Woodworking machines are essential equipment for those who want to create a useful and beautiful product by working wood. But here it is important to understand that only with the right choice of a suitable tool is it possible to create a truly beautiful object made of wood.

Until today, handmade wood products have a high price, since the process requires a lot of effort and worker time, compared to factory assembly line production.

Main types of woodworking machines

There is a certain classification according to which woodworking machines can be divided into several types, based on the purpose and operation performed:

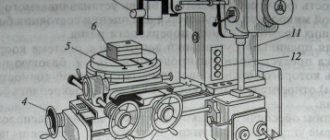

Universal woodworking machine

- sawing;

- pressing;

- planing;

- Drilling and filler, radial, and vertical machines are suitable for drilling holes;

- milling;

- grinding;

- sharpening involves processing a cylindrical product. Here you need wood lathes.

The sawing machine provides the ability to:

- trimmings;

- cutting parts;

- curved, transverse and longitudinal cutting of the workpiece.

In this case, woodworking machines are presented in the form of a jigsaw and band saw.

The pressing unit is designed to produce MDF, chipboard, and plywood. To carry out such procedures, you will need to have hand presses and presses.

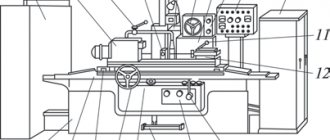

The planing unit involves processing parts on profiles and planes. Using the tool you can create a perfectly flat wooden surface. In this case, the following mechanisms will be needed:

- thicknesser;

- jointers;

- woodworking planers.

Planer design

Milling cutters are necessary for artistic work with wood, its processing, as well as profiling parts, they are:

- four-sided woodworking;

- copy-milling;

- milling

Grinding machines are needed to:

- remove a hangnail, a wave;

- remove the sag;

- smooth out the sharp edge;

- calibrate the part;

- to give a certain surface roughness.

Belt sander for wood

Operating principle

The operator working with the device checks the readiness of the machine, inserts the desired cutter, selects a program and installs the product. The machine does the rest. The motor of the device sets a certain torque to the cutter, thanks to which it begins to perform rotational movements. The spindle (metal shaft for mounting the cutting tool) is attached to the moving portal.

The CNC operator sets a certain command, after which the portal moves in a three-dimensional plane and the cutter, in contact with the surface, removes a layer of wood in the desired direction. This is how wood carving happens.

The machine has its own software, which, using special codes, “translates” a computer command into a mechanical one, carried out by the device’s electric motor. The operator selects the desired file with already recorded thread parameters and starts the workflow.

The main advantages of the tool

Woodworking machines have many advantages when working with them, namely the following aspects can be highlighted.

During work, the master spends much less effort compared to hand tools, since this option leads to rapid fatigue, loss of observation and wasted time making the part.

The machines guarantee high quality of the product. When working with it, even novice craftsmen will be able to achieve high levels of accuracy.

This advantage is explained by the fact that when operating an electric or manual tool, the master moves the tool, and when working with a machine, the parts. Thanks to this, you can more easily and better control the procedure, as well as inspect the cutting area.

Significant increase in labor productivity. The machine makes it possible to produce several times more parts in the same period than with an electric or manual one.

Types of machines

Depending on the configuration, execution method, and installation methods, CNC woodworking machines for wood carving are divided into the following categories:

By spindle location

- horizontal. Most often used for processing large parts due to the convenience of their location under the portal without compromising the integrity of the product;

- vertical. Used for making thin multi-faceted patterns on small parts. Such machines are more popular.

According to the type of installation table

- fixed. In this option, the spindle itself moves relative to the table, creating a good overview of the product;

- mobile. In this form, the table moves relative to the axes of the surface being processed

Types of woodworking machines

There are several types of woodworking equipment:

- special;

- specialized;

- universal.

During production, certain equipment is often used, designed to process identical parts that differ only in size. For example, special ones include format-cutting devices - thanks to them, slabs and panels are cut. This equipment is most often used to create doors and cabinet-type furniture.

Edge grinding machine KSO 1500F

Specialized equipment includes those tools that are intended to perform a specific operation. For example, edge grinding machines allow you to level the frame, profile, and edges of the board. This tool is used in carpentry and furniture shops.

The universal machine is distinguished by its ability to be used in a variety of areas. With their help, you can successfully perform a number of different operations. A universal machine can replace several special ones, but, unfortunately, it will be inferior in terms of efficiency and accuracy. But in the case of small workshops or workshops, this option is the best choice. It will not only save time, but also money.

But if the above-mentioned tool is ideal for serial or small-scale production, then the home workshop can be safely supplemented with combined machines. Using it, you can perform a variety of operations: make a hole, plan and saw products, etc.

Recommendations for choosing a wood processing machine

When choosing woodworking equipment, you need to understand what maximum load it can withstand. In this case, the most important technical parameter is power - the efficiency, effectiveness, quality, and speed of the work performed will depend on it.

In addition, it is important to pay attention to the following characteristics and features of the woodworking unit:

Adjusting the cutting depth

- maximum cutting depth;

- maximum planing width and depth;

- the minimum length of the product used as a workpiece;

- maximum drilling depth.

You should also pay attention to what type of bed is used. For example, equipment with a welded frame can be used for medium- to small-sized production when processing medium-sized parts. There are also units that have a cast frame - this option is used when working with large-sized products - the price for such a device is slightly higher.

Other important characteristics of woodworking equipment for the workshop:

- Thanks to the built-in protective system, the equipment automatically turns off when overheated.

- High level of security.

- Maintenance and setup do not require any special knowledge or skills - everything can be done quickly and effortlessly.

- Minimal noise during operation guarantees comfortable work.

- Availability of cost.

Wood carving with an engraver for beginners

When a suitable device and attachments have been purchased, and the workpiece is already on the workbench, you can begin to work. We will work in stages: 1. Drawing a sketch . Using a soft pencil, apply the intended design to the workpiece. We advise you to do this as accurately as possible, since correcting the drawing with an engraver will be problematic. 2. Preparing the engraver . Insert the grinding attachment into the engraver, connect the device to the network and set the power. 3. Compliance with safety . Be sure to wear safety glasses over your eyes, otherwise redness and itching after work are simply inevitable. Handle untreated workpieces only with gloves. Picking out splinters with a needle is not the most pleasant experience. 4. Engraving process . If the workpiece needs to be shaped, grind it at medium speed. Bring to the final shape at low power with low pressure on the drill. After processing, proceed to the drawing. Using a large sanding attachment, we first apply the largest elements of the design, then change the attachment to a smaller drum. After all more or less large elements have been applied, change the nozzle to a thin “needle” coated with diamond. We use it to draw the smallest details. 5. Polishing . For the last time, change the attachment to a polishing attachment (made of felt or cotton). We quickly go over the entire workpiece, clearing away any remaining chips and smoothing out minor irregularities. 6. Painting . We paint the finished product at our discretion. It is better to use regular stains. Before painting, be sure to erase any remaining pencil residue, otherwise it will be visible! 7. Varnishing . After the stain has dried, apply a thin layer of varnish so that the product shines beautifully and is not damaged over time. Once the varnish has dried, your work is finished.

This completes the process of wood carving using an engraver. As you can see, there is nothing complicated in the work itself; the selection of the device and attachments for it takes more time. However, we immediately warn you that making large items or entire statues will not work in this way. Still, an engraver is just an alternative method of carving for small workpieces, and not a full-fledged substitute for knives, chisels and saws.

Selection of equipment according to its functional purpose

When purchasing, you should consider functionality. Machines can be divided into 3 types:

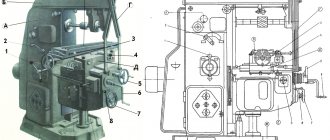

Functions of a woodworking machine

- highly specialized;

- universal;

- household machine.

A highly specialized machine is the best solution when it is necessary to perform high-quality and precise processing. The equipment is used for a specific task, and this makes it possible to cope with the work at the highest level.

Ultra-precise processing of parts in large production is carried out by using machines whose power reaches 2500–12000 W. Each industrial machine is characterized by large cutting depth and planing width. In addition, they have a variety of additional functions.

Universal. This equipment is used in small and small production, in the workshop. They are characterized by a low power of 450–3000 W. They are characterized by multifunctionality, as they are capable of:

- to saw;

- to joint;

- mill;

- drill the material.

A universal tool makes it possible to replace a number of installations designed for a specific area, and this guarantees significant savings in working space.

Household woodworking machine MD

The household machine is ideal for the home workshop. The cost of such a product will be optimal when compared with other products.

Despite the fact that the machines are quite low in power and price, they are made from durable parts, so they can serve for a long time. Each device is equipped with an electric motor, allowing it to be used in everyday conditions.

A high-quality machine is distinguished by the presence of a comfortable tabletop, as it provides space for convenient completion of the task. There are various types of wood processing machines on the market - the choice depends only on the purpose and the availability of the necessary functions for a certain type of work.

Benefits of using CNC machines

There is hardly a woodworking complex that is not familiar with the universal assistant and its capabilities. Today, computer technology is an integral and necessary part of the production process. The main advantages of using numerically controlled machines:

- Quality. Unlike hand-made parts, machine-made products do not contain defects or defects. If it is necessary to produce a large number of identical structured workpieces, it is necessary to launch an automated process so as to obtain identical products at the output.

- Multifunctionality. The ability of a machine to perform both the simplest tasks of the same type and complex tasks is one of the main advantages for a manufacturing enterprise.

- Economical. Replacing manual labor with automated labor can significantly save financial investments. In addition, the service life of a CNC machine, with proper operation and timely preventive maintenance, can increase production efficiency several times.