The ability to skillfully wield a tool and process material in such a way as to obtain a variety of subtle shapes and sizes is the true talent of a true master. But on top of everything else, this is painstaking and long work. In the article we will look at CNC woodworking machines for wood carving, operating principles, types, capabilities and advantages of use.

New technologies have been coming to the aid of people for a long time. In particular, machines with numerical control or, more simply, CNC machines are an excellent assistant in milling.

Operating principle

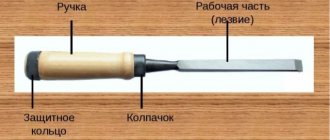

The operator working with the device checks the readiness of the machine, inserts the desired cutter, selects a program and installs the product. The machine does the rest. The motor of the device sets a certain torque to the cutter, thanks to which it begins to perform rotational movements. The spindle (metal shaft for mounting the cutting tool) is attached to the moving portal.

The CNC operator sets a certain command, after which the portal moves in a three-dimensional plane and the cutter, in contact with the surface, removes a layer of wood in the desired direction. This is how wood carving happens.

The machine has its own software, which, using special codes, “translates” a computer command into a mechanical one, carried out by the device’s electric motor. The operator selects the desired file with already recorded thread parameters and starts the workflow.

Goals

First, a little theory. Types of wood carving do not and cannot have a strict classification simply because several techniques are often combined in the creation of one work of art.

However, the techniques themselves can still be divided into several categories, which usually require different tools:

- Through slotted carving is done with cutters and chisels.

- Through-cut, in contrast, requires the use of a saw or jigsaw.

- Flat grooved carving involves the creation of shaped indentations on a flat background.

- In flat-relief carving with a cushion background, the design and background are on the same level; During the processing process, only oval contours are cut.

However: there is also a flat-relief carving with a selected background, which is made below the main image. The main tool for sampling the background level is chisels of various shapes.

- Finally, sculptural wood carving is the most complex because it requires the carver to have remarkable artistic talent: vision of perspective, sense of proportions and spatial imagination. In terms of choosing a tool, creating wooden sculptures with your own hands is the most diverse. Literally everything is used here - from blunt knives to... chainsaws.

Sample of sculptural carving.

Types of machines

Depending on the configuration, execution method, and installation methods, CNC woodworking machines for wood carving are divided into the following categories:

By spindle location

- horizontal. Most often used for processing large parts due to the convenience of their location under the portal without compromising the integrity of the product;

- vertical. Used for making thin multi-faceted patterns on small parts. Such machines are more popular.

According to the type of installation table

- fixed. In this option, the spindle itself moves relative to the table, creating a good overview of the product;

- mobile. In this form, the table moves relative to the axes of the surface being processed

Features of CNC wood milling machines

Modern computer-controlled machines make it possible to carry out a large volume of work, and in a short time, which is especially important for creating blanks for machines and mechanisms. Moreover, modern CNC engraving and milling machines can work not only with wooden blanks, but also with composite materials, model plastic, metal, plexiglass and various polystyrenes. Thanks to this, the scope of practical application of CNC mechanisms is extremely wide, which determines the relevance of their production.

To gain access to a woodworking CNC milling machine, the operator undergoes special training, after which he begins to perform the work. Unlike conventional machines, CNC machines are safe because the master is located at a distance from the equipment, and processing is carried out in a fully automatic mode. Today, such equipment is represented by different models, which differ in overall dimensions, the ability to create 2D and 3D blanks, power and other technical characteristics.

Technological capabilities

The use of a CNC machine for wood carving is multi-functional and multi-purpose. The use of manual labor is reduced to a minimum thanks to the improvement of programs for automated processing on the machine.

The high speed of the process (5 thousand revolutions per minute) allows the use of such machines at large woodworking enterprises. And the presence of a rotating device and a set of cutters with different functional purposes allows you to produce complex shapes.

Many types of lathes are equipped with a self-cleaning system, which helps prevent chips and wood dust from getting into the bends and joints of workpieces. Most often, such a system is absent in horizontal devices, due to the natural fall of debris onto the floor.

New generation machines are capable of processing parts in a three-dimensional plane using 3D programs. The use of such machines for the consciousness of three-dimensional figures in furniture factories, when designing complex architectural projects, etc. is very popular.

Types of wood carving

For general information, I will tell you about the main types of wood carving. We must pay tribute to Rinat Zufarovich - with his students they use almost all types, from the simplest to the most complex.

1. Flat grooved thread . In the school workshop, the geometric type of such carving is more often used. It is performed using wedge-cutting notches along the contour of geometric shapes - triangles, squares, etc. A unique pattern is formed due to the difference in depth, size, and number of edges in each recess.

Casket. Work of an 11th grade student. Linden, stain, varnish.

2. Flat-relief carving. Often beginners start with it. To create the pattern, you need to remove the excess wood around the outline. The sampling can be made uniform in depth - then the height of the pattern will be the same over the entire surface. But you can experiment with different sampling depths. This also includes oval threads. As the name suggests, there are no sharp edges or edges here, as they are rounded everywhere.

Coat of arms of the Republic of Bashkortostan. Work of a 10th grade student.

3. Relief carving. There are practically no flat surfaces here. There are bas-relief, high-relief and “Tatyanka” carvings. The first two are more technically complex. And “tatyanka” implies completely filling the surface with a pattern in the form of woven lace. Usually, a floral ornament is chosen for it, where the elements smoothly flow into each other.

Casket. Work of a 9th grade student. Linden, stain, varnish.

4. Sculptural carving. The name speaks for itself. A piece of wood is taken and a three-dimensional figure is cut out, while the background is completely removed.

Fawn. Work of a 9th grade student. Linden, varnish.

5. Slotted thread. Often used in the manufacture of furniture or other interior elements. The background is partially cut out, thus forming a solid pattern.

Painting “The Old Man” in mixed media. Work of a 9th grade student. Linden, stain, varnish.

In fact, there are many options for classifying types of carvings according to different criteria. The school workshop mainly uses the listed techniques in various combinations. The material can be solid wood of almost any species: from apple tree to cedar. Schoolchildren are provided with linden (it is soft and more affordable in our region). Those who are younger (5th grade) cut out on plywood.

Unfortunately, funding for this work is allocated very little or not at all. Rinat Zufarovich makes the basics of the boxes himself. Students can also make cases from plywood. The Trudovik also finds materials independently through his connections. The only thing is that the school has equipment - different types of machines on which blanks are made and then glued together. But they are already gradually fulfilling their useful life, are written off, and new ones are not supplied, which, of course, is very sad.

And here is the promised master class.

Benefits of using CNC machines

There is hardly a woodworking complex that is not familiar with the universal assistant and its capabilities. Today, computer technology is an integral and necessary part of the production process. The main advantages of using numerically controlled machines:

- Quality. Unlike hand-made parts, machine-made products do not contain defects or defects. If it is necessary to produce a large number of identical structured workpieces, it is necessary to launch an automated process so as to obtain identical products at the output.

- Multifunctionality. The ability of a machine to perform both the simplest tasks of the same type and complex tasks is one of the main advantages for a manufacturing enterprise.

- Economical. Replacing manual labor with automated labor can significantly save financial investments. In addition, the service life of a CNC machine, with proper operation and timely preventive maintenance, can increase production efficiency several times.

Specialist consultation

Do you have questions about the selection, configuration or maintenance of machines?

We don’t just sell machines, but first of all, we manufacture them, so we know all the technical features. Leave a message and we will contact you and tell you about everything in detail Sale of equipment

8

Boris Vlasov

Customer Service

Golubev Danil [email protected]

Unlike conventional milling machines, CNC models have greater functionality in terms of functionality. Thanks to this, they can be used to produce products of complex shapes. The operation of machines of this type is based on software control, which not only improves the quality of workpiece processing, but also eliminates the possibility of technical errors and human factors. In this regard, CNC milling machines for wood are becoming more and more in demand in production every year.

Pantograph

A wood carving machine that allows you to work with any wooden workpiece. The pantograph performs various milling and copying work on wood on a plane, as well as volumetric work. It is also possible to process rotating, arched and bent parts for the production of furniture, as well as panels and statues.

Photo 1 - Pantograph

$ Pantograph price from 15,000 UAH.

Safety precautions when working with wood carving equipment

Foreign objects must not interfere with work. Be sure to use safety glasses during operations that are accompanied by any release of dust, wood particles and other materials. It is also recommended to wear protective gloves while working. Never exceed the rated power of the device.

Wood carving equipment will greatly simplify and automate the process of creating products. The scope of application of such devices is extremely wide, depending only on the availability of special attachments. Such machines are suitable for both industrial and home use.