Wood saw - select tooth size

Even if you already have a hacksaw on your farm, it is quite possible that it will not be suitable for your purposes, so sooner or later you may need to go for a new saw. When choosing this tool, knowledge about its structure and features will be useful. If the saw has straight teeth, it will be easiest for it to cut wood crosswise; to cut wood along the grain, you will need a tool with inclined teeth. In accordance with their inclination, the hacksaw will be transverse or longitudinal. If you craft often, you'll need both options.

A hacksaw with large teeth cuts the fastest, but you won't get a straight edge with it. For working in the garden or quickly cutting rough boards, this saw is quite suitable for you. For a cleaner cut edge, a tool with a fine tooth is used, but working with such a hacksaw is slower - it is more difficult to remove sawdust from the cut.

For cutting coarse-grained wood across the grain, a saw with large teeth is best; for general sawing needs, choose a medium tooth, and if you need precise work, choose a hacksaw with a fine tooth.

A carpenter's saw with a very fine tooth is used by professional carpenters; it is unlikely to be useful on the farm. There is also a mechanical hacksaw - this is a small machine with a mechanically movable blade, these are used in factories for sawing metal pipes and other metal elements; in a home workshop it will be replaced by a hacksaw for metal.

Hand saws for wood: garden tool parameters

There are several types of classification of hand garden saws. To choose a hacksaw, you need to take into account differences in the characteristics of the blade, type of teeth, steel grade, and variations with the handle.

For the manufacture of this tool, mainly alloy steel is used. The silicon and carbon in the composition must correspond to certain grades to produce a durable fabric. Hardness parameters usually do not exceed 45 HRC, but experts recommend paying attention to products with a higher hardness of 15-20 units. They have a darkened shade of resistant teeth and excellent blade flexibility.

The canvas should be without bends. This indicates the quality of the metal used to make the saw.

A hacksaw blade for wood has two main parameters: length and width. Long ones make it easier and faster to cut wood. And short ones are less springy and make the work more neat from an aesthetic point of view. Therefore, models up to 0.35 m are suitable for hard raw materials and one-time, rather than daily, operations. But a garden saw is more relevant at 0.5 m or more.

A wood blade for a hacksaw with a width of 0.1-0.2 m. Wide ones are intended for cutting bulky objects, narrow ones for thin ones.

You might be interested

How to choose a good chainsaw: advice from professionals

How to choose a good garden tool

Garden pruners: recommendations for choosing and caring for a tool

Tempered saw - what is characteristic of such a hacksaw?

The steel from which the tool blade is made must be elastic and durable. Curvature of the blade when jammed, rapid dulling of the teeth indicate low quality steel. To maintain the sharpness of the tool for as long as possible, without compromising the elasticity of the blade, manufacturers resort to a small trick - they harden only the teeth. In this case, they acquire a blue-black color, which makes it very easy to distinguish a hardened instrument from a regular one. Such saws are especially convenient for cutting artificial materials such as plywood, plastic, and plaster. However, it must be protected from getting on nails, otherwise, if such teeth are damaged, it will no longer be possible to restore their former sharpness.

If you still have your father’s old tools in your workshop at home, you don’t need to throw them away, you just need to know some of the features of caring for them. For example, to prevent the hacksaw blade from jamming when cutting, it is necessary to regularly set the teeth apart and sharpen them.

How to saw correctly

You should always cut from the cutting side, close to the marking mowing line. This applies to both rough cuts with a hacksaw and precise cuts with a saw with small teeth. Next, it is very important that the workpiece being processed has a stable support in the form of a workbench tabletop or an ordinary desktop. For large-sized workpieces, it is better to use sawhorses. During the sawing process, the part must always be held firmly with your hand (large-sized workpieces should also be held with your knee) - in other words, only the saw should move.

Sawing begins with the first small movements at an angle of 30 to 45 degrees. Only after the saw blade has entered the wood and is fixed in it, you can start working with the saw along the entire length of the blade.

At the edge of the cut, cut only in small, sharp strokes. This will avoid breakages on the underside of the workpiece.

Cutting along wood fibers is always a “critical” situation, especially if the tree species has a large strand. The saw naturally wants to follow the path of least resistance, and if it is not restrained, it will begin to “walk.” In other words, in such cases you have to press harder on the saw than usual, which, in turn, requires a very stable position of the workpiece.

When making huge cross cuts, an ordinary hacksaw can jam. In such cases, it is better to use a rip saw with very spaced teeth. Honor only needs that the cut strip be significantly thicker than the saw blade.

to saw fresh or damp wood if the saw blade is lubricated with wax or soap.

hacksaw for longitudinal cutting of wood

The workpieces are firmly pressed against the lintel, its right edge guides the saw.

Other varieties

There are other types of wood hacksaws. Among them there is a garden hand saw, equipped with a narrow blade, for the production of which chromium steel is used. It is armed with widely spaced teeth, inclined towards the handle. It is comfortable to work with such equipment in cases where you have to focus on yourself while cutting.

There is a two-handed saw that can be used to comfortably saw huge logs or cut down trees. Two people should work with it.

A chain hand saw is a short chain with hardened teeth and two handles at the ends. It is compact and suitable for use on backpacking trips. You can work with it either by one person or by two people.

A modern and universal tool is an electric hacksaw, with which you can perform a large volume of various works. In some cases, it completely replaces a circular saw. When changing blades, they use it to saw not only wood , but also plastic and metal.

How to sharpen a hacksaw for wood - step by step diagram

Step 1: Align the teeth in height

To determine which tooth is lagging in height, take a smaller file and run it along the top of the teeth. Untouched tips will show us defects in the saw. In this case, all other teeth must be filed with a file to the lowest level. To avoid injuring your hands, you can cut out a nest for a file in a piece of wood, secure it in it, and then safely straighten the teeth.

Step 2: Saw the canvas

Check the teeth for their relationship to each other. Short elements make cutting difficult, especially after several sharpenings. In this case, cuts are made in the blade itself, which lengthen the teeth. We clamp the tool blade in a vice, setting the teeth at the same level as the edges of the vice to prevent the cut from being too deep. You will need a hacksaw for metal - use it to cut the blade to the desired tooth height. The saw will work best if the width of the teeth is one and a half times smaller than their height.

Step 3: Spread the teeth

It's time to start setting up the saw.

If you do the cutting with ordinary pliers, then you will never be able to achieve a uniform, precise spreading to the sides - as a result, the saw will begin to tear the wood, creating a lot of waste and creating a sloppy cut. Therefore, prepare in advance a simple tool that you can make yourself - cut a groove in a strip of thin metal into which a tooth can easily fit, and drill several holes in it to secure the limiter. The limiter can be cut with metal scissors, giving it the angle required for wiring. We attach the limiter to the bar and test it in practice, increasing or decreasing the bend angle if necessary. Using such a tool, the wiring will be exactly the same. It does not need to be done often, once every two or three sharpenings. Obviously, the teeth need to be moved in different directions, taking turns. When setting, you should not go too far with the distance at which the top of each clove is bent - too small a distance will not do anything, too much will complicate the cutting process and turn a large amount of material into sawdust.

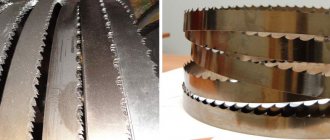

Band saw routing

Device for setting saw teeth

Setting the cutting edge in different directions eliminates the possibility of the blade getting stuck during operation. An example is the case when, when cutting a thick log, the blade cannot be moved and removed. Also, the saw can jam due to the heating of the metal and its expansion, the hot part can heat the resin and turn it into a kind of glue.

You should use a tool for setting the teeth of hacksaws in order to avoid such problems. Do not forget that mistakes made during work can lead to even bigger problems. The procedure in question can be carried out using the following tools:

- There are special mechanisms. They allow you to manually shift individual elements relative to each other. It is worth considering that this version is manufactured for specific products.

If sawing is carried out frequently, then experts recommend purchasing a special device that allows you to quickly set the required angle.

Recipe. how to cut straight with a simple hacksaw

Sharpening a hacksaw for wood with your own hands

If the annotation for the blade does not indicate clear characteristics, the layout is done according to the general rules: The width of the cutting edge overhang should be 1.5 - 2 times the thickness of the blade. Wider routing is done for damp wood, or in the case of cutting along the grain. If, when processing such wood, the width of the teeth is small, the blade will jam in the cut.

On the contrary, with a wide spread, it will be awkward to process normal wood across the grain. The cut will be uneven, and you will have to put more effort into passing the saw.

There are convenient tools for setting teeth, with which you can straighten a long blade in a couple of minutes. But such pliers are not cheap.

Hacksaw - simplicity and safety

A hacksaw is a simple tool that is quite suitable for the job. And although the cutting speed is low and considerable physical effort is required, such a saw is the most acceptable option for home use.

to cut wood correctly The main condition for a high-quality cut of the material is to make the cut correctly. To simplify the task, you can use a regular flat block, which is used as a guide.

The question often arises of how smoothly with a hacksaw at an angle. For this purpose, a special carpentry device is used - a miter box. Moreover, it will help not only to make a cut at the desired angle, but will also allow any beginner smoothly .

You can also saw off the timber with a hacksaw. The only problem when working with such a workpiece is that you have to put in a lot of effort.

The last option is to use an angle grinder with a wheel with teeth installed for the work. But since the “grinder” is not intended for cutting wood, this method can only be used as a last resort: attempts to cut a board can result in serious consequences. It’s better to use a hacksaw - it’s labor-intensive, but safe.

All my life will now take place in my VKontakte group, https://vk.com/club37090442 here I only post videos, without discussions or comments.

Serge_msv:

Well damn…

Mila Solovyova:

exciting film. Myocardial infarction!!)))) (according to TO) And so - super!! Thank you!

How to cut plywood with a hacksaw

Installation of laminated veneer sheets involves varying degrees of processing. The greatest difficulties arise when cutting is necessary; cutting plywood is more labor-intensive due to the layering of the material. To achieve a high-quality result, you need to choose the right device, which will allow you to avoid problems and obtain parts without chips.

Hand saw

When cutting plywood with a hand saw, physical effort is required due to the significant density of the material. This tool is used when it is necessary to cut a sheet of plywood into identical fragments.

A hand jigsaw is considered the best tool and allows you to decide in advance how to cut plywood without chipping, eliminating the need to purchase electric tools. It can be used to produce a small number of elements of complex shapes. Having certain skills in working with a jigsaw, you can make a neat cut, however, due to high labor costs and low productivity, this method cannot be called optimal.

If you don’t have electric tools or a simple jigsaw at hand, you should resort to using a simple hand saw. To make cutting a sheet convenient and to avoid chipping, the tool blade must have a large number of small and well-sharpened teeth. The angle of the saw to the plywood sheet should be sharp. It is recommended to avoid jerking and make even movements with strong pressure.

Tip: The cut of a regular saw is rough, so it is recommended to sand the end parts after finishing the sawing.