It is possible to achieve ideal beam geometry only if you use high-quality woodworking equipment. In this short note, we will talk about machines for the production of corrugated timber, including cup cutters and cutters, thanks to which the assembly of a house from finished material can be simple and technologically advanced.

Stages of manufacturing profiled timber

During the production process, a wooden blank goes through several stages of processing. The best option is to use ready-made timber of square or rectangular cross-section. Its surface is subjected to milling - finishing and formation of mounting grooves.

A machine for the production of profiled timber consists of a support frame on which the workpiece is placed. A processing unit is installed in the upper part of the structure. It has an electric motor that drives the working shaft. Cutting knives are installed on it - from 2 to 4 pieces. Depending on their configuration, the workpiece is finished aligned or a recess (groove) is made on one side and a tenon on the other.

In order to make a roll forming machine with your own hands, you should decide on the design features of the main elements of the equipment:

- processing unit – mobile or stationary. For homemade structures, it is best to make it motionless. This will simplify the manufacturing process;

- number of processing shafts. In industrial models, their number varies from one to three. In the latter case, it becomes possible to comprehensively process the workpiece from three sides. For do-it-yourself machines, a scheme with one working shaft is most often used.

- possibility of installing cutting knives of various configurations. This eliminates the need to use multiple types of cutters. To perform the next operation, it will be enough to install other knives on the shaft.

Homemade designs use a manual workpiece feeding system. On the frame there are guide rollers along which the timber moves towards the workpiece block.

To remove chips, an enclosing screen with a socket for connecting a forced air circulation system is made in the front part of the cutting unit. This prevents waste from getting into the working parts of the machine.

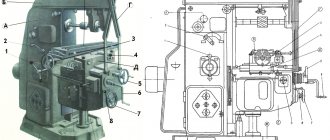

Milling machine device:

Tabletop Bed Motor Cutter

The bed is a fundamental part of the entire system. The bed should not become loose, it should be strong and have good support.

Where is the frame attached?

Often the frame is attached to the floor of the room using a metal fastener. It’s not so often that you see a frame being installed without securing it. In this case, fixation occurs due to the device’s own weight. If you need a machine that will perform light woodworking, then in this case you can do without fastening. The result will be a kind of manual milling machine.

Manual milling machine

Without fastening, work will be fast and super mobile.

The countertop is the 2nd most important component in this structure. The main characteristic is its size.

Where is the tabletop attached?

The tabletop is attached to the frame. It must also have a horizontal, flat surface.

Tabletop drawing for a milling machine

The table for the milling machine should not contain: knots, gaps, there should be a limiter on the edge in the form of a wooden or metal strip. Holes are made on the side for installing metalworking tools (cutters).

Metalworking tool (mill)

The fixed cutter is installed so that the axis of rotation is located in a vertical position. When processing lumber, it is important to carry it horizontally along a stopper with a hole. If you need to process boards or beams, it is very important to have the ability to replace and adjust the placement of the cutter in height. To do this you need to use one of 2 options:

Option 1. If you fix the tabletop to the frame, you get a movable tabletop. This option is not very practical, but quite feasible. Option 2. Attach a metalworking tool (mill) to a movable object that will be attached to the frame; you can also use a screw lift under the guise of a lifting system, or any other regulatory mechanism.

Milling machine motor

The motor of a widely universal milling machine must be placed next to the cutter and connected to it.

You can install it in several ways:

- Place under the countertop

- Place above the countertop

In method 1, the motor must be secured from below to the frame. In this case, there is no need to increase the size of the woodworking machine. 2nd method. In this case, the frame needs to be secured above the tabletop, and the motor mounts must also be placed on it.

If you need a more complex turning-milling machine, then, if desired, you can select other locations of the metalworking tool (milling cutter) and engine. Example: first equip a horizontal milling machine, but before that you need to prepare a drawing of the milling machine in advance.

Also, for safety reasons, it will be important to conduct electricity to the motor and securely fix it, because when there is strong vibration on unsecured locks, then with large and powerful turns the motor can fly out of the device, since the fastenings are more likely to be seriously damaged due to the enormous overload.

When the stage of connecting to the power supply occurs, you need to rely on the standard household voltage of 22O V.

Milling specialists advise not to change the motor winding in any way, since in this case this will not increase the efficiency factor (efficiency), there is a very high probability that it will reduce it.

Home Milling Machine Safety

In order to guarantee safety, in addition to equipping with limiters, it is necessary to provide good lighting to the work surface.

For the purpose of productive activities when processing on milling machines, the motor must be used with a specific power:

0.5 Kilowatt - this power is the lowest, it allows you to remove the outer layer from wood, sand, or select a slot; Up to 1.5 Kilowatt - devices with this power make it possible to carry out the most in-depth processing of lumber, and this power is also easily suitable for daily use. 2.5 Kilowatt is the best type of power, since such a device will be able to maintain full functionality, combine any cutters with different configurations or volumes, however, such powerful devices are used only by specialists, for this reason, beginners are not advised to install this engine.

Recommendations for making your own machine

To draw up a diagram according to which a machine for profiling timber will be made, it is recommended to take the factory model as a basis. An important point is the choice of cutters or blades. The shape of the finished timber depends on their configuration. Making them yourself is problematic, so it’s best to buy ready-made models.

The forming machine is most often made of the frame type. To do this, a welded structure is made from square profile pipes. Additional stiffening ribs will ensure its stability. Additionally, it is necessary to make clamping guides, which are needed to position workpieces of various widths into the processing zone. These can be steel strips with the function of changing the position on the frame.

Recommendations for making equipment components yourself:

- processing unit. The engine must be placed separately, the transmission of torque to the working shaft is carried out using a belt mechanism. The processing unit must be height adjustable. To do this, you can use hydraulic cylinders (increase positioning accuracy) or a worm gear;

- changing cutting knives on the shaft. This process should not take much time, so it is recommended to purchase a factory model of the shaft. This will help improve the quality of processing;

- additional components. These include measuring rulers, with which you can adjust the height of the processing unit and protective mechanisms that prevent overloading of the electric motor. The latter is an important design element.

In addition, you should take into account the main technical characteristics of the machine for the production of profiling beams:

- maximum and minimum dimensions of a wooden workpiece - width and height;

- speed of material supply to the processing zone;

- working shaft width. This indicator affects the possibility of forming groove/tenon joints of various configurations;

- electric motor power.

An important factor is the dimensions and weight of the machine. They affect the minimum dimensions of the working space and the requirements for installation of the plant. These indicators are calculated in advance.

For example, you can watch a video that shows the operation of a factory model of the machine:

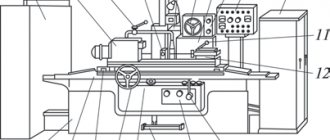

Woodworking milling machine

But there are machines that allow you to do all these stages on one machine with one installation of a log. Machines of this type are called multifunctional milling machines. This technique is equipped with removable tools, which are changed before each new step of wood finishing. The quality of the resulting corrugated timber is affected by the quality of the cutter used on such equipment.

The groove knives on a similar machine are removable and have different profiles. Therefore, without much effort, you can obtain a thermal lock from a conventional single-groove to a complex “comb” shape. This allows the range of goods in production to be increased to the limit and increases the profitability of production.

It is necessary to briefly consider very popular models of machines for the production of corrugated timber.

Machine for profiling timber: device and performance characteristics

Timber is very popular in the construction of a wide variety of structures, and the demand for this type of product is steadily growing every year, so many entrepreneurs and artisans are thinking about producing such products themselves.

To work, you need a special machine for the production of profiled timber, and if you decide to engage in such activities, then it is important to choose the optimal equipment option for certain conditions. In this review, we will tell you which parameters you should pay close attention to.

In the photo: machines for the production of profiled timber can have different configurations depending on what functions it should perform

What does the production process include?

First, let's look at what operations the production of profiled timber includes:

| Procurement of material | Everything here is extremely simple - for work you need wood, which is harvested by specialized forestry enterprises. The best types of wood for timber are pine, spruce, larch and cedar, so work should begin where there are no problems with wood, otherwise transport costs will significantly increase the cost of production |

| Preparing elements | It is impossible to cut a finished product from a log; you need to cut the round timber into pieces of the required size, and for this purpose special installations are used, which can have very different designs. It is important that the prepared elements are cut as accurately as possible, without distortions or distortions |

| Drying of raw materials | In order for the product quality to be at the highest level, it is necessary to properly dry the workpieces. This can be done in two ways - either naturally (in special stacks under canopies without access to direct sunlight), or in a chamber that provides better drying conditions and allows you to maintain optimal parameters of the elements |

| Profiling | At this stage, the products are given the desired configuration, this can be done either in one or two passes, depending on the type of equipment, after which the timber can be used to build a wide variety of structures |

Important! It is not necessary to have all the equipment described above; some manufacturers simply purchase prepared and dried workpieces and process them. Profiled timber costs much more than regular timber, so this option is also profitable and economically feasible.

Drying is a complex process in which it is important to maintain optimal temperature and air humidity parameters

How to make profiled timber with your own hands

Every year the range of lumber is only increasing, and the types of products for building a wooden house or cottage are becoming closer to ideal. But what to do with simple non-profiled timber, which is gradually being replaced by its brothers - laminated veneer lumber and profiled timber. After all, using an inexpensive version of edged timber is much cheaper. Craftsmen solve this problem in their own way.

How to make profiled timber with your own hands, saving money?

There are several options for making profiled timber from ordinary timber, which allows you to save money and obtain higher quality material for construction. All you need is a little patience and free time, as well as the ability to handle some tools.

Many people ask questions: “Is there any point in making profiled timber with your own hands?”, “Maybe it’s easier to buy a ready-made one?” Of course, buying ready-made material is much easier. However, there are many reasons why the production of profiled timber is especially important:

- The profile must be of such a geometric shape that it is not blown through. Moreover, you are doing this only for yourself, which means your profile will be made with high quality.

- By making profiled timber yourself, you will save 3-5 thousand rubles from each cube of material. Of course, much more time will be spent.

- Walls made of this material do not require additional finishing, since the insulation will be invisible.

- The crowns can be made more accurately, and the connecting ones will fit as tightly as possible to each other.

Which profile is better?

When choosing a profile, it is better to calculate your skills and strengths. Making a profile on a block on your own seems like a simple matter. It takes a lot of perseverance and time to carry out such a task more efficiently. When choosing a profile, you should focus on the simplest designs. To implement them, you don’t have to use many types of tools and you don’t have to do a lot of calculations.

Carefully read GOST 9330-76 “Basic connections of parts made of wood and wood materials”, it will allow you to calculate everything correctly. As a rule, two types of profiles are made: profiling through a triangle or profiling through a rectangle.

It is important to understand that before making a profile, you need to calculate its height, depth and width. Moreover, for each section of timber it is different and GOST helps. Be that as it may, when building a house from this timber, insulation (at least 5 cm thick) is laid between it.

How to make profiled timber with your own hands: methods

- Using a cutter.

This is perhaps the easiest way. The milling cutter must be powerful, at least 1.5 kilowatts, and have a special attachment. If the profile is simple, then the radius of the cutter used will be 4-5 cm. If it is complex, then it is produced by several types of cutters. If desired, you can even make a D-shaped side of the beam with this tool. But here you will also need an electric planer and a sander.

But this option also has disadvantages:

- a milling machine is quite expensive (5-10 thousand rubles);

- It is not always possible to buy the right attachment; it may not exist for the milling machine that you have in stock.

Well suited for cutting straight grooves.

- Using a circular saw.

A good way to make the connection yourself is to use the tools at hand. For example, using a hand-held circular saw. Such a tool will cost you 3-5 thousand rubles (the price depends on the manufacturer). The main thing is that it can be sawed at the required angle and make a cut of 65 mm.

Line for end splicing of lamellas

The most important parameter is the length of the resulting workpiece. The press on simple splicing lines is configured for a fixed length of lamellas: 3, 4.5, 6 m, which is not always convenient when making timber, because when sorting the boards, many different lengths appear.

An alternative is continuous splicing lines, which do not press the entire lamella, but a specific segment or each individual joint. In this case, the “infinity” of splicing depends on the length of the roller table. The best option is an automatic line, which performs several functions continuously: it replaces the tenon-cutting machine, producing the necessary mini-tenons, applies glue to the ends of the workpieces, splices and cuts the lamellas to the programmed length.

The performance of such a line reaches 4,000 - 9,000 m/h. For comparison, a semi-automatic line is characterized by a productivity of 400-800 m/h, with manual feed and press control – 200-400 m/h.

When choosing an end splice line, the following parameters must be considered:

- maximum permissible cross-section of the workpiece;

- dimensions of the resulting lamellas;

- roller conveyor parameters;

- press pressure per 1 m of workpiece (for glue polymerization, the optimal figure is 100 kg/m, but the greater the press force, the faster the equipment operates and the higher the quality of gluing).

- type of press (mechanical, pneumatic, hydraulic). Hydraulic presses have the highest performance, but pneumatics are less demanding in operation and easy to maintain. Another important parameter for the press is the presence of side and top pressure rulers - this ensures the alignment of the lamellas and the accuracy of the geometric shape.

Equipment price:

- semi-automatic lines with manual feed – from RUB 1,400,000;

- vending machines – from RUB 2,000,000.

How to profile timber yourself

Profiled timber is much more expensive than non-profiled timber. Is it possible to save money by completing the missing operations yourself?

Timber profiling machine

What are the advantages of profiling timber with your own hands:

- Financial savings, and quite significant ones.

- The profile can be made to suit specific needs (in particular, either reducing or making it impossible to blow through the house).

- There is no need to finish the facade.

SPB-200 – a unique machine model

Among the most popular and in demand machines for profiling timber, it is worth noting the SPB-200 model. This type of technology is focused on planing and producing material that can be dry and have a natural moisture level. The device copes well with different types of wood with a width of no more than 220 mm.

The modern machine for profiled timber SPB-200 has a number of key characteristics. The equipment has 2 cutters. The device rotates at a frequency of about 4.5 thousand revolutions per minute. This functional machine that produces profiling parts requires an electrical power of at least 7.5 kW. The weight of the device is more than half a ton.

As for the advantages, the main advantages of the device are:

- availability of replaceable cutters;

- compactness;

- relatively affordable price;

- high and prompt payback.

Modern SPB-200 machines for profiling timber are also a unique opportunity for correcting curvature and other deformations of wood blanks. The operation of this type of equipment can be seen in the video.

How to choose the final profile and the necessary equipment

First of all, we note that profiling the timber with your own hands will require the contractor to spend a significant amount of time. Therefore, it is worth choosing the least labor-intensive profile to manufacture, “adjusting” the frame of the future house to it. It is recommended to perform profiling either “into a block” or “triangle”, as in the photo.

DIY profiling

To perform any of the options, special equipment is required. In particular, you will need a mobile woodworking milling machine with an appropriate set of cutters and a power of at least 1.5-2 kW. To improve the accuracy of an already completed profile, you cannot do without a grinding machine. The disadvantage of this option is the high cost of the equipment, which will most likely have to be purchased for rent. But you can profile timber with almost any cross section.

If it is necessary to make a straight groove along the entire length, a circular saw is often used, which is cheaper and more common in the household. Profiling a straight groove with a circular saw is somewhat easier, since the depth of the groove (more often a triangle groove is made) can always be controlled. True, the time to profile the timber will increase somewhat, and cleaning the finished groove will be impossible. In addition, you should clarify the characteristics of the saw itself - it should allow the possibility of cutting a groove with a depth of 65 mm.

Ideally, a home craftsman should have both a router and a circular saw.

Profiling technology

When purchasing non-profiled timber, you need to inquire whether the semi-finished product has undergone preliminary antifungal impregnation. If not, then after final readiness the material must be treated with an antiseptic composition. The presence of cracks is also dangerous: if they are identified, then before profiling they must be covered with special mastics.

In addition, it is very important what degree of filing of the sides in the proposed source material:

- in the so-called double-edged timber, only two opposite edges are processed;

- three-edged has three processed surfaces;

- the four-edged one is distinguished by all pre-sawed edges.

When profiling independently, the most labor-intensive processing will be the processing of double-edged timber, while the next two types have no practical difference in profiling time. Moreover, sometimes for the external attractiveness of the house, and in the absence of the need for subsequent external finishing, they opt for a three-edged, cheaper beam.

Profiling timber with your own hands is much more convenient as needed in the finished material, as can be seen in the video. Some dimensional distortions can be quickly corrected when profiling the next row of timber. This eliminates any problems with inconsistency.

Gluing machine

Gluing machines for wooden structures are equipped with either glue rollers or a pouring mechanism. Gluing machines significantly reduce the cost of equipment, but, as practice shows, they are unproductive in the production of timber, where high quality gluing is required.

In addition to the low drawing speed (about 20 m/min), such rollers are initially designed for PVA adhesives, which are not used for making timber. Some manufacturers solve the problem by regrinding the rollers, by applying small notches, but this modernization does not affect the broaching speed.

Therefore, for small volumes (up to 150 m3/month), it is more effective to use manual glue spreaders.

This device consists of a small container that holds 1.5-2 kg of glue, a handle, a dispenser and a glue roller. In 4 minutes, 2 operators can prepare lamellas for one load of a 6-meter press. In fact, it is 2 times faster than working with a glue roller machine. The main disadvantage (apart from the human factor) is that it is impossible to control the exact consumption of glue.

Therefore, the best option for a timber production enterprise is belt-type glue-applying installations with feeding and receiving roller conveyors.

Divided into two large groups:

Constant circulation machines

– when passing the lamellas, the glue is applied in a continuous curtain. The consumption is set in advance, the remains of unused glue and glue spilled past the board fall into the tank, from where it is sent back to work using a pump. The machine can be equipped with mixers (relevant when working with EPI), or apply glue and hardener separately (when using MF compounds). When operating mixers, periodic washing of the equipment is necessary, which results in losses of unused adhesive mass - about 1.5 kg. With the separate application technology, washing is not required and the loss of adhesive components is almost zero.

Mix application machines

– equipped with a static mixer, which looks like a spiral of a certain length and diameter with multidirectional turns. The ingredients of the adhesive mixture are pumped through this spiral under high pressure, which ensures their displacement, after which the adhesive mass enters the tube. The system operates on a “start/stop” principle - the supply of glue begins as soon as a lamella appears under the tube and stops after it has passed through, ensuring maximum material savings. Glue loss – 150-200g/shift.

All filling machines are equipped with accelerating blocks, which provide a drawing speed of 80-150 m/min, fast loading of the press and the same quality of gluing of lamellas in the package.

By the way, many glue manufacturers provide their glue-applying machines (for a nominal rental or free of charge) when using their products. But such conditions are offered only to large enterprises that can ensure consumption of adhesive compositions of at least 1.5 tons/month.

Profiled lumber

Profiled timber is a high-tech product for the construction of wooden country (country) low-rise houses.

Such lumber is made mainly from coniferous trees:

- ate;

- larches;

- pine trees;

- cedar (see the article for more details: What are the advantages of laminated cedar beams)

Features of the material

Profiled building products are distinguished by the presence of specially shaped grooves and tenons, thanks to which it is possible to create a strong and airtight connection. The block is already well planed and can be immediately opened with varnish or paint.

It does not require any special processing. Depending on its purpose, the profile material is made of different sections. (for more details, see the article Treating timber against rotting is the key to long-term operation of the building)

Appearance of the profile bar

The machine for the production of profiled timber ensures the production of lumber that has a flat or semi-oval outer side. If desired, you can remove the chamfers.

Various profile beam options

The inner side is made smooth, planed, and the side edges of the log, after processing on the machine, take the form of a groove and a tenon to ensure a reliable connection with each other. The sides of the lumber should have mirror placement of tenons and grooves. In some types of profiles, insulation can be placed in the grooves to increase the insulating properties.

Advantages over other materials for construction

A machine for the production of profiled timber allows the production of building materials that have a number of advantages compared to other materials:

- good aesthetic appearance of a house assembled from profile products;

- easy assembly of the structure;

- absence of wall seams due to high laying precision;

- factory cuts provide increased resistance to deformation and cracking;

- thanks to the presence of special tenons and grooves, good thermal insulation of the structure can be ensured;

- there is no need to caulk the building, since rainwater does not get into the joints between the bars even during heavy rains; (see more details in the article Joining timber along the length - connection options)

- buildings are characterized by high performance characteristics;

- the price of houses assembled from profile lumber is much lower than from other building materials.

Manufacturing technology

To save financial resources, if you have the necessary equipment, you can make profiled lumber with your own hands.

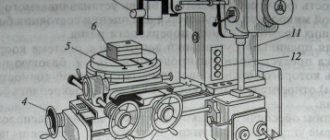

Technical devices for the production of profile material

Profiling of wood building material is provided by a timber profiling machine.

Profile cutting machine

The machine is a four-sided planing unit with profiling knife cutters. Thanks to this device, a high-quality profiled building material is obtained from a rectangular wooden blank.

For reliable fixation and safe feeding of the workpiece in manual or automatic mode, the design provides a work table with end clamps. Powerful, modern machines are characterized by good performance and provide fairly high accuracy of dimensions and proportions.

Modern equipment for the production of lumber with profiles is characterized by its versatility. The machines allow you to simultaneously perform the entire range of work necessary for the manufacture and processing of building materials from wood, from splitting to milling.

Stages of manufacturing products with a profile

Building material with a profile can be obtained by using a machine for profiled timber.

The manufacturing process is divided into two main stages:

Processing logs with cutters

At the first stage, the workpiece is given the required shape. The front sides are made round or straight. At the milling stage, a mirror profile in the form of tenons and grooves is cut. This process is called profiling.

Independent production of profile products

Before you start manufacturing building material with a profile, you need to familiarize yourself with GOST 9330-76, which sets out the basic requirements regarding connections of wood products (parts).

To make wood with a profile yourself, you need to perform the following amount of work.

- First, the wooden blank from which it is planned to make a building product with a profile must be given a regular quadrangular shape. To do this, the workpiece must be sawed on a special sawmill, where it will be cut into a block of the required cross-section;

Rectangular wood blanks

Advice! It is not recommended to use laminated wood to build your house, as it does not meet environmental standards and will not create a unique microclimate in the building.

- Wood must be properly dried before being processed into a profiled timber machine;

Drying workpieces in ventilated stacks

Advice! When purchasing a finished product, you need to pay attention to the moisture level of the wood. Only with high-quality drying of wood is its shrinkage and deformation minimized.

- When making your own, it is advisable to choose a simple profile for cutting wood materials. It is also necessary that the resulting connections make it possible to use insulation (at least 5 mm thick);

- To make a rectangular cutout on a product, you can use a manual milling machine;

Photo of making a groove with a circular saw

- Triangular grooves are cut using a hand-held circular saw. The working platform of such a saw must ensure cutting at the required angle. In this case, the cutting depth (straight) must be at least 65.0 mm. The waste from the triangular section can later be used to connect the bars to each other;

- If it is necessary to manufacture building materials with corner joints, it is necessary to give preference to one-sided (double-sided) locking grooves. You can cut a groove on the desired side using special tools and a milling machine.

Altai machine: characteristic differences

The popular machine for profiled timber Altai differs from those versions that are sometimes created with your own hands. What are its features? First of all, its versatility stands out. The device is aimed not only at profiling the timber, but also at cutting it through. Such machines make it possible to produce building materials with various specified groove parameters. The thing is that the Altai device is equipped with 4 milling carriages. The device for the production of profiling parts is presented in the format of a rail table, complemented by clamps for timber and stops. The profile here is installed, as a rule, of a rectangular or square type. All carriages are started manually by the operator. Each cutter cuts only one side of the workpiece. As for the profile parts of the Altai device, figured knives are installed on them. It is precisely these kinds of elements that allow you to set the desired groove shape on the beam. Knives may also be used:

- straight;

- semicircular;

- aimed at giving the workpieces a cylindrical appearance.

SF-250 equipment: nuances of operation

Modern profiling machines for timber SF-250 are designed not only for profile planing, but also for flat planing. The device is aimed at creating house-building parts that are necessary for small and medium-scale work.

The excellent planing machine SF-250 is suitable for processing material in solid format, characterized by natural moisture. The device is also intended for profiling timber from the laminated veneer lumber category. The device is equipped with special spindles that differ in average rotation speed. It does not exceed 5000 rpm. Profiling machines SF-250 are a guarantee of high quality. The treated surfaces on hand-made devices turn out completely different. It is a professional machine for profiling timber that allows you to obtain ideal parts for construction. However, it is worth noting the advantages of independently created technology. It is great for those who make fragments in small quantities for personal use. You can make a wonderful machine for profiled timber with your own hands using an extremely simple scheme. Even those who rarely encounter such questions in everyday life can figure it out. Such profiling devices do not require special skills to operate. You can always adjust them yourself, without the help of professionals.