Arranging a country house in the absence of common communal water supply and sewerage systems is a difficult task for any homeowner. In addition to providing residents with drinking water, it is necessary to solve the problems of draining gray water and sewage, while not forgetting about the insulation of external sewer pipes.

This problem can be solved in various ways; to select the appropriate option, it is useful to know how external sewerage pipes in the ground are insulated and to study this technology. This will allow for proper and long-term insulation of the sewer system with minimal time and financial losses.

Rice. 1 Sewerage of a private house - device

Bury pipes deep into the ground

The most reliable way of insulation is to deepen them into the ground. The deeper the pipe is, the less likely it is to freeze. After all, at a certain depth the temperature does not change even in winter.

How to determine the optimal depth for laying pipes? It is impossible to give universal advice for every locality. In each climate zone, the soil freezes to a different thickness. In some areas it is enough to bury it a meter deep. In others, the ground can freeze up to two meters. Having consulted the climate atlas of your area and determined the depth of freezing, you will be able to carry out excavation work correctly. True, builders advise adding extra space and going a little deeper.

Burying pipes deep into the ground is a good option. However, in practice, this effective and low-cost method of insulation is not always used. Why? Excavation works cause complications even in cases where pipes must be buried a meter deep. If you need to dig deeper, you want to come up with another way to insulate a sewer pipe. In addition, the sites are often located in areas where excavation work is either impossible or very expensive.

By digging deep, you will create another problem. Let's say there is a problem with the system. You're not even sure if there's a leak, but you need to check the pipe. And to do this, you will have to turn over mountains of soil again, inspect, look for damage and bury them back. What if you need to replace one or more sections?

Thermal insulation materials

Insulation materials are often used to insulate sewers, for example:

Pipe thermal insulation diagram with material names

- foam or polystyrene - collapsible cylinders. This material is available in different calibers, where the inner diameter must exactly match the outer diameter of the pipe. This insulation has a special tongue-and-groove locking system, which is assembled like a shell;

- basalt fiber - or natural stone wool, which has positive characteristics and high thermal insulation properties. Thanks to the latest technological processes, thin threads are pressed into airy rolls or mats. A special cylindrical material is produced for pipes, the outer side of which is reinforced with foil - practically the most expensive type of insulation of all known, but also one of the most effective;

This is what basalt fiber looks like for pipe insulation - glass wool is the cheapest means of insulation, with good characteristics, but there are also disadvantages:

- It contains small glass fragments, so you need to work with it in special clothing, gloves, glasses and a respirator.

- It has the property of caking, which is why its thermal insulation properties are reduced to almost nothing.

- This insulating material must be protected from moisture - it absorbs it. Therefore, sewer insulation measures are carried out together with the installation of a protective coating.

Glass wool sewer insulation scheme - polyethylene foam – cylindrical shell, detachable. This material is very microscopic with excellent thermal insulation abilities. To improve insulation, models are produced with foil-coated outer surfaces. The sizes of the material vary, depending on the caliber of the sewer pipes.

In sewer insulation, other materials are also used for thermal insulation, for example, bulk materials:

An example of pipe insulation with expanded clay

- metallurgical slag;

- vermiculite;

- expanded clay

These materials are used to fill boxes with drainage systems. Sometimes the use of mineral wool and glass wool involves additional work to protect them, since under the weight of the soil, this material loses its properties.

Often the same pipe is used, only of a larger diameter, which is placed over the insulating material and acts as a rigid protection, thereby preventing the insulation from creasing.

Good or bad

The high price of a heat-insulating material does not always indicate its excellent properties. There are unscrupulous manufacturers, and among sellers there are those who like to “inflate” the price. Before choosing and buying insulation, you need to thoroughly study its characteristics and think carefully about everything. It is very good if you can get a sample and conduct some experiments:

- Bring a small piece of thermal insulation material to a bright lamp. Translucent - bad. If sewer pipe insulation allows light to pass through, heat will also pass through it. Such a check is not necessary for materials with additional coating (foil and the like).

- If we are talking about foam material, you need to look at the cut. The air cells should be small, ideally approximately the same. Large air chambers will not retain heat well.

- Set the sample on fire. High-quality insulation does not burn. Some materials for heat insulators are initially flammable, which can be eliminated with the help of special additives.

- Try to pull and tear a fragment of the heat insulator. If this happened very easily, the strength is in doubt. Such material can simply be accidentally damaged during the installation process.

This due diligence will help you make your final choice.

Why is insulation carried out?

Sewage performs an important function in human life - it removes waste and wastewater. We all know that the water begins to become covered with slushy ice already at zero temperature. All wastewater leaving the house has a temperature of +30-40 degrees. If the septic tank or storage tank is located close to the house, then there is no need to worry, since the water, traveling such a short distance, does not have time to cool to zero.

Drawing with dimensions of insulation of sewer pipes

An example of the internal structure of insulation for a sewer pipe

If the distance to the storage tank is large, then in the cold season, you may not have time to reach it and an ice plug will appear, which will grow over time. As a result, the sewage system stops working satisfactorily, and wastewater will accumulate in the pipes. As soon as the ice plug reaches a critical size, an accident may occur - rupture of pipes due to frozen waste. Based on the above, it is obvious that insulating communications is strictly necessary for its correct use. Insulating sewer pipes will help avoid such situations.

The process of insulating a sewer pipe

Insulation scheme

Insulation for sewer pipes

Since we are talking about insulating the external sewer system in a private house, let’s consider how to insulate pipes with your own hands

The most important thing in the process of insulating external sewerage is the choice of material that will determine the installation features and provide a given level of reduction in heat loss

It should be noted that sewer insulation, as a separate type, is a non-existent material. Those. There is no single solution, and in each case it is necessary to select insulation based on the individual characteristics of the pipeline.

Thermal insulation of sewer pipes is carried out by any of the thermal insulation materials on the market.

There are only two determining factors when choosing insulation:

climate zone. The lower the winter temperature, the lower the thermal conductivity index the insulation should have;

pipe laying method. The choice of pipe insulation depends on the depth to which the pipes are laid (below or above the freezing level). The technology for insulating external sewers using thermal insulation comes down to two methods: the pipe is wrapped with insulation in several layers or a box is built around it.

Which insulation for sewer pipes is better to choose?

A good building thermal insulator must meet a number of requirements:

- low thermal conductivity coefficient;

- ease of installation;

- resistance to various factors: moisture, biological activity, ultraviolet radiation, mechanical or chemical influences;

- tightness of insulation;

- resource of use;

- price.

Heating of external sewerage using cable

Electric cable is a modern means that is used to protect external sewers from freezing. This method of thermal insulation is much more effective than the previous one, which concerns the installation of sewage systems at a certain depth.

The electrical cable is laid along the entire external pipeline. The heating cable can also be used at important components of the sewer system. As a result, heating can be carried out at any temperature.

To heat the external sewerage system, a special cable is used. It is fixed with adhesive aluminum tape. First of all, the tape is applied to the pipeline. The cable itself is laid on top of it. After this, the tape is applied over the heating element. This allows you to securely fix the cable on the surface of the pipeline.

Video: insulation of external sewerage with a heating cable

This method has some disadvantages. First of all, this concerns an increase in energy consumption. If the electrical cable is laid over a fairly long section, this will lead to a colossal increase in the electricity bill.

It is also worth considering that a power outage will cause the cable to stop heating. A generator is used as a backup source. But its installation will entail significant investment.

Methods for insulating sewer systems

Let's look at several ways to insulate sewer systems that will save you money and won't take much effort during installation.

There are also several other easy ways to insulate sewer pipes.

Method one

The easiest way, it seemed, was to bury the pipes below the freezing level of the soil. But, taking into account that depending on the continental location, each city and suburb has its own level of soil freezing.

Burying pipes below freezing ground is one of the simplest ways. Click to enlarge.

And you will be lucky if it is no more than a meter on your site.

Then there are many more factors why this method of protecting sewer pipes may not be available.

The main factors include the structural features of the soil, proximity to groundwater, the presence of harmful substances and insects that destroy the structure of the pipes. Therefore, such insulation of sewer pipes may not be possible.

It is also worth taking into account repairs in case of a pipe break. It is not necessary that the water supply can freeze; there are a lot of influences, the results of which lead to malfunctions on any section of the laid pipe

It is not necessary that the water supply can freeze; there are a lot of influences, the results of which lead to malfunctions on any section of the laid pipe.

And in order to repair the damaged area, you will have to dig up the pipe again, and it will be good if it is noticeable where the breakdown occurred, and if not, then dig it out completely, and in this case you will have to change it.

So, although this method will cost you little, it is not practical.

Second way

The second method involves insulating sewer pipes by laying an electrical cable. This method is quite reliable, and applies not only to external insulation, but also in houses with a poor heating system.

And the main thing is complete dependence on power supply.

That is, if your electricity is turned off for some reason, you will not receive heating of the pipes.

The second drawback is the hefty bills for electricity consumption. And if something burns out there, or a pipe bursts, it can lead to a short circuit, or, even worse, a fire.

Third way

How to insulate a sewer system in a way that is not resource-intensive and safe, a method is proposed that involves the use of appropriate insulation materials.

Before purchasing such materials, you should pay attention to important properties:

- Durability

- Moisture protection

- Ease of installation

- Flammability

- Material cost

It is also worth considering the characteristics of the insulating material and the possibility of reuse.

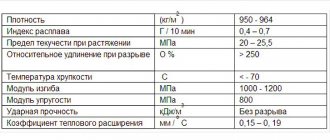

Foamed polyethylene as insulation

This material is produced by foaming polyethylene with carbohydrates. The final product has high elasticity and elasticity. Its structure has a closed cellular structure. It has the following release forms:

- Rolls;

- Sheets;

- Harnesses;

- Shell.

The density of polyethylene is 40 kg/m3, which is not so much. The thermal conductivity coefficient is approximately 0.05 kV/m*K. The thickness of the material is insignificant, which allows you to save space or insulate pipes where there is simply not enough space for other materials. However, to achieve better results and use polyethylene in rolls, it is recommended to wrap the pipes in several layers.

Let's consider the advantages of the material:

- Absolutely does not absorb moisture, which helps protect the surface of the pipes from the development of corrosion and condensate accumulation;

- It has noise and shock-absorbing properties, making it an excellent sound insulator;

- Despite its synthetic origin, it is environmentally friendly;

- Resistant to various aggressive substances, such as liquid concrete or cement, lime, gypsum, various oils and gasoline;

- High elasticity and flexibility allows you to insulate not only flat areas;

- Easy to install and reusable;

- Low cost.

For thermal insulation of sewer pipes, polyethylene in the form of tubes or sheets is best suited. Hollow cylinders are designed for insulating steel, copper, and plastic pipes with a diameter of 7 to 114 mm. In this case, the thickness of the insulating layer can be from 6 to 20 mm. For pipes with a large diameter or non-circular cross-section, it is more convenient to use sheets or rolls with an additional foil layer. The material is secured with special glue, staples or adhesive reinforced tape.

Ways to fight

You can avoid emergency situations and prevent sewer pipes from freezing in the ground by using the following tips:

The laying of the sewerage pipeline must be carried out to a certain depth. It is recommended to place it below the freezing level. The fact is that temperatures at this level do not fall below 1-2°C. This indicator is optimal and allows work to be carried out without the use of insulating materials. If the work is carried out by non-professionals, then this rule is not observed. Pipes are laid above the freezing level, which can create an unusual situation during severe frosts and lead to a breakthrough. This method of deepening is needed when sewer insulation is carried out in a private house, and the owners do not live here permanently. Special materials designed for thermal insulation should be used. The pipes are carefully covered with material that has high thermal insulation properties. It slows down the cooling process and heat loss. Pipe heating is also used using an electric cable specially designed for this purpose. If it is necessary to insulate a device that is subject to freezing, then the pipes are sloped. It is at least 2 cm for every meter. In this case, an electric cable is laid outside the pipe, performing the functions of a heater. In its absence, the pipes freeze, and the frozen water in them forms ice jams.

As a result, the sewer system fails. It is important to properly insulate ventilation pipes. They are located outside, and are brought to the roof surface from the sewer riser

Some of them come from underground and serve to ventilate a septic tank or sewer tanks. When wastewater evaporates, it settles on the inner sides of the pipes. Over time, they freeze and fill the entire system. Residents begin to smell the stench due to a broken ventilation system. The situation can be corrected by pouring a bucket of water into the frozen riser. Only after this should it be insulated. If an electric cable is used for insulation, it must be packaged in corrugation. A plastic container will also work. This will ensure the longevity of the ventilation system.

Insulation with mineral wool

According to the standards, the material belongs to the fibrous class and is made using molten rocks and metal slag. There are three main types of mineral wool:

- Glass wool - a mineral thermal insulation material that is obtained from the same materials from which glass is produced. It has received great demand due to its affordable cost and low thermal conductivity - 0.030...0.052 W/m*K. Cotton wool also exhibits good resistance to vibration loads and chemical resistance. Density in a loose state is no more than 130 kg/m3. Glass wool differs in its properties from other varieties. It has a fiber thickness of 3-15 microns, and a length 2-4 times greater than that of stone (basalt) wool. The insulation is resistant to temperatures up to 450 °C. The disadvantages include the fragility of the material and its increased fragility. Also, when working with this material, it is necessary to reliably protect your hands, since upon contact, small sharp needles easily penetrate through the gloves and cause an unpleasant burning and itching. Inhalation of air in which glass wool particles are floating is considered more dangerous. They immediately cause long-term irritation of the lungs and are eliminated very slowly. The same applies to the organs of vision;

- Slag wool – produced from slag waste obtained during iron smelting. It has high friability and residual acidity. In this regard, when used in conditions of high humidity, oxides form on its surface, which negatively affect the surface of plastic or metal pipes. The thickness of its fibers is 4-12 microns. The thermal conductivity index is significantly higher than that of glass wool - 0.46...0.48 W/m*K, as is the water absorption coefficient. In addition, slag wool has low environmental properties. The insulation retains its properties when heated to a temperature of no more than 300° C, but is unstable under temperature changes. Because of this, the service life is significantly reduced;

- Stone or basalt wool – made primarily from molten gabbro-basalt rocks. It is a non-flammable material that can withstand record high temperatures without starting the melting process - up to 870°C. However, when exposed to temperatures reaching 600-700°C, it begins to disintegrate and turn into dust. The structure of the material is porous, due to which it has high thermal and sound insulation. The thermal conductivity coefficient is quite low - 0.035...0.039 W/m*K. This is achieved due to the fact that the air in the pores of the material is in a static state. The vapor permeability indicator is 0.25...0.35 mg/m kV.*h*Pa. Stone wool density indicators range from 30 to 200 kg/m3. and depend on the form of release. For example, stone wool slabs can withstand a load of 700 kg/m2.

Glass wool and stone wool can be produced with an additional protective layer of foil, fiberglass or kraft paper. Stone wool does not absorb water, but constant exposure to moisture can gradually damage the structure of the insulation.

Installation of insulation for sewer lines in the ground

The insulation is installed when all the pipes have already been laid and connected to the sewerage system itself.

In this case, all pipes run at a slope of 1 centimeter per linear meter.

When installing insulation, you should pay special attention to ensure that there are no bare areas left, otherwise this whole procedure will be useless. The beginning and end of the pipe and joints are also carefully processed

In such places, you can put several layers of insulation to be sure.

The beginning and end of the pipe and joints are also carefully processed. In such places, you can put several layers of insulation to be sure.

Otherwise, installation of insulation is very simple and takes little time.

Installation features

Having chosen the desired insulation, immediately read the instructions for it, since each of them has its own characteristics.

If you are additionally doing waterproofing, you should immediately calculate how much material you will need.

More careful insulation and waterproofing should be done on pipe bends; any of the above materials will be suitable for this. Thanks to their convenient cylindrical shape and plasticity, they can repeat any bend without breaking.

You can additionally insulate sewer pipes using a pipe heating cable. It maintains the temperature of the pipe well, preventing it from freezing.

The cable can be an independent insulation, but most often it is wrapped on top with another layer of any insulation.

You can see an approximate diagram of insulation with a heating cable in the figure below.

Insulation with heating cable

This cable provides an almost 100% guarantee that the pipe will not freeze in any conditions.

Installation rules

Insulation with the selected material is carried out before filling the pipe with earth, and all pipe edges and seals must be sealed with sealant so that moisture from the pipes does not spoil the material.

If you choose foam shells for insulation, then you just need to put them on the pipe and additionally secure it with aluminum self-adhesive tape.

If it is mineral wool or basalt fiber, then they must be laid with the foil side out, as shown in the photo below.

Installation of glass wool with waterproofing

In this case, all joints must be glued with construction tape very carefully so that there is no access to moisture.

Also, pipes are insulated only in dry weather; dirt and other debris must be removed from them so that nothing prevents the insulation from tightly joining the pipe.

Laying pipes in the ground

As you know, soil has its own thermal energy, which is used when laying communications as insulation. Above-zero temperatures are achieved thanks to the deep layers of the earth, which warm up in the summer.

As you know, the level of freezing in all areas is different; in order to find out, just contact the meteorological service, or look at climate maps on the Internet.

The process of laying pipes in the ground

This method of laying pipes has limitations:

- High level of bottom waters. Wet soil is considered a heat exchanger - in cold weather, water cools the pipe. If the winter is cold, the water in the ground will freeze, which can lead to an ice blockage in the pipe. Of course, you can try to arrange a drainage system, but this involves additional costs, and it is not always effective, for example, communications lie in swampy areas.

Backfilling a trench with pipes with gravel - Permafrost in the northern regions. The earth does not have time to warm up in the summer. Therefore, there is always a subzero temperature zone at a certain level. At the same time, the soil layer, which never thaws, is tens of meters long.

- When laying the main line, it is necessary to maintain a slope that does not allow the sewer to silt. In permafrost conditions, this slope is impossible to maintain. Therefore, there is a high probability of defrosting due to stagnant water.

How to protect sewer pipes from freezing

- engineering;

- using insulation;

- active.

Engineering method

The engineering method is the simplest solution to the question of how to insulate sewer pipes on the street. It consists of the following - pipes are simply laid below the freezing level of the soil. As practice shows, for this they sometimes have to be laid to a depth of 2 m or more. For each region, depending on the climate, the laying depth will be different. This method is implemented as follows:

- A trench is dug to a given depth under the drain pipeline with a slope of 1 cm per meter of its length. The depth can be found in a special table for each region.

- At the bottom of the dug trench, make a sand cushion or a cushion of fine gravel (grain size no more than 20 mm), at least 10 cm thick.

- The pipes are being laid.

- Cover them with a layer of sand or fine gravel. The layer must be located above the pipe at a height of at least 20 cm and be thoroughly compacted.

- Fill the trench with previously removed soil.

Scheme of laying a sewer pipe below the freezing level

Thermal insulation method

What insulation to use is indicated above. The choice of material depends on many factors, among which, first of all, cost and thermal insulation properties should be highlighted.

So, let's look at how to properly insulate a sewer pipe. Installation of an external drainage system using thermal insulation material must be performed in the following sequence:

- The place where the trench will pass is marked.

- A trench is dug, and its width must be at least 60 cm, and its depth must correspond to the design data with a margin of 5–10 cm. The trench is constructed with a mandatory slope (1 cm per 1 linear meter) to ensure gravity flow.

- Sand or gravel at least 10 cm thick is poured into the bottom of the trench and compacted.

- The pipeline is assembled on the surface next to the trench.

- The seal and the edge of the pipe must be lubricated with sealant.

- The insulation is put on the pipe and fixed (usually with tape) so that it does not move.

- The pipe is lowered into the trench, covered with a layer of sand or gravel, and then compacted.

- Next, the trench is finally filled with soil, making sure that it does not contain stones, broken glass or hard soil.

Internal sewerage, as a rule, is not insulated. Only the riser exit to the roof of the house is subject to thermal insulation, since with a sharp temperature change it can simply burst. The material for insulating the riser can also be either mineral wool or foam polystyrene.

Thermal insulating shell for external sewerage pipes

Active method

The most expensive method of thermal insulation is the so-called active insulation. It consists of laying electric heating cables along the pipes. These cables, when heated, transfer heat to the pipeline and prevent it from freezing. The heating system is regulated by a temperature sensor with automatic equipment connected to it. As soon as the temperature around the external sewer system approaches zero, the sensor is triggered and the cable heats the pipeline. When the ground temperature rises, the system automatically turns off.

When using active insulation in practice, you will also need to install an insulation system, because the heating cable will heat the ground, not the pipes. This method is quite expensive both during implementation and operation, and not everyone can afford it.

How to insulate a drain pipe facing the street? The simplest and cheapest method is a foam shell, which will insulate it well. In everyday life, glass wool is more often used, which is simply wrapped around the drain pipe and tied with tape.

Scheme of heating a sewer pipe with a heating cable

Insulated external sewer pipes will last longer if one of the thermal insulation methods described above is implemented. In addition, when laying the system, it is recommended to use smooth pipes made of polyvinyl chloride and polypropylene with an orange surface.

Materials for external drain networks and their prices

Insulation for external sewerage should be chosen correctly, and the price in this case is an important factor. It is important to understand that the insulating coating laid in a well or septic tank will be the key to reliability.

Of the most popular materials for external drainage systems, we can highlight:

- Styrofoam. It consists of small granules. This option does not require additional waterproofing. This building material is produced by sintering granules. This product is very easy to use, is environmentally friendly and lasts a long time.

- Mineral wool. It belongs to the traditional options and is characterized by low cost. However, it is not preferred for sewer mains. Mineral wool cakes over time, plus it has a high hydroscopicity rate. Insulation made from wet mineral wool completely loses all the necessary protective properties.

Foamed polyethylene. This method of insulation for external sewerage is characterized by ease of installation. It is also not afraid of dampness; in such conditions, unlike the previous insulation, it will not lose its properties from getting wet. This type of insulation in rolls has a small thickness, so many layers must be wound onto pipelines for high-quality insulation. You can buy foamed polyethylene in the form of a canvas or in the form of ready-to-use covers of various sizes.- Expanded clay. This method is preferable for external insulation. They simply fill the trench where the highway is located. Only expanded clay is allowed to be used in dry recesses, otherwise its protective properties are lost.

Folgoizol. Produced in two types: SRF and FG. This building material is equipped with fiberglass, which is glued with plastic film. In the production of foil insulation, aluminum or corrugated foil and a bitumen-polymer binder layer are used. A special feature of this type is its very long service life in external communications.

Foamed synthetic rubber. This is a flexible, closed-cell insulation material. It goes on sale in the form of sheets and pipes. Tubular casings can be used for pipelines of any volume. Recently, the popularity of foamed synthetic rubber has decreased.- Expanded polystyrene. Made from suspension polystyrene. During the production process, a foamed material is obtained, consisting of granules securely welded together. The advantage of the material is its high rigidity.

- Penoplex. This is a foamed type that consists of a large number of granules. This option is called the most suitable because penoplex is able to withstand large mechanical loads. This property becomes very important in the current situation. It should be added to the above that penoplex, as an option for drain lines in the ground, can be used in conditions of high humidity.

- Isopon. Most often used as thermal insulation when laying domestic and industrial systems. Its main advantage is its strength and resistance to moisture. Laying isopon is very fast.

- Polyurethane foam. The peculiarity of this type is installation using a special installation, and this costs a lot of money.

- Extruded polystyrene. Has a cellular structure. Ideal for insulating pipelines that are subject to severe loads during operation.

- Basalt. It is made from basalt fibers, which are stitched with glass lines.

- Glass wool. It is characterized by high density. It is often used to insulate metal-plastic sewer pipes. During the thermal insulation process, it is necessary to use additional insulators that protect the insulation from negative environmental factors.

There are also other thermal insulation materials on the market that have certain differences. So, a popular option is considered to be insulation that has a foil layer. This layer reflects thermal energy, which improves the efficiency of insulation.

Foam plastic shells, which are easily mounted on external pipelines of any diameter, are also considered a good option.

Speaking about options for drain lines in the ground, it is necessary to note their affordable cost.

The exact price can be checked with managers when ordering. Also, when ordering, you can receive complete information about the selected product and its characteristics.

Insulation of hood for sewerage background riser

Separately, it should be noted the need to insulate the external sewer system, which means a ventilated background riser (exhaust) - a sewer pipe led to the roof (or to the surface of the ground from a septic tank) and providing ventilation for the pipeline.

The background riser is designed to suck in air so that the pressure in the system is equalized when the toilet is flushed. And in the septic tank, gases are formed from the activity of bacteria, which are also removed through the background pipe.

The ventilation (background) pipe can freeze (condensation freezes and an ice plug forms) and needs to be insulated. Any material that is reliably protected from moisture and destruction by ultraviolet radiation is suitable for thermal insulation. For example, you can put a Stenoflex “stocking” on the pipe. The part of the pipe that is located above the roof is insulated. And you cannot put a cap on top of the pipe; it must be free, otherwise it will freeze in this place.

How to insulate a background riser with your own hands

On the forum, one user suggested an interesting way to get rid of the build-up (freezing) of condensation in a background pipe.

You need to take copper wire (necessarily from pure copper, without braiding, this is important), wind it into a voluminous, but at the same time “liquid” lump (so that air can easily pass through it). Place this lump of wire into the pipe from above, and bend the ends of the wire so that you can secure the wire at the top of the pipe (otherwise it will fall inside)

Place this lump of wire into the pipe from above, and bend the ends of the wire so that you can secure the wire at the top of the pipe (otherwise it will fall inside).

The point lies in the chemical properties of copper; it has very high thermal conductivity. Warm air rises through the pipe, the copper accumulates heat and melts the freezing condensate.

Conclusion

Insulation of sewerage in a private house is an important measure that will maintain the normal flow of sewer pipes in winter, prevent freezing of the pipeline and extend its service life

How to insulate a sewer system in a private house

If there is a need to insulate a plastic sewer pipe in a house, you can use all of the above materials. From an economic point of view, ease of installation and aesthetics, the largest number of homeowners prefer isolon. It is simply fixed on the insulated surface through a side cut, and can be glued or connected with adhesive tape. An additional advantage of the material is its highest noise absorption among all heat insulators.

Fig. 11 Insulation of external sewer pipes in a private house with isolon

When deciding how to insulate underground sewers, they take into account climatic conditions, ease of work, and cost of materials. The optimal choice of insulation for underground sewerage, with a wide variety, is not too large - it can be an electrical cable or a shell made of hard, moisture-impervious materials - polystyrene foam or polystyrene foam. Often a combination of a heating cable and an insulating shell is used for thermal insulation.

Laying the pipeline below the frost depth

When laying a sewage system on your own, you can try to lay the parts to a depth that will be 10 centimeters below the soil freezing level. With this arrangement, additional thermal insulation of sewer pipes will not be required. Naturally, this is considered an ideal option, but it is used extremely rarely.

Causes:

- The presence of a large amount of work that will have to be carried out when preparing a trench for laying, as well as for digging a hole for a septic tank. If special equipment is not involved, then it is extremely difficult to make such a volume with your own hands.

- In the middle zone, the depth of soil freezing is one and a half meters. It turns out that the pipes will have to be laid to a depth of 1.6 m. In addition, the pipeline must be laid with a slope, so the septic tank must be laid at a depth of two and a half or three meters. The use of such a drainage system is irrational.

- When sewer pipes are too deep, it will be impossible to repair the drain, especially in winter.

It turns out that the choice of the option of deepening below the soil freezing level can be selected only in the case when it is possible to attract special equipment for the work.

Application of special cable

Insulation of sewer pipes in the ground is carried out using a cable that can be run along the surface of the pipe or along the inner wall. In the second option, the gasket is made in a special channel made of protected material. In the case of active insulation of the sewage system, pipes can be laid to a depth of half a meter. However, it is important to remember that such a sewage system will be energy independent. If there is a power outage in the area, the pipes will stop heating. For insulation, you can choose a self-regulating or regular cable. Of course, the second option will be much cheaper. However, the pipe will heat up along its entire length, which will lead to uncontrolled energy consumption.

Heating cable

Principle of operation

The principle of operation of a self-regulating cable is based on cyclicity, that is, only those parts of the system are heated where the temperature level drops below the permissible norm. The high price of a self-regulating cable will quickly pay for itself due to the low costs of maintaining performance.

Laying the main below the soil freezing level

Placing the sewer pipe below the freezing point of the soil seems to be the simplest option. It is enough to find out the indicator for your region in reference books and dig a trench of the required depth. But not everything is so simple, in addition to the significant amount of excavation work for the trench, one should take into account the depth of the septic tank. The main line for the gravity flow of wastewater must have a slope of 2 cm at every meter, this means at 10 meters the difference in the position of the pipe is 20 cm. In areas with cold climates, the freezing level reaches 1.5-2 m, and if you add a slope, you will have to significantly to deepen the septic tank, and this is irrational. Also, placing the highway at great depth makes repair work difficult.

Regardless of the size of the trench for the sewer pipeline, its bottom is carefully compacted and a sand cushion of up to 20 cm is poured. It is recommended that the pipeline be backfilled with sand to a height of up to 15 cm, and then the excavated soil is dumped into the trench. It must be sealed on the sides, but not above the pipe.

Laying pipes below the frost line

Advice. This method is acceptable when performing the entire volume of excavation work using special equipment.

Causes of external pipe freezing

Insulation of the external sewer pipe is not considered mandatory. With proper installation of the system, the wastewater does not stagnate in it, and its high temperature allows the liquid not to freeze while moving to the septic tank. Why do situations with sewer icing occur? At low negative thermometer readings, an ice plug may form in the pipes, precluding further use of the sewer system and causing a rupture of the system. Several factors lead to an emergency:

- An error in choosing the slope of the pipes - due to the slow movement of the drains, the water has time to freeze.

- Pipe diameter is less than 110 mm - insufficient cross-section causes freezing of drains over a long section.

- Emergency leakage of plumbing - a small volume of water does not have time to reach the septic tank and freezes in the pipe with gradual layering until it completely blocks the flow of waste.

- Placing pipes at shallow depths - laying a pipeline above the freezing level of the soil due to the reluctance to carry out a large volume of excavation work leads to the formation of an ice plug.

- Clogging - when large debris gets into the system, a plug of dirt and ice forms.

It is very difficult to warm up frozen pipes, because the pipeline is long and is located under snow and soil. Often this situation remains until warming occurs. Timely insulation of pipes will allow you to avoid difficulties in winter.

Installation of thermal insulation products

A big plus of pipe insulation is its ease of installation, which can be easily done with your own hands. The shell is selected according to the diameter of the pipe, usually the cross-section of the external sewer is 110 mm. The two parts are laid on the bottom and top of the pipe and taped along the seam and at the joints. For turns and bends, shaped elements are produced from polystyrene foam and polyurethane foam. If necessary, the material can be easily cut with a hacksaw.

Advice. To improve the thermal insulation properties, materials with aluminum coating (foil) are offered, but they are expensive. Such material will become effective insulation for external pipelines.