Design parameters of hand hacksaws for metal

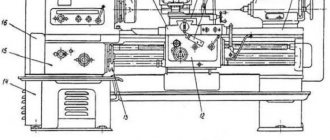

A manual hacksaw looks quite simple:

- “U” shaped base or frame, predominantly made of metal

- Handle of different shapes for hand work

- A metal blade for a hand saw or a cutting element fixed at the edges of the frame

These are the main elements that make up hand hacksaws for metal. An important detail is the canvas, which has a characteristic appearance of teeth. Fine teeth are designed specifically for working with hard materials.

to the frame . Alloy steel is used to make the frame. Frames come in different types, shapes and designs. Professional hand-held devices have the function of adjusting the angle of inclination of the blades. There are frame options that can slide apart. This feature in the tool allows you to install cutting elements of different lengths.

The handle is also an important component, as it can provide convenience and comfort in using the tool. Handles come in different shapes and are also made from materials such as wood, metal, plastic. The simplest handle is made of wood, and the most comfortable devices are considered to have a two-component composition: metal and a rubber insert.

A blade for a hand hacksaw for metal is a thin strip that is made from hard types of steel and has different lengths. There are wedge-shaped teeth on one or both sides. The hacksaw blade is the most fragile element of the tool, so when working it is important to control the rigidity of its fastening. Cutting elements for hand saws are made using the method of heat treatment of teeth, which allows you to extend the service life of the product.

It is important to pay attention! The blade for a hand saw is not intended for sharpening, so when the teeth wear out, it must be replaced. Today, blades made of bimetal and hardened metal (nickel-plated stainless steel) are produced. They differ in color: the bimetallic sheet is painted in different colors, and the completely hardened one has a dark color.

When choosing a canvas, attention is paid to its length. The length of the blade can be from 10 cm to 70 cm. A classic manual mechanical hacksaw allows you to use blades 30 cm long, since these are the dimensions of the tool that are the most comfortable and convenient for work.

Elements of a hacksaw: what main parts does it consist of?

The instrument became popular also because of its structure. Outwardly, it resembles the letter C, to the ends of which a cutting blade is attached. This tool contains the following elements:

- Pen. Modern hacksaws have handles that are made using two-component materials. This allows you to increase the service life of the tool. The shape of the handle is made so that it is very convenient to use. Usually it is located either at the top or on the side. In the first case, the tool is used to work in places where it is difficult to get to.

- Frame. Takes on the main load. It is this that dampens all vibrations that occur during operation. Modern hacksaw frames are made from a wide variety of materials. Very often, an element is installed on the tool that regulates the tilt of the blade, which allows you to work in places with difficult access. Frames come in two options. They can be solid or have the ability to move apart. It is possible to place a canvas of any length on the sliding frame.

- Canvas. To cut metal, it is made from very hard alloys. It is very thin and fragile. There are many small teeth throughout. The work requires special care. You need to buy a fabric that is hardened. If it is not there, then it will fail very quickly. An element with sparse teeth is more productive. A high-quality cut can only be achieved by those with closely spaced teeth. Recently, bimetallic sheets have begun to appear on sale.

@pilous-mim.kz

Why do you need hand hacksaws for metal?

Hand hacksaws for metal are intended for sawing metal materials. This is not the only purpose of the tool, as it has proven itself well in relation to materials such as plastic, chipboard, polystyrene foam, polystyrene foam, plexiglass, ceramics, laminate.

The saw in question for sawing metal is a very necessary tool in the household, because in the absence of a grinder, it can always help in the current situation - sawing off the head of an oxidized bolt or sawing through a steel wire. The big disadvantage of such a tool is the large expenditure of physical strength and time. The presence of small teeth affects the time to achieve results. To obtain results, the master requires the application of not only titanic strength, but also patience. The result of long and hard work with the tool is the most accurate result, which is sometimes superior to cutting with a grinder.

It is important to pay attention! The cutting line with a hand hacksaw for metal is as thin as possible, which is due to the presence of small teeth in the design of the blades.

Types of hacksaws, characteristic features of products

A hacksaw is a carpentry tool; it is a type of saw. Its main purpose is to cut blanks and products made of different materials.

Hacksaws for metal can be manual or electric.

Saws are divided into manual tools and electric hacksaws. The latter option is equipped with a motor, which ensures fast and less labor-intensive work. This reciprocating hacksaw can be presented in the form of a corded or battery-powered tool. The first type of device operates from the electrical network. This hacksaw is quite a powerful device. Its only drawback is the presence of a cord, which limits the operating area.

Reciprocating tools can be divided into electric hacksaws for metal, wood and stone; their blades differ in length, shape, size and number of teeth.

A cordless hacksaw is a more mobile device that runs on a battery. This type of device is characterized by lower productivity. One battery charge is not enough to operate the tool for a long time.

Depending on the purpose, there are hand saws for wood and for metal. The first type of device consists of a working blade equipped with sharp teeth and a handle for comfortable grip. This tool is often used for cutting drywall and aerated concrete.

Hand hacksaws can be used for both metal and wood.

A hand saw for wood can be classic, circular or tenon. The first option is used for longitudinal or transverse cutting of the workpiece. The teeth of the blade have a triangular shape and are located in increments of 1.5-6.5 mm. To increase sawing efficiency, you should study information on how to sharpen a hacksaw.

A circular saw is used to cut curved parts, which is achieved thanks to a narrow blade with fine teeth, which can be located on one or both sides. A tenon jig is used to remove protruding grooves and tenons to obtain a clean cut.

A hacksaw for metal is a universal tool that can cut a workpiece made of any material, including plastic, wood, foam, aerated concrete, etc. The working blade of such saws has fine teeth, making the cut more accurate and clean. During operation, small chips are formed.

Types of hand saws for metal

There are the following types of hacksaws for metal:

- Homemade. The simplest options that every master has in his kit. Such devices are considered an outdated option, but their production continues to this day. The advantage of these tools is their simplicity of design. The handle is made of wood and is located in the same plane with the blade

- Professional ones are intended for use during long-term work. Such products are equipped with a more comfortable handle, which in addition can be rubberized. Some expensive models are equipped with a mechanism for adjusting the angle of the cutting part during operation

- Mini hacksaws or a metal saw have a special shape that differs from the first two types. Such products are intended for use only when difficulties arise with access to the part being cut. The device has the shape of a knife with an additional point for fixing the blade. The handle is made of plastic and metal with rubber

Types and areas of application of the tool

In the construction market, a hacksaw for metal is found in electric and manual form. The main purpose of the tool is to saw a metal product, as well as create grooves and some other elements. When using special materials at the time of manufacturing the blade, it can also cut plastic, ceramics, organic glass and other surfaces. Conventionally, a mechanical hacksaw for metal is divided into three main groups:

- Home models. This design option is very common and is optimal for solving simple problems. Characterized by ease of use. To fasten the working blade, a tension screw mechanism is installed, which greatly simplifies the process. Do not forget that if the working part has weak tension, then there is a possibility of serious deformation. A home-type hand saw is much cheaper.

- There are also professional hand tools. They are designed to last for a long time and produce high-quality cuts. Distinctive characteristics include the presence of a comfortable handle, as well as a special mechanism that simplifies the process of changing the working blade. The purpose is to frequently carry out cutting work on various parts.

- The hacksaw-handle belongs to a separate category. It is characterized by having the shape of a staple. To use this type of tool, you do not need to apply much force. The area of use is to treat hard-to-reach places. The design of the metal hacksaw allows installation even of broken blades.

There are also electrical appliances on sale that are characterized by increased performance. Their use is possible only if there is a source of electricity.

How to properly saw with a hand hacksaw for metal

A hand saw for metal requires the craftsman to comply with the following operating rules:

- Adopting the correct stance for the master. Your feet should rest well on the floor, and work with the device is performed exclusively with two hands, so initially make sure that the workpiece is securely fastened in the vise jaws

- Reliable fixation of the canvas. Hacksaw blades are very fragile, so if the product “fidgets” from side to side if it is poorly secured, then at one point it will simply break

- Correct saw movements. To cut a part, you need not only to hold the tool correctly, but also to work with it. The tool is pressed against the part being cut when moving forward, and when returning to the reverse position, the clamping pressure is weakened. If you do not reduce the clamping pressure when moving the tool back, the teeth of the blade will quickly become dull

It is important to pay attention! The blade on the frame of a hand hacksaw for metal should be fixed in position with the teeth directed in the opposite direction from the handle.

Hacksaw blade

Contents: Hide Open

A hacksaw blade for metal is the main cutting element of a hand hacksaw or the equipment of a hacksaw cutting machine, which is a thin and narrow plate with two holes and teeth on one or two edges. The cutting of the material is carried out thanks to the reciprocating movement of the tool with simultaneous pressure.

Choosing a tool or what you need to pay attention to

To choose the best hand saw for metal, pay attention to the following parameters:

- Length of tools and blades. The blades have different lengths, but if you choose a device, then you need to choose one that is convenient to work with. If a tool is selected for a specific purpose, then remember that the length of the hacksaw should be 2 times longer than the part being cut

- Lever. To choose the best device, you need to take several models and hold them in your hand. The difference is felt immediately, as some of the handles are uncomfortable. It is better not to take tools with hollow handles, as they are not reliable. The handle should be comfortable and fit well in the hand

- Canvas. The main characteristics of the blades are: tooth shape and pitch. Depending on what part will be sawn, the appropriate blades with tooth sizes are selected. Since few people pay attention to this in household use, it is better to take several different products

- Price. The price depends on the quality and functionality

- Manufacturer. If you are strict about the selection of tools, then pay attention to models from well-known manufacturers. A popular brand specializing in the manufacture of hand tools is IRWIN

Such a reliable tool as a hand hacksaw is necessary in the household, so it is worth choosing it responsibly and competently. After using the canvas, you should not throw it away, as it can be used for making additional tools: knives, cutters, compasses and even chisels (provided that the teeth are not worn out or dull). Everything depends on the imagination of the master, so it’s never too late to start implementing your ideas, and don’t forget to share your inventions with others. The video talks about the correct operation of hand hacksaws for metal, which will also be useful and interesting to learn.

Characteristics of swivel chair with hacksaw

A rotary miter box with a hacksaw is represented by equipment consisting of a saw and an adjustable stand, with which you can adjust the cutting angle from 15 to 135 degrees. The miter box can be made of metal or plastic. The first option is used for cutting molded elements of small thickness, and the second - for a small amount of work.

A stand in the form of a miter box is used to give the instrument additional rigidity, while simultaneously acting as a limiter. A hacksaw with a blade equipped with small cutters can have a length of 290-600 mm.

When cutting a workpiece, the cutting element enters it at a certain angle, simultaneously in the vertical and horizontal plane. Thanks to this two-plane tool, it is possible to form a bevel at the end of the workpiece of any configuration.

A device with a rotating miter box is one of the best professional-type hacksaws for wood and metal. It is advisable to use it for carpentry work of increased complexity. The weight of the equipment is 2-4 kg. The price of a hacksaw for metal with a miter box is 2 thousand rubles.

The rotary miter box adjusts the cutting angle from 15 to 135 degrees.

To operate such a tool, the frame must be secured to the working surface using self-tapping screws or a clamp. Markings should be applied to the workpiece to be processed indicating the cutting locations. The product is fixed on the miter box so that the mark coincides with the slots on the plate. Then you need to set the cutting angle degree and secure the hacksaw so that it works in the same plane. After this, the workpiece is cut.

Design Features

A hacksaw for cutting metal is a fairly simple design consisting of several elements:

- Load-bearing U-shaped frame, which is made of a rigid metal profile;

- Handle, which comes in different shapes;

- A cutting steel blade attached to the frame at two ends.

Here the working part is a hacksaw blade, which looks like a thin strip with fine teeth. Hard steel grades are used for the production of blades.

Moreover, the cutting elements undergo thermal hardening. But even such processing does not guarantee that the fragile fabric will not break under heavy loads.

Therefore, you need to work with a hacksaw smoothly and without sharp bends of the blade to the sides. This rule especially applies to medium and long “cutters” (the length of the standard blade is 25-30 cm, but there are smaller and larger consumables - 10 and 70 cm, respectively).

The frame is usually made of alloy steel. In section it can be round, square, rectangular.

The main thing is that the profile is hollow, which contributes to the lightness of the entire structure. It will also not be superfluous to adjust the angle of inclination of the cutting part.

Other frames can be moved apart by means of longitudinal threads and inserts to tension the tape by a few millimeters.

The latter is fastened using pre-designed holes at both ends. All that remains is to insert the bolts that come with the thematic tool into these holes.

The handle is a unit for comfortable grip of the hacksaw. It can be wooden, metal, plastic. It is better to pay attention to models whose handles have reliefs and grooves.

The palm does not slip off such a surface. To ensure that the handle of the product heats up quickly, you need to choose wooden or rubberized options.

For reference. Thin hacksaw blades cannot be sharpened. When working with a thematic tool, you need to lubricate its cutting part and the workpiece with technical oil.

It also makes sense to regularly check the teeth for wear.

DIY tool box according to drawings: instructions with step-by-step guide- Form for paths - a large selection of forms and a simple method for creating a beautiful and comfortable garden (photo + video)

Do-it-yourself snow blower - we remove snow easily, an overview of designs and types for a suburban area

To ensure that their service life does not disappoint, it is recommended to choose a dark, hardened version made of nickel-plated stainless steel. There is a budget bimetallic analogue that can be painted in other colors.

How to use a hand saw

Working with a hand saw for processing metal alloys does not require special knowledge and skills. But there are certain rules:

- Do not forget about the importance of the correct positioning of the master’s body relative to the cutting areas. The arm should be bent at a right angle and the feet slightly turned out. This way you can increase stability.

- Before installing the cutting blade, it must be straightened to the width of the frame. The element is then secured with nuts. Proper fastening of the blade makes it possible to avoid all kinds of vibrations during operation. But excessive fixation often leads to breakage of this part. It is better to adjust the tension the very first time you tighten the nuts.

- When cutting, the tool must be held with both hands. Movements should be uniform and calm.

- It is recommended to fix the workpiece with a special vice. This minimizes the likelihood of cutting blade breakage.

Criterias of choice

So, you need to select a tool based on the following characteristics:

- The shape of the teeth varies depending on the inclination of the cutting element located in front.

- Teeth pitch - this characteristic determines the thickness and strength of the materials with which the tool can work. The choice depends on the size and material of the workpiece. When working, two or three cloves should be used.

- The size of the canvas depends on the size and volume of the workpieces. The average saw blade length varies from 290 to 700 millimeters. The canvas must be smooth, clean and keep its original shape. There should be no cracks or traces of rust on the surface.

- Handle - try to avoid hollow variations. Such a tool can break even with slight pressure. When choosing, hold the device in your own hands. The palm should fit tightly around the handle.

- Price - the cost of a saw for processing metal products depends on the material and type of blade, as well as the configuration of the teeth. It is not advisable to choose too cheap models, as well as to rely on famous brands.

Having chosen a good hacksaw, do not forget to replace the saw blades in a timely manner and use the tool correctly.

Types and areas of use of the tool

The purpose of this tool is to cut products from durable metals, cut grooves and seams, trim metal blanks, etc. Among other things, using a hacksaw you can cut metal alloys, and, for example, ceramics, plastic, foam, wood and organics.

There are three types of metal saws:

- Models for home use are the most affordable and popular option, suitable for solving simple household problems. Characterized by ease of use. In most cases, such devices are equipped with screws and a wooden handle, which is located longitudinally to the cutting blade.

- Professional-grade hacksaws can work for a very long time, creating high-quality cuts. Professional hand saws for metal are often equipped with a comfortable and durable handle and allow you to set the blades at a certain angle, which is required to create cuts of unusual shapes.

- “Handle” - has a special shape that resembles a staple. This allows you to use this type of hacksaw in hard-to-reach places. This tool is perfect for internal cuts.