hole will be formed and using a core to make a small indentation at a given point. Whenever possible, when working with pen-shaped drills, it is better to use a drill with variable speed control. The thing is that in this case the diameter of the pen is directly dependent on the cutting speed: the larger the size of the cutter, the lower the shaft rotation speed should be, and vice versa. If you neglect this rule, you may encounter an unpleasant moment when, at high speed, rapid wear of the cutters will be provoked or the drill will simply break.

If you need to drill deep holes, initially purchase a special extension. Such an auxiliary device, installed on wood drill bits, is equipped with a locking element, which is clamped using a 3 mm hexagon, making the cutter itself and its extension turn into a single piece.

To correctly outline the contour of the groove at the beginning of drilling, set the minimum rotation mode of the drill shaft; for this, it is recommended to use an adjustable power tool. The feather drill should be installed on the surface of the workpiece strictly perpendicularly, while moderate pressure is applied to it. Please note that due to the design features of the pen, sawdust is not thrown upward during the drilling process, as is the case with Forstner drills, so do not forget to periodically stop the work and remove the chips from the groove.

Selection rules

All companies that produce carpentry tools produce feather drills, so to select a quality sample, do not be lazy to familiarize yourself with the following product parameters:

- configuration - must be symmetrical;

- cutting elements must be smooth, which indicates the decent quality of the factory model;

- the absence of any defects on the drills is mandatory, since chips and all kinds of irregularities are more likely to be characteristic of handicraft products.

In addition to the signs listed above, pay attention to the color of the pen drill, because it can tell a lot about the quality of the metal. If the cutting element in front of you is steel-colored with a gray tint, then it did not lend itself to additional processing that improves the quality of the drill. Dark metal indicates that the manufacturers strengthened the product with steam, thereby increasing the strength of the nozzle.

If the drill is produced using a special technology that involves removing material by internal pressure, the metal will acquire a golden color. The highest quality factory drills have a bright golden color, which is typical for products coated with a layer of titanium nitride. This coating significantly increases the service life of the tool by enhancing its strength characteristics, which means that with its help you can drill grooves longer, and you will need a mandrel for feather drills much less often.