For summer residents, the issue of water supply is always one of the most pressing, which is why a pump for irrigation from a barrel can be a solution to many problems. All garden crops need timely saturation with vital moisture, because without water not a single living organism on our planet can exist.

Kärcher barrel irrigation pump

Factors influencing choice

The choice of pumping station is based on technical characteristics such as power, performance and the presence of filters. But before purchasing a specific device, there are other factors to consider:

- distance from the barrel to the edge of the irrigated area;

- changes in ground height;

- time of device use;

- area allocated for irrigated crops.

Knowing the distance over which the hose will be pulled, you can calculate the required power of the device and its pressure. When calculating productivity, it is worth considering that about 5 liters of water are usually consumed to water a square meter. When choosing a specific product, you should take into account its pressure. In many areas, devices are used with a pressure of at least 50. When choosing a device based on power, it is necessary to take into account that low-power units are suitable for drip irrigation, and for sprinkling it is necessary to choose more expensive models.

When choosing, you should take a closer look at the more popular models, since they are the ones of higher quality. If watering will be done rarely, you can buy an inexpensive low-power model.

Accessories

Very often, barrel centrifugal pumps are supplied complete with accessories. Typically, the delivery kit for a drum pump includes:

- fitting for connecting the pump pipe to the hose;

- chemical hose (sleeve) up to two meters long with connecting clamps;

- dispensing pistol for more accurate pumping of liquid and timely shutdown of the supply line without turning off the electric motor;

- barrel adapter for correct and convenient installation of the pump in the container from which pumping is carried out;

- Wall mount for proper storage of the pump after use.

To more accurately determine the amount of liquid pumped, as well as the liquid remaining in the barrel, it is necessary to use a flow meter that is attached directly to the pump pipe. If the pump is used for a barrel with a removable top cover, a special device is additionally used to secure the pump to the open container. If there is a possibility of large particles getting into the pumped liquid, it is necessary to install a protective filter mesh. The filter is simply put on the “heel” of the pump. There are times when the barrel needs to be completely emptied. So that as little liquid as possible remains at the bottom. You can use a bottom check valve for this. The bottom valve is screwed onto the pipe from below instead of the pump heel, and when the electric motor stops, the remaining liquid will remain in the pipe and will not flow back to the bottom of the container.

It is possible to use a barrel pump with a level sensor. The pump electric motor is connected to a special insulator, which is powered by the mains. A level sensor is connected to the box and when the liquid level in the barrel drops below a certain value, the insulator, based on a signal from the level sensor, turns off the electric motor. When pumping a flammable liquid in a room with a high explosion hazard category, in addition to an explosion-proof pump, it is imperative to use a potential equalization cable and a special explosion-proof plug and socket. Before starting work, the potential equalization cable is attached with one end to a stainless steel pipe, and the other to the barrel from which pumping is carried out.

Features of drum pumps

The described devices differ from other types of similar products in their ease of use. They are often chosen by site owners because they are light in weight and produce a small amount of noise during operation. Such devices operate at a depth of up to 1.2 m, so they can be installed in barrels of different sizes.

The pump is fixed on the barrel and then connected to the network. Using the pressure regulator, you can select the optimal pressure during watering. Such products have a built-in filter that does not allow solid particles to pass through. It is worth remembering that in most cases, built-in filters are not able to completely filter water, so over time the system becomes clogged and has to be cleaned.

To avoid the problems described, it is worth installing a homemade filter. It can be created from old tulle. To do this, simply lower the watering pump from the barrel into the fabric and only then immerse it in water. It is important to securely fasten the material to the edges of the barrel. The pumps are protected by a filter so that fabric will not be drawn into the device.

It is worth remembering that the filter elements of the described devices are located in the lower part of the body, so the system can become clogged during use with fertilizer residues and rust accumulating in a metal barrel.

There are many models of various capacities on sale; when purchasing, you should focus on the size of the plot. If gravy needs to be done over a large area, you should give preference to two-stage mechanisms. Such devices have a higher cost, but are designed for a large amount of work.

If there are only a few flower beds on the site, it is worth purchasing low-power devices. The maximum capacity of barrel pumps is about 4 thousand liters per hour.

Types of pumps, their advantages and disadvantages when used for irrigation

Choosing a pump for watering a garden is not an easy task - you need to decide on many parameters, take into account the features of pumps and water sources. You need to select such a “pair” so that it is convenient for you to water, and the equipment works in normal and not emergency mode.

Submersible

Submersible pumps can be used to pump water from any source of sufficient volume - a well, a borehole. Pumping from a pond or river even with a sufficient amount of water is problematic - the water is not clean, and ordinary models only feel normal with it. If you really want to, you can make a filter chamber in which to place the pump itself. But this is also a controversial option - the walls of the chamber may tear or become clogged.

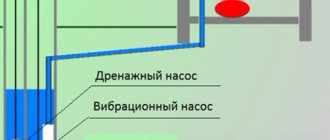

Both vibration and centrifugal submersible pumps can be used in wells or boreholes. The difference is that water is transported over long distances and raised from great depths. Vibrating ones have more modest characteristics, a shorter resource, and are more demanding on water purity, but their price is much lower. This explains their popularity.

There are different types of submersible pumps (vortex and vibration), they can work with different water - clean, dirty and very dirty

As for the river and pond, they have already said that there are still some containers left. You can’t put a centrifugal unit into a barrel or a Eurocube at all - it will pump it out in a few seconds. The vibrating one will create a very strong roar, although it will “pull” the water for several minutes. But the noise is so loud that the neighbors might come. So it’s also not very suitable for such working conditions.

So, a submersible pump for watering a garden is suitable if the water source is a well or a well without sand.

Drainage

Drainage pumps are mostly of the submersible type. What sets them apart is their ability to work with muddy and contaminated water. In this regard, drainage pumps are used specifically for watering the garden from open water sources - rivers, ponds, etc.

But just remember that dirty water is not duckweed and mud, but water that contains solid particles no larger than 5 mm in size. But some manufacturers define other limits for their equipment - often the particle size should not exceed 3 mm. Therefore, if the reservoir is heavily polluted, the same chamber with mesh walls is required that will trap large contaminants. If you don’t want to bother with this, and the water is really dirty, you can use a fecal pump rather than a drainage pump for irrigation. It can even pump mud. There are models with a grinder that crush large objects in seconds.

A submersible drainage pump can supply water from a river or pond

So, a drainage pump for watering a garden is good if the water has a significant amount of impurities, but all of them are no more than 3-5 mm. For large contaminations, it is more advisable to use a fecal aggregate.

Barrels

Another type of submersible pump designed specifically for irrigation from small containers is barrel (barrel) pumps. They have low productivity, low power and size, and low noise levels. As the water level in the tank decreases, they gradually increase the pressure so that the outlet pressure remains stable. In general, such a pump for watering a garden is a good purchase, but... if you are satisfied with the price.

The irrigation pump for barrels is very convenient and quiet, but the prices are not encouraging

The inlet of the barrel pump is closed with a mesh - a filter from large contaminants. But this is not always enough. If there is a lot of dirt in the barrel, an additional filter is made. You can even lower a piece of gauze or other mesh fabric (old tulle, for example) into the barrel and secure it so that it does not reach the bottom a little. The unit can be lowered into this fabric. In this case, it will work longer without maintenance (it is necessary to periodically clean it from dirt that accumulates inside). The fabric will not be pulled inside during operation - there is a mesh there, so the option is quite functional.

External

For watering a garden from a river or pond, external pumps are more suitable. Only the hose is lowered into the source, and the unit itself remains on the surface. Just keep in mind that the hose must be reinforced - a regular one will simply be flattened by the negative pressure created during operation.

The disadvantages of this type of equipment include their weight - they are usually quite heavy, which makes them difficult to carry. Their body is made of steel or cast iron, and it is clearly not lightweight. To eliminate this drawback, special garden pumps were invented. Their body is made of plastic, which makes them much lighter - even a woman can easily handle them. In addition, garden pumps are better suited for pumping water that is not entirely pure. So for watering a garden from a river, this is a good choice.

Everyone enjoys outdoor pumps, but filling them before starting work is not the most interesting activity.

There is one nuance when working with external suction pumps: in order to start them, you must first fill the pump itself and the hose with water. An external pump for watering a vegetable garden can be self-priming in its mode of operation, then you only need to “fill up” a little - just the container in the pump, which is several hundred milliliters. If the model has normal suction, you need to fill the entire hose and capacity of the unit, and this can be more than a dozen liters. Since watering is a periodic action, refueling such a system every time is tedious. Therefore, to water the garden, they use self-priming external pumps or look for something else.

There are external vortex (centrifugal) pumps, but they are only suitable for clean water. That is, this is another option for a well or borehole, but with a shallow depth. Their advantage is that you don’t need to fill them, although due to their weight, carrying heavy ones from place to place is problematic.

Pumping stations for watering gardens

If desired, you can use a pumping station rather than a pump to water your garden. This, in principle, is an ideal option - the pressure is stable, and it can be adjusted within a fairly wide range, while the motor operates in normal mode - it turns on and off. But there are no shortcomings either. Pumping stations are usually equipped with surface pumps for clean water. They will have to be filled before launch, that's two. They are heavy - that's three. And the price is not always pleasing - it's four.

Pumping station for watering a garden - convenient, but not cheap

True, if you wish, you can assemble the station yourself, based on any pump (drainage pump, for example). You will need a hydraulic accumulator, a pressure switch, a pressure gauge and a five-pin fitting or a set of flexible hoses with nuts of suitable diameters. You can also assemble the entire system on polypropylene or plastic, as you are used to. It's not that difficult, so it's really easy to figure it out.

Features of surface pumps

Surface devices allow you to pump water from any clean source. They can also be used when watering an area from a barrel. The performance of the described pumps is quite high. Many people choose such pumps because they can be easily repaired with their own hands.

Advantage of surface devices:

- compactness;

- low price;

- the devices are easy to maintain and operate;

- durability.

Surface barrel pumps for watering gardens also have disadvantages, these include high noise levels during operation and sensitivity to impurities in the water.

Important! The described products should only be installed on a level surface. Typically, such devices do not need to be secured.

Reviews

Buyers praise German Karchers and Gardens for their reliability.

And after five years of service, they do not lose their performance at all. Those who have something to compare with say that barrel pumps are the easiest to use.

So. In the old days, when there was only one way to get water from a barrel - with buckets, folk craftsmen invented and made homemade devices.

There is no point in doing this today. Modern barrel pumps will still be better than any homemade one, and they are also very inexpensive!

Choosing a deep-well pump for a well requires a competent approach. Deep well pumps: which one to choose? Selection criteria, price level, user reviews.

You will learn everything about the design and applications of a fecal drainage pump in this article.

Submersible pumps

These devices are usually purchased for pumping water from wells and wells, but can also be used to water an area from a barrel. Such products are divided into the following types:

- Vibrating. Such barrel pumps are more popular because they are low cost and have good performance. They consume a small amount of energy during use. But it is worth noting that if the mechanism breaks down, it is quite difficult to restore it.

- Centrifugal devices. Such pumps are characterized by high performance, so they can be used for irrigation of large areas. The price of the described products is quite high, but they are more reliable than vibration ones.

Features of drainage pumps

When purchasing drainage pumps, it is worth considering that they are used to pump out dirty water. Watering plants is just an additional function of such products. They consist of a sealed housing in which the pump unit is located.

The housing of drainage pumps is made of steel or plastic. When choosing a specific model, it is worth considering that the larger the diameter of the suction hole, the larger particles the pump can pass through. Many similar products are equipped with a float switch, which helps to turn off when there is no water.

The advantages of drainage pumps include:

- high reliability;

- Ease of use;

- the ability to pump water with large impurities;

- low noise level during operation.

It is worth noting that in the event of a breakdown, quite a large amount of money is spent on repairs.

Features of using pumps for irrigation

During operation, several rules must be observed:

- during operation, you should not allow situations in which the barrel pump for irrigation runs idle;

- in winter, it is necessary to drain the water from the device;

- To prevent the product from overheating, you should not pump high-temperature water into it if the device is cooled by liquid;

- The product must be used only in the conditions for which it is intended.

Features of products from famous manufacturers

The most popular products are from the following manufacturers:

- Karcher.

- Gardena.

- Bison

Karcher German devices are distinguished by their reliability and high quality. They help to significantly facilitate the process of watering the site. Such pumps can be used in the morning and evening without worrying that the noise may disturb people who are on the site.

High pressure allows you to connect several main lines to the product. Almost all Karcher pumps have protection against dry operation. Thanks to this, they can be used without breaking large enough strings.

Gardena products are characterized by high performance and low energy consumption. Almost all devices have float switches that help shut down when there is no water. At the bottom of such pumps there is a filter to purify water from solid particles.

Devices from the described manufacturer have a reliable sealed housing, so water cannot enter the engine.

Bison products have protection against heating of the windings. Almost all pumps are made of impact-resistant plastic that can withstand heavy loads. While using the pump, you can adjust the pressure. Before operating such devices, it is important to ensure that they are correctly assembled and securely fastened.

Manufacturers and prices

Among domestic manufacturers of submersible pumps, the following models can be noted:

- Baby. The cost of such pumps will be from 1000 to 2000 rubles.

- Dwarf. Its price varies from 5 to 15 thousand rubles.

- Belamos. Its cost varies from 10 thousand and above.

- Vortex. It costs from 6000.

Foreign models include:

- Karcher. The most famous brand that produces pumps of all sizes, including small ones. The cost of its products will vary from 3,000 to 15 thousand rubles.

- Elpumps. Its price ranges from 6,000 to 14 thousand.

- Grinda. The cost of all submersible pumps ranges from 2000 to 5000 rubles.

- Gardena. The price range for such a brand is in the range of 4,000 – 20,000 rubles.

Details about pumps for automatic irrigation systems are described here.