Residents of holiday villages and rural settlements from time to time are faced with the need to pump out dirty water containing a large number of various types of insoluble inclusions, including long-fiber ones.

A borehole or sump pump designed to work only with clean water will be useless in such a situation.

Here you need a special unit, which is called a surface pump for pumping out dirty water. Let's consider the most affordable and easy-to-use type of this equipment, namely a surface pump for dirty water, and learn how to choose it correctly.

Scope of application

Unlike pump models designed for lifting and transporting clean water through pipelines, a pump for contaminated liquids is not afraid of hard and soft insoluble inclusions . Nevertheless, the capabilities of the models are different - while some are capable of pumping water with sludge, others are able to cope even with thick viscous compositions, essentially liquid mud. This point must be clarified at the selection stage, taking into account the intended scope of application of the pump.

In a private house or country house, a surface centrifugal pump for dirty water can be used for:

- draining a basement or cellar during a flood or in the event of an emergency,

- pumping liquid from inspection wells,

- drainage of storage or drainage ditches and pits,

- draining pools, fountains, artificial reservoirs when cleaning, repairs are necessary or before the onset of winter,

- supply of partially purified or ground water from pits or drainage pits (wells), storm water storage tanks for watering plants,

- installation of an irrigation system using a natural reservoir,

- draining pits during the construction of a house or outbuildings, if groundwater is located high on the site.

Choosing a surface drainage pump

When choosing a pump for dirty water, pay attention to its main parameters:

- productivity and pressure;

- body material;

- the ability to pump clean water;

- mobility.

Performance and pressure

Both parameters are related to each other by an inverse relationship - the greater the pressure the pump must develop, the lower its performance will be.

The product data sheet contains a graph or table, called the main characteristic of the pump, which displays the relationship between these values.

To determine productivity, you should divide the volume of liquid that needs to be pumped out by the time it takes to do it.

For example, if we want to drain a cellar with an area of 8 square meters. m with a ceiling height of 2 m for at least 5 hours, we will need a pump with a capacity of (8x2) / 5 = 3.2 cubic meters. m/h.

Next, we determine the required pressure. To do this, the length of the pipeline through which the liquid is discharged must be divided by 10, and then the difference in height between the drain point and the pump must be added to the resulting value.

All that remains is to look at the main characteristics of several models and select one that can develop sufficient pressure at the required performance.

In order to get rid of waste water in private homes, a drainage well is used, since a conventional pump is not suitable for this purpose. Selecting a drainage pump for dirty water: device, types, selection criteria.

Do you know what a pump is used to increase water pressure? You can learn more about this here.

And in this topic https://aquacomm.ru/vodosnabzenie/zagorodnyie-doma-v/avtonomnoe-vodosnabzhenie/istochniki/rucheek-nasos-tehnicheskie-harakteristiki.html all about the features of operating submersible vibration pumps “Rucheek”. Technical characteristics and features of repair for various types of breakdowns.

Housing material

Some models have a plastic body.

They are cheaper than metal ones and produce less noise during operation.

But their resource is relatively small, so in this regard, the concept of savings is relative.

In addition, plastic breaks easily from impacts or when dropped.

Ability to pump clean water

You should be aware that not all drainage pumps can operate on clean water. If you plan to pump water with or without contaminants, look for a universal model.

Mobility

Drainage pumps are available in both stationary and portable versions. The former are more powerful and are used in a permanent workplace, for example, for watering a garden or periodically draining a storm sewer storage well.

The latter are less productive, but they are light in weight and have a convenient shape, making them easy to transport to different sites. There are also quite powerful mobile models equipped with a chassis.

Types of pumps

When choosing a pump model, it is important to remember that a surface pump for dirty water, the price of which seemed attractive to you, must have certain capabilities. Having assessed the expected operating conditions and assigned tasks, compare them with the characteristics of the model. To make it easier to navigate the variety of assortments, you should know the characteristics characteristic of certain categories.

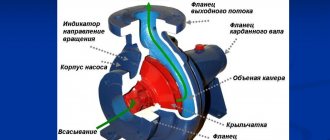

- Centrifugal pumps are capable of pumping liquids with a high content of impurities, provided that the maximum linear size of inclusion particles does not exceed 10 mm. To ensure the longevity of the pumps, it is important that the transported medium is not chemically aggressive in relation to the elements of the pumping equipment. The most popular products in this category are the console-monoblock type.

Calpeda Surface Centrifugal Pump for Dirty Water - Self-priming drainage pumps are characterized by high power and wider capabilities compared to other products. Such units are also capable of pumping liquid with insoluble inclusions up to 10 mm, however, drainage machines allow a higher content of impurities, as well as the ability to transport liquids with solid inclusions (such models are called slurry). The advantage of pumps in this category is a wide range of operating temperatures (from -10° C to + 90° C depending on the model). The self-priming design allows the liquid to rise to a height of up to 9 meters.

- Screw pump models are capable of pumping viscous, highly contaminated liquids, as well as wastewater with fairly large inclusions. Therefore, fecal pumps for dirty water have this design. If there is a pond on or near the site, even a small and very dirty one, a screw surface pump will allow you to use fertile sludge to fertilize the beds. Pumps in this category are capable of transporting liquids with temperatures up to +75° C.

- Self-priming membrane products allow the presence of up to 50% of insoluble particles with a linear size of up to 50 mm in the pumped water. Using this technique, it is possible to drain canals and trenches, since in such cases the water may contain not only sand and clay impurities, but also small stones, clods of earth, etc.

A surface pump for pumping out dirty water can be stationary or mobile . In the first case, it is advisable to choose a design for permanent or frequent use. For example, when using storm drains or water from a reservoir for irrigation, it is better to install the equipment locally rather than transport it there each time.

The Wilo surface self-priming drainage pump can be installed permanently or used as a portable device

Mobile pump models can be portable (have low power) or equipped with wheels like a trolley (with high technical characteristics). They are chosen for periodic use, for example, in emergencies, for draining the pool, which is required no more than several times a year, etc.

Device

The most common drainage pumps are the following designs:

- Centrifugal: the pumped medium is spun by the impeller, as a result of which centrifugal force begins to act on it. Thanks to it, the liquid rushes into the outlet pipe with strong pressure. Unlike pumps for clean water, drainage units have an open impeller, which helps avoid jamming when pumping water with impurities. The maximum particle size for most surface centrifugal gray water pumps is 10mm.

- Screw: according to the principle of operation, this pump resembles a conventional meat grinder - liquid is supplied from the suction pipe to the discharge pipe using a screw. Such units are capable of pumping highly contaminated liquids with high viscosity and large inclusions. Most fecal surface pumps for dirty water are screw pumps. They are often used to organize irrigation of garden plots with water from natural reservoirs, even very dirty ones. In this case, watering is combined with fertilizer, since fertile silt, as well as crushed algae, leaves and various organic debris will fall onto the site along with water.

- Diaphragm: the suction and discharge pipes of such a pump are equipped with valves, and the liquid is pumped by a flexible membrane that oscillates. The membrane itself is attached to a magnet, which is driven by an alternating magnetic field. In industry, fire-resistant diaphragm pumps are used - in them the membrane is driven not by electricity, but by compressed air. The pumped medium may contain particles up to 50 mm in size.

The main purpose of diaphragm pumps is pumping viscous liquids.

Features of surface pumps for contaminated waters

Any surface self-priming dirty water pump has both advantages and disadvantages, so it is important to fully evaluate the models when choosing.

The advantages of pumping units of this type include:

- Unpretentiousness and ease of operation, thanks to which the equipment can be easily transported and installed in almost any necessary place. Sufficient conditions are only the presence of a flat area and the ability to connect to the electrical network.

- High values of the main operating parameters of pumps, including lift height and pressure required for horizontal transportation through a pipeline.

- Increased wear resistance of main components and parts, due to the need to cope with heavy loads, as well as contact with solid inclusions in dirty water, which may have abrasive properties.

- The ability of pumps to operate for a long time without technological interruptions.

- Lower cost compared to submersible units.

The disadvantages of surface pumps are:

- The inability to lift water from the bottom of deep wells, trenches or reservoirs (as a rule, the lifting height of models of this type does not exceed 8 m).

- pumps constantly or frequently operating in the house or near windows on the site are placed in soundproof booths to ensure comfort).

- The need to accurately follow instructions when installing a suction hose or pipe due to the high probability of an accident in case of violations. If the home owner does not have the necessary experience, it is better to use the help of a professional.

What types of surface sump pumps are there?

Unlike submersible pumps, surface pumps operate outside the pumped medium. It can enter the working chamber of the unit in two ways:

- By gravity (normal suction pumps): liquid can come from a container next to the pump or be supplied to it by another pump (cascade scheme). Units of this type can be started without pre-filling.

- Due to the vacuum created (self-priming surface pumps for dirty water): such a pump is able to draw in the pumped medium, even if it is located much above its surface. The theoretical maximum depth from which liquid can be raised in this way is 10.34 m (at normal atmospheric pressure). In practice, the maximum suction depth for the most advanced models does not exceed 8 m - the design features and hydraulic resistance of the supply hose have an effect. Therefore, in cases where the water surface is below this mark, a submersible pump will have to be used instead of a surface pump.

Before starting, water must be poured into the self-priming pump through a special hole. Moreover, you need to fill not only the working chamber, but also the supply hose. The latter must be equipped with a check valve to prevent water from flowing into the source.

For unknown reasons, the check valve, without which the operation of a self-priming pump is impossible, is not always included in the kit; it often has to be purchased separately. When comparing the cost of individual pump models, this must be taken into account.

Self-priming surface pump

Also, the supply hose must have reinforcement, otherwise it will be pinched by ambient air pressure.

If the pump’s passport indicates that it is a drainage pump, this does not mean that this unit is able to cope with any contaminants. The capabilities of a dirty water pump are determined by the maximum particle size it can pump. These data are indicated in the product specifications. Some models are designed for slightly polluted water containing a small amount of sand. Others can easily handle small and even large stones. The maximum size of hard and soft insoluble particles for the most “omnivorous” models is 5 cm.

The consistency of the pumped medium is also important. Some units are designed to work with liquid substances, for example, water and sludge. Others are designed to pump thick and viscous mixtures, such as liquid mud.

Fecal pump with knives Belamos DWP 1300 CS

Among the drainage units there is also a special group - fecal pumps. They are not afraid not only of large debris, but also of long-fiber pollutants (hair, threads, etc.), which easily “kill” equipment that is not adapted to them. The thing is that fecal pumps have a shredder installed at the inlet, which quickly deals with any debris that gets into it.

From what has been said, it becomes obvious that before purchasing a pump for dirty water, you need to clearly understand exactly what tasks it will have to solve.

For source depths greater than 8 m, you can use a special surface pump model equipped with a remote ejector. Such a unit is capable of lifting water from depths of up to 50 m. However, it is characterized by unstable operation.

Operating rules

Despite the versatility of all pumps of this type, you should inquire in advance about the possibility of using them to transport clean water. It may seem that a pump capable of pumping dirty liquid can also handle clean liquid, but in most cases the design features of the machines do not allow this possibility (for example, due to the inlet opening being too wide).

Surface pump for pumping out dirty water Aiken

There are other rules, the observance of which will ensure the durability and trouble-free operation of the surface pump:

- Models of any type should not be immersed in water.

- The connection to the power source should be made through a safety circuit breaker, which will prevent failure of the pumping unit during voltage surges.

- It is imperative to comply with the operating conditions of the pump regarding the composition of the liquid (percentage of impurities, their maximum permissible size, chemical aggressiveness of the environment, liquid temperature, abrasiveness of inclusions).

- Do not transport (including move, tilt, pump) a running pump.

- When using the pump year-round, it is important to take care of thermal insulation and heating of the system to avoid freezing.

If you need to choose a water pump for a well to supply clean water, we recommend reading our separate article.

We talked about hand pumps for water in this material. You will learn what they are and how to choose the appropriate option.

How the pumping station is connected to the well is described on this page https://okanalizacii.ru/vodosnabzhenie/nasosy-i-stancii/podklyuchenie-nasosnoj-stancii-k-skvazhine.html

How to use it correctly

It is worth considering the fact that most pumps for dirty water are not capable of transporting clean liquid. If such a function is required, you should check the capabilities of the product in advance.

Rules

In order for the equipment to work properly and for a long time, it is enough to follow a few rules.

- The product must not be immersed in water.

- The connection to the power supply should be done through an automatic fuse; this will protect the device from surges in the network.

- Pump only liquids with permissible impurity content.

- A running pump must not be moved, tilted or rocked.

- A pump that operates on a constant basis all year round needs to be insulated and soundproofed. The room must be heated. Otherwise the unit may freeze.

Criterias of choice

What criteria should you use to choose a pump:

Performance. How much liquid the unit pumps over a certain period of time.- Created pressure. 1 vertical meter is equal to 10 horizontal meters. The liquid must not only be lifted from depth, but also transported over a certain distance.

- Product power. The higher the power, the greater the performance.

When choosing, do not neglect such questions as:

- material of manufacture

- safety

- service

- electricity consumption.

Advice on choosing a pump

To determine the required technical characteristics, you can use some rules:

- Capacity is easily calculated by dividing the volume of liquid being pumped (for example, a garden swimming pool) by the time during which this volume must be moved (pumped out). More efficient pumps have higher power.

- to assess the pressure characteristics if you consider that each meter of lift corresponds to 10 meters of horizontal liquid transportation. Thus, despite the partial truth of the statement that the pressure should be less, the shallower the depth of the reservoir or reservoir, it is worth including in the calculation the need to move the pumped liquid over a certain distance.

Popular models and prices

The most popular and at the same time practical and functional pump models include the following pumping units:

Surface pump Pedrollo

- Pedrollo NGA from a well-known Italian manufacturer - pumps designed for installation indoors and under sheds. The machines are capable of operating at external temperatures down to -10° C, while the temperature range of the pumped liquid is from -10° C to +90° C. The design feature is the presence of an open impeller, thanks to which the pump is able to pump heavily contaminated liquid. The stainless steel wheel is resistant to corrosion and the abrasive effects of solid particles. Features of operation include the need to fill the system with water through a special hole before starting. The price of the pumps is 17.2-17.6 thousand rubles.

- Calpeda C machines are also of Italian origin. They have proven themselves to be reliable and unpretentious pumps designed for pumping liquids with an average content of impurities (linear size up to 4 mm). Depending on the performance characteristics, they can have a cost from 14.6 thousand rubles (power - 0.15 kW) to 28.8 thousand rubles. (1.1 kW).