How to connect plastic pipes

There are several ways to install polymer pipes, each of which has its own characteristics. Experts recommend choosing how to connect plastic pipes depending on several conditions:

- purpose of the pipeline - water supply is often welded, sewerage is joined with sockets, heating is assembled with couplings of different types

- material of the products used - most polyvinyl chloride pipes are equipped with sockets; the industry produces compression couplings for assembling polyethylene lines; polypropylene pipes are soldered with manual or mechanical soldering irons

- scope of work - for heating pipes, installation of water supply, it is easier to buy a manual soldering iron, do the work yourself, connecting the external pipeline with sockets, for welding large diameters the services of specialized teams will be required

For polymer products, threaded connections are not used, since they cannot ensure sufficient tightness of the pipeline.

All other technologies remain available, with welding, sockets, and couplings being the most effective.

Non-welding connection for various types of plastic pipes

Connecting plastic pipes without soldering can be done in various ways. The choice of specific technology depends on the type of polymer water supply:

Compression fittings

HDPE polyethylene pipes are connected using compression fittings. No specific equipment is required for installation; muscular effort or, in extreme cases, a crimp wrench is sufficient. This DIY installation of plastic pipes will be simple, but it will take some time, since each joint will need to be carefully crimped. In addition, this method is still less reliable compared to soldering.

2. Polypropylene pipes are connected to each other by socket welding using a special apparatus. If you need to connect the metal parts of the pipeline with polypropylene, you will need threaded fittings (they have a thread on one side and a soldering coupling on the other).

A flange connection is also used as a detachable connection - metal flanges can be slip-on or welded. This installation method is optimal when creating systems from large-diameter pipes, and also ensures quick dismantling for preventive or repair operations. To maintain the tightness of threaded connections, use sealing paste or Teflon thread.

3. Metal-plastic pipes are not welded, since the metal layer present in them will not melt at standard welding temperatures. How to properly connect plastic pipes for this type of water supply? Using fittings of the appropriate size. In this case, it is possible to use easy-to-install compression fittings , more reliable press fittings , as well as push fittings . The last type of design provides the most advantages - installation is simple and quick, from the entire arsenal of tools you only need a calibrator and a cutter. Errors during this installation are almost completely eliminated, and the connection is as reliable as possible.

Connecting a metal-plastic pipeline with press fittings

4. PVC pipes , often used in utility sewer networks, are assembled into a socket - each pipe at one end has a socket with a rubber O-ring. In the process of creating a pipeline, the smooth end of the product is coated with silicone grease, and it is inserted into the socket until it stops. The place where the tubes are completely inserted is marked, after which the product is removed 10 mm back.

PVC pipe in section

You can also use glue for PVC pipelines . To do this, the joints are sanded with sandpaper to create a rough surface, then degreased with methylene chloride, and glue is applied to the prepared surfaces. The adhesive composition is applied to the entire section of the pipe that will be inserted into the socket, and to 2/3 of the length of the inner surface of the socket. The pipes with glue are combined until they stop, and then rotated 90° and pressed for a maximum of 60 seconds. All operations, from degreasing to gluing, must be carried out very quickly, but you will have to wait several hours until the glue dries completely.

5. The cross-linked polyethylene pipeline is assembled using coupling joints . The fittings required for the work are an equal coupling for connecting plastic water pipes, 2 mounting sleeves and a special tool for flaring polyethylene pipes.

The connection process itself occurs as follows: 5 cm is cut off from the end of the working pipe, after which the end is chamfered. A sleeve is put on the chamfered pipe (the groove located inside is used). The end of the pipe, placed in the sleeve, is flared using hand or hydraulic tools. After this, you need to insert the coupling into the flared pipe and slide the sleeve onto it. All operations in the same sequence should be repeated for the other pipe. The result is a sealed and incredibly reliable connection that is suitable for pipelines for a wide variety of purposes.

flange connection can also be made - this will require adapter bushings welded to the ends, or slip-on metal flanges (profile or flat). Such a connection must be supplemented with sealing material.

A quick-release connection without welding is also made using compression mounting elements . This method is suitable for pipes with a diameter of up to 63 mm or for systems with a large number of branches, where welding greatly increases the cost of the installation process. The tightness of the joint is ensured by an internal rubber seal, and the clamp itself can withstand pressure within 2.5 MPa. The most important thing in this case is to accurately select the size of the fittings. Non-pressure systems can also be created using socket joints.

Copper pipes and fittings for water supply have their own installation specifics. There is information about it, as well as about the characteristics of pipes made from this material, in a separate article.

Find out more about tools for installing metal-plastic pipes using press fittings. This connection is the most reliable for pipes of this type.

There is information about welding polypropylene pipelines at this address https://okanalizacii.ru/truby/montazh/instrukciya-po-svarke-polipropilenovyh-trub.html

Connecting polymer pipes with couplings

HDPE compression couplings solve the question: “How to connect plastic pipes?” in drainage and water supply systems. They are used for standard sizes 50 – 16 mm, provide the necessary tightness and do not cause blockages.

The ends of the pipes are clamped with nuts, cone-shaped sealing rings that withstand the pressure of pressure water pipes, sewage drains, and heating circuits. There are compression couplings that are rigidly attached to the pipe body of a one-piece type.

In addition, threaded connections are used with flaring of the ends of the products after putting nuts on them. Each method is used depending on local conditions; the decision on how to connect plastic pipes is made depending on the material of the parts being joined.

In addition to compression couplings, there are similar fittings: tees, bends, plugs, flanges, saddles, taps.

Fittings for polypropylene pipes and other types of polymer products

Polypropylene pipes are used to create reliable and durable water supply and heating systems. They are durable, resistant to high temperatures, high pressure, and mechanical stress. When installing a pipeline to connect its individual elements, make branches, transitions and turns, it is necessary to use a variety of fittings for PVC pipes .

Fitting: structural elements for plastic pipes (read more)

Fittings provide reliable and durable pipe connections.

Connecting polymer pipes by welding

Polymer welding is present in 50% of household communication systems; the joints have improved characteristics, since the process occurs at the molecular level.

The user manuals included in each set of welding equipment describe in detail the technology of how to connect plastic pipes and select the heating time depending on the wall thickness.

Hand soldering irons are used for products 50 – 16 mm; large diameters are soldered with mechanical welding machines. Removable sleeves heat the ends of the pipes, after which it remains to press them with slight force for a few seconds.

Welding with electric couplings is an improved version of the previous method, since the heating and joining process is controlled by a program. The quality of the joint increases, there is no need for fixation. Devices with electrodes are used to supply voltage to the heating elements inside the coupling.

Connection types

Different types of plastic pipes can be joined using several technologies. The choice in favor of one or another option is determined, first of all, based on the purpose of the future pipeline system, its diameter and the type of polymer material itself:

- In the bell. The end of one of the pipes is placed in the socket at the end of the other. The joint is sealed with a rubber gasket and additionally treated with sealant. This method has proven itself well in the construction of sewer pipelines and other networks in which the media is not distributed under pressure.

- Flange connection. Welded bushings or overhead steel flanges are used. The best option for joining metal and plastic sections of the pipeline.

- Threaded connection. Also used when installing elements made of plastic and metal.

- Docking using collets. It is convenient to connect products of small cross-section. Installation is carried out using compression fittings equipped with rubber sealing elements. During the crimping process, sharp metal teeth cut into the top layer of the pipe, creating a secure connection.

- Use of electric couplings. The device is put on the joint, and when an electric current is passed through it, it contracts. The joint turns out to be quite reliable, but it is not recommended to use this connection method for plumbing or heating networks.

- High temperature welding. The ends of the fastened products are melted using a special welding machine, and then connected. After cooling, the joint is as strong as the main pipeline. Welding can be carried out using fittings or butt welding. The last option is acceptable only for networks without strong pressure drops.

- Gluing. Two options are also acceptable: the use of cold welding, or special adhesives intended for polyvinyl chloride products. The first provides more reliable contact, since it affects the elements being glued at the molecular level.

We recommend that you read: Instructions for creating a porch from a profile pipe

Special connection methods

Push fittings, press fittings, flanges are special compounds of polymer materials.

They also solve the problem of how to connect plastic pipes in difficult cases: a joint with a metal main, a connection of different diameters. Push fitting allows you to use a minimum of tools (calibrator, knife). The fastening element consists of polyvinyl soufflon, brass, suitable for heating and water supply circuits.

The connection is considered permanent, the tightness is ensured by rubber rings. The pipe is inserted all the way into the fitting body, after which it is impossible to remove it back. Press fittings are crimped onto the body of the pipe with a hand wrench; they are also non-removable and are suitable for heating and water supply.

Source: aquagroup.ru

Features of installation of couplings for various types of pipes

To install most couplings, no special tool is required; one or two adjustable wrenches are enough; to seal joints in metal products, you will need flax tow or plumbing thread, fum tape for plastic threads. To fasten polypropylene pipes or install press fittings, you will need a special tool and some skills; if you do the work yourself, it is easier to rent the necessary equipment from a construction tool rental.

Rice. 12 Installation of plastic sewer pipes

Sleeve compression connection

Crimp compression couplings are dismountable connections; their installation does not require specialized tools (except for two wrenches); the process of joining with a metal-plastic pipe includes the following operations:

- Prepare the end of the pipe for installation of the coupling fitting; to do this, cut it at an angle of 90 degrees to the axis with scissors and insert a calibrator inside, turning it slightly to expand the seat.

- Place a nut and a ring with a slot on the pipe, insert the fitting body fitting inside it, and move the ring with the clamping nut to the end of the body.

- One wrench holds the fitting body, the other screws the clamping nut.

Techniques for connecting plastic pipes with pipes made of other materials

When replacing outdated plumbing and heating systems, service companies are increasingly choosing plastic that is easier to install. Entire multi-storey entrances are equipped with polymer pipes.

This lightweight material, which is easy to cut, can give the impression that assembling a connection to a battery or bathtub will not pose any difficulties even for an inexperienced craftsman.

How to build a polymer riser for hot water or how to connect a plastic pipe to a metal one in a bathroom is a job the master must know thoroughly.

Features of connecting plastic and metal pipes

Connecting plastic pipes with metal pipes is necessary in cases when repairing an old sewer or water supply system where steel or cast iron elements are present.

Connection of plastic and cast iron in the sewer

If plastic and cast iron pipes are joined in a sewer system, then installation of the joint is very simple, using special adapters, which are available in various sizes. But the methods that are traditionally used for joining cast iron pipes are not suitable in the case of plastic. In particular, due to embossing, the plastic pipe is deformed, and there will be no question of the reliability of the connection. It is also not advisable to seal the joint between a polymer and cast iron pipe with cement - after all, plastic and cast iron expand differently due to heating - it will be enough to fill the pipes with hot water just a few times for the joint to lose its tightness and become unusable.

How to connect plastic water supply pipes with metal ones? Greater reliability will be required here, since the pressure in the water supply system is higher. In particular, if the water supply is created from pipes up to 4 cm in diameter, then the joint is created using an appropriate fitting. It will have a thread on the metal side, and a standard coupling on the plastic side.

Important: Do not forget to carefully seal the connection on the side of the metal pipe - traditional materials and technologies, for example, flax fibers impregnated with drying oil, are suitable for this.

If we are talking about installing a pipeline with a diameter exceeding 40 mm, then it is advisable to use a flange connection to connect metal and plastic parts. This greatly simplifies the installation process, especially since it will not be difficult to select the appropriate adapters.

And when pipelines are assembled from different materials, where the environment will be under high pressure, then it is worth using a metal hose. To attach such a part to a plastic part, you will need an appropriate fitting, and it is attached to metal with a threaded connection.

In this way, you can create the most reliable joint and move from old metal structures to more practical and durable plastic ones. These methods are applicable for both heating and plumbing systems.

Characteristics of polymer pipes

Plastic pipes are a good alternative to outdated metal water pipes. Even a master inexperienced in technical aspects can easily name their advantages:

- reduced noise level from fluid movement compared to a metal counterpart;

- hermetic connection by monolithic soldering of homogeneous materials;

- resistance to environmental influences, and specifically to rust;

- smoothness of the inner surface, which does not allow sediment to accumulate.

Plastic pipes, which do not appear durable, are in fact only susceptible to strong impacts and sudden compression. Even an increase in internal pressure is less dangerous for them than for pipes made of metal or metal-plastic.

When transporting hot water, the pipe can expand, thereby reducing the risk of rupture. There are no difficulties in deciding how to connect plastic pipes to each other so that water hammer does not lead to an accident: a high-quality seam makes the joint no less durable than the walls of the pipe elbow itself.

The disadvantages of plastic communications are not so obvious, but we should not forget about them. First of all, these are the properties of expansion when heated up to a certain point, which is an advantage.

With significant heating of the environment, pipes can not only expand, but also elongate, which leads to loosening of threaded assemblies and non-monolithic connections. The critical temperature for polypropylene is considered to be +140°C, and this level is quite achievable in the event of a failure in the heating system.

The consequences of such an incident do not seem critical: the risk that the pipe will burst is practically eliminated. But the pipe can bend significantly and even destroy the masonry if placed in a hidden manner.

However, the advantages of plastic pipes are difficult to overestimate. This is the optimal material for cold water supply: by specifying how to connect the tap to a plastic pipe, you can set up a summer shower in a country house in a matter of hours, without using any specific equipment.

In addition, manufacturers of reinforced plastic pipes cope well with the problem of resistance to heat. A layer of plastic or fiberglass forms a kind of skeleton inside the pipe, preventing it from deforming under the influence of heat and pressure. You just have to take into account that when installing communications, pipes made of monolithic plastic and reinforced ones are considered different materials.

When deciding how to connect plastic pipes and plastic pipes with reinforcement, it is impossible to do without additional fittings, such as plastic fittings.

Features of polypropylene pipes and fittings for them

Polypropylene pipes are very popular when installing hot and cold water supply systems, radiator and floor heating systems. This is explained by the fact that the products are characterized by strength, corrosion resistance, durability, resistance to high temperatures, and the ability to withstand freezing and thawing without changing the structure. Due to the presence of a smooth internal surface, the system does not become clogged and deposits do not accumulate in it, which is important for non-pressure sewer networks.

Polypropylene pipes are strong and durable.

Products made of polypropylene (photos clearly show this) can be solid or reinforced. The first type is suitable for organizing a cold water supply line, and the second is more preferable for installing a hot water supply system and a heating network. This is explained by the fact that solid pipes under the influence of high temperatures are capable of deforming in length, which reinforced products lack due to the presence of a frame made of fiberglass or aluminum foil. This contributes to a low coefficient of thermal expansion.

To join pipes of the same or different diameters, to form branches, corners and contours, special elements called fittings for polypropylene are used. Thanks to such fittings, it is possible to shut off the system and, if necessary, dismantle it. With the help of these connecting elements, a backbone network of any configuration and complexity is created.

The connection of polypropylene pipes and fittings is carried out by soldering the components of the system. As a result, it is possible to obtain reliable and sealed connections, which guarantees uninterrupted and durable operation of the network. The process is quick and easy due to the fact that polypropylene products are chemically neutral.

Installation of a pipeline made of plastic pipes

There is no question of how plastic pipes are connected to each other if they are the only material of the entire system. The plastic is mounted by soldering or connecting and/or distribution fittings made of the same material.

The use of metal components is not recommended: the difference in thermal conductivity will affect the quality of the connection. Methods for connecting plastic to other components depend on the material and type of reinforcement.

Building up

It is not difficult to understand how to connect plastic pipes for sewerage or water supply to extend them. The fitting for this type of material is a piece of a similar tube with a slightly larger diameter.

This capsule is placed over the cleaned and degreased edges and compressed with a special soldering iron set to medium temperature.

It’s not difficult to understand the working technique: soldering irons are designed for a certain standard diameter, so you don’t have to control the level of pressure and temperature. The connection turns out to be non-separable and even unnoticeable.

Connection with metal pipe

Connecting dissimilar pipes is more problematic. When figuring out how to connect a cast-iron sewer pipe with a plastic one or an outdated metal heating system with a modern one made of reinforced plastic, it is worth focusing on several important aspects:

- before choosing fittings, you must carefully measure the diameter of the metal elbow;

- to cut and strip a metal pipe you will need a grinder; The adapter between metal and polymer will be a plastic socket.

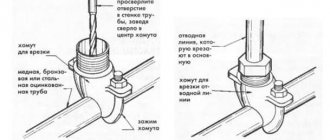

Having decided where and how to connect the plastic pipe to the cast iron one, you can begin installation. The operating procedure is as follows. The metal piece is cleaned and degreased. The seal is placed in the grooves of the socket and pressed tightly against the inner walls. After placing the pipes, the system is intercepted with clamps.

This technique is often used when installing a toilet. A successful alternative to such a system is a drain with a corrugated drain: since it is much easier to connect the corrugation with a plastic pipe.

Instead of fastening clamps, glue or sealant is used. Connection with a metal-plastic pipe To connect a plastic pipe with a metal-plastic pipe, collet fittings are used. Their basis is a thread applied to the outer part of the capsule. A pipe of the appropriate diameter is screwed onto it.

Collet fittings are commercially produced only for communications with a combination of materials, but also units designed for joining pipes of different diameters to each other. The use of press fittings with plastic materials is irrelevant.

You can install water supply and heating systems yourself, saving on calling a specialist. This can only be done if you are fully confident that your skills are sufficient to carry out such work.

Otherwise, the savings may be tripled to eliminate the consequences of the breakthrough.

Source: trubsovet.ru

Types of threaded pipe connections

Threaded connections are used for various cases. In order to make a connection, a special external pipe thread is cut, and on the connecting and attached elements, a pipe internal thread is cut.

The most common threaded connections include the following:

To do this, you will need fittings in the form of couplings - a small piece of pipe that has an internal thread with the same diameter on both sides.

Connecting pipe sections to each other.- Transitions between pipes with different diameters. This requires transition fittings in the form of couplings with threads located inside and with different diameters, or fittings - special parts with external and internal threads and different diameters.

- Rotate pipe wiring without laborious pipe bending operations. To do this, use carbon fittings with a rotation angle of 90 degrees. Much less often you can find and use fittings that have a rotation angle of 30 and 45 degrees.

- Branching and branching. Fittings in the form of crosses and tees are used.

- Connection of gas, plumbing and other appliances. To do this, use the threads on the fittings and pipes of the devices. For devices that need to be regularly disconnected, American ones are used - connection elements that have a union nut.

- Muffling pipes that are not in use and outlet pipes using various devices. Caps and plugs are used.

As you can see, there are not so many varieties.

Features of solderless connections

Connecting plastic pipes without soldering will not require large financial expenses. And you won’t have to get expensive soldering equipment from somewhere (obviously, not everyone has it) either.

It is worth admitting that the soldering process itself seems very complicated to some. A person must be able to properly handle a soldering machine, set the required pressure and temperature, and select solder. In general, in order to solder pipes efficiently, you really need to know a lot of nuances.

There is also an option such as soldering polypropylene pipes without a soldering iron. To do this, you simply take solder paste (this is a mixture of flux, solder powder and lubricant sold ready-made), apply it to the joint and heat it up.

Moreover, instead of a soldering iron, it is proposed to use a gas burner or lighter. But this method may also cause rejection for some, since here you have to deal with open fire.

Let's imagine a force majeure situation: there was a break in a plastic water pipe. It can take a long time to restore its seal by soldering. And restoring the tightness of pipes connected without soldering can be carried out much faster - this is a really important advantage.

Types and diameters of polypropylene pipes

Polypropylene pipes and fittings for them can be classified depending on the nominal fluid pressure in the system. There are four groups of fittings: PN10, PN16, PN20 and PN25. The first class includes products with a small wall thickness. They are able to withstand pressures of up to 1 MPa and temperatures of transported liquids of up to 45 °C. Products are produced with a diameter of 20-110 mm, have a wall thickness of 1.9-11 mm. Such elements are ideal for installing a low-temperature underfloor heating system.

The marking of polypropylene pipes PN16 indicates that the products are designed for coolant temperatures up to 60 °C and operating pressure in the system up to 1.6 MPa. You can use such PP pipes and fittings for high pressure water supply. Products are produced with a diameter of 20-110 mm, wall thickness - 1.9-11 mm.

The third type of elements is designed for operating pressure in the system up to 2 MPa. The temperature of the pumped liquid can reach 80 °C. Pipes are produced with a diameter of 10-73 mm with a wall thickness of 1.6-11 mm. These products can be safely used for arranging water supply and heating systems.

Polypropylene pipes are available with diameters ranging from 2.15 to 7.8 cm.

The last type of pipes, marked PN25, defines elements that can withstand pressures of up to 2.5 MPa and coolant temperatures of up to 95 ° C, which is achieved by reinforcing the elements with aluminum foil. The dimensions of polypropylene fittings and pipe dimensions are in the range of 21.5-78 mm (diameter), wall thickness - 2.7-16.4 mm. Such products can be used for installing a heating system and hot water supply line.

The diameter of the pipe is selected based on the throughput and resistance to the temperature of the pumped medium. Depending on this, for internal wiring of cold and hot water supply systems, you should choose products with a diameter of up to 25 mm. For external networks, elements measuring 40-100 mm are suitable. At the same time, for cold water supply, a cross-section of 20-40 mm and a wall thickness of 1.9-11 mm is sufficient, and for hot water it is worth purchasing products with a diameter of 20-100 with a wall size of 2.8-15 mm.

On a note! To create a reliable and durable system, you should choose pipes and fittings with higher characteristics than declared.

For internal sewerage, products with a diameter of 32, 40, 65, 63 and 75 mm are used, and for external sewerage - at least 100 mm. The heating system is laid using elements with a cross section of 16-75 mm with a wall thickness of 3.4-10.5 mm, which is determined by the dimensions of the room and the type of boiler.

PP pipes are divided into four classes, which are marked: PN25, PN20, PN16 and PN10.

Connection with fittings

To connect plastic pipes without soldering, press fittings (also known as compression fittings) or new Belgian push fittings, which are actually fixed by themselves, are very often used.

Standard press fittings are usually made from steel alloy or cast iron. And they are best used for polypropylene or other plastic pipes of small diameter.

The advantage of these plumbing products is that they can be used to build transitions between pipeline elements and connect them at different angles.

Most often, fittings are installed on bends and branches of a plastic pipeline. An ordinary press fitting consists of a main body, a cover, a sleeve and two rings: a clamping ring (it is located in a special socket) and a seam ring (it is used to fix the plastic pipe).

If we are talking about fittings with a diameter of less than fifty millimeters, then they can be installed manually, without additional devices and equipment.

And one more important rule. The plastic pipe must first be prepared before installing the fitting - cut, remove burrs, clean from dust and degrease. Such preparation must be carried out in any case, regardless of the chosen connection method.

After the plastic product is brought into an acceptable condition, you need to install a nut on it, previously removed from the fitting. Next, a clamping ring is put on this nut. Now you can insert the pipe into the fitting as far as it will go and secure it. The same actions must be done with the second pipe being connected.

Rules for the operation of plastic structures

Depending on how the selected plastic pipes are connected, it is possible to increase their service life of pipelines.

It is recommended to connect plastic pipes for water supply systems using welding units, since this connection method gives the best result of structural integrity and does not require constant tightening of fittings.

The correct location will be important, since in many cases the reason for violation of operating rules is physical impact and the inability to control the state of connections, if required. Another important point of operation is the use of the structure in temperature conditions that correspond to the technical characteristics of the product. If you plan to build a structure in rooms where the temperature will drop below zero degrees, it is recommended to use special insulating materials that will allow plastic pipes not to freeze during temperature changes.

Proper operation will allow you not to worry about the integrity of the pipeline for decades.

Using flanges

You can connect plastic pipes with flanges without soldering. This joint is considered very reliable - metal flanges can withstand enormous positive temperatures and high pressure.

Today, even large-diameter pipelines are equipped with flanges. They provide a really strong connection.

Flanges for assembling household plastic pipelines are always threaded on one side only. As a rule, they are designed for a pressure of 1.6 MPa. At the same time, in stores you can find flange options with different sections - from 20 to 1200 mm.

The connection algorithm using flanges is quite simple. First of all, you need to carefully pull the flange onto the pipe and put on the rubber sealing gasket. The gasket should extend beyond the edge of the plastic pipe no more than one centimeter. Then the flange is carefully pushed onto this gasket.

At the next stage, joining with exactly the same flange of another plastic pipe is carried out. And the bolts here should be tightened very carefully. If you apply too much force, the plastic surface may crack.

Types of material for making polypropylene fittings

PP pipes and fittings can be made using polypropylene of different compositions, which affects the thermal stability of the product. Depending on this, there are three modifications of the starting material: homopolymer, random copolymer and block copolymer.

Polypropylene fittings are available in homopolymer, block and random copolymer types.

The first type of products is marked PRN or PP-1. The elements are made of polypropylene with the addition of modifying additives in the form of fire retardants, nucleators and antiseptics, thanks to which the final product has certain properties. Such pipes and fittings are used exclusively for the installation of a cold water supply network.

The second type of polypropylene pipes and fittings is marked PPCR, PRR, PP-3. The material has a crystalline structure, which allows products to withstand a wide range of temperatures (from -170 to +1300 °C) without compromising the integrity of the structure. This type of PPR pipes and fittings belongs to the universal class and can be used for the installation of any engineering communications.

Products made from block copolymer are designated PPV, PP-2, PP-S. For their manufacture, a polymer is used, consisting of homopolymer micromolecules, which are arranged in a certain order. These products are characterized by increased impact strength, the ability to withstand high temperatures without compromising the integrity of the material, good resistance to bending and abrasion, low vapor and gas permeability, and excellent dielectric properties. This type of pipes and fittings is ideal for organizing a main hot water supply network.

The characteristics of polypropylene include a parameter such as MRS, which indicates the shortest duration of strength. This indicator determines the maximum permissible pressure in the system at which pipes and fittings can last about 50 years when transporting water at a temperature of 20 ° C. This characteristic depends on the wall thickness of the products.

Block copolymer fittings are characterized by strength and resistance to temperature changes.

The maximum permissible pressure value can be determined by the numerical value added to the abbreviation PN. The higher this indicator, the higher the pressure the pipe and fitting can withstand.

Using couplings

An ordinary coupling for plastic pipelines is a fairly simple part in its design. It consists of:

- cast iron body;

- two nuts;

- rubber gaskets;

- four metal washers.

The coupling can be found at the nearest plumbing store, or, if you have certain skills and knowledge, you can make it yourself. In this case, the characteristics of the coupling must strictly correspond to the dimensions of the products being connected.

Ordinary couplings are suitable for both pressure plastic pipelines and pipelines without pressure. With their help, they provide a reliable connection of polypropylene without the use of a soldering iron.

To form a connection, the ends of the pipes must be inserted into the coupling so that they touch in the middle. The ends must pass through washers, gaskets and nuts. Then you need to tighten the nuts tightly so that the pressure on the gaskets is strong enough.

Joining plastic pipes with a coupling provides a 100% sealed seam, even without the use of soldering. But in certain cases, for example, if the pipe is short or adjacent directly to the floor (or other horizontal surface), it is not possible to install an ordinary coupling.

For such difficult cases, a clamping coupling was invented. How to use it? First you need to clean the edge of the plastic pipe. Then you need to unscrew the coupling and put all the fastening parts on the plastic product in the correct sequence. Moreover, the sealing ring should ultimately be located at a distance of at least one centimeter from the edge of the product.

Then you need to insert the body of the clamping coupling into the end of the plastic pipe. And then you need to move all the existing rings to this body and tighten the bolt. And to the thread located on the other side of the coupling, it will be necessary to attach an “American” fitting with a plastic pipe connected to it.

To control the strength of the connection, you must carefully pull the coupling towards you, holding the pipe to which it is attached with your free hand. The coupling must remain stationary.

If it moves, it means that the wrong size part was selected. That is why it adheres so poorly to the pipeline. However, this is easy to fix - you just need to tighten the threads.

Connecting coupling for plastic pipes

Plastic products are widely used in individual construction and currently completely replace not only steel pipeline communications, but also many types of fittings, and for connecting HDPE in everyday life, plastic is the main component.

In a private house, a polymer pipeline made of cross-linked polyethylene and metal-plastic operates in heating systems, underfloor heating, hot and cold water supply. Ordinary polypropylene and its varieties (reinforced with fiberglass or PP-R aluminum) are widely used for heating and supplying hot and cold water to the house.

Internal sewage systems are installed from polyvinyl chloride (PVC) polymers, and outdoor sewer pipes (orange) are made from unplasticized polyvinyl chloride (UPVC).

Water pipes made of low-pressure polyethylene (HDPE pipes) are used to supply cold water to the house; in the industrial sector, polyethylene is a material for outdoor sewer lines and for laying gas lines.

In all the above examples, for domestic use, joining is carried out using couplings; special equipment is required for soldering polypropylene or installing press fittings.

Rice. 5 Compression coupling for HDPE pipes

Compression and press couplings for HDPE and metal-plastic PEX

HDPE pipes are used to organize individual water supply; they are used to supply water to a house from a well or a well, if the water intake is carried out by a submersible electric pump or station located in a caisson.

A solid line is laid underground without breaks, the water supply is connected only at the exit from the well and the entrance to the house, very often a polyethylene section is used as a pressure line and is connected to an electric pump, removed from the well head.

In all of the above cases, pipes are connected using plastic fittings; the peculiarities of their installation with a coupling are that they not only connect pipe sections, but also ensure their connection to the equipment.

Types of fittings for low pressure polyethylene pipes

Adapters are used to attach shut-off valves to the system. This type of fitting is used when connecting pipes made of different materials. To change the direction of the highway, bends with an angle of 45, 60 and 95° are installed. Tees and crosses are used to make branches.

To connect HDPE pipes, adapters, bends, crosses, tees, clamps, and flanges are used.

To create a secondary branch on the main line, you need saddles in the form of a clamp, crimp-type elements and linings, which are attached to the pipe by means of electrodiffusion welding. Such products are used for inserting new parts into an existing manifold and are often represented by fittings for 32 and 40 mm HDPE pipes.

Depending on the technology for connecting system elements, fittings for HDPE pipes can be one-piece, fixed using a welding machine, or prefabricated, which are mounted using plumbing wrenches. The second type of products is represented by compression, crimp, threaded, flange elements and press fittings.

One-piece products are designed for arranging an external water supply system. Installation of compression fittings for HDPE pipes is carried out using a union nut, and the reliability and tightness of the connection is ensured thanks to the O-ring. Threaded fittings are purchased for non-pressure systems and for joining cable ducts.

Flange elements are used when connecting a plastic pipeline to a metal one. Such products consist of a steel flange and bushing. The first part is fixed with studs or bolts to the mating flange, which is welded to the metal pipe, and the second part is connected to the plastic section of the line.

Flange fittings are used if you need to connect a HDPE pipe to a metal pipe.

Fittings for polypropylene pipes: overview of shaped elements

To install water supply, sewerage and heating systems, it is necessary to purchase different types of fittings for polypropylene pipes, thanks to which network sections, branches, transitions, bypasses, and connections to plumbing fixtures are connected. The shaped parts are represented by socket elements, as a result of which they are put on the end of the pipes, which are preheated using a welding iron. The sizes of fittings in mm for polypropylene pipes are selected according to the dimensions of the products.

Note! PP pipes and fittings for them must be made of the same material and designed for the same pressure and temperature of the transported liquid.

Polypropylene fittings can be made entirely of plastic or combined, in which case metal inserts with external or internal threads are pressed into place. The first type of product is used for any method of laying a highway, including hidden ones. Such fittings are characterized by increased strength and at the same time have a higher cost. The system elements are connected by soldering, which ensures reliable and tight seams.

In combined products, metal is combined with polypropylene. Fittings of this type are used exclusively for open installation or with a combined installation method, which involves partial installation of false panels, covering with tiles, decorative grilles or plasterboard, which is necessary to monitor the condition of the connections.

Fittings are selected for a specific size of PP pipe.

It is also important to know what types of fittings there are for polypropylene pipes based on their design principle. Shaped elements are divided into cast and segmented. The first option is represented by a one-piece product, which is characterized by maximum strength and reliability. Segment fittings consist of individual polypropylene elements that are connected by soldering. Such products have a large number of seams, which reduces their reliability, durability and cost.

Characteristic features of fittings for HDPE pipes

Low-density polyethylene is one of the types of polymers that is environmentally friendly, resistant to chemicals, able to withstand temperatures up to 80 ° C, abrasion resistance, high density, dielectric properties, good elasticity, which reduces the likelihood of damage due to water hammer. It is advisable to use this universal type of product for arranging cold water supply systems, sewerage systems, transportation of gaseous and liquid substances, as well as flammable gases.

Fittings for HDPE pipes are easy to install and last a long time.

On a note! There is a special type of polymer, the so-called cross-linked polyethylene, which is characterized by increased thermal stability, due to which it can be used for the installation of heating systems.

HDPE pipes and fittings can withstand pressure in the range of 6-16 atm. The products are characterized by a long service life, ease of installation and affordable cost.

Fittings for polyethylene pipes are produced in several types. To connect parts of the system, equal bore, compensation elements can be used, providing a transition from a larger diameter of products to a smaller one, and flange couplings (from a smaller section to a larger one).

Types of PVC fittings

Depending on the method of connecting PVC pipes and fittings, fittings can be adhesive, threaded, detachable, intended for soldering, or combined. The first type of fittings is fixed to the pipe using cold welding. PVC elements have sockets into which the ends of the pipes fit with a minimum gap, which are treated with special glue.

Threaded fittings are attached using a nipple equipped with a male thread and a nut. The elements are made of a more rigid polymer, which is characterized by a lower elasticity coefficient. This technical solution provides a high density of threaded connections.

Detachable fittings are mounted using elastic rubber couplings. Such products are not able to withstand high pressure. It is advisable to use them for installing a non-pressure drainage system. Solder fittings provide a reliable and tight connection using a low-temperature apparatus.

PVC fittings come in detachable, adhesive, threaded and combined types.

In combined versions, a pipe is glued on one side of the product, and on the other side a threaded connection is used using a union nut. This option is used in places with increased requirements for tightness and mechanical strength of fasteners.

Depending on the operational characteristics, fittings for PVC pipes are pressure (for water supply systems), non-pressure (for sewers and storm drains) and used for discharged environments. According to their purpose, PVC shaped parts are divided into connecting, branching and regulating.

Polypropylene is considered a universal polymer. Using products made from polypropylene pipes with your own hands using fittings, you can arrange various utility lines. Elements made of HDPE and PVC have some limitations in their scope of application, which is associated with the technical characteristics of the material. To create a reliable and durable system, it is necessary to purchase fittings and pipes from the same material, and an important criterion is the correct choice of method for installing network elements.

Fittings for reinforced polypropylene pipes

To connect reinforced polypropylene pipes, pressed and compression type fittings are used, which are made in a brass body.

For PP-reinforced pipes, compression and pressed fittings are used.

You can solve the question of how to make a detachable connection for polypropylene pipes using a compression fitting. The product consists of a body, a fitting, a ferrule nut and o-rings. The connection between the pipe and the shaped element is ensured by squeezing the sealing material when crimping the pipe. To do this, use an adjustable or open-end wrench to tighten the nut. The connection is characterized by reliability and durability. It can withstand pressure up to 35 bar. The service life is about 30 years.

Note! It is advisable to use compression fittings in an open installation of the system, where it is possible to observe the connection and periodically tighten the nuts if necessary.

The connection of polypropylene pipes without soldering is carried out using press fittings. Such fittings are represented by a body and a fitting with a crimp sleeve. To make a hermetically sealed connection you will need a special tool in the form of pliers. A system with such fittings can withstand high pressures of up to 75 bar, lasting about 50 years. It can be laid in both open and closed ways inside monolithic structures.

Characteristic features of American pipes for polypropylene pipes

Another name for a fitting for polypropylene pipes, made in the form of a detachable coupling, is American. Such elements are additionally equipped with union nuts. American ones are used in systems that require periodic removal of elements for cleaning. Such fittings are often installed in front of meters.

Installation of the American is easy and quick, which is done by tightening the nut. This not only facilitates installation, but also makes it possible to instantly shut off the pipeline in case of leaks. This type of fitting is convenient to use when replacing a section of a network or inserting new inputs. In this case, the pipes are not destroyed due to their rotation, since they remain motionless.

American fittings are produced in the form of a detachable coupling.

American fittings for polypropylene pipes are convenient to use for joining system elements in hard-to-reach places. Such fittings are equipped with their own seal, which eliminates the need to use additional gaskets, and the tightness of the connection is quite high.

Note! The American is considered a universal type of fitting and can be used as a coupling, adapter, plug and locking element.

Polypropylene American ones, depending on the design, come with internal or external threads, with a union nut and a solder end, as well as combined ones. The thread can be conical or cylindrical. The first option ensures high tightness of the connection without the use of additional gaskets and withstands the effects of aggressive environments and temperature changes. American women with cylindrical threads require the use of seals. Such units require periodic inspection with possible replacement of the worn gasket.