New technologies and materials in construction appear constantly, gradually displacing traditional materials. A good example of this is plumbing. Just fifteen years ago, metal was used in most cases - in general, there was no alternative. Today, almost everywhere, metal is being replaced by polymers, since they are easier to install, cost less, and last the same or even longer. One of the most popular modern materials is propylene. The good thing about installing a water supply system from polypropylene pipes is that you can do it yourself. To do this you will need a special soldering iron and some experience. A soldering iron can be rented, but experience is acquired. You can practice on the most inexpensive fittings and small sections of pipe.

You can do the installation of a water supply system from polypropylene pipes yourself.

Marking and scope

You need to start installing a water supply system from polypropylene pipes by choosing the type of pipes. They are single-layer and three-layer, they also differ in wall thickness and, accordingly, have different purposes. To make it easier to navigate, they are marked:

- PN10 - single-layer pipes designed for cold water in pipelines with low pressure. Suitable for installing polypropylene water supply in private homes.

- PN16 - single-layer pipes with a thicker wall. They can be used both for transporting cold water in systems with high pressure (centralized), and for distributing a hot water supply system. Maximum permissible temperature +50°C.

- PN20 - three-layer pipes with a fiberglass reinforcing layer. They can be used for installing water pipes for transporting hot water and low-temperature heating systems. Maximum temperature +90°C.

- PN25 - three-layer pipes reinforced with aluminum foil. They are used mainly for heating; they can be used for hot water supply, but this is not economically feasible: these are the most expensive pipes, and their qualities for hot water supply are excessive.

By color there are polypropylene pipes in gray and white. This does not affect the quality in any way, so choose according to aesthetic preferences. Some companies (mostly German) paint their products green. If the wiring is hidden - in the walls or in the floor - you will not find anything better, since the Germans are leaders in quality.

To install a water supply system made of polypropylene pipes, you will also need fittings

To make it easier to navigate by area of application, colored stripes are applied along the PPR pipes. Those intended for cold water are indicated in blue, those for hot water supply and heating are indicated in red, and those intended for universal use are indicated in orange. Some manufacturers have adopted different labeling. They mark products for heating and hot water in red, but do not mark those intended for cold.

From the above, we can draw the following conclusions: installation of water supply from polypropylene pipes in an apartment is best done from PN 16 for cold water and PN20 for hot water. In a private house, you can get by with PN 10 for cold water and PN 20 for hot water.

Installation features

Single-layer PPR pipes PN 10 and PN 16 have a high coefficient of thermal expansion: with a temperature difference of 100°C, each meter becomes 1.5 cm longer. Even taking into account the fact that such a temperature difference is unattainable in real life, this is a very large figure. To prevent this increase in length from destroying the water supply system, compensation loops (compensators) are provided in the system.

Types of compensators for polypropylene water supply

If the length of the pipeline is short and cold water is supplied at the same time, there is no need to make a compensator - the difference in length will be small, but for hot water supply it is advisable to make at least a basic L-shaped compensator (see figure).

Connection principle

Polypropylene pipes have many advantages, but one of the disadvantages is that they do not bend. Therefore, when installing a water supply system from polypropylene pipes, fittings are used for all branches and turns. These are special elements - tees, angles, adapters, couplings, etc. There are also taps, compensators, bypasses and other elements of the system, also made of polypropylene.

Polypropylene fittings

All these elements are connected to pipes using soldering. The material of both parts to be joined is heated until melted, then joined. As a result, the connection is monolithic, so the reliability of the polypropylene water supply is very high.

There are special fittings for connecting with other materials (metal), for connecting to household appliances or plumbing fixtures. On one side they are completely polypropylene, on the other they have metal threads. The thread size and type are selected according to the type of device being connected.

Material counting

Required number of pipes, connecting elements, fasteners. Adapters and other materials are determined based on the design and measurements, and depend on the choice of wiring option, the size of the premises and the system, the material and diameter of the pipes and the number of consumers.

It is recommended to purchase all materials with a small reserve in case of their replacement, errors in calculations or unexpected changes in the design of the water supply or heating system. This will significantly reduce the time needed to install pipelines.

System planning

Due to the fact that PPR pipes do not bend, when developing a wiring diagram it is necessary to create as few detours and turns as possible. After all, they are all made using fittings, and they have a significant cost (compared to a pipe). Therefore, we try to optimize the wiring - make as few turns, detours and bends as possible.

Serial (Tee) connection

Installation of water supply from polypropylene pipes with serial connection of consumers (plumbing and household appliances) is used in small systems. Usually they have 5-6 connection points. With this arrangement of the water supply system, one pipe leaves the riser and it sequentially bypasses all connection points. In the case of PPR plumbing, all branches are made using tees, which is why this type is also called tee.

Installation of water supply from polypropylene pipes with serial connection of consumers

The advantage of this system is that a small number of pipes are needed, and the disadvantage is that the pressure on each branch drops. As a result, with one or two working disassembly points, the third, located further from the riser, may simply not have enough pressure.

Parallel (collector) wiring

A parallel connection circuit is also called a collector circuit. This is because after the outlet from the riser, a special device is installed - a collector. This is an element with one input and a number of outputs. Available in polypropylene and metal. For water supply, polypropylene manifolds are more suitable (and cheaper).

The connection diagram is such that a separate pipe runs from each branch to each consumer (sometimes to a small group of consumers).

Parallel scheme for installing a water supply system from PPR pipes

The advantage of such a system is that the pressure at all water points is the same, the disadvantage is that a lot of pipes are required. Another plus is that if any branch fails, only one consumer does not work. The rest of the system is functioning normally. By the way, in order to be able to turn off individual devices, valves are installed at the outlet of the collector (usually ball valves, but if you need the ability to adjust the pressure, you can install a valve).

Plumbing and household appliances

In each method of installing a water supply system made of polypropylene pipes, a pipe is suitable for a specific consumer. There are two ways to connect to the system: flexible and rigid connection.

Rigid liner is more reliable: PPR pipes and fittings have high strength. Moreover, in this case there is only one thread - at the consumer connection point. But this type of eyeliner requires high precision: the error can be only a few millimeters. This is difficult to achieve when installing a polypropylene water supply with your own hands, so flexible hoses are often used. Just be careful, in some cases it is impossible to use it: connecting gas boilers or gas water heaters, supplying water to storage water heaters, water heated towel rails is recommended only using a rigid connection.

Rigid liner options

Soft eyeliner, on the contrary, does not require high precision - errors are leveled out by a flexible stainless steel braided hose or a hose that is used to connect a washing machine or dishwasher. The tubes are removed approximately in the area where the equipment is installed or the plumbing is connected. It ends with an adapter for metal, to which a flexible hose is connected (its other end is connected to the device).

Flexible hoses are connected to the adapters

This option is less reliable, since much depends on the quality of the flexible liner. Also not the most pleasant moment is the presence of two threaded connections, and this is a potential place for a leak to appear.

Soldering plastic parts

For soldering you need a special apparatus and a jigsaw (for cutting plastic).

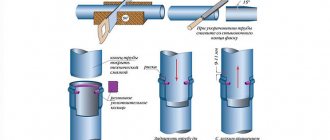

Soldering of plastic products is carried out as follows:

- The products are separated and cut into pieces of the required length.

- The ends must be connected and stripped.

The marker indicates the depth of the entrance to the connecting fitting. To prevent the pipe cap from resting on the coupling, leave a gap (at least 1 mm).

The fitting and tube are placed on the nozzle, both parts must be heated at the same time. If some parts do not fit well, they are rejected. The heating/cooling time depends on the cross-section of the product.

The heated parts are combined with the marks that were first made, after which a small force should be applied with which they are attached to each other. The initial setup can only be performed a certain number of seconds after mounting.

Internal or external installation

One of the advantages of polypropylene water supply is that it can be embedded into walls and floors without any problems. This material does not corrode, does not react with any materials, and does not conduct stray currents. In general, if the connection is made correctly, you can hide the pipes in the wall or floor without any problems. The trick is to make the connection well.

Polypropylene water supply can be hidden in walls or floors

To make sure that the assembled system will not leak, it is checked - pressure testing is carried out with excess pressure. There are special devices for this. They connect, pump in water, increase the pressure. The water supply is left under this pressure for several days. If no leaks are found, then at operating pressure everything will work for a long time and without problems.

Advantages of plastic pipes

Polymer pipes, which are often called polypropylene, have a large number of advantages, such as:

- long service life;

- no sediment, condensation;

- low noise level;

- light weight;

- no corrosion;

- normal installation;

- strength (products are ready to withstand pressure);

- resistance to strong impacts.