Corrugated sheeting is corrugated metal; these days it is actively used in construction. The popularity of corrugated sheeting is explained by its reasonable price, practicality, and aesthetic appeal. This material is distinguished by its purpose, the length of the sheets, their thickness, shape, and wave height. Corrugations are rectangular, trapezoidal, sinusoidal and even more complex in their structure.

Modern manufacturers offer us a variety of types of corrugated sheeting, each type of this material is designed for a specific purpose. It is no secret that absolutely all types of profiled sheets are made from rolled galvanized steel using the cold rolling method. It is the specificity of production that ensures this unique material preserves its polymer coating. The main types of corrugated sheeting are roofing, wall (also called “facade”) and load-bearing (used as a frame).

Relevance of marking corrugated sheets

Today, profiled sheets are used everywhere in construction.

It is difficult for a person who does not understand the nuances of construction to navigate the wide range of products presented. This situation complicates the selection of materials. To level out problems with selection, a system for marking corrugated sheets has been thought out, which can be deciphered as follows:

- The first letter indicates the type of material and scope of application, for example, roofing or suitable for building a fence.

- The first digit deciphers height values from 6 to 114 mm. The higher this parameter, the more loads the sheet can withstand.

- The second number indicates the thickness - from 0.45 to 0.9 mm. The load-bearing profiled sheet is made from thick steel, for walls - from thin steel.

- The third number indicates the width of the profile material. The indicator depends on the height of the profile - the larger this parameter, the narrower the corrugated sheet. Maximum values – 1150 mm.

- The last digit in the marking code is not always prescribed by the manufacturer, since it indicates the maximum length, which reaches 12,000 mm.

Bent profiled sheets with trapezoidal corrugations are produced in accordance with GOST 24045-2016. The regulatory document provides technical conditions for the manufacture of products. Gosstandart also determines the requirements for raw materials, coating, completeness, dimensions, etc.

Types of metal profiles

Profiled sheets, although they do not have such a variety of types as metal tiles, still, as they say, there is plenty to choose from.

Types of profiled sheets:

By type of decorative coating:

- Galvanized - a profiled sheet of light gray metallic color without applying decorative colored coatings (often used for cladding the frame of prefabricated buildings, construction sheds, hangars, retail boxes).

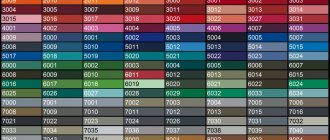

- Polymer – galvanized sheet with subsequent application of a colored (smooth, embossed, matte, glossy) decorative layer. This is the most common finishing option for profiled sheets. In this form, corrugated sheeting is used for fences and roofs in private housing construction. The material used to create various types of metal profile coatings is the same as for metal tiles (for detailed characteristics of the polymer layers of corrugated sheets, see here).

- Printech is a type of polymer coating when a pattern imitating wood, stone, or brick is applied to a galvanized sheet using offset printing. This metal profile is used for fences and wall cladding.

- Paint and varnish - instead of a polymer coating of corrugated sheets, a layer of paint 40-300 microns thick is applied. Painting a metal profile is the worst option, because... Periodically it is necessary to restore the paintwork. At the same time, if you paint the sheets with your own hands, you cannot achieve an even layer of equal thickness. In addition, peeling paint on a corrugated sheet looks unsightly.

By number of painted surfaces:

- Double-sided - decorative coating is applied to the front and back sides of the sheet. This metal profile is used for structures that can be viewed from both sides (fences).

- Single-sided - one side is tinted according to the RAL system, the other is a gray metallic color. Such profiled sheets are purchased for cladding walls and roofs.

By purpose:

- For fences and wall cladding (facade). Wall corrugated sheeting does not carry a special load, therefore it has a low profile height. For more information on which sheets you should buy for a fence, see here.

- For the roof. A roofing metal profile differs from a wall profile in its greater rigidity (due to the need to withstand snow loads) and the method of longitudinal connection (overlapping). In addition, an anti-condensation coating can be applied to the inner surface of the roofing sheets. Read more about corrugated roofing here.

- For loaded floors. Such sheets have the greatest rigidity due to their high profiles. They are made of metal with a thickness of 0.7-1.3 mm.

Also, corrugated sheets vary in size and thickness of the sheet, height and profile shape. Next, we will consider in detail the technical characteristics of profiled sheets.

Explanation of markings

Traditionally, profiled sheets are made from sheet steel coated with aluminum or galvanized aluminum. In the latter case, the marking on the profiled sheet is designated as “AC”; in the first case, there is no designation. However, if electrolytic technology is used to deposit zinc, the abbreviation “EOTSP” is established.

The material is also covered with an aluminum layer, which is reflected in the marking as “AL”, or with aluminum-silicon – “AK”. These types of spraying increase the wear resistance of the sheet, so the material belongs to the premium class.

To decipher the markings of corrugated sheets, it is enough to familiarize yourself with the alphanumeric designations.

Letters

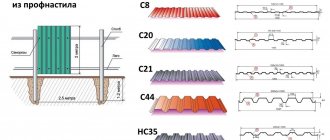

Wall corrugated sheet C8

The first in the designation is the grade of corrugated sheet, consisting of one letter or set. To decipher letters, you also need to know the purpose of the material. After reviewing the information, you can independently choose the appropriate material, according to the requirements and purposes of construction. The basic classification is as follows.

- MP is a metal polymer. This material has high strength. Used as decorative protection for the product. The characteristics include the size and type of wave. The basic properties are similar to polycarbonate, used to create transparent inserts on the roof. This type of corrugated sheet is often used for roofing in the attic. Strength depends on the thickness of the product. The most reliable models can withstand wind forces of up to 25 m/sec.

- N – carrier. The designation of corrugated sheets with this letter indicates that the material is suitable for covering roofs, fences, and is also used for cladding frame houses. A high level of rigidity and strength is achieved by increasing the parameters of the waves and central grooves. The corrugated product can withstand strong gusts of wind, snowfall and other atmospheric phenomena.

- C – wall. Material with such a letter has low load-bearing properties. The product is used only for cladding structures from the outside. Due to its small thickness and relief, the profiled sheet is vulnerable to physical influences and wind.

- NS – load-bearing-wall. The presence of such markings on a corrugated product expands the scope of application. The material is used for cladding houses, industrial buildings, canopies, roofs and permanent formwork. The presented brand is available for purchase at the construction market or in a store.

The dimensions of the product are indicated in the sequence - height, width, thickness (mm).

Numbers

Deciphering the markings of a profiled sheet, you can see that the code consists of a set of letters and a combination of numbers that indicate the technical characteristics of the corrugated product. The first characters indicate the profile height, measured in millimeters - 20-75. The higher the indicator, the more pronounced the structure and relief of the product.

The second number is also indicated in millimeters and shows the user the strength properties and degree of rigidity. The third symbol indicates the width for installation, which may differ depending on the brand. The last number stands for the maximum length of the material. All indicators are measured in millimeters.

Necessary materials for construction

A standard set of materials for building a fence with your own hands consists of the following elements:

- Sheets of corrugated sheets.

- Metal poles or pipes with a round or square cross-section. They are installed vertically with an indentation of 2.5-3 meters.

- Transverse pipes that need to be fixed in 2 rows (if the pillars are higher than 2 m, then there may be more of them).

- X-brackets or welding to attach crossbars.

- Colored roofing screws or rivets for fastening corrugated sheets.

- Paint and primer to protect metal surfaces from corrosion.

Material calculation example

Fencing construction scheme

To perform calculations, it is necessary to measure the length of the perimeter of the site, determine the width and position of the gate. After you have found out the necessary data and decided on the choice of metal profile brand, you can calculate the material consumption using the dimensions of the corrugated sheet for the fence, which we indicated above (see also the article Calculation of a fence from corrugated sheets: calculator, calculation diagram and work planning).

Let's say we decided to make a fence whose perimeter is 100 m, and the standard height is 2 m, therefore, we will take the cladding of this height. To cover the fence we will use C20 corrugated sheet. The posts need to be fastened every 2.5 meters. If you buy a ready-made gate, then subtract its width from the perimeter.

In our case, the instructions for calculating materials will look like this:

- Divide 100 m (perimeter) by 1.1 m (useful width C20) = 90.9. It is advisable to make a supply, so we will purchase 92 sheets.

- Now let's count the number of pillars. We divide 100 meters by 2.5 and get 40 pieces, add to this amount 3 posts for the gate and gate, we get 43 pieces. We calculate their height taking into account the deepening into the ground of 1-1.5 meters.

- To calculate the lag, we simply multiply the total perimeter by 2 rows, we get 200 linear meters of transverse pipes.

- We buy fasteners at the rate of 8 pieces per square meter (approximately every 12.5 cm). To do this, we calculate the area of the skin by multiplying its height by its length: 2 * 100 = 200 m2. 200 * 8 = 1600 fasteners.

The final price of construction will depend on the profiled sheet you choose and the height of the fence. the number of logs, the method of fastening the pillars, the presence of a wicket and gate. The photo below shows the approximate cost of construction, by which you can compare the costs of various configurations.

Comparison of prices for metal profile fencing

As you can see, galvanized sheathing is the cheapest. The polymer coating will cost almost the same, but its appearance is much more presentable. Double-sided polymer coating is the most expensive, but it protects the metal from corrosion as much as possible and increases the beauty on both sides.

Popular brands

Profiled sheet C10

Corrugated products can be used not only for cladding buildings and erecting fences, but also for making canopies and canopies. When choosing a model, pay attention to the alphanumeric dialing.

C10

The most popular model of corrugated product, which in terms of performance is not inferior to polymer siding panels. However, due to the small thickness of the steel, the material does not have high reliability parameters. The brand is inexpensive and, when painted, imitates lining.

C17

This marking often denotes corrugated sheets with a galvanized coating. The model is universal in application and has a distinct structure. The building material is used for cladding frame structures, creating canopies and roofs on outbuildings. Sheets can be painted and decorated on both sides with a protective coating.

C18

Wall material with increased height. Products are made from durable steel. Despite belonging to the load-bearing category, the corrugated product is used to create pitched roofs in regions with low levels of precipitation. The material is also suitable for constructing temporary fences.

NS 44 1000

Similar markings are applied to universal profiled sheets. The model has mounting parameters - 1 meter. The main area of use is the construction of fences and roof coverings. In this case, the quality corresponds to the price charged.

NS 35

A universal version of profiled sheets. Flooring with this designation has a long service life. The scope of application of NS35 is quite wide, for example:

- erection of temporary fencing;

- construction of fences;

- creation of roofing;

- exterior wall cladding;

- arrangement of partitions in utility rooms, warehouses, pavilions and hangars.

The thickness of galvanized corrugated sheeting of 0.8 mm ensures the reliability of the structure. The owner does not have to worry about the safety of the structure even in aggressive environmental conditions.

The manufacturer must attach an accompanying document with technical designations to each shipment of products.

Criterias of choice

To ensure that the corrugated roof covering does not allow water to pass through and lasts 20-25 years, it is necessary to choose the right material in accordance with the technical features of the design. Experienced craftsmen claim that roofing profiled steel sheets must meet the following requirements:

- Experienced craftsmen use profiled sheets with a polymer coating for roofing, as it better protects the material from corrosion. The paintwork is easily damaged during operation, which is why it lasts less.

- When purchasing corrugated roofing sheets, pay attention to the metal content of the zinc coating of the material. Economical options last less than premium ones, protecting the steel base less well from contact with water.

- The wave height of the roofing profiled sheet should not be less than 20 mm to ensure the outflow of melt and rain water from the roof slope.

- To save material, choose corrugated sheeting with the maximum usable sheet area. Typically, 7-wave options are considered the most economical.

- If the material is purchased directly from the manufacturer, it makes sense to order sheets with a length corresponding to the size of the slope in order to remove horizontal joints.

Experienced roofing craftsmen advise that when choosing a material, pay attention to the appearance of the corrugated sheet, the integrity of the packaging, and compliance with the GOST markings. There should be no damage or scratches on the surface of the sheet, the edges of the corrugated sheet should be smooth, without chips, then it will last the period stated by the manufacturer.

Options for using corrugated sheets

Installation of profiled sheets

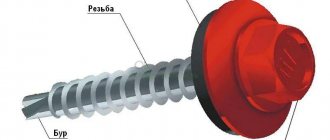

When installing corrugated sheets, it is important to ensure a strong fixation of the product. Self-tapping screws used when installing corrugated steel sheets must be securely attached to the deck. The average number of self-tapping screws for securing one sheet of corrugated sheeting is 6-8 pieces. In order to ensure the quality of the building's design, it is advisable to select self-tapping screws that have a color similar to the steel sheet. Painted fasteners are protected from exposure to precipitation, which increases the service life of the product.

When installing fences, self-tapping screws with a rubber washer are used. To fix one sheet used to make a fence, an average of 5-8 fasteners are required.

Production of corrugated sheets