What is the device?

In the set of replaceable attachments for brush cutters, manufacturers have recently increasingly begun to mention such a device as a cultivator or weeder. Unlike classic attachments in the form of disks for mowing grass or a mowing head for synthetic fishing line, the cultivator is designed to work directly with the soil. The trimmer attachment is designed to loosen the soil in cultivated areas and partially in places where there is turf cover.

The attachment on the trimmer for weeding potatoes consists of

- from a housing with a worm mechanism;

- and the working body - disk, reciprocating or drum milling attachments.

The weeding trimmer attachment is attached to the rod instead of the lower gearbox. Conversion of a trimmer into a weeder is carried out within 1-2 minutes and does not require additional tools and equipment. The entire process is carried out using hex keys included in the brush cutter tool kit.

Using a brush cutter makes weeding much easier

The device body is collapsible. The housing contains special devices for adding lubricant. The body material is aluminum alloy, the cutters are made of steel. The shaft on which the cutters are installed is forged steel, the gear is bronze.

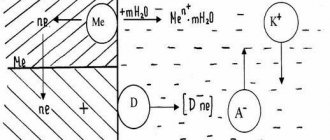

The principle of operation of the trimmer is simple - from a two-stroke engine through the clutch, rotational motion is transmitted to the shaft in the rod. Further, through the shaft, the movement enters the connecting shaft with a worm mechanism, from which the working shaft with cutters begins to rotate through a bronze gear.

The speed of the cutters is adjusted by adjusting the engine speed through the throttle handle - the more the carburetor damper opens, the higher the speed of rotation of the cutters.

Cultivator attachment for trimmer

Boat motor from a gasoline trimmer

Fishermen who have a boat, but have not yet had time to purchase a motor, can take advantage of the rational offer from modern manufacturers of gasoline-powered tools. Attention should be paid to the attachment of the outboard motor for the lawn mower. The equipment is suitable for propelling wooden, rubber and even metal boats, but it all depends on the power of the motor of the trimmer used.

boat propeller

The attachment is also called a “boat propeller”, as it is a rod with a fixed three-blade propeller, which is driven by a trimmer motor. The gas of the tool is output to the handle, which also serves as a steering wheel. Only the motor is used from the trimmer, so the rod is completely detachable. The internal combustion engine is attached to the nozzle using four bolts. The device with the engine is fixed to the boat using a built-in clamp.

Naturally, a boat with such a drive will not develop high speeds, but it is quite suitable for going out into open water to a fishing spot. The maximum speed developed by the drive, consisting of a boat propeller attachment and a trimmer motor, is up to 20 km per hour, which depends not only on the power, but also on the load of the vessel. Fuel consumption does not exceed 1 liter per hour, so the equipment is recommended to all fishermen as an alternative to expensive outboard motors.

This is interesting! For metal boats, it is better not to use such a drive, since due to heavy loads, rapid overheating of the internal combustion engine and failure of parts cannot be ruled out.

The principle and effectiveness of the weeding method

Weeding as a treatment with a cultivator aims to destroy the weed by the method of exhaustion - after treatment, the plants need time to recover and gain the necessary strength. At this time, potatoes or other vegetable crops will be able, on the contrary, to continue their successful growth.

Weeding potatoes with a trimmer is usually carried out using three methods:

- mowing weeds with a mowing head or disc attachment;

- processing with a cultivator with a drum attachment;

- processing with a cultivator with saber or disk attachments.

Mowing is usually carried out when the weeds reach a height of 7-10 cm. In this case, only the part that is above the ground is mowed, and the roots remain intact. Usually, after this, rapid growth of green mass begins, so the effectiveness of such treatment is low.

When weeding with a trimmer is carried out using a drum cutter, the roots of the weeds are also treated. The big advantage of this method is that the top layer of soil fluffs up, and thus the air exchange of the soil increases. The effectiveness of this method is much higher than simple weeding by hand or working with a mechanical cultivator. The drum cutter allows you to loosen the soil to a depth of 3-5 cm.

When using saber or disk attachments, the efficiency increases even more - the processing depth increases to 5-7 cm. At the same time, plant roots, as well as the green mass of weeds, are repeatedly ground, which contributes to the rapid decomposition of plant residues in the soil. After such weeding, repeated weeding is usually carried out at least 10-14 days later. True, there is one nuance that needs to be taken into account - when working with drum cutters, the width of the processed strip is about 30 cm, but when working with reciprocating or disk cutters, the width is no more than 15-20 cm.

Weeding potatoes with a trimmer

Cultivator on a brush cutter - an effective replacement for a shovel and hoe

To loosen the soil, you can use a shovel or a cultivator attachment for a trimmer. The first tool has only one advantage - the ability to always maintain physical shape. Now about the advantages of a cultivator for lawn mowers:

- High speed of site processing.

- Efficiency - the cultivator not only loosens the soil, but also crushes it. Immediately after cultivation, the land is ready for planting various crops.

- Does not reduce the amount of black soil. Shallow cultivation helps preserve the fertile soil layer.

- No physical fatigue. The process of cultivating with a trimmer is the same as cutting grass.

Cultivator

A cultivator from a gas trimmer is used for cultivating the soil between rows - fluffing up and controlling weeds, which is why the device is also called a motor-hoe. When choosing a cultivator attachment for a trimmer, it is important to consider the following recommendations:

- quality of cutting elements - when choosing cheap devices, you will most likely encounter the fact that when processing compacted soil, deformation of the knives will occur;

- the presence of a protective cover is a mandatory attribute, the absence of which is unsafe for the operator, since small stones and dust will fly into the operator’s face;

- sufficient weight of the device - the nozzle must have a mass of at least 5 kg, otherwise it will be thrown upward due to vibrations.

This device is used by summer residents to weed potatoes, simultaneously fluffing up the soil and removing weeds. The cost of this device, which is also called a soil mill, varies from 10 to 20 thousand rubles. The device justifies itself when there are large volumes of work, so it is recommended to evaluate the cultivator trimmer attachment at its true worth. A significant drawback of the equipment is the significant load on the shaft and motor, so it is very important to take breaks as often as possible and use powerful units for work.

Pros and cons of the method

Weeding a garden with a trimmer, and especially the area where potatoes grow, has its own characteristics and specifics. First of all, you need to pay attention to the fact that you need to choose the right tool for the job. It is preferable to choose powerful four-stroke engines as a working engine. Such brush cutters have lower gas consumption and greater productivity compared to two-stroke ones. For two-stroke engines, the recommendations boil down to choosing a higher engine power; the more powerful the engine, the more efficient the work.

Weeding potatoes, unlike making hay or mowing the lawn, is a more labor-intensive process, so you need to be prepared for the fact that after work not only your back, but also your arms and legs will hurt. The fact is that during work you will have to keep the nozzle suspended, preventing the lugs from completely burying themselves in the ground. In addition, you will have to move the unit along the surface from right to left, which also requires significant effort.

But from an economic point of view, such potato weeding will be much more effective than manual weeding - in a season, using a cultivator, you can cultivate a much larger area than with your hands. In this case, repeated processing will be required after a longer period of time.

Alas, there is also a minus. This is a lot of gas mileage. In normal mode, gasoline consumption is usually 0.44-0.92 liters of combustible mixture per 1 hour of operation of the unit, depending on the design and type of engine. With the device installed, this figure increases by approximately 35-40%. So you have to choose either saving time and quality of work or saving money.

Cultivator attachment in action

Types of attachments for lawn mowers and trimmers - features of their use

The nozzle is the working part that does not have a drive. A gasoline engine from a brush cutter is used as a drive device. The cost of nozzles depends on their varieties, but in any case, they are tens of times cheaper than buying a full-fledged tool with a drive, for example, a motor pump.

If the household has a gasoline scythe, which gathers dust in the garage most of the season, then we suggest you learn about the hidden capabilities of this universal tool. Modern manufacturers produce the following types of garden attachments for trimmers:

- Pruner or lopper.

- Cultivator, weeder or hoe.

- Blower.

- Lawn aerator.

- Edge cutter.

The trimmer can be used not only as a garden tool, but also as a construction tool. For this purpose, the following types of devices are produced:

- drill;

- sweeping brush;

- motor drill

Let’s look at what attachments there are for brush cutters and trimmers in more detail, and find out not only their advantages of use, but also their disadvantages.

Weeding trimmer attachments

For work, it is recommended to use a factory-made cultivator attachment. This is both easier and cheaper than making the device yourself. When selecting, it is recommended that you first take your trimmer and measure:

- rod diameter;

- number of splines on the shaft.

This information will allow you to choose the right nozzle. Typically, the description of the nozzles indicates the outer diameter of the rod - 26 or 28 mm and the number of splines on the shaft - 7, 9, or the cross-sectional shape of the end - square. To accurately select the right size, you should also measure the diameter of the shaft itself - they also differ in size, there are shafts with a diameter of 7, 8 and 9 mm.

If you are using a branded tool from well-known world brands, and not Chinese consumer goods, then it is better to order a branded attachment. This will extend the life of both the attachment and the brush cutter. In Moscow, for example, it is worth visiting branded stores, where professionals will select the nozzle; here you can also consult on the procedure for servicing the units.

To work on small areas, a regular disc cutter will be sufficient, but for large areas it is better to use reciprocating and drum cutters.

It is recommended to sharpen the cutters before each use.

When selecting a working tool, you need to focus on the dimensions recommended by the manufacturers. The hand will not be able to hold the blades that are too large, and the blades that are too small will not cope with the task. If you can select several sets of cutters for a cultivator, then you should consider purchasing cutters of different diameters - this will allow you to choose a tool for each specific type of task.

Water pump for pumping water from the trimmer

You can use the motor from a trimmer to transport water from a well, lake or river for watering garden beds. To do this, you will need to purchase an attachment called a pump for a brush cutter, and attach it instead of a spool to the tool bar. The performance of such devices is not as high as that of a full-fledged motor pump, but the equipment paired with a trimmer motor copes well with raising water to a height of up to 8 meters and pumping it over a distance of up to 30 meters.

Motor pump

There are two types of pumps for brush cutters:

- Fixed to a bar - when choosing them, it is important to know the diameter of the lawn mower bar, as well as the number of splines on the drive shaft. Such devices are characterized by low performance and low cost. The photo above shows just such an option.

- Connected to the motor housing. Such pumps are more expensive due to their high performance. There is no need to select such attachments for the tool, since they are driven directly from the clutch of the lawn mower. The photo below shows how the pump is attached to the trimmer.

The pump is equipped with a built-in filter for large particles, which prevents premature failure of the impeller. The body of the equipment is made of aluminum, so the service life of such devices is quite long. The nozzle will be useful not only for summer residents caring for vegetable gardens and orchards, but also for owners of private houses, for example, when it is necessary to pump out water from a flooded cellar or fill a shower container.

Rules for weeding with a trimmer

The rules for growing potatoes provide for several operations - continuous cultivation until the potatoes have sprouted, weeding the rows, hilling the bushes.

For simple cultivation, drum cutters are used; for weeding, you can use disk, saber, or drum cutters. But for hilling it is better to make a stacked structure - make the internal cutters of a larger diameter, and the outer cutters of a smaller diameter. This design ensures ease of use of the tool when hilling under a bush.

Weeding rules are quite simple:

- a sunny day is chosen for work, so that the weeds dry out in the sun as quickly as possible;

- For protective equipment, you should wear goggles and a respirator, and for shoes, boots;

- when working, as well as when mowing grass, it is recommended to use a shoulder strap;

- weeding is carried out with a deepening of 1-1.5 cm, this is enough to loosen the top layer and increase gas exchange in the soil;

- It is recommended to weed the entire row spacing until the plants rise to a height of 10-15 cm;

- Weeding is done in a zigzag, the nozzle is first moved to the left, and then at an angle to the right. The next move to the left, taking over the next lane.

- Hilling is done to a depth of 10-12 cm, with the first movement being forward in the center of the row spacing, and after that, turning the nozzle left and right, a mound is formed near the bushes.

- It is recommended to select the operating mode with short breaks so that the trimmer has time to cool down;

- At the end of the work, the nozzle must be cleaned, unscrew the screws of the technological holes and add molybdenum grease to the gearbox.

Motor auger and ice auger from a lawn mower

When installing fences and fences, it is necessary to make round depressions in the ground, which are needed for pouring concrete or metal posts. A hand drill is certainly a useful tool, but if it is necessary to make a large number of holes in the ground with time limits, you will need third-party help, led by a motor from a brush cutter. The material at the link shows a motor drill made from a chainsaw, but if you only have a lawn mower at your disposal, then you can also make this useful tool from it. The motor drill attachment for the trimmer is shown in the photo below.

Motor drill

The operator can only attach a gasoline engine to the device and begin drilling holes in the ground. It is important to understand that powerful engines from lawn mowers should be used for such an attachment, otherwise this will lead to overheating and rapid wear of parts.

In addition to the fact that the trimmer can be used as a motor drill, it can also serve as an ice drill, which is especially important for winter fishing. This material describes the process of making an ice drill from a screwdriver, but using a trimmer motor paired with a special attachment will make the task of drilling holes in ice much easier.

This is interesting! The ice drill attachment from the trimmer copes with drilling holes in ice effectively, but its main disadvantage is the noise when the engine is running.