When planning to install an autonomous sewer system on a private plot, it is important to understand that before starting work directly, you need to draw up a design and diagram of the sewer system.

To do this, you need to use the standards specified in the relevant paragraphs of SNiP.

Only then will the system work correctly and the likelihood of any malfunctions occurring soon can be eliminated.

Construction of a sewer well according to SNiP

What requirements exist in SNiP for sewer wells?

First of all, you should consider the requirements for sewer wells, which affect the choice of material for their manufacture.

Structures must have high levels of tightness and strength.

SNiP allows the use of the following materials in the construction of wells:

- ready-made structures made of plastic or polyethylene. They are initially manufactured by specialized factories in full compliance with GOSTs, so the question here will only be in determining the appropriate dimensions of the structure;

Plastic wells

- reinforced concrete products are concrete rings produced by factories in accordance with GOST standards. Here you will need to calculate the number of required products and the diameter of the rings;

Reinforced concrete well

- rubble stone or moisture-resistant brick - these materials can also be used to construct wells, but due to the labor-intensive nature of the work, they are used quite rarely today.

Well made of rubble stone

The sizes of wells are also regulated by standards.

They will depend on the diameter of the sewer pipes used in the construction of the sewerage system. The following relationship is observed:

Diameter of sewer well, drawing

- for pipes with a diameter of less than 300 mm, the diameter of the well must be at least 1000 mm;

- for pipes with a diameter of 300 mm or more, the diameter of the well must be 1500 mm or more. You can install square wells. Here the length of one side should not be less than 1 meter.

There are also strict requirements regarding installation work. Let's consider them further.

Mixtures based on mineral binder

When waterproofing a well made of concrete rings, the method of spraying a protective layer can also be used. A mixture based on a mineral binder fills all voids in the concrete structure and between structural elements, guaranteeing a high degree of protection against water and moisture.

Here you will need a special installation that will allow you to evenly cover the entire surface of the concrete with the material under high pressure, qualitatively filling seams, joints, and various defects. The method is suitable for external and internal work.

If the composition is chosen correctly and applied correctly, no additional waterproofing agents will be needed. When a layer is applied inside a drinking well, it is advisable to also insulate it with a membrane or paint in order to reliably protect the water from various impurities getting into it.

Requirements for installing sewer wells

Before installing sewer wells according to SNiP, you need to determine the location of the structures.

If we are talking about inspection wells, then they are installed in increments of 40 meters if the diameter of the sewer pipes is 150 mm and in increments of 50-60 meters if the diameter of the pipes is 200 mm.

As for storage and filtration wells, SNiP gives completely different location standards.

They are based on the distance of the well to a certain object:

Requirements for the location of the well according to SNiP

- at least 5 meters from a residential building;

- 1 or more meters to outbuildings;

- 3 meters to the fence of the site or highway;

- 30 meters to drinking water wells or reservoirs;

- 20 meters to the garden or vegetable garden.

By complying with these standards, you protect yourself and the environment from the possible consequences of a well failure, which threatens the penetration of wastewater into the ground and its distribution by groundwater.

There are also some requirements for the technology of constructing sewer wells.

They consist of the following points:

Requirements for SNiP device technology

- the depth of the pit dug for a well cannot exceed 2.5 meters;

- the bottom of the filtration well should be at a distance of 1 meter from the maximum possible groundwater level;

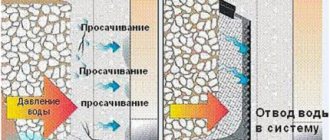

- when the groundwater level is high, waterproofing must be installed;

- the diameter of the pit should be 50 cm larger than the diameter of the well;

- a sand cushion 10 cm high must be placed at the bottom of the pit;

- There should be a distance of 0.6 meters between the bottom of the well and the bottom of the sewer pipe.

This is what requirements with accurate data are all about. If we talk about the procedure for installing a sewer well, it involves the following sequence of work:

Installation of a well according to SNiP

- digging a pit of the required size;

- compacting the bottom of the pit;

- laying a sand cushion;

- installation of the bottom of a sewer well;

- installing a concrete ring on the bottom;

- joint sealing;

- installation of the next ring with subsequent sealing of the seam;

- supply of sewer pipes;

- arrangement of waterproofing and thermal insulation;

- installation of ceiling;

- installation of an inspection hatch.

Installation of a plastic well

If we talk about installing a plastic well, then after immersion on a sand cushion, it must be securely fastened to it using special belts.

Then the container is filled with water, and the space between it and the walls of the pit is backfilled.

For this purpose, a mixture of sand and crushed stone is used.

A layer of thermal insulation is placed on top of the plastic container to prevent freezing of the drains in the winter.

Coating and roll materials

The easiest to process and most popular materials of this type are various mastics based on polymers, composites, sprayed liquid rubber, and bitumen. They are usually used where waterproofing of a well made of concrete rings from the outside is needed. These compositions should not be used for internal treatment of water intake wells, since gradually harmful substances from the composition can peel off and enter process/drinking water.

Waterproofing with coating materials is carried out several times; additional non-woven reinforcing mesh (usually made of polyester fibers) is used.

All kinds of paints, rubbers, and mastics, upon hardening, guarantee additional effective sealing of the entire surface of the structure (and not just joints and seams), since they close the pores of the concrete and do not allow moisture to enter its structure.

Roll materials for insulation from moisture are made on a soft frame; they also protect concrete well. Usually the sheets are attached using mastic or other methods. The main advantage of rolled materials is the ability to do all the work yourself, without the need for special skills or knowledge.

The most popular rolled materials for waterproofing are waterproofing, roofing felt, etc. They are used only for external work, created from a base based on aluminum foil, asbestos, fiberglass, with special substances and compositions of polymers and bitumen applied to it. The layer lasts for about 30 years.

The layer protects the entire walls of the well, so during the installation process it is necessary to ensure access to the ring around the entire perimeter. Therefore, waterproofing with roll materials is preferably carried out at the construction stage.

What does service mean?

The concept of “well maintenance” includes constant monitoring and inspection of the condition, periodic preventive maintenance and repair of structures and equipment as necessary. Each type of structure has its own specific services, but there are also general activities.

The following maintenance work for any wells is distinguished:

- Visual inspection . It is carried out on a permanent basis; there is no need to issue an order for this. Responsible persons are obliged to monitor the presence and serviceability of the hatch, the integrity of structural elements, the degree of contamination, access, i.e. for all parameters that do not require penetration into the mine. In addition, a scheduled inspection of the technical condition with penetration inside is carried out at certain intervals, as well as an unscheduled inspection after the occurrence of unforeseen circumstances that could lead to malfunctions or destruction.

- Well cleaning . Scheduled cleaning of the mine is carried out on average 2-4 times a year, depending on the purpose and operating conditions of the structure. The order of the controlling organization approves the schedule for such events, and responsible persons are obliged to strictly comply with it. Unscheduled cleaning is provided based on the results of the inspection, in the presence of significant contamination that can impair the performance of the structure.

- Repair and maintenance. Several categories of such work should be distinguished: prevention, routine, minor and major repairs. Prevention includes lubrication of rubbing and rotating parts, anti-corrosion coating, disinfection, etc. Current repairs include inspection and replacement of quickly wearing parts, such as gaskets. Carried out at established intervals (the order approves the routine repair schedule). Minor unscheduled repairs are carried out based on the results of the inspection, as well as as necessary. It can be carried out with a short-term stop in operation or while the well is in operation. Finally, to carry out a major overhaul, an order is required from the relevant service, and this is provided during a complete shutdown of operation.

Carrying out water treatment

After carrying out any work inside the well or if unpleasant changes in the quality of water are detected, disinfection is carried out. Typically, this procedure is carried out using a bleach solution of 3% concentration. This composition is sold ready-made, but you can also prepare it yourself.

The preparation of this antiseptic includes the following stages:

- Bleach in an amount of 300 g is poured with a small volume of cold water to a mushy consistency and thoroughly mixed to remove all lumps (lumps can retain hypochlorites, chlorides and calcium hydroxide, which can deteriorate the quality of water).

- The prepared gruel is diluted with cold water in a volume of 10 liters with stirring, after which it settles for 2-4 hours in a cool place.

- A clear liquid is used, which is filtered through gauze folded in several layers.

The walls of the shaft are disinfected, onto which the solution is applied using a spray bottle. The water itself is also treated with this composition. To do this, simply pour a solution into the well at the rate of 10 liters of mixture per 1 cubic meter of water. After treatment, the well mouth is tightly closed with a lid and kept in this state for 22-25 hours. At the end of the event, the water is completely pumped out of the well shaft.