Parts and workpieces made of strip, rod or sheet material may be bent, crooked, warped, or have bulging, waviness, etc.

The metalworking operation, called straightening, allows you to give workpieces or parts the correct geometric shape, in accordance with the requirements of the drawings or functional purpose.

Straightening of parts and workpieces is carried out in a cold or heated state. In the latter case, it is allowed to heat steel blanks and parts to a temperature of 1100–850 °C, and duralumin – to 470–350 °C.

Metal straightening can be done manually or by machine (on straightening rolls, presses and all kinds of devices).

When choosing a straightening method, take into account the nature of the material, the size of the part (workpiece) and the amount of deflection.

Straightening equipment

Manual straightening of sheet metal and blanks made from it is carried out with hammers on straightening plates and special straightening headstocks.

Straightening plates (Fig. 1, a) can be made of gray cast iron of a solid structure or with ribs or steel (Fig. 1, b).

Rice. 1. Correct stove: a - cast iron; b - steel

The working surface of the stove must be smooth and clean. The slab must be massive, heavy and stable enough so that there are no shocks when the hammer hits.

The slabs are installed on metal or wooden supports, which can provide, in addition to stability, the necessary horizontality.

There should be enough space around the stove to allow you to work freely.

Straightening headstocks (Fig. 2, a) are made of heat-treated steel. The working surface of the headstock can be cylindrical or spherical with a radius of 150–200 mm. A rail 0.5–1 m long has proven itself well as a straightening headstock for straightening. The rail has good stability, is little movable when struck by a hammer, does not leave marks from the hammer, does not deform and is convenient for moving across the slab.

Rice. 2. Tools for straightening metal: a - straightening headstocks; b - hammer

When straightening by hand, it is better to use hammers with a round rather than a square striker, since the corners of the square striker can damage the surface of the sheet being straightened. The straightening hammer must have a smooth and well-polished striker surface (Fig. 2, b).

For straightening parts with a finally processed surface, as well as thin steel products or blanks made of non-ferrous metals and alloys, hammers made of soft materials are used - copper, brass, lead, wood.

When straightening particularly thin metal, metal and wooden bars - smoothers - are used.

Straightening of parts with a treated surface with a steel hammer should be carried out using a soft metal spacer.

Metal and wooden smoothers and bars are also used for straightening thin sheet and strip metal.

Basic techniques for straightening metal by hand

Workpieces received for metalworking may be deformed and require straightening, sometimes they say straightening. A sheet metal workpiece may be deformed during loading and transportation, or deformation may occur as a result of residual stresses after mechanical or heat treatment, etc. The wavy surface of a sheet metal workpiece may be formed as a result of the presence of compressed fibers, residual stresses on one of the sheet surfaces, what determines the direction of concavity; bend along the length in the plane; edge bending indicates that the edge of the workpiece, where the bend is directed, is compressed or deformed more than the opposite; if the workpiece has a deformation in the form of a spiral, then this indicates that the edges of the workpiece are more elongated than the center line, etc.

It is necessary to find out the reason for the deformation of the workpiece in order to decide on the method of straightening and straightening it.

Straightening of the strip material along the plane is carried out in the following sequence. The curved strip is placed on the slab and, holding it with the left hand, blows are applied to the convex places of the strip with a hammer, while the blows are applied first along the edges of the convexity of the wide side and gradually approach the middle of the convexity, turning the strip from one side to the other as necessary. The impact force is adjusted depending on the size of the strip and the degree of curvature.

When editing, the hammer is held by the end of the handle, lightly squeezing it in the hand. When striking, the hammer must be lowered onto the sheet vertically with the entire area of the striker. At the moment of impact, the hammer will definitely bounce back. You should learn to control this movement so that the rebound of the hammer from the sheet upwards is directed vertically towards the plate.

The straightening results (straightness of the workpiece) are assessed by eye or on a straight plate using a ruler.

Having straightened the wide side of the workpiece, proceed to straightening the ribs. After one or two blows, the strip is turned from one edge to another.

When straightening a strip curved on an edge, blows are applied over a wide plane. Pressing the strip against the slab with your left hand, strike with a hammer along the entire length of the strip, gradually moving from the bottom edge to the top. In Fig. 3 shows the arrows diagram of the directions and sequence of blows when editing the curve of the workpiece onto the edge.

Rice. 3. Scheme for straightening the curve of the workpiece to the edge

Strong blows are applied at the lower edge, and as they approach the upper edge, the force of the blows is reduced, but their frequency increases. With this method of straightening, the lower edge is gradually extended more than the upper edge, and the strip is aligned. Editing is stopped when the top and bottom edges become straight.

The straightening of a curved sheet with transverse waves - waviness - is performed on a straight plate, holding it with one hand, and with the other, light blows are applied with a hammer to the protruding parts of the sheet along the transverse waves. First, the sheet is straightened on one side, and then it is turned over and straightened on the other side.

If there is a bulge in the middle of the workpiece, it is placed on a plate and the bulges are outlined with chalk. Then apply frequent blows with a hammer from the edge of the sheet towards the convexity. As you approach the convexity, hammer blows should be made more often and weaker. If the workpiece has wavy edges, then blows with a hammer are applied in the direction from the middle of the workpiece to its edges.

After removing the bulges and waviness, the sheet is turned over and its straightness is finally restored with light blows of a hammer.

During the straightening process, you need to ensure that no marks from hammer blows remain on the surface of the sheet. This work can be conveniently performed by moving the workpiece along the straightening headstock or along the surface of the rail on which straightening is performed.

When straightening thin sheet material, light wooden, copper, brass or lead hammers are used. The editing techniques are the same as with steel hammers.

Straightening of very thin sheet material is carried out on a clean, flat (without nicks or other irregularities) surface by sliding, without much load, metal or wooden smoothing bars that have a flat and smooth surface. When editing, the sheet is periodically turned over.

Roll dressing and cleaning

Roll dressing

Straightening in rollers allows you to relieve sheet material from internal stresses and give it the specified flat characteristics

.

Flatness in modern sheet metal working

Most modern sheet metal processing technologies involve mechanical or thermal action, which inevitably causes the formation of internal stresses in the material, edge hardening and warping of the resulting parts. The severity of such phenomena depends on the chemical composition, initial indicators of metal tension, as well as a number of other characteristics. As a result, a number of difficulties arise related to the subsequent processing of such parts, obtaining the specified geometry and the percentage of finished product rejection.

When bending a part, spontaneous release of internal stresses occurs, causing deformation and deviation from the specified geometry or damage to the integrity of the material structure. In most of these cases, the part is rejected, which entails additional costs and repetition of the entire production cycle.

During the manufacture of shells, the specified radius is not observed, which requires additional processing. Particular difficulty here is created by the length and weight of the metal sheet, as well as the preparatory work associated with loading and unloading the part into the pipe rolling mill. Subsequent welding of parts that have not been straightened requires lengthy and labor-intensive preparation. However, the use of automated robotics in this case is practically impossible, since additional fixing equipment is required. The quality of the weld on parts that have not been straightened also leaves much to be desired.

Straightening in rollers allows you to “temper” the material and give it the necessary flat characteristics, which greatly facilitates subsequent processing and has a positive effect on the quality of the finished product. The classic method of straightening the material has always involved preheating the workpiece and using a hammer. Such work was carried out mainly by experienced specialists and took a lot of time and effort. The use of circular bending equipment and presses also did not give the desired results. The most effective method of material straightening is, of course, roll straightening, which is based on the principle of plastic deformation of metals.

The principle of straightening in rollers

The leveling rollers are combined into lower and upper blocks, while the upper block has automatic tilt adjustment. Each lower roller fits into the gap between the two upper ones. When processed on an ARKU sheet straightening machine, the part is subjected to a series of alternating bends. As the part passes through the straightening zone, the distance between the upper and lower leveling rollers gradually increases. The first alternating bends are carried out with great force, then the force decreases, so the straightening process itself can be compared to a damped sinusoidal oscillation.

Servohydraulics

The servo-hydraulic system for adjusting the working gap between the upper and lower rollers allows you to effectively straighten parts with complex geometry, different cross sections and technological holes. Parts after plasma, laser cutting and punching, which required several hours for manual editing, are processed in a matter of minutes. At the same time, with high levels of flatness and a complete absence of internal stresses. All subsequent welding and bending work is simplified. Finishing costs and, as a result, the percentage of defects are reduced many times over.

Advantages of roll leveling

- Good flatness and absence of internal stresses in parts

- Minimizing rejection and finishing of finished products

- Simplification of all subsequent technological operations

- Reduced production costs

- High quality of finished products

Straightening sheet metal on rollers

Rollers can also be used to straighten sheet metal parts.

In manual rollers, sheet blanks up to 3 mm thick are usually processed. Rollers 1 and 3 are located one above the other (Fig. 4), and depending on the thickness of the workpiece 2, they can be moved away from each other or brought closer together. The third roller 4 located at the rear can also be raised or lowered. The rollers must be adjusted so that they are not pressed too hard against each other.

Rice. 4. Scheme of operation of manual rollers

The workpiece (sheet or strip) is placed between the two front rollers and, by rotating the handle clockwise, is passed between the rollers.

Often, to completely remove bulges and dents, the workpiece must be passed between the rolls several times. Workpieces with a thickness of 3–6 mm are straightened on electrically driven rollers.

Wood and metal processing

Rolled steel coming from metallurgical plants often has deformations (Fig. 1) that arose during the rolling process, as well as during transportation.

Deformations of sheet steel are eliminated on sheet-straightening rollers, channels and I-beams - on horizontal straightening presses, and angle steel - on angle-straightening rollers. After editing, waviness, warping, local bulges, and unevenness between the sheet and a 1 m long steel ruler placed edgewise on the sheet should not exceed 1.5 mm. The curvature of the profile steel after straightening should not exceed 1/1000 of its length and be more than 5 mm, grinding and grinding should not exceed 1 mm per 100 mm of flange width.

The saber shape of universal steel is determined by the size of the gap between the longitudinal edge and the tensioned string.

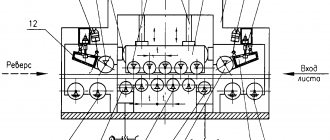

Sheet straightening rollers (Fig. 2), used in metal structures factories, straighten sheet steel with a maximum width of 2000...3200 mm and have 7, 9, 11 rolls. For straightening sheet steel with a thickness of 6...25 mm, seven-roll rollers 25X3200 are usually used. The deformed sheet is placed in the gap between the upper and lower cylindrical rolls, arranged in a checkerboard pattern. Beforehand, a gap is set between the upper and lower rolls that is slightly smaller than the thickness of the sheet to be straightened.

Steel is fed to sheet straightening rollers (Fig. 3) by driven roller conveyors. After the rollers, the straightened sheets enter the conveyor. Sheets are fed onto conveyors and removed from the conveyors by overhead cranes.

The size of the gap between the rows of rolls, as well as the excess of the outermost rolls of the top row, is determined using special tables and set using an indicator type indicating device. After this, the mechanism of the lower rollers of the sheet-forming rollers and the mechanism for rotating the rollers of the feed conveyors are turned on. The conveyor rollers feed the sheet into the rolls, and then it moves due to friction between the sheet and the lower rolls. When moving, the sheet bends many times and the waviness deformations in it are eliminated. The sheet steel passes through the rolls onto a receiving roller conveyor and, depending on the need, is either reversed through the rolls for re-straightening or removed from the conveyors by an overhead crane for stacking.

The saber-like appearance of universal steel is eliminated on sheet-straightening rollers. To do this, steel spacers with a thickness of 2...4 mm are placed on the concave zone. The rollers, compressing the sheet in the place of the spacers, straighten the saber shape.

Small sheet parts obtained as a result of cutting with guillotine shears are corrected this way. On a large backing sheet with a thickness of 25...30 mm, parts of the same thickness are laid in one layer and passed through rollers several times.

Editing hardened parts

Hardened parts are straightened with the nose of a hammer (Fig. 5). In this case, it is better to place the part not on a flat plate, but on a straightening headstock that has a smooth surface. When straightening, blows are applied not on the convex side of the part, but on the concave side.

Rice. 5. Editing hardened parts

When straightening, a hardened strip (ruler, etc.) is placed on the straightening head with its convex side down, and with the nose of the hammer, not strong but frequent blows are applied to the cavity, starting from its middle and gradually moving to the edges; then, grabbing the part by the second end with your left hand, they edit its other part. During the straightening process, the deflection of the part is periodically checked.

Hammer blows should not be strong so as not to break the part.

TECHNOLOGY AND EQUIPMENT FOR ROLLED STRETCHING

The straightening principle is based on the creation of plastic tensile deformations in shortened fibers.

The sheets are straightened using rollers (roller sheet straightening machines) or straightening machines. Straightening on rollers consists of passing the sheet between two rows of rotating rollers, which, entraining the sheet with the friction forces that arise, repeatedly bend it.

When bending, the compressed fibers of the sheet stretch plastically and take on the same length as the fibers outside the tension area, as a result of which the sheet is straightened in the longitudinal direction. Straightening in the transverse direction is carried out using spacers, which are sequentially laid lengthwise on the stretched areas of the sheet during the rolling process. In places where gaskets are laid, the stretched metal fibers, under the influence of compressive forces directed normal to the surface, stretch and reach the same length as the rest of the fibers. Thin strips of mild steel 200–250 mm wide and 1.5–2 m long are used as spacers. Sheet straightening rollers have from 5 to 21 work rolls. Sheets with a thickness of 6 mm or more are usually straightened on five- or seven-roll rollers. Sheets less than 6 mm thick have increased springback and require a large number of wave formations during rolling. Therefore, when straightening thin sheets, rollers with nine to seventeen rolls are used. When straightening very thin sheets, this does not always give satisfactory results, and sometimes they are straightened on a thick backing sheet, which is rolled in rollers along with the straightened sheet.

The sheet straightening rollers have work rolls (1) of the lower row, supported by bearings mounted in a stationary frame. The upper work rolls (2) have bearings located in a movable frame and can move along with it in height. The deflection of the rolls during rolling is eliminated by intermediate supports (3) in the form of rollers that transmit forces to the bed and the upper frame. To prevent the sheets from bending when leaving the rollers, there are two auxiliary rollers (4), which can move in the vertical direction not only together with the upper working rollers, but also independently, using a hand wheel. To eliminate sagging of the sheet during straightening and to facilitate its insertion between the rollers, roller conveyors are installed in front of and behind the rollers, which are a series of rollers (5), the bearings of which are supported by a welded metal frame table.

Rice. 4.1. Scheme of sheet straightening on a five-roll leveling machine.

1 – lower work rolls; 2 – upper work rolls; 3 – support rollers; 4- auxiliary rolls; 5 – roller table rollers.

The gap between the upper and lower rows of work rolls of a sheet-straightening machine is determined by the formula:

,

where S – sheet thickness, mm;

σт – yield strength of the sheet material, Pa;

t – distance (step) between the axes of the work rolls of one row, mm;

k – elastic zone coefficient (k=0.25 when the number of rolls is 9 or less; k=0.20 when the number of rolls is 11 or more);

E – elastic modulus of the material, Pa.

The principle of straightening on straightening-tensioning machines is based on elastoplastic stretching of a sheet or profile, bringing deformations in its sections to values exceeding those corresponding to the elastic limit. In this case, sections of the leaf that did not die are stretched to the length of the wavy ones, while the latter are simultaneously straightened, and the leaf is straightened. Tensile straightening can be used for those materials whose ratio of tensile strength to yield strength is greater than 1.15-1.2.

Straightening and stretching machines have jaws with notches as a clamping device, which damage the clamped sections of the sheet length, as a result of which these sections have to be cut off after straightening, which is a disadvantage of these machines (the length of the cut sections can reach 300 mm).

The stretching straightening machine has a hydraulic tension cylinder and front and rear movable heads. The sheet is fixed in a horizontal position between the front and rear heads. When pressure is created in the hydraulic cylinder, the heads diverge and the sheet stretches. The machine has a control system that regulates the stretching speed and automatically turns off when a certain stroke or force is reached.

Straightening on straightening machines compared to straightening on sheet straightening rollers has the following advantages:

— increases labor productivity by 6–8 times and at the same time increases the accuracy of editing;