Countersinking: tools and features

Countersinking is an intermediate process for processing holes, usually located between drilling and reaming. This is semi-finishing of a hole with the purpose of:

- increasing hole accuracy to 4th and even 5th class;

- roughness improvements;

- giving a strict geometric shape.

Countersinking is also used when processing holes obtained by casting or pressure treatment.

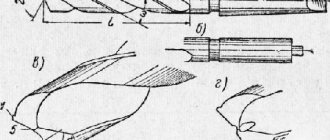

Processing is carried out using a countersink, a tool that looks similar to a drill, but has a number of design differences. The main differences are an increased bridge between the cutting edges, an increased number of working edges and a cut corner. All this ensures high stability of the countersink and its alignment with the hole being processed. Thus, the presence of 3-4 cutting edges ensures a smooth distribution of forces in the contact area of the countersink with the workpiece. The geometry of the cutting part ensures that the hole is processed without removing metal in the longitudinal direction.

Countersinks differ in the number of teeth (3 or 4) and design - mounted, solid and inserted. The choice of tool depends on the hole diameter. Thus, the use of plug-in countersinks (with plug-in knives) is recommended for holes with a diameter of 20 mm or more; solid ones are used for small diameters (from 12 mm).

To obtain more precise and complex surfaces, combined types of tools with a large number of cutting edges (up to 8) are used. In this case, prefabricated countersinks are used in conjunction with other metal-cutting tools - drills, reamers, etc.

Purpose of the deployment operation

The reaming operation is in many ways similar to countersinking. It is also designed to form holes of optimal size with the possibility of shape correction. But if countersinks prepare holes for the subsequent use of rivets and bolts, then reaming allows you to obtain precise calibrated niches for shafts, plunger parts and bearings. Also, the deployment of holes allows us to minimize friction in the treated area and ensure high contact density between elements. These objectives are achieved by reducing the roughness of the hole surfaces.

Equipment

For countersinking and countersinking, various types of drilling machines are most often used. A machining center or lathe can also be used - almost the same equipment on which drilling operations are performed. For both operations, it is not recommended to use hand tools due to insufficient positioning accuracy.

News

Oleic acid - in stock!

Oleic acid, coolant available

Carbide inserts - catalog expansion!

Large expansion of the range of plates in stock!

Face milling cutters

End mills in stock!

Articles

Grit of diamond wheels

Features, classification of grain size of diamond wheels

Tapered pipe thread

Tapered pipe threads: how to connect different threads

Metal beveling

Metal beading – sheet metal processing process

One of the main tools used when machining holes in metal parts is a countersink. With its help, the diameter is increased, the quality of the side surfaces of the hole is improved, and it is also possible to obtain a higher accuracy class. Countersinking, which is what this operation is called, is similar to countersinking, which can mislead a non-specialist. The difference between these two categories will also be explained in this article.

Countersinking technique

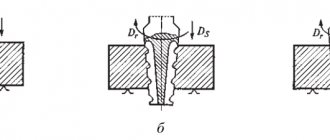

Typically, countersinking is performed on drilling machines. Just like drills, countersinks are installed in appropriate chucks or clamping mechanisms. Next, the outlet parts of the holes are processed with conical countersinks. This technique produces tapered recesses suitable for rivet heads and countersunk screws. Recesses for bolts are made in the same way, but with cylindrical countersinks. This tool is also used for trimming ends, selecting corners and protrusions. Both countersinking and reaming of holes on the machine are controlled by the operator. Modern models of pneumatic and electric machines allow processing in semi-automatic and automatic modes. CNC machines can use similar countersinking settings for serial part maintenance.

Countersink. Purpose and types of tools

A countersink is a tool designed for semi-finishing metal. Externally, it is a metal shaft with cutting surfaces, reminiscent of a drill. It is created specifically for the metalworking industry. Produced in accordance with GOST 12489-71, GOST 3231-71 or TU 2-035-923-83 in accordance with the type of device.

By type of fastening in the machine chuck:

By design features:

By geometric shape:

In the direction of the ribbons and grooves:

- right rotation;

- left rotation.

Solid shank countersinks are most similar to drills, but differ in the presence of more cutting edges. In their cross section there are from 3 to 6 such sharp teeth. For production, high-speed tool steels R9, R18 are used, as well as alloy plates with increased hardness and wear resistance VK4, VK6, VK8, T15K6. The permissible cutting speed for models with carbide inserts is higher, which increases their efficiency.

Mounted countersinks do not have a tail and are attached using a mandrel, for which a groove is provided in the body of the tool.

There are strictly 4 teeth in diameter. The nozzle itself is sometimes equipped with removable working blades made of hard alloys. The cutters are fixed with wedges and can be replaced as needed.

A conical countersink is similar to a drill; the working part of the tool tapers towards its end. Used for processing inclined circular surfaces. Manufactured from alloy steel and metal-ceramics.

The ribbons of the countersink drill can be twisted in different directions; accordingly, the profiles of right and left rotation are distinguished. Left-hand rotation countersinks are used in semi-automatic lathes that feed material from the right side.

The choice of type of countersink is directly determined by the size of the hole in the workpiece and its material. With a diameter of up to 12 mm, they work with solid countersinks, starting from 20 mm - with countersink attachments and tools with inserted alloy blades. When it is necessary to make smoother and larger holes, combined models are installed in the machine, where there can be up to eight sharp teeth, and these countersinks are optionally combined with drills, reamers and other drilling and cutting tools.

Deployment Tool

Reamers are also tools that resemble drills. The working part in this case is provided by teeth located around the circumference of the rod. In addition, there are auxiliary functional parts of the cutter. These are the intake, calibrating and cylindrical parts. Direct cutting is performed by a guide cone, the edges of which remove the metal allowance, but at the same time protect the top of the cutting edge from nicks. And here we can distinguish individual structural parts that distinguish between this technique and countersinking. Countersinking and reaming converge in cutting operations, but the calibrating portion of the reamer also serves as chip guiding and removal functions. Special grooves are designed for this, making the tool more independent.

The difference between countersinking and related operations

Countersinking is similar to reaming holes; the cutting edges of the tool remove excess material from the stenoctium, reduce roughness and increase the diameter. This is a semi-finish operation, which means it is followed by another processing step. Deployment is the final procedure. During countersinking, defects in drilling, stamping and casting are eliminated. In the process, you can slightly adjust the binding to achieve better alignment for the future connection. Accuracy can be increased to 5, and sometimes even to 4th class.

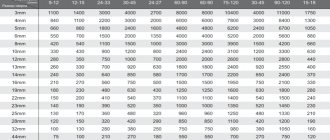

When setting the cutting mode, you need to remember that the thickness of the metal removed during countersinking is equal to half the allowance for a given hole diameter. Compared to drilling, the feed can be made 1.5-2 times larger, but the speed can remain the same. Specific cutting parameters are calculated using formulas given in the regulatory literature.

Since a countersink has greater rigidity compared to a drill, due to the increased number of sharp protrusions, the accuracy of the direction of movement increases, as well as the quality of processing, smoothness and cleanliness of the surface. For comparison, drilling gives a roughness of 20 microns and grades 11–12, countersinking gives a roughness of 2.5 microns, grades 9–11, and reaming gives a roughness of 0.25-1.25 microns and grades 6–9. Quality is the precision of manufacturing a part; as its value increases, tolerances increase and accuracy decreases. If the technological process for processing a product requires both countersinking and reaming, then they are performed in one installation and alignment of the workpiece on the machine.

Countersinking and countersinking are often confused due to the similarity of names. In fact, countersinking has a completely different purpose, and it uses a great tool called a countersink.

This type of machining creates recesses to accommodate fasteners flush with the surface of the part. In addition to chamfering, a countersink is used to cut conical-shaped recesses. Another purpose will be to clean and process recesses before installing fasteners; this is done using flat or end countersinks, also called counterbores, which is more correct.

The most widely used on the market are conical countersinks with working angles of 90 and 120º, which create recesses to hide the heads of bolts and screws. In the metalworking industry, countersinks with a flat tip are also used, used for cleaning recesses for fasteners. Countersinks are installed in the same machines as other tools for processing holes for fasteners.

Features of countersinking

Countersinking is the mechanical processing of holes to create various geometric recesses for the hidden placement of fasteners. It is also used for cutting internal chamfers. For these purposes, there is a special tool - a countersink, which has different shapes. The choice of countersink depends on the desired end result.

Main types of countersinks

- Cylindrical countersinks . They are used to produce cylindrical recesses in drilled holes for installing bolts and screws.

- Conical countersinks . Used for cutting cone-shaped holes inside a part, as well as for cleaning sharp edges, chamfering and preparing recesses for fasteners. The most commonly used tools are those with a cone angle of 90° and 120°.

- Flat or end countersinks, you can also see the name counterbore. Mainly used for cleaning and processing recesses before installing fasteners.

The countersink consists of a working part and a shank with a special pin that acts as a guide belt. The journal is necessary to control alignment during the process of cutting recesses.

How to countersink metal correctly

If an amateur craftsman can take a drill and a drill for countersinking, then in an industrial environment the following machines can be used for this:

The countersinking process takes place in strict accordance with the technology, the general points of which can be described in the form of the following recommendations:

- In cast parts with an uneven margin for subsequent metalworking, it is necessary to bore the hole to a depth of 5–10 mm for the correct direction of movement of the cutting tool.

- For the countersinking operation, an allowance of 1–3 mm is left, depending on the final diameter.

- Countersinking of steel products is not complete without cooling with special oil solutions. When working with cast iron, as well as non-ferrous metal, it is not mandatory.

- The optimal version of the countersink and the operating mode are selected taking into account the required hole diameter, processing accuracy, its depth, the metal of the part and the options of the production machine.

- The cutting tool mount must fit into the slot that is on the workstation.

- In the case where finishing processing by reaming is expected, then during countersinking a part of the allowance, from 0.15 to 0.3 mm, is left for further work.

- To process products made of hardened and alloyed steels, countersinks with carbide inserts with a diameter of 14-50 mm and 3-4 teeth are used.

- When processing non-ferrous metals and iron alloys with a high carbon content, feather countersinks are used.

- High-speed steel tools are used to process products made from ordinary structural steel. For holes larger than 40 mm, the equipment is supplemented with nozzles with a diameter of 32–80 mm.

The discrepancy between the process and the established technology is often the cause of defects. If the tool wears out a lot, the resulting hole will be smaller than the design. When the master has overestimated the feed, or waste has stuck to the teeth of the countersink, the cleanliness of the processing may not satisfy the quality. Other defects: part of the surface is not processed, the resulting diameter is larger than required, are the result of an incorrect choice of countersink or its incorrect installation.

Performing a deployment

Machine reaming follows the same principles as countersinking. The tool is fixed in the chuck and then directed to the area to be processed by the machine. The only difference is higher requirements for cooling the working equipment during operation and lubrication of the holes. Mineral oil, turpentine and synthetic emulsions are used as lubricants. Otherwise, manual processing of holes is performed. This type of reaming involves initially securing the workpiece in a vice. Next, the tip of the reamer is inserted into the hole and the result is achieved by twisting the knob. Moreover, the tool can be rotated only in one direction - until the necessary parameters of the product are formed.