Diamond pencil for straightening abrasive wheels: purpose, structure, types. Materials for editing. Classification according to the location of the abrasive material. Features of marking. Editing with cutters. Circle test.

A diamond pencil, used for dressing abrasive wheels of different densities, is a dressing-type tool with a high degree of wear resistance, with the help of which their original configuration and cutting properties are restored by grinding. It is a product of a certain shape, 40÷80 mm long, 80÷100 mm in diameter with an insert in which diamonds of certain sizes are attached using a special binder composition. The tool body is made of A20 steel. It can be cylindrical, conical or stepped. The working surface of the tool is diamonds of natural or synthetic origin, which are arranged in a certain way in an insert made of steel or copper, differ in weight, dimensions and quantity. Dressing diamond wheels is a type of machining. The operation consists of destroying the abrasive material with the working surface of a diamond pencil. They are used for dressing the rough and finishing surfaces of abrasive wheels, including disc, disk, and single-thread thread grinding types.

Materials for dressing abrasive wheels

Wear of abrasive wheels occurs for various reasons. These include chipping of grains, destruction of grain shape, abrasion and salting. Correction of such defects can be carried out not only with metal-diamond pencils, but also in the following ways:

- cutters;

- carbide or diamond type rollers;

- steel knurls;

- diamonds located in a special frame;

- diamond circles.

The use of any of these methods will restore the cutting ability of the circle and the geometric shape of the working surface. When performing straightening, using an appropriate tool, remove a layer of deteriorated abrasive from the working surface.

Editing modes include:

- rotation speed indicated in m/min;

- longitudinal and transverse feeds;

- number of passes.

The selection of the material with which the processing will be performed depends on the task at hand. The products have a working part in the form of grains of diamond powder of natural and synthetic origin, embedded in the metal. It differs not only in the origin of the diamond grains, but also in their location and size. Correct pencils must comply with GOST 607-80 and the manufacturer's specifications. There are products where diamonds are arranged in the form of a chain, layer by layer, non-oriented and on the surface in the form of a sphere. Editing can be performed using diamonds and raw materials of different quality, composition and origin, as well as from the AKTM composite.

With diamonds arranged in layers. Such instruments are produced in 2 types, differing in the number of grains ranging in size from 0.1 to 0.2 carats in each layer. In the first case, their number does not exceed 5 diamonds, in the second their number reaches 10. These correct tools, classified as fine-grained with increased wear resistance, are used for finishing dressing of wheels. Belong to type 02 (C).

With diamonds on the surface in the form of a sphere. Products are produced with diamonds located on such a surface, with a number of grains ranging in size from 0.05 to 0.2 carats. Belong to type 03.

Unoriented or chaotic layout. They differ in the size of the abrasive and its qualitative properties. They belong to type 04 (H).

Used to level the surfaces of circles with a fine-grained structure.

Other types of instruments

There are several other editing methods, including:

- Running in. Special rotational mechanisms are used here, which can be divided into cone stars, rollers, silicon carbide wheels, as well as special steel wheels. This method is quite complicated, since it is not possible to achieve high accuracy.

- Editing by grinding. The same principle is used here as in the previous version, only the tools are already driven by their own engines. To solve such problems, different types of diamond rollers, silicon carbide, diamond or CBN wheels are used.

As you can see, there are several ways to edit using different tools, which should be purchased to solve only specific problems.

A detailed description of the ruling pencil for diamond wheels is in this video:

Tweet

Marking

In the technical documentation and when ordering, indicate the product code and GOST. For example, when ordering a conical product type 02 Ø12 mm with a length of 60 mm from diamond powder with a grain size of 3150/2500, it will look like this: pencil 3908-0077 GOST 607-80.

The following is applied to the body of the product itself:

- trademark or business name;

- a short code designation that excludes the first 6 digits, adding the letter C if the diamonds are of synthetic origin;

- product number.

Design features and applications of the grinding wheel

The grinding wheel consists of an abrasive surface, which is made up of interconnected fractional grains.

The distinctive features of the circles are determined by the scope of their use. During long-term work, there is a possibility of grinding off the end part, which leads to uneven grinding and can cause damage to the part.

Soft wheels are self-sharpening. When the surface layer wears off, new grains located underneath come into play. This does not affect the functionality of the circle itself.

Hard wheels are deprived of this opportunity due to greasing and dullness. This is caused by clogging of the pores of the wheel fractions with the material being ground. The grinding wheel ceases to perform its functions and needs to be corrected.

Application area

Using cutters equipped with sharp teeth, grinding wheels are dressed, the dense structure of which consists of abrasive grains of minimal size. If, with the help of sharp-toothed cutters, you start dressing wheels made of abrasive grains of medium and coarse fraction, then the dressing tool will simply ruin their working surface, causing serious damage to it. In such cases, a blunt-toothed cutter is used, specially designed for dressing medium- and coarse-grained abrasive wheels.

The high efficiency of using star cutters is ensured by the fact that processing with their help is carried out at a high rotation speed. It should be borne in mind that the dressing of grinding and grinding wheels is carried out not with one cutter, but with a whole set of them, placed on a special axis equipped with a lubricating nipple.

Special holder for cutters

Considering the fact that the roller-cone tool experiences serious mechanical impact from the abrasive wheel during use, its working part must be subjected to high-quality hardening.

Indications for editing

Dressing is a process of cleaning contaminants between abrasive fractions, which allows you to restore the sharpness of cutting edges and geometry. You can understand the need for this procedure by the following signs:

- The appearance of defects on the treated surface - you can detect wave-like transitions, gaps, abrasions that arise due to a violation of the geometry of the abrasive edge. It is impossible to achieve a perfectly flat surface with such a circle.

- The formation of chips on the edge of the circle can be noticed visually, but with small chips the trouble is more visible precisely on the workpiece.

- Increased noise and vibration of the tool during operation is manifested due to disturbances in centrifugal force and imbalance.

- Adhesive loading - microparticles of the material being processed are clogged into the pores, which makes the abrasive smooth. Can be seen with the naked eye and upon tactile contact with the surface. Carrying out work with such a circle will take several times longer than usual.

It is not uncommon for a spark to occur. This indicates the need to completely replace the wheel and the impossibility of straightening it.

Editing does not always allow you to return the original quality of the wheel. In case of incorrect manipulations and complete wear, it is better to replace the consumable with a new one.

Methods for dressing grinding wheels and their features

There are several options for restoring the geometry and sharpness of the grinding wheel, each of which has its own characteristics.

Grinding

This method involves breaking down the greasy surface layer of abrasive and releasing new particles that will do the bulk of the grinding work. The work is carried out according to the following scheme:

- Place the dressing tool on the tool rest.

- Start the grinding wheel, to which cutters or needles are brought for grinding.

- Monitor the angle of interaction between the two planes and increase it if necessary.

- Adjust the rotation speed of the disk; the higher it is, the more abrasive the surface will be.

It is possible to understand that the editing process was performed correctly only after assessing the surface. To do this, take a regular ruler and apply it to the circle. If all its parts are in close contact with the surface of the circle, then the editing was successful. The formation of irregularities can be eliminated with additional spot processing of irregularities.

Grinding is one of the simplest and fastest straightening methods. It is important to take all safety precautions when working.

Breaking in

A round-shaped tool is suitable for the job; when it comes into contact with the grinding wheel, it will grind down the top layer to the desired boundaries. This method is convenient in the presence of deep chips and severe contamination of the abrasive. The following high-strength materials are used:

- rollers made of hard alloys;

- rollers;

- silicon carbide discs;

- steel circles with hardened coating.

The best option in terms of price and quality is to use cutters. During contact with the working surface, the rollers also begin to rotate, which enhances the effect. Disadvantages of use include increased dust formation and the need to use a respirator.

Grinding

This method involves exposing the surface of the grinding wheel to a heavy-duty material that evens out the surface and geometry. Most often, diamond wheels are used, which have their own axis of rotation. To achieve maximum results, the disc is fixed permanently.

Grinding is performed at low speeds, as this allows you to control the force of pressing on the surface and the depth of grinding.

Operating principle

The operating principle of a cutter for dressing grinding wheels is quite simple. A set of such tools, assembled into a single unit, is placed on a special axis equipped with a handle for the operator, and is brought into contact with a rotating abrasive wheel. As a result, a set of cutters also begins to rotate on an axis, rolling and sliding along the surface of the circle being processed. Since the working part of the cutters is hardened and has high hardness, when they interact with the wheel, a layer of abrasive is removed from it, which means its surface is leveled.

A dressing tool works on a similar principle, the working body of which is a diamond, or rather, a set of diamonds mounted on a special mandrel in a certain order or randomly. Sets of sprocket cutters can not only be fixed on manual straightening devices, but also used as part of devices installed on a fixed base.

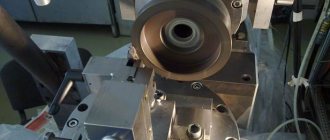

The cutters are assembled into a holder, which is installed on the machine tool rest until it touches the emery stone.

Read also: Do-it-yourself wood sanding

The disadvantages of a roller-cone tool for dressing abrasive wheels include:

- low accuracy of the processing performed;

- a large amount of dust generated during the straightening process.

The problem with dust, even when using hand tools equipped with cutters, can be solved quite easily. To do this, a hose connected to the vacuum cleaner is attached to its hollow handle.

Of course, one cannot fail to note the advantages of straightening using cutters. This should include:

- high productivity;

- eliminating smoothing of the abrasive wheel processed by the dressing tool.

A device based on rotating cutters demonstrates the greatest efficiency in cases where it is used to straighten abrasive wheels used for grinding work.

Method of dressing grinding wheels by rolling

When performing straightening using cutters, the rolling method is used. Its essence lies in the fact that the tool, rolling around the circle being processed, crushes, chips and removes abrasive grains and the material holding them together from its surface. Thus, the surface of the abrasive wheel is cleaned of foreign inclusions and leveled.

Today, many manufacturers are creating more advanced dressing tools based on cutters. The working body of such devices is a cassette, in which a set of cutters placed on the shaft is already assembled and securely fixed.

The process of abrasive processing of products with a grinding wheel is inevitably accompanied by gradual abrasion of the tool itself, and with uneven production - a violation of its geometry. In this case, the performance of the wheel depends on the nature of wear and the characteristics of the binder of abrasive materials.

In softer wheels, the process of chipping of worn grains occurs while maintaining the abrasive properties of the wheel. At high hardness, the wheel becomes dull, smoothing and clogging of the grains occurs with a significant deterioration in cutting ability, a decrease in the quality of processing and productivity. The solution to the problem is timely dressing of abrasive grinding wheels using various technologies and tools.

Technology for dressing diamond wheels with cutters

Cones are the most common means for dressing grinding wheels. These metal sprockets have sharp or blunt teeth, which determines the type of their use for each specific option. For abrasives with the smallest grain size fraction, only blunt-toothed cutters are used. In other cases, pointed analogues are used.

For editing, not one cutter is used, but a set of them. The parts are secured in a special holder, and the quantity depends on the dimensions of the wheel being processed.

The technology for performing the work is as follows:

- The rollers are collected in a holder, securely fastened.

- The formed device is installed on an axis that has a handle for the operator.

- Bring the circle to the rotating cutters, adjusting the pressure and the angle of inclination.

Within a few minutes you can get a perfectly flat surface without flaws or chips. When working, it is important to use a respirator that will protect against large amounts of fine dust entering the respiratory system.

Dressing diamond grinding wheels with cutters: technology and features

Let's start with the fact that the standard cutters most often used for dressing diamond wheels can have blunt and sharp teeth.

Photo No. 4: sharp-toothed (right) and blunt-toothed (left) cutters

Devices of the first type are used for dressing diamond grinding wheels with grains of minimal size. This is due to the fact that a sharp-toothed cutter will only spoil the circle with grains of large and medium fractions. Blunt-toothed devices are suitable for straightening such products. As you might have already guessed, you can’t edit circles with fine grains using blunt-toothed cutters!

Note! To dress diamond grinding wheels, not just one type of cutter is used, but sets of devices. They are fixed in special holders.

Photo No. 5: cutters fixed in a holder

Technology for dressing diamond grinding wheels with cutters

The process of dressing diamond grinding wheels with cutters looks like this.

- A set of devices is assembled into a single block.

- It is secured in a holder.

- The resulting device is installed on a special axis equipped with a handle for the operator.

- The tool is brought into contact with a rotating worn diamond blade.

This grinding wheel dressing technology has its advantages and disadvantages. Let's start with the positives.

- Editing goes very quickly.

- Cutters for dressing diamond wheels are cheap.

- High efficiency of editing is ensured. The working surfaces of the circles are not smoothed.

- The technology is easy to use.

The main disadvantage of the method is the release of a large amount of dust, but the problem is easily solved with the help of an industrial vacuum cleaner.

Rules and features of dressing diamond grinding wheels with cutters

- Wear safety glasses and use a dust mask.

- Do not use cutters that are not the right size for straightening.

- Work the circles above their centers. This will prevent the teeth from excessively deepening into the abrasive surfaces.

- Move the holder with the cutters as smoothly as possible.

- When dressing, try to maintain a steady pressure on the diamond wheel.

- When sparks appear, increase the pressure.

Preventive measures and recommendations for operation and storage

To minimize the frequency of dressing, it is important to follow all the rules for operating the grinding wheel, namely:

- The wheel should fit freely onto the spindle; there is no need to use force or install grinding wheels of inappropriate dimensions on small spindles.

- Always check the operation of the circle at idle speed. This way you can identify various damages even before the material being processed is damaged.

- Editing should only be performed with equipment specifically designed for this purpose. No files, sandpaper, etc. are suitable.

- Face grinding with a conventional wheel is prohibited, as this leads to a complete violation of the geometry. For such types of work, suitable circles are used.

- Compliance with all storage rules will increase the service life of the device.

Editing - diamond wheel

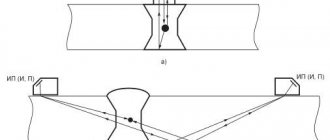

Dressing of diamond wheels is carried out using the following methods (Fig. 98): abrasive tools (grinding with bars, grinding with wheels); rolling in circles with relative sliding and without sliding; finishing with free abrasive grain; electrochemical methods (chemical etching, electroerosion); by supplying abrasive lubricant during operation of the diamond wheel. [2]

Dressing of diamond wheels on metal bonds can be carried out during the process of sharpening the tool by supplying a lubricant containing abrasive micropowder. [3]

Dressing of diamond wheels by grinding is carried out with plenty of cooling. Manual rotation of the diamond wheel is unacceptable, since the consequence of uneven rotation is non-roundness or non-flatness of the working surface after dressing. [4]

Dressing of diamond wheels on a metal bond using the electrochemical grinding method is carried out on modernized machines for electrochemical grinding with reverse current polarity. During the dressing process, diamond grains are exposed due to the dissolution of the wheel bond metal. [5]

Dressing of diamond wheels is carried out using the following methods (Fig. 98): abrasive tools (grinding with bars, grinding with wheels); rolling in circles with relative sliding and without sliding; finishing with free abrasive grain; electrochemical methods (chemical etching, electroerosion); by supplying abrasive lubricant during operation of the diamond wheel. [7]

Dressing of diamond wheels is carried out using the following methods (Fig. 7): with abrasive tools (grinding with bars, grinding with wheels, rolling with wheels with relative sliding and without sliding); finishing with free abrasive grain; electrochemical methods (chemical etching, electroerosion); by supplying abrasive lubricant during operation of the diamond wheel. [8]

Dressing of diamond wheels should be done with abrasive stones or KZ (or KCh) wheels with grain size A25 - A16, hardness CM1 - CM2, on a ceramic bond. [9]

Dressing of diamond wheels on surface grinding machines is carried out with bars secured in a vice mounted on the machine table. [10]

Dressing of diamond wheels is carried out mainly to eliminate wheel runout or to give it the required profile. Dressing of diamond wheels is carried out by grinding on a cylindrical grinding machine, as well as by rolling in on a profile grinding machine. [eleven]

Dressing of diamond wheels during operation is carried out in exceptional cases, since during proper operation it is not necessary. [12]

Dressing of a diamond wheel is carried out by grinding with a profile wheel made of silicon carbide with a knurled profile roller with abundant cooling. [13]

Dressing of diamond wheels is carried out only when the surface of the diamond-bearing ring is coated with metal particles and when it is unevenly worn, leading to blockages of the cutting edges of the sharpened tool, as well as to restore the geometric shape of the profile wheels. [14]

Dressing of diamond wheels with an abrasive tool should be carried out with abundant cooling in the following modes: peripheral speed of the abrasive wheel 25 - 30 m / s, longitudinal feed 1 5 - 2 m / min, transverse feed - 0 03 - 0 04 mm / in. The movement of the dressing abrasive wheel should ensure that it extends at least 5 mm from each side of the diamond wheel. During the dressing process using the rolling method, the abrasive wheel rotates due to contact with the diamond wheel. The longitudinal feed of the abrasive wheel should be 0 8 - 1 2 m / min, and the transverse feed - up to 0 02 mm for 6 - 8 double strokes. [15]

Intensive use of sharpening machines leads to disruption of the geometry of the working surface of the abrasive wheel. It is not uncommon to see rounded edges or a dimple in the center that prevents the part from being processed. Defects are formed due to breaking, abrasion, dullness, chipping and salting of grains. As a result, cutting efficiency is significantly reduced. This is followed by a deterioration in the quality of processing and an increase in the likelihood of burns on the surface of the part.

To restore the geometric shape of abrasive and grinding wheels, the following types of dressing are used:

- turning;

- running in;

- grinding;

- tangential turning.

These technological operations are performed with diamond and non-diamond tools. For sharpening, a diamond ruling pencil is used.

Why do you need to edit diamond grinding wheels?

No matter how high-quality diamond grinding wheels are, they sooner or later deteriorate and wear out during use. Happens:

- smoothing in some areas;

- breaks;

- abrasion;

- salting

There are much fewer problems when using soft grinding wheels. They have the property of self-sharpening. As grains fall out, new layers are exposed. Solid instruments do not have this property. To restore the characteristics of such diamond grinding wheels, editing is needed. After it, the instruments get a new life. The cutting properties and geometric shape of products are restored.

Types of diamond pencils

The list of types and types of wheel dressing tools produced is regulated by the state standard. Diamond pencil GOST 607–80 is a cylinder with a length from 40 mm to 80 mm and a diameter from 8 mm to 10 mm, made of high-quality tool steel.

The main difference by which the classification occurs is the location of the crystals on the working surface.

- Arrangement in a chain, one after another (C).

- Arrangement in layers ©. In this case, the layers may intersect with each other or not overlap.

- Unoriented arrangement (N), chaotic.

To secure the crystals together and in a certain order, a special material is used, which has identical thermal expansion equal to diamonds . This eliminates additional deformation of the stones.

Arrangement in a chain

This arrangement of diamonds is typical when using crystals of natural origin. Used when leveling the surface of medium-hard circles. The first digits of product 3908 are not indicated .

Editing by turning

This procedure is the treatment of the surface of a diamond wheel with the help of special substances in order to increase the quality of its surface or, as they say, to sharpen the material. There are several types of editing, one of which is grinding. It involves the use of special tools that destroy the ligaments of the wheel and thus sharpen the diamond.

Several types of products can be used here, among which are:

- Diamond needles.

- Diamonds in a setting are products in the form of rods, on the end of which a relatively large diamond stone is mounted.

- Diamond pencils are characterized by an extended surface on which a layer of diamonds is deposited in a specific pattern.

- CBN cutters, etc.

Working with such a tool is quite simple and is performed on a special stand. This allows you to clean the rotating surface of the circle efficiently and evenly. When there is no special tool, you can use special grinding CBN inserts for such purposes, which are fixed using ordinary pliers.

Using Diamond Rules

A diamond pencil for dressing abrasive wheels is highly resistant to abrasion, ensures a constant profile of the wheel, and the technological process is quite simple. It does not require any additional devices or effort.

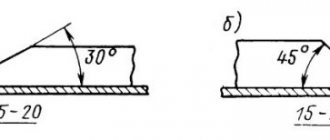

With a diamond pencil you can edit not only the outside of the circles , but also the inside. To make maximum use of the working surface of the pencil, place it on a tool rest or in a device, tilting it along the path of rotation at an angle of 10° - 15°. Because of this, the cutting edge will be 2 mm below the center axis.

During operation, small chips and grain particles of the wheel material fill the pores, after which the surface becomes viscous. Removing such a layer from the surface provides a dressing tool, restoring processing characteristics.

A diamond pencil for dressing grinding wheels is also used for new wheels. The manufacturer guarantees the integrity and safety of the abrasive tool, but in most cases new products have runout. This fact can be verified simply. While rotating, slowly bringing a chalk or marker to the surface, it will leave a mark on it. This indicates excess material that needs to be removed.

Using a diamond pencil, the price of which depends on the type of crystal and its weight, is more profitable than resorting to replacing the wheel every time. The cost of the “rule” is quite high, but it is much lower than the amount spent on regular replacement of an abrasive tool.

Diamond in a frame (GOST 22908-78)

This GOST describes the standard for diamonds in frames, which are used for dressing straight and shaped grinding wheels. Diamonds in settings, according to this GOST, are produced for export and the needs of the national economy.

The requirements regulated by sections 1 and 2 (except for clauses 2.3 and 2.9), as well as clause 3.1, sections 4 and 5, are mandatory. The remaining requirements of GOST 22908-78 are advisory in nature.

Types and main sizes

1.1 — Diamonds in settings must be manufactured in the following options:

- cylindrical;

- cylindrical with head;

- conical;

- threaded

1.2 — The main dimensions of diamonds in settings must correspond to those indicated in the drawing and table below:

Cylindrical diamond in a setting (type 1)

| Weight of diamonds in ct. | Dimensions, DxL, mm | Diamond weight, ct. | Price, rub. without VAT | |

| 90 gr. | 120 gr. | |||

| 3908-0101 | 3908-0102 | 6x25 | 0,02-0,04 | 1 000 |

| 3908-0105 | 3908-0106 | 6x25 | 0,05-0,10 | 1 000 |

| 3908-0111 | 3908-0112 | 6x50 | 0,05-0,10 | 1 000 |

| 3908-0113 | 3908-0114 | 6x25 | 0,11-0,20 | 1 000 |

| 3908-0117 | 3908-0118 | 6x50 | 0,11-0,20 | 1 000 |

| 3908-0121 | 3908-0122 | 7x8.5 | 0,31-0,40 | 1 900 / 2 200 |

| 3908-0123 | 3908-0124 | 7x18 | 0,31-0,40 | 1 900 / 2 200 |

| 3908-0125 | 3908-0126 | 8x25 | 0,21-0,30 | 1 300 / 1 600 |

| 3908-0131 | 3908-0132 | 8x50 | 0,21-0,30 | 1 300 / 1 600 |

| 3908-0133 | 3908-0134 | 8x25 | 0,31-0,40 | 1 900 / 2 200 |

| 3908-0137 | 3908-0138 | 8x50 | 0,31-0,40 | 1 900 / 2 200 |

| 3908-0141 | 3908-0142 | 8x25 | 0,41-0,60 | 2 600 / 3 300 |

| 3908-0145 | 3908-0146 | 8x50 | 0,41-0,60 | 2 600 / 3 300 |

| 3908-0147 | 3908-0148 | 8x25 | 0,61-0,85 | 3 700 / 4 100 |

| 3908-0153 | 3908-0154 | 8x50 | 0,61-0,85 | 3 700 / 4 100 |

| 3908-0155 | 3908-0156 | 10x50 | 0,21-0,30 | 1 300 / 1 600 |

| 3908-0157 | 3908-0158 | 10x50 | 0,31-0,40 | 1 900 / 2 200 |

| 3908-0161 | 3908-0162 | 10x50 | 0,41-0,60 | 2 600 / 3 300 |

| 3908-0163 | 3908-0164 | 10x50 | 0,61-0,85 | 3 700 / 4 100 |

| 3908-0165 | 3908-0166 | 10x50 | 0,86-1,10 | 6 100 |

| 3908-0167 | 3908-0168 | 10x50 | 1,11-1,35 | 7 100 / 7 900 |

| 3908-0171 | 3908-0172 | 10x50 | 1,36-1,60 | 8 100 / 9 100 |

| 3908-0173 | 3908-0174 | 10x50 | 1,61-2,10 | 11 000 |

| 3908-0175 | 3908-0176 | 12x50 | 0,21-0,30 | 1 300 / 1 600 |

| 3908-0177 | 3908-0178 | 12x75 | 0,31-0,40 | 1 900 / 2 200 |

| 3908-0181 | 3908-0182 | 12x75 | 0,41-0,60 | 2 600 / 3 300 |

| 3908-0183 | 3908-0184 | 12x75 | 0,61-0,85 | 3 700 / 4 100 |

| 3908-0185 | 3908-0186 | 12x75 | 0,86-1,10 | 6 100 |

| 3908-0187 | 3908-0188 | 12x75 | 1,11-1,35 | 7 100 / 7 900 |

| 3908-0191 | 3908-0192 | 12x75 | 1,36-1,60 | 8 100 / 9 100 |

| 3908-0193 | 3908-0194 | 12x75 | 1,61-2,10 | 11 000 |

Notes on the table:

1. The maximum deviation of diameter D over a length of 10 mm should not exceed 0.5 mm. 2. At the special request of the consumer, by agreement, diamonds can be produced in settings with a diameter of D = 8 and 10 mm, length I = 25 and 50 mm with diamond weight groups of 0.05-0.10 and 0.11-0.20 carats . 3. At the request of the consumer, it is allowed to produce diamonds in settings with a length L different from that indicated in the table. 1.

For diamonds in settings with a diameter of D = 7 mm, the surface roughness is Ra = 1.25 µm and maximum deviations along f 9 along the entire length.

Diamond in a setting with a head (type 2)

| Weight of diamonds in ct. | Dimensions, DxL, mm | Diamond weight, ct. | Price, rub. without VAT | |

| 90 gr. | 120 gr. | |||

| 3908-0195 | 3908-0196 | 10x6x32 | 0,21-0,30 | 1 300 / 1 600 |

| 3908-0197 | 3908-0198 | 10x6x32 | 0,31-0,40 | 1 900 / 2 200 |

| 3908-0201 | 3908-0202 | 10x6x32 | 0,41-0,60 | 1 900 / 2 200 |

| 3908-0203 | 3908-0204 | 10x6x50 | 0,61-0,85 | 3 700 / 4 100 |

| 3908-0205 | 3908-0206 | 10x6x50 | 0,86-1,10 | 6 100 |

| 3908-0207 | 3908-0208 | 10x6x50 | 1,11-1,35 | 7 100 / 7 900 |

| 3908-0211 | 3908-0212 | 10x6x50 | 1,36-1,60 | 8 100 / 9 100 |

| 3908-0213 | 3908-0214 | 10x6x50 | 1,61-2,10 | 11 000 |

| 3908-0215 | 3908-0216 | 12x8x32 | 0,21-0,30 | 1 300 / 1 600 |

| 3908-0217 | 3908-0218 | 12x8x50 | 0,21-0,30 | 1 300 / 1 600 |

| 3908-0221 | 3908-0222 | 12x8x32 | 0,31-0,40 | 8 100 / 9 100 |

| 3908-0223 | 3908-0224 | 12x8x50 | 0,31-0,40 | 11 000 |

| 3908-0225 | 3908-0226 | 12x8x32 | 0,41-0,60 | 1 900 / 2 200 |

| 3908-0227 | 3908-0228 | 12x8x50 | 0,41-0,60 | 1 900 / 2 200 |

| 3908-0231 | 3908-0232 | 12x8x32 | 0,61-0,85 | 3 700 / 4 100 |

| 3908-0233 | 3908-0234 | 12x8x50 | 0,61-0,85 | 3 700 / 4 100 |

| 3908-0235 | 3908-0236 | 12x8x32 | 0,86-1,10 | 6 100 |

| 3908-0237 | 3908-0238 | 12x8x50 | 0,86-1,10 | 6 100 |

| 3908-0241 | 3908-0242 | 12x8x32 | 1,11-1,35 | 7 100 / 7 900 |

| 3908-0243 | 3908-0244 | 12x8x50 | 1,11-1,35 | 7 100 / 7 900 |

| 3908-0245 | 3908-0246 | 12x8x32 | 1,36-1,60 | 8 100 / 9 100 |

| 3908-0247 | 3908-0248 | 12x8x50 | 1,36-1,60 | 8 100 / 9 100 |

| 3908-0251 | 3908-0252 | 12x8x32 | 1,61-2,10 | 11 000 |

| 3908-0253 | 3908-0254 | 12x8x50 | 1,61-2,10 | 11 000 |

Notes on the table:

1. By agreement between the manufacturer and the consumer, it is allowed to produce diamonds in settings with a diameter of D = 10 mm, a length of L = 32 mm and a diameter of D = 12 mm, a length of L = 32 and 50 mm with diamond weight groups of 0.05-0.10 and 0 .11-0.20 ct. 2. At the request of the consumer, it is allowed to produce diamonds in settings with a length L that differs from that indicated in the table above.

Conical set diamonds (type 3)

| Weight of diamonds in ct. | Dimensions, DxL, mm | Diamond weight, ct. | Price, rub. without VAT | |

| 90 gr. | 120 gr. | |||

| 3908-0255 | 3908-0256 | 10.3x8x28 | 0,31-0,40 | 2 200 / 2 500 |

| 3908-0257 | 3908-0258 | 10.3x8x28 | 0,41-0,60 | 2 900/ 3 600 |

| 3908-0261 | 3908-0262 | 10.3x8x28 | 0,61-0,85 | 4 000 / 4 400 |

| 3908-0263 | 3908-0264 | 10.3x8x28 | 0,86-1,10 | 6 400 |

| 3908-0265 | 3908-0266 | 10.3x8x28 | 1,11-1,35 | 7 400 / 8 200 |

| 3908-0267 | 3908-0268 | 10.3x8x28 | 1,36-1,60 | 8 400 / 9 400 |

| 3908-0271 | 3908-0272 | 12.2x10x32 | 0,31-0,40 | 2 200 / 2 500 |

| 3908-0273 | 3908-0274 | 12.2x10x32 | 0,41-0,60 | 2 900 / 3 600 |

| 3908-0275 | 3908-0276 | 12.2x10x32 | 0,61-0,85 | 4 000 / 4 400 |

| 3908-0277 | 3908-0278 | 12.2x10x32 | 0,86-1,10 | 6 400 |

| 3908-0281 | 3908-0282 | 12.2x10x32 | 1,11-1,35 | 7 400 / 8 200 |

| 3908-0283 | 3908-0284 | 12.2x10x32 | 1,36-1,60 | 8 400 / 9 400 |

Note to the table:

By agreement between the manufacturer and the consumer, it is allowed to produce diamonds in settings with diamond weight groups of 0.05-0.10, 0.11-0.20, 0.21-0.30 carats.

Threaded diamonds in settings (type 4)

| Weight of diamonds in ct. | Dimensions, DxL, mm | Diamond weight, ct. | Price, rub. without VAT | |

| 90 gr. | 120 gr. | |||

| 3908-0285 | 3908-0286 | M10x1/8.9x50 | 0,11-0,20 | 1 500 |

| 3908-0287 | 3908-0288 | M10x1/8.9x50 | 0,21-0,30 | 1 800/2 100 |

| 3908-0291 | 3908-0292 | M10x1/8.9x50 | 0,31-0,40 | 2 400/2 700 |

| 3908-0293 | 3908-0294 | M10x1/8.9x50 | 0,41-0,60 | 3 100/3 800 |

| 3908-0295 | 3908-0296 | M10x1/8.9x36 | 0,61-0,85 | 4 200/4 600 |

| 3908-0297 | 3908-0298 | M10x1/8.9x50 | 0,61-0,85 | 4 200 / 4 600 |

| 3908-0301 | 3908-0302 | M10x1/8.9x36 | 0,86-1,10 | 6 600 |

| 3908-0303 | 3908-0304 | M10x1/8.9x50 | 0,86-1,10 | 6 600 |

| 3908-0305 | 3908-0306 | M10x1/8.9x50 | 1,11-1,35 | 7 700/8 400 |

| 3908-0307 | 3908-0308 | M10x1/8.9x50 | 1,36-1,60 | 8 600/9 600 |

Notes on the table:

1. By agreement between the manufacturer and the consumer, it is allowed to produce diamonds in settings with a length of L = 50 mm with a diamond weight group of 0.05-0.10 carats.

2. At the request of the consumer, it is allowed to produce diamonds in settings with a length L that differs from that indicated in the table above.