Metal drilling tools and equipment

The following basic tools and equipment are used for drilling metals.

- Household and industrial drills.

- Holders for them, rigidly fixing the tools and allowing them to be fed smoothly and accurately.

- Portable drilling machines.

- Stationary machines for metal drilling (vertical and horizontal types, deep drilling, etc.).

- Various metal drills.

Photo No. 2: portable drilling machine ECO.50-T on a magnetic base

How to drill in the right place?

If you think about this question a little, the answer should come to your mind even without a hint. Well, at least it seems so to me. But if you don’t want to think, then read.

For this case you will need a core. This is a tool made of durable steel, having a cylindrical shape and a point at the end.

We place the tip at the desired drilling location and hit the roll on the other side with a hammer several times.

Now that you have finished drilling, place a drill on the surface of the roughness and start drilling - the tip will not run away anywhere.

Technologies for drilling holes in metal used in everyday life

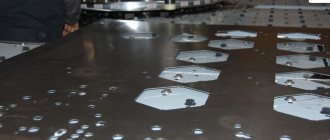

In everyday life, three technologies are used for drilling holes in metal. Workpieces and sheets are clamped using clamps and a vice. Most often, ordinary household drills and cylindrical twist drills are used at home.

Conventional drilling

This metal drilling technology is familiar to everyone.

- Marking is taking place.

- The hole is marked using a hammer and center punch.

- The workpiece is clamped in a vice or using a clamp.

- A drill of the required diameter is inserted into the drill chuck and clamped.

- The tool is centered.

- Drill a through or blind hole.

Photo No. 3: drilling metal at home

Reaming

Metal drilling is a technology aimed at increasing the diameter of a previously made hole. To do this, take drills of large diameters.

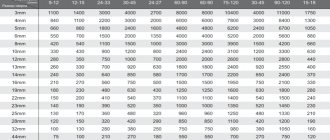

At home, holes usually have to be drilled in stages, gradually increasing the diameter of the tools used. This is due to the fact that in many cases the power of a household drill is not enough to drill large diameter holes in thick workpieces. In addition, the step-by-step approach reduces the axial pressure on the drills. This significantly reduces the likelihood of breakdowns.

Image No. 1: the principle of drilling large diameter holes in thick metal at home

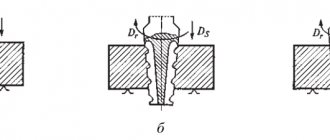

Reducing the diameters of the deep parts of the holes

In this drilling technique, a shallow, large-diameter hole is first drilled and then smaller tools are used. The technology looks like this.

Image No. 2: technology for reducing the diameters of holes in metal

Technologies for drilling holes in metal used in industry

In industry, more complex types of metal drilling are used. They use massive two-handed drills and special machines for drilling metal (portable and stationary).

Let's talk about the features of various technologies for drilling metal in production.

Metal deep drilling technology

Deep drilling is the drilling of a hole in metal whose length is 25 or more times the diameter. This operation requires forced periodic removal of chips and the use of cutting fluids (coolants). They are needed to cool the tool and workpiece to prevent breakage and deformation.

The process of deep metal drilling involves the use of different coolants. They are selected depending on the materials of the workpieces. Let's list the most effective cutting fluids.

| Workpiece material | coolant |

| Stainless and heat-resistant alloys | A mixture consisting of oleic acid (20%) and sulforesol (80%). The latter can be replaced with kerosene (30%) and sulfurized oil (50%) |

| Aluminum and alloys based on it | Kerosene, emulsion, mixed oils. Allows deep drilling without cooling |

| Nickel | Emulsion |

| Copper | Mixed oils, emulsion. Deep drilling without cooling is allowed. |

| Brass | Emulsion (3–5%). Deep drilling without cooling is allowed. |

| Zinc | Emulsion |

| Bronze | Blended oils. Deep drilling without cooling is allowed. |

| Iron casting | Kerosene, emulsion (3–5%). Deep drilling without cooling is allowed. |

| Malleable iron | Emulsion (3–5%) |

| Alloy steel | Mixed oils |

| Tool steel | Mixed oils |

| Structural steel | A mixture of sulfurized oil and kerosene |

| Carbon steel | Sulfurized oil, emulsion |

Photo No. 4: deep drilling using cutting fluid

For deep drilling, spiral and core drills for metal are most often used. Coolant is added manually or using automatic supply systems equipped with specialized machines.

The technology of deep metal drilling does not involve haste. Periodically, the process is stopped, the drill is removed and the chips are forcibly removed. When using spiral tools, deep drilling is carried out in stages, gradually expanding the hole to the desired diameter.

Technology for drilling thick sheets of metal

To drill thick sheets of metal, either cone drills (for holes with a diameter of up to 30 mm) or core drills (for holes of large diameters) are usually used. They are equipped with drilling machines or powerful drills. The main requirement is that the equipment must support operating mode at the lowest speeds.

Photo No. 5: core drills for metal

The technology of drilling thick sheets of metal with core drills is highly efficient. Energy consumption is minimal. Holes after drilling with crowns are smooth and precise.

Technology for drilling thin sheets of metal

Tapered drills are usually used for drilling thin sheets of metal. With this technology, the diameter increases gradually. The sheets are not deformed.

Photo No. 6: drilling thin sheets of metal with standard cone drills

If step-type conical drills are available, these are the ones to use. Marked steps make it easy to drill a large number of holes of a certain or different diameters in one sheet of metal.

Photo No. 7: drilling a thin sheet of metal with a conical step drill

Features of drilling through holes in metal workpieces

The main feature of drilling through holes in metal workpieces is the need to protect the surface of a workbench, tabletop or machine from the drill going far beyond the boundaries of the workpiece. To avoid damage to tools, furniture and equipment, craftsmen use the following methods.

- Use workbenches with holes.

- Place a wooden block or metal part with an existing hole under the workpiece for free passage of the drill.

- Reduce cutting speed when drilling is completed.

Photo #8: Using a wooden backing when drilling metal

Features of drilling blind holes in metal workpieces

Blind holes are drilled to a certain depth. There are the following methods to install it.

- Use of rulers available on machines.

- Installation of sleeve stops on drills.

- Limiting the length of drills using chucks with adjustable stops.

Photo No. 9: drill with bushing stop installed

Modern machines are equipped with automated feeding systems. If it is available, the technology for drilling blind holes in metal is greatly simplified. You just need to set the cutting parameters.

Note! When making long blind holes in thick workpieces, it is necessary to interrupt the metal drilling process several times to force the removal of chips.

Technologies for drilling complex holes in metal workpieces

Half holes at the edges of the workpieces are drilled like this.

- Clamp two workpieces or a workpiece with a lining in a vice, pressed tightly against each other.

- Center the drill in the desired location at the junction of the parts.

- Drill a full hole.

Drilling cylindrical workpieces along tangents is a more complex process. It takes place in two stages.

- An area perpendicular to the hole is prepared using milling or countersinking.

- A hole is drilled.

The technology for drilling holes in metal at an angle looks like this.

- The site is being prepared.

- The lining is securely fastened between the planes at the desired angle.

- The hole is drilled.

Wood pads are placed in hollow workpieces before drilling. Holes with ledges are made using the technologies of drilling and reducing the diameter of the holes described at the beginning of the article.

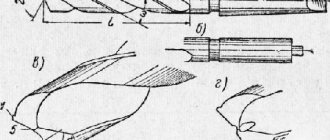

Making a homemade drill

If necessary, a drill can be made from hardened steel. Among the main recommendations for carrying out such work, we note:

- Rods are selected that are made from tungsten and cobalt alloys. People call this metal victorious. Compared to a conventional drill, this version is characterized by increased wear resistance.

- To process the workpiece, you need to secure it in a small vice. Otherwise, the work will be quite difficult.

- To sharpen such a surface, a diamond stone is required. The usual one will not withstand long-term work.

- The end surface is sharpened to create a surface that resembles a flat-head screwdriver. The cutting edges are then sharpened to produce a sharp tip.

In order to reduce the degree of surface machinability, oil is added. This ensures long-term processing due to reduced friction and lower temperature.

Homemade drill bits

In conclusion, we note that processing of hardened steel should be carried out exclusively with the use of special tools. The work requires a drilling machine, since a manual one will not allow you to get the required hole.