Purpose and principle of operation

A reamer is used to ream holes - the process of finishing them mechanically after drilling or countersinking.

The use of this tool allows you to achieve a high class of roughness of the hole walls and the accuracy of their geometry. Depending on the type and characteristics, it is used to perform specific technological tasks, including calibrating holes and cleaning them from burrs at the final stage of part processing.

- A special feature of this tool is a large number of teeth (usually from 6 to 16), which allows you to remove a small allowance, thereby adjusting the actual dimensions of the hole to the required ones with high accuracy.

- As for the shape of the holes, you can work with a reamer either along the cylinder or adjust the cones for various tasks, for example, for installing tapered pins.

- The teeth of the tool remove a layer of material by fractions of a millimeter; processing occurs through its rotation, as well as simultaneous longitudinal feed.

Device and characteristics

A standard scan consists of the following parts:

- The working part has a direct impact on the material and is formed by longitudinal teeth.

- The transition neck is a cylindrical zone of the tool that acts as a transition link between the previous and next parts.

- Shank - necessary for clamping a tool in a driver or chuck of machinery.

The working part is divided into several zones formed by the edges of the teeth:

- The intake part, at the very beginning of which there is a guide cone. In this zone, each tooth has a sharply sharpened cutting edge that selects material from the inside of the hole.

- The calibrating part is responsible for calibrating the hole. Here the edges of the teeth form a so-called cylindrical strip (flat surface), which increases the dimensional stability of the tool.

- The rear cone is where the teeth join the transition neck.

- Between the teeth there are grooves that remove chips.

- They are straight (most common) and spiral (helical, preferable when working with discontinuous surfaces).

- In the latter case, the direction of the screw formed by the grooves is opposite to the direction of rotation of the tool.

- This ensures resistance to seizing and self-tightening.

Material

In the manufacture of reamers, we mainly use tool alloy steel grade 9ХС, as well as high-speed steels P18 and P9.

The grade of steel used in the production of tools is selected taking into account the material that is supposed to be processed.

Dimensions

- Cylindrical manual models reach a length of 80 - 360 mm, where the working part occupies 40 - 190 mm.

- The diameter of the tool is in the range of 3-50 mm, and the length of the cutting part is 4 – 10 diameters.

- The front angle is from 5° to 10°, and the back angle is from 5° to 12°.

- The length of the conical manual options is 55 – 170 mm, of which the cutting part occupies 24 – 90 mm.

- The maximum and minimum diameters of the cone reach 7.67 - 45.715 mm and 6.39 - 40.978 mm, respectively.

- As for machine reamers, in addition to standard options, there are models with an extended working part, the design and dimensions of which are specified in GOST 11175-70.

- Reamers with a diameter of 1 – 120 mm with an allowance for finishing are designated by numbers from 1 to 6.

- This numbering establishes a correspondence between the nominal diameter of the tool and its maximum deviations.

Teeth

- The number of teeth varies from 6 to 14 pieces, however, there are options for 16 teeth, which are used mainly on high-precision equipment.

- In general, the number of teeth depends on their own rigidity, and in inverse proportion.

- The more of them, the higher the cleanliness of the final hole, but the worse the removal of chips and the lower the strength of each tooth.

To make it easier to control the reamer diameter, the number of teeth is always set to even.

- Depending on the inclination of the teeth relative to the axis of rotation of the tool, the reamer can be straight-toothed or helical.

- In addition, different models may have equal or different pitches, that is, the distance between adjacent teeth.

- As for sharpening, there are sharpened (pointed) and backed teeth.

GOST

A fairly large number of regulatory documents have been developed for sweeps, among which the main ones are:

- GOST 29240-91 – types, definitions and terms.

- GOST 11173-76 – for models with allowance for finishing.

- GOST 7722-77 – for manual options.

- GOST 1672-80 – for one-piece machine models.

What is the difference between a reamer and a drill?

A drill is a tool that creates holes by drilling into a material. Reamers are physically incapable of drilling, but bringing already formed holes to the required dimensions is exactly what they are created for.

Both tools are similar in appearance, however, they are not interchangeable, that is, each of them is capable of performing only the task for which it was created.

It should be noted that the holes after the drill almost always have deviations in geometry, which are eliminated by reaming. The surface accuracy after using the latter is equal to quality from 6 to 9, while the roughness (Ra) is 0.32 - 1.25 microns.

Types of scans and their prices

Mechanical processing of holes can be performed with tools of different designs.

Solid scan

It has a monolithic design and is widely used due to its relatively low cost (from 20 rubles per piece). Solid versions are cast from high-speed or tool steel.

Mounted

- It is a tube, on the outer side of which there are teeth, and in the center there is a hole for installation on the shank, which is then mounted in the machine chuck.

- The diameter of such an instrument can reach 30 cm.

- Cost 300 – 1300 rubles.

Combined

It is a combination of two tools at the same time, and/or has two working surfaces. A striking example: a countersink reamer.

Unregulated

With fixed diameter.

Adjustable

Essentially a universal reamer, the diameter of which can reach 50 mm. This is a special tool that, due to the ability to adjust the diameter (albeit within small limits), can replace several non-adjustable options.

According to the adjustment method, it can be expanding or sliding. The average price is from 350 rubles, but can exceed 3 thousand rubles.

Awl-reamer

Designed for manual adjustment of holes in soft and thin materials, such as plastic, cardboard, plywood, thin and soft metal.

There are two options:

- tetrahedral, differs from a regular awl by a tetrahedral tip of small diameter, mainly used for paper;

- collapsible - consists of two parts: the handle and the tip itself. Here the hole diameter can be expanded to 14mm.

According to the shape of the working part, the development is:

Cylindrical

For use with standard holes. Cost – from 50 to 100 rubles.

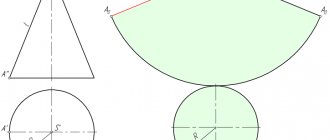

Conical

For processing both standard and conical holes, resulting in only a conical hole to fit the dimensions of the tool itself. The shape resembles a cone with a cut off top.

Price – from 50 rubles per piece, depending on the taper and diameter.

Stepped

It is much less common and looks like a conical version, but with a stepped bevel. Used for making holes in sheet metal.

Also, the division of the tool is carried out according to the accuracy of its work:

- According to the quality for cylindrical models.

- According to the quality of processing for conical. This can be a rough reamer (grinding, with teeth arranged continuously along the entire length), an intermediate reamer, and a finishing reamer for final finishing.

- By numbers from N1 to N6 for cylindrical options with calibration allowance.

According to the method of operation for which the tail section is manufactured, the reaming can be:

Manual

- For installation in a driver, with a square shank.

- The diameter usually does not exceed 50 mm, and as it increases, the difficulty of turning the tool increases due to increased friction.

- Price – from 20 rubles.

Which scan to choose and how?

When choosing reamers, you should take into account the characteristics of the upcoming hole processing, the nature of the holes and the result (final roughness and accuracy) that you want to achieve:

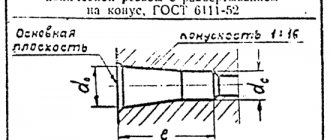

- For manual work, models with a square shank are purchased, and for processing on machines - with a cylindrical or Morse taper.

- If you need to ream an intermittent hole with a keyway, then a floating reamer or a model with straight grooves is not used. Here a tool with a screw arrangement of teeth becomes necessary.

- If you need to ream a hole whose depth does not allow the use of a standard tool, or a special adapter sleeve, you will need either a reamer with an extended mandrel or a model with an extended working part.

- For professional work, it is recommended to immediately purchase a set of reamers of different sizes, which are usually sold in a convenient wooden or plastic box.

From a purely economic point of view, the choice of reamers is influenced by the serial production.

So, if you plan to massively deploy holes on any scale, preference is given to universal options that can be configured, adjusted, re-sharpened or repaired.

These could be, for example, adjustable products, models with removable knives.

Of course, one unit of such a tool will cost more than simple one-piece options, however, in terms of durability they still occupy a leading position.

As for the dimensions of the purchased reamer, they always depend on the depth and diameter of the hole with which to work.

In terms of material, the situation is similar - to work with hardened or simply hard metals, a tool with carbide plates is required.

Hole reaming technology, reaming types

A metal reamer is used for finishing cylindrical holes of small diameters.

The accuracy and roughness of the reaming are higher than when using other blade tools, so reamers are used for finishing after drilling, reaming, countersinking or boring.

A typical reamer is a multi-edge tool with fixed or adjustable cutting surfaces and a cylindrical or tapered shank.

Reaming is performed with a small allowance and at low speeds, so its implementation does not require the equipment to have an adjustable cutting force. This operation usually does not have the problem of chip removal, since very thin chips are cut due to the presence of a large number of blades.

For all-metal products, the geometric parameters are ensured by high precision sharpening of the working surfaces, and for prefabricated adjustable reamers - by precision mechanical devices for aligning replaceable plates.

Reaming can be performed on machines of turning and drilling-milling groups. The main requirement for this type of processing is high accuracy of alignment of the tool and the reamed hole.

The essence and principle of deployment processing

In terms of its working movements, the reaming of holes is similar to operations using drills and countersinks. Even externally, many types of reamers (except adjustable ones) are similar to drills or countersinks, although they have grooves of shallower depth and a flatter cutting edge angle.

Their main functional difference is the high accuracy and quality of processing with quality up to 6 and roughness Ra from 0.5 to 2 microns. Such indicators are ensured by small allowances (from 0.05 to 0.5 mm) and a small cutting depth, as well as structural rigidity.

Reaming of cylindrical surfaces is carried out at low cutting speeds: with an all-metal tool - 5÷15 m/min, adjustable with carbide inserts - up to 40 m/min.

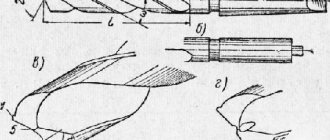

As a rule, reamers have straight cutting edges, but for reaming holes in viscous materials, a special type with spiral teeth is used. In the photo below there are two cutting parts: on the right - with spiral teeth, on the left - with straight teeth.

Main design elements

Both solid metal and adjustable reamers include three basic design components: the working part, the neck and the shank.

The first is designed to form a hole with a given geometry and profile and geometry, and with the help of a shank the rotational force is transmitted, which can be manual or machine.

The working part contains cutting blades, which can be straight or spiral. They are separated from each other by grooves. Their number is always even and can vary from 6 to 16.

The working part includes the following elements: an intake (cutting) part with a conical slope and a calibrating part with a reverse cone. Immediately behind it there is a neck, which is necessary for the exit of the grinding tool after finishing sharpening the reamer (adjustable ones do not have it).

The shank of the manual version ends with a square head for the wrench attachment, while the shank of the machine version is made in the shape of a cone or cylinder. The working part of machine reamers is several times shorter than that of manual reamers, so when cutting it is necessary to apply much more controlled force to them.

During the deployment process, the blades and plates become dull and lose both their cutting properties and their specified size. Therefore, in mass production, prefabricated adjustable products are usually used.

In this case, their sharpness is restored by replacing the inserted carbide inserts, and the size is adjusted using a diameter-adjustable body or by sliding out of the inserts using a threaded mechanism.

The principle of operation of sweeps

The hole is reamed either immediately after drilling, or after drilling or countersinking. The diameter of the reamer used, measured along the edges of the opposing blades (or the edges of the plates for the adjustable version), must exactly correspond to the specified hole diameter after processing.

The all-metal tool is brought to the exact size on special sharpening machines, and the adjustable one is set using built-in mechanical systems and measuring tools.

When fed into the hole, the reamer begins to work with the input cone of the cutting part (for adjustable ones, with the leading edges of the replaceable plates), removing the main part of the allowance as it moves. And bringing the hole to a given diameter and surface cleanliness is carried out by the next calibrating part.

At its rear end there is a reverse cone - a small section of the blades, beveled towards the shank with a height deviation of several tenths of a millimeter. It is necessary so that when exiting the hole, the back of the blades does not damage the treated surface.

For the same purpose, the rear part of the replaceable plates of the adjustable tool is made with a slight bevel back. A conical reamer works under more severe cutting conditions, so it has transverse grooves along the entire length of the blade to break and remove chips.

The rotating force is transmitted through a shank, at the end of which for manual reamers there is a square head for a wrench, and for machine reamers there is a conical or cylindrical end.

Modern all-metal and adjustable hole reaming tools typically have a modular design in which the working part can be used with different types of holders. In the video below: unfolding a stainless steel pipe on a lathe under the barrel of a rocket launcher.

Machining conical holes

Using the technological operation of reaming, conical holes can also be machined, which previously had a cylindrical shape or were drilled with ledges, for which drills of different diameters were used. Making a preliminary hole with ledges in such cases allows you to leave a smaller allowance for further development.

The implementation of the deployment of conical holes is practically no different from the technological scheme for processing cylindrical holes. To perform such a technological operation, as a rule, roughing, intermediate and finishing tools are used.

Sequence of processing of conical holes

To check the results of such deployment, a special cone gauge is used. In this case, the check is performed both along the plane of contact of the surfaces of the formed hole and the gauge, and along the depth of passage of the control tool.

Tapered center hole gauge (KKTSO)

This check is carried out according to the following scheme.

- Several pencil lines (usually 3–4) are applied to the side surface of the cone gauge along its axis, placing them at approximately the same distance from each other.

- Using slight pressure, the gauge is inserted into the tapered hole in the part.

- Then the gauge is turned 1/3 of a turn.

- Having taken out the gauge, check the condition of the pencil lines applied to its surface.

The fact that the deployment operation was performed efficiently is evidenced by the uniform erasing of pencil lines on all areas of the side surface of the caliber.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

Reaming holes

Reaming is a technological metal-cutting operation of finishing a hole to the required parameters. Using a reamer, you can change the shape and size of the hole, its accuracy class and roughness.

Let's consider the basic rules for carrying out this operation, what you should pay special attention to in order to obtain a high-quality result.

Tool used

The finishing of the hole is done with a special tool, a “reamer”, manually, on a drilling or lathe. It is subdivided:

- Depending on the installation location, manual and machine.

- The shape of the hole is cylindrical and conical.

- Depending on the type of fixation in the cartridge - tail and attachment.

- According to the location of the cutting edges - uniform and uneven. The latter make it possible to impart different degrees of roughness to areas of the treated surface.

Manual reamers differ from machine reamers in that they have elongated cutting teeth and a square shank for installation in a driver.

The tool, designed for drilling machines and electric drills, allows you to machine deep holes thanks to its short working part and long neck. The shank has a cylindrical or conical shape.

Order of operation

The selection of the reamer is carried out according to the type of tool (roughing, finishing, manual, machine) and its diameter. Rough ones have an allowance from 0.1 to 0.15 mm, finishing ones from 0.05 to 0.1 mm. To obtain a large diameter hole (for example, 30 mm) with the required roughness value, you must:

- Drill a hole with a diameter of 15 mm.

- Drill it out to a diameter of 29.8 mm.

- Perform rough reaming with a 29.95 mm tool.

- Complete the reaming with a finishing tool with a diameter of 30 mm, removing an allowance of 0.05 mm.

It should be noted that the accuracy of the resulting surface depends not only on the quality of the tool and the correctness of the operation, but also on the choice of cutting fluid. Thus, when processing steel products, an emulsion mixed with mineral oil is required, which is not used for bronze and brass.

Features of application

When manually drilling holes, you must adhere to the following procedure:

- Select a reamer based on the requirements for the hole parameters.

- Securely fix the part or workpiece in a vice.

- Insert the reamer into a pre-drilled or cast hole.

- Place the knob on the tool shank.

- Rotate the knob clockwise (in the direction of the cutting edges) avoiding sudden movements. During operation, periodically pour coolant onto the tool.

- After completing the roughing pass, the tool must be removed without turning back.

- Place a finishing reamer in the hole and put the knob on.

- Rotate with minimal feed clockwise.

- Once completed, remove the tool without reverse rotation and check the roughness and hole size using a gauge or other measuring equipment.

The cutting mode during machine reaming (speed and spindle rotation frequency) is selected according to special tables based on the diameter of the hole, the grade of steel from which the part is made and the material of the tool.

Before machine reaming, it is necessary to wipe the shank cone and the mounting hole in the spindle. When processing, the reamer axis must coincide with the axis of the hole in the workpiece.

Source: https://mekkain.ru/stati/razvertyivanie-otverstij-primenenie-poryadok-i-ispolzuemyij-instrument.html

Use of hand tools

Manual countersinking and deployment are carried out according to a similar scheme, which involves performing the following technological operations.

- Based on the parameters of the initial and final holes, a tool is selected to perform rough and finishing reaming.

- The workpiece is securely fixed in a vice if its dimensions allow this to be done. If it is of significant size, then it is not secured before deployment.

- A rough reaming tool is inserted into the hole in the part, which was previously obtained during the process of casting the workpiece or drilling it.

- A knob is placed on the tool shank, which has a square cross-section.

- The outer surface of the reamer and the inner surface of the hole are lubricated with a special liquid.

- The reamer, using a knob, begins to rotate in the direction of its cutting edges. As the tool rotates, which should be done slowly, without sudden movements, lubricant is constantly applied to its working surface. While rotating the reamer, it is necessary to carefully move it towards the processing, which ends after the layer of metal left for allowance has been completely removed from the inner surface of the hole.

- After the rough reaming is completed, the tool is carefully removed, but it is not allowed to rotate it back.

- A finishing tool is placed into the hole processed by a rough reamer, and a wrench is also placed on the square shank of the tool.

- The finishing reamer is rotated clockwise, and this rotation is carried out very smoothly and carefully, constantly using a lubricant. The amount of tool feed in order to obtain a hole with the required internal surface roughness parameters must be minimal.

- After finishing finishing is completed, the reamer is removed from the hole and its geometric parameters are checked using a smooth limit plug gauge.

Manual Deployment Techniques

Scan. Types and work. Application and care. Peculiarities

A reamer is a highly specialized metal-cutting tool designed to create a smooth surface inside previously drilled holes. It is used in cases where it is necessary to achieve perfect accuracy. The production of high-tech equipment, in particular internal combustion engines, machine tools and other mechanisms, cannot be done without it.

High processing accuracy is ensured due to the fact that the tool has several cutting edges, up to 16 pieces. During operation, an equal counterforce is created over the entire surface of the tool.

This eliminates misalignment, as happens with a drill that only has two cutting edges in contact. When using a reamer, a smooth surface is created, the roughness of which ranges from 0.32 to 1.25 micrometers, depending on the class of the reamer.

What does a scan look like and what does it consist of?

Externally, the tool is a rod along which there are multi-edged protrusions, sharpened to cut into the metal being processed. The number of cutting edges, depending on the modification of the tool, usually ranges from 6 to 14 pieces. A rare exception are 16-blade reamers, used only in high-precision production.

Main types of metal reamers

The classification of reamers is carried out according to various design, technological and functional characteristics. Among them are the main ones:

- by design features (all-metal, prefabricated, adjustable, etc.);

- by type of processing (cylindrical and conical);

- by force generation method (drive and manual);

- by processing class (roughing and finishing);

- according to the shape of the cutting surface (cylindrical and conical).

In addition, there are special types of reamers (both solid and adjustable), which are intended only for certain technological operations (step, boiler and others). Recently, the world's leading manufacturers have been producing systems of prefabricated modular tools for machining, in which different holders can be connected in different versions with both solid and adjustable cutting parts. The finished assembly can be classified according to how it is used.

Hand tools

Unlike a machine, a manual reamer is made with an uneven distribution of blades around the circumference.

This asymmetry of the teeth is done so that the next time the hand crank is turned, the cutting edge does not end up in the same place, since in this case the formation of a wavy surface is inevitable. The intake part of the hand tool has a gentler slope: no more than 2º, which makes work easier, since less force is required to cut it in. And its adjustable length is provided by a set of extensions with a square protrusion for the knob. Manual adjustable reamers are mainly used when performing repair work at equipment installation sites. There are two main methods of adjustment: changing the diameter of the body by spreading it and moving the cutting edges. The expanding reamer has slots along the blades and a conical hole inside the body in which the ball is located. A controlled increase in diameter occurs when the ball moves under the influence of the adjusting screw in the axial direction. When using adjustable interchangeable plates, the exact size is adjusted using a mechanism that allows the edges of the plates to be raised above the surface of the body.

Machine reamers

A machine reamer always has an even number of cutting blades (for an adjustable tool - replaceable plates), evenly distributed around the perimeter of the body. The level of processing directly depends on their number: the more blades, the higher the geometric accuracy and roughness class. Due to the absence of restrictions on drive power, such a tool has a short intake part with steep leading edge angles (up to 45º). To be compatible with machine tool spindle tapers and standard arbors, most machine reamers are manufactured with a tapered shank. To adjust the diameter increase, they use the same mechanisms as manual ones. This tool is universal, therefore it can be used with equal success on lathes, drilling and milling machines.