Where to begin

The installation scope of work allows you to do without professional knowledge and too expensive specialized tools. However, you will still have to study for what purposes this or that profile is used, since the market range of products and the features of the technology for constructing an object from plasterboard include many options for frame products.

Fixing profiles to walls

From the article you will learn what it is used for:

- U-shaped version of the product;

- L-shaped type, which has an angular placement method;

- H-shaped mounting profile.

It would be useful to study the existing dimensions of frame products for plasterboard structures in order to use them for accurate calculations of the required amount of materials.

Each of these elements has its own characteristics, properties and placement principle. Each of them has its own functional side.

Basic principles

According to GOST No. 8240-97, the product range includes all-metal profiles with a wide range of possible parameters. With this variety on offer, it is quite difficult to make a choice: which brand is most suitable for its purposes. Of course, manufacturing companies take this nuance into account. Product marking is used to designate channels, and according to it, a complete picture is given of the characteristics and dimensions of U-shaped rolled products.

Marking “U” - inclined edges

According to GOST number 8240-97, the following markers are distinguished: 1) numbers, 2) letters. The numbers that come first in the designations “tell” about the distance between the shelves. The letter determines what type a particular product is.

- The internal edges of the shelves are inclined - the letter “U”. They are used mainly for high-strength structures in construction and mechanical engineering;

- The edges run parallel - “P”;

- Economical channels – letter “E”. Can be used for all kinds of frames;

- Light plan - “L” - in lightweight structures of various types;

- Special purpose - “C” - for frames and structures of a special nature.

If you need to find out the remaining parameters and profile sizes of a specific brand taken from the assortment, the tables where they are indicated will help (shown below - tables numbered 1-5). The selection of brands, as a rule, is carried out depending on the loads for which the structure made of channels and other material is intended.

Channel "P"

According to GOST 8240-97, the geometric characteristics and dimensions of the P (parallel edges of the shelves) and U (slope of the internal edges of the shelves) series are practically the same. Their main difference is only in the radius of curvature. The key parameters in markings are width and height. Additional designations for the tables below:

- I—moment of inertia;

- W is the moment of resistance;

- i is the radius of gyration.

Channel with sloped edges (U)

Table 1

With parallel edges

Table 2

Economical profiles

Table 3

Light profile series

Table 4

Special channels

Table 5

Deviation limits

According to GOST No. 8240-97, metal U-shaped profiles may have permissible deviations in their design. We offer information in the following table.

Table 6

Theoretical weight

Table 7

General provisions for metal frame parts

It is wrong to think that the metal profile is of secondary importance. On the contrary, without it, gypsum board loses many of its capabilities.

Without supporting the frame base with plasterboard you cannot:

- level the plane of the wall;

- build a partition;

- get rid of uneven ceilings.

Using a frame, drywall is fixed to surfaces that need construction treatment. Each mounting profile in such a frame has its own location and function.

A wooden frame is also used as lathing. This method has its advantages, but compared to the metal version, it has many more disadvantages.

The weakness of wood is the likelihood of the development of putrefactive processes. Temperature changes or exposure to moisture will reduce installation work to nothing. Even treatment with protective compounds will not help.

Read also: Converting a Bosch screwdriver to lithium batteries

Metal lathing on the ceiling

The metal mounting profile has different characteristics. In comparison with the wooden beams from which the frame is constructed, this element has one drawback - cost. Although it cannot be called significant, since the price of metal products is only slightly higher than the cost of wood.

- resistance to external influences (temperature, humidity);

- the strength of the element itself and the entire structure resulting from installation;

- reliability of fixation;

- durability due to the galvanized steel from which it is made (material thickness reaches 0.6 mm);

- possibility of repair and restoration.

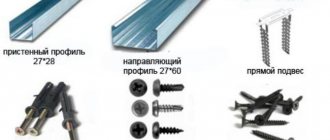

We distinguish two types of profile

There are main and guide profiles. Each product option deserves separate consideration.

- products are marked with the letters PP or PS;

- main purpose is to support high weight loads;

- used as a basis for fixing gypsum boards;

- products, in accordance with the marking, have a U-shaped or C-shaped edge.

- products are marked with a combination of letters PN;

- used as a horizontal base for vertical posts;

- Designed for fixing gypsum boards.

Frame elements

Production technologies

There are cold-rolled (bent) and hot-rolled technologies for the production of these products. In the first case, the channel is obtained by cold profiling from appropriate blanks. In the second - using hot rolled profiles.

Also, U-shaped channels are different in their design. For example, there are products with parallel edges of shelves (brand P) and with inclined edges (brand U). Regardless of the options used, the range of profiles determines their low weight and excellent rigidity. It is these properties that make it possible to use channels of different sizes for the manufacture of structures with increased loads for construction and other purposes. Among the advantages of profiles is the ability to withstand bending, as well as various types of loads: for example, rupture or compression.

Explanation of markings

Main markings installed on:

- ceiling guides for gypsum boards (PPN) - frame elements for fixing the finish to the ceiling;

- ceiling main profiles (PPS) - installed in rooms when forming suspended ceiling structures, plasterboard is attached to them;

- wall rack elements (PS) – used as vertically located racks, intended for walls;

When installed, the rack-mount version of the product has a stacked structure. This means that this profile is mounted in the form of segments. This approach allows you to adjust the size of the material and save money, but ultimately will not affect the quality of the structure.

- wall guides (PN) – used to secure cladding sheets on walls.

Additional details

There are two more types of profiled elements: arched and corner. They are used much less frequently and are used in cases where they create a structure that is complex in shape.

The corner version is mounted on top of plasterboard sheathing. The fact is that protruding corners in structures are the most vulnerable spots. The corner profile serves to protect these areas from possible mechanical damage that occurs during further operation.

When constructing plasterboard ceilings, the corner type is placed around the perimeter of the room. When working with partitions and walls, it is attached to the ceiling and floor.

Corner element

The arched version is used by builders to create radius shapes or non-standard structures. The scope of its application is not limited strictly to walls or just the ceiling.

The arched element is also used when facing uneven corners or in the construction of arch-shaped objects installed in doorways or close to walls. To fix this frame part, use ordinary self-tapping screws.

Example of using a profile on a video:

When working with rounded objects, it is recommended not to underestimate the bend radius. It should not be less than 50 cm. Otherwise, the metal base may not withstand the double load that comes from both the bend and the weight of the installed parts. There is a possibility that at such indicators the frame will burst.

A U-shaped steel profile is a strong beam made of a metal alloy or pure steel, shaped like the letter U. There is a wide range of U-shaped steel channels on the market in any size, the choice of profile depends on the quality of the alloy, strength, ductility, length and thickness of the metal. The U-shape makes the structure rigid; the shelves on the profile are located on one side of the wall. This material serves as the basis for any structure and is widely used for the manufacture of metal structures, in the construction industry and in interior design.

Read also: Conductor for eccentric coupler

TPP/PP/PN (thermoprofile; purlin profile)

TPP is a purlin-type thermal profile with perforations along the entire length of the profile from 4 to 8 rows. Used as a guide profile and as a pair for a rack profile. Possibility of manufacturing the following thicknesses: 1.0 mm; 1.2 mm; 1.5 mm; 2.0 mm; 3.0 mm.

Characteristics and properties

The aluminum U-shaped profile, despite its different sizes, has one significant advantage - minimal wall thickness.

The channel easily replaces a steel pipe of similar size, if this is permissible according to calculations. At the same time, it weighs less, does not create pressure on the foundation and has an aesthetic appearance. The profile replaces load-bearing and purlin materials. The geometry of the channel allows the construction of any structures for construction and repair.

Anodized channels

Advantages of aluminum profile:

- The service life with proper operation will be more than 10 years;

- The minimum possible weight of the material and strength characteristics make the metal profile universal for the construction of objects;

- The profile is resistant to external factors and temperature changes;

- Suitable for various types of processing - thermal, mechanical and welding;

- Easy to install;

- Plastic, allows you to create objects of various sizes and shapes;

- The smooth surface does not allow dirt to accumulate;

- Suitable for any type of fittings;

- Has a high level of thermal and electrical conductivity;

- Made from high-quality environmentally friendly materials;

- Has an aesthetic appearance;

- Affordable;

- Recyclable.

U-shaped steel profile in construction and its features

U-shaped steel profile is often used when installing reinforced concrete structures; it is found on the market in all its variety, from stainless steel to galvanized with many types of markings, i.e. for different purposes. According to GOST standards, only high-quality steel for structures is used for the manufacture of shaped steel profiles; after primary processing and forming, the steel is rolled at high temperatures, hardened and receives a new property - rigidity.

Modern steel profiles are divided into three types according to the processing method:

- hot rolled profile;

- bent profile;

- special profile.

Hot-rolled steel profile is used for interior work in industrial and office premises for the construction of plasterboard partitions; it is rigid, but easy to cut; with this material the structure will be durable. The special profile has a high density, goes through several processing stages and is used mainly in the heavy and automotive industries to create metal structures and production equipment. Bent steel profile is divided into two types:

The U-shaped bent steel profile is manufactured on a profile bending machine from several types of steel and differs from other types of U-shaped profiles by its rounded edges and outer corner:

- carbon steel;

- low alloy steel;

- cold rolled steel.

The flanges of bent and hot-rolled steel channels can be parallel or built-in with an internal slope of about 10%. This factor does not affect the physical properties and quality characteristics, but one or another profile will have different purposes.

Manufacturing of U-shaped profile

To calculate the cost of your order, please tell us the required dimensions and material of the product. The calculation is made free of charge in 15 minutes.

+7 (495) 134-29-54

Possible profile lengths are from 30 to 3000 mm.

Possible profile thickness is from 0.5 to 8 mm.

Possible materials for production are steel 3, cold-rolled steel, galvanized steel, stainless steel, aluminum, copper, brass. Certified metal from trusted suppliers!

Thanks to modern CNC machines, manufacturing accuracy is +-1 mm.

Payment methods - bank transfer, cash, transfer to card. Possibility of working with VAT and without VAT. For large volumes there are discounts.

Launch of production according to payment order. Urgent production possible.

A drawing of the product for approval is free.

With a volume of 1000 l.m. – free trial sample

We will purchase metal, bring it to our production, manufacture products as soon as possible in accordance with GOST and drawings, and ship the finished product to you.

You can receive your order by pickup, or we will arrange delivery to the desired address.

For your convenience, we have a personal manager who is attentive to your wishes, we are in touch from 8-00 to 22-00.

We are waiting for you to visit our production site! Tea, coffee and a visual demonstration of the process! Work examples

They come back to us again! Reviews

Still have questions? You can ask them by sending a request by email

[email protected] or by calling +7 (495) 134-29-54.

You can also leave your contact details, and our managers will contact you to discuss the details of the order.

A U-shaped profile is a rolled metal product in the shape of the letter “U” of varying thickness, manufactured by cutting sheet metal and subsequent bending of the blanks on specialized high-tech bending equipment.

In construction, such products are used quite often, since they provide about 20% savings in metal. In addition, the weight of future structures is reduced, and their reliability and strength will remain as high, because The U-shape enhances the bending rigidity of the structure due to the side walls, which act as spatial stiffening ribs.

According to production technology, the U-shaped profile can be bent or hot rolled. Externally bent profiles differ from hot-rolled ones by the rounding of their external corners.

Profiles are also divided into equal and unequal flange. The first type has shelves of equal length, while the second type has shelves that differ in length.

U-shaped profile is widely used in construction, repair, and mechanical engineering. The main areas where bent profiles are used are frames for cladding external and internal surfaces of walls, for creating a variety of ceilings, roof purlins for internal partitions, shelves or warehouse structures, guides, for the prompt and most accurate formation of docking units in suspended, electrical, prefabricated designs. They are also used as a decorative element under which communications can pass.

We can produce a wide range of bent steel profiles according to individual sizes for each individual project from steel grades St3 and St09G2S, stainless or galvanized steel.

Having our own production facilities gives us the ability to produce angles and various profiles with thinner walls, which reduces weight and reduces the cost of construction, as well as the ability to flexibly configure equipment and promptly produce small batches according to customer sizes.

Length from 0.2 m to 3 m, metal thickness - 0.5 to 8 mm. Can be made from customer's material. The cost of production is calculated individually depending on the type and thickness of the material, size, and required circulation.

You can buy a U-shaped profile by sending a request by email

[email protected] or by calling +7 (495) 134-29-54.

You can also leave your contact details, and our managers will contact you to discuss the details of the order.

Advantages of working with us:

— competitive price for services provided

— compliance with delivery deadlines

— both your own material and the Customer’s material can be used

— organizing the delivery of finished products throughout Moscow and the Moscow region, as well as to any region of Russia.

— highly qualified personnel

- Individual approach to every customer

Purpose of steel U profile

The purpose of using a steel U-shaped GOST profile can be determined by the profile series, which is displayed in the markings on each segment:

- P – steel profile with parallel flanges;

- S – special profile;

- L - light steel channel with parallel flanges;

- E - economical profile with parallel shelves;

- U - steel profile with shelves with an internal slope.

A number will be indicated next to the marking on the profile. The number shows the distance between the shelves in centimeters. The features of the production of n channels are not limited to this, because For different types of structures, a profile of a certain thickness and density is required, then the material has an additional designation B or V. The letter B denotes a profile of increased accuracy, and the letter B indicates normal accuracy. To build complex structures in rooms with and without climate control, different metal structures are used. For rooms where air humidity is high, mold constantly forms due to dampness or there is no heating during the heating season, a profile made of stainless steel or galvanized is suitable.

The stainless U-shaped perforated steel profile is made of alloys that contain anti-corrosion elements and properties; in addition, such a profile is coated with metal antiseptics, which counteract moisture and protect the surface from rust formation. This material easily withstands temperature changes, climate change, and off-season periods and can be used for outdoor work and the construction of external metal structures. The main advantage of galvanized and stainless steel profiles is flexibility during installation and cutting and durability, because Over time, the material loses its elasticity.

Read also: Checking the density of battery electrolyte

Standards for manufacturing steel U profiles

All types of steel channels require manufacturing using a specific technology; for each of them, a separate GOST has been developed with a clear establishment of standards for quality, durability and environmental safety. Each type of channel can only be used in certain premises and used in accordance with established rules. It is quite possible to buy a U-shaped steel profile inexpensively on the rolled metal market, because the manufacturing technology and extraction of the material do not require any special costs.

To create high-quality steel profiles, only environmentally friendly alloys with an organic composition are used, so using a channel in a residential area will not cause difficulties or problems, especially with the health of residents. From an installation point of view, a steel profile is the best material; it has no physical defects, it can withstand any mechanical damage and has precise dimensions. The price of a U-shaped steel profile will pleasantly surprise buyers, since the material is very popular in construction, it is about 15% stronger than hot-rolled steel, it is convenient for welding and makes the structure durable. This material is used not only in the construction of new houses, but also for the reconstruction of buildings that are more than 100-150 years old. Hot rolled steel profile is suitable for wall construction in high-rise buildings.

Advantages of steel profile

To create a durable structure, there is no need to order parts of a certain length; for a U-shaped steel profile, the dimensions are standard, but they are assembled into one line or shape, like a construction set. The shortest is 3 m, and the longest reaches 12 m in length. In total, there are three types of profiles according to length:

Before purchasing channels, you need to measure the parameters and weight of the structure, calculate the number of sections and select the correct type of profile. The weight of the material depends on the alloy; if you need a lightweight structure for building partitions in a room, a hot-rolled stainless steel profile will be sufficient. If the steel frame must withstand a significant weight load, it is better to use a galvanized hot-rolled profile, it is cheaper in cost and can withstand environmental influences.

The perforated U-shaped hot-dip galvanized steel profile is easy to use and is considered an almost eternal building material, and the cold-galvanized steel profile does not corrode. The bent profile is indispensable in the construction of industrial premises, entertainment and shopping centers, and warehouses. Steel profile serves as the main material for strengthening reinforced concrete and internal plasterboard structures. The material goes well with all types of decorative finishes, including laminate, wood, clay and glass. The square profile is excellent for the construction of load-bearing structural elements and can withstand high weight loads, while the rectangular profile is used for the construction of suspended ceilings and light partitions, which can be rebuilt or disassembled over time, like a construction set.

In what areas is this profile type used?

U-shaped metal profiles are actively used in the construction of prefabricated buildings. The following construction areas can be identified for which the use of this type of metal elements is relevant:

- Agricultural sector (construction of prefabricated structures in the form of hangars is relevant);

- Commercial sphere (structures of supermarkets, shopping centers, office buildings, hotels, warehouse buildings are constructed from this type of metal profile);

- Housing construction (construction of residential buildings).

The categories described above relate to the creation of prefabricated metal structures, where a U-shaped metal profile plays the role of purlins or ceilings. It is also important to use this component for the installation of finishing profile structures for finishing facades (internal or external type). Due to this shape, this profile can act as a load-bearing base of the structure or be installed as interfloor ceilings. Mechanical strength determines stability and strength at any rated load.

The use of such a steel profile in interior finishing work is important for creating a frame when installing partitions or a profile for drywall. In such cases, thin-walled galvanized profiles with perforations are used, which can be bolted together without welding. A similar profile can be installed on the walls for further finishing with a primer. This is necessary in order to create an even layer without flaws.

A larger U-shaped metal profile is used for the construction of light metal structures. Often it acts as a supporting structure and is mounted vertically as a base, and also horizontally as purlins. It is also relevant for the construction of tent structures during the construction of hangars or warehouse complexes. For connections, welding or bolts of various diameters are used.

Another area of application for the U-shaped metal profile is installation for wiring or other systems. For this purpose, a thin-walled metal profile with perforations is used for practical bolting. Wiring and other networks in the profile are protected from external influences. In addition, the metal’s resistance to high temperatures prevents wiring from burning out or catching fire.

The U-shaped profile frame serves as a high-quality element for creating ventilated facades. However, for this purpose only thin-walled components are used, which have low weight but high mechanical strength. Any finishing sheet materials or window systems can be mounted on profile systems. The small specific gravity of the U-shaped profile is also relevant for the construction of advertising structures and frames of shopping pavilions.

It is worth highlighting a separate area of application of these elements - light metal structures. This technology involves the rapid construction of buildings in residential, industrial or commercial areas. The frame is based on beams, and the purlins and ceilings are formed from a similar type of profile.

The main prefabricated component is considered to be a similar profile for exhibition stands, advertising structures or seasonal structures. For example, when assembling temporary trade pavilions or warehouse structures (this explains the popularity of using a U-shaped profile for the installation of agricultural structures, including tent hangars or warehouse complexes).

Characteristics of the U-shaped profile in various fields of application

U-shaped profiles have similar geometric parameters to profile pipes of similar dimensions. Due to this, they are actively used in the construction industry as a replacement for profile pipes. This reduces the overall weight of the structure, reducing the load on the load-bearing frame structures.

Please note that aluminum and steel profiles of this shape do not have established operating parameters. For example, the manufacturer does not set strict operating parameters for such metal blanks. A temperature of 100 degrees Celsius in negative and positive values will not change the plasticity parameters of the metal or its deformation parameters. Additionally, the blanks have a high heat conductivity parameter, so they can serve as the basis for prefabricated residential, commercial or industrial buildings with an established microclimate.

One of the secondary, but no less important reasons for using profiles of this type is their bending strength parameter. Side walls significantly strengthen the structure, eliminating deflection of structures or disruption of the primary shape of structures.