Every man should have such things as a grinder and a drill in his assortment of tools. A grinder can clean metal from old paint and corrosion. In everyday life, a drill can greatly facilitate repair work if you need to stir any mixture or tighten screws.

But each of these tools has a common goal - cleaning the surface from rust and corrosion. For this, metal brushes are used. You can find photos of metal brushes on the Internet so you don’t make a mistake in choosing. In this article we will look at the types of brushes.

Brushes for drills and grinders

Tools such as drills and grinders can clean any surface from rust and corrosion. Let's look at the main types of brushes.

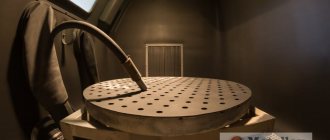

Cup brush

The brush is capable of cleaning the surface from traces of concrete and corrosion. This kind of metal brush for grinders and drills is often used for processing flat steel products.

If you need to treat a wooden surface, you should use a nylon brush.

Adviсe

Using a sponge made of steel threads, you can clean not only grease from dishes, but also stubborn dirt from vegetables (beets, potatoes, carrots).

It is enough to wipe the root crop with a scraper, and then wash off the adhering dust under running water. By placing a metal dish scourer in the place of the bathroom drain, you can forever forget about the problem of hair clogs.

If you don't have sandpaper at hand, an old metal dish sponge will help you sand painted wooden surfaces. A metal dish sponge will help you quickly sharpen your scissors . All you need to do is cut the washcloth into several pieces.

Disc brush

If you need to clean a large area of the surface, then use a disc brush. It has high rigidity and strength, so you can use it for a long time.

The brush for stripping metal is manufactured using the latest technologies. This brush is usually called a brush brush and is used in industry.

Corbrush

Brushes are used to clean parts from rust and flux deposits. Also, if it is necessary to give the product a marketable appearance, this type of brush is used.

In industry, a good and correct brush is used in the production of aluminum radiators for various brands of cars.

Technical wire brushes

You can get advice on application, order and buy Lessmann and Klingspor rotating and manual brushes at the Abrasivkomplekt office in Moscow, St. Petersburg, and Yekaterinburg. The goods are delivered to the warehouse of the transport company with dispatch throughout Russia.

Lessmann brushes - competitors, features and our advantages

Lessmann brushes for mechanical or manual surface treatment are today the number 1 technical brushes in the world. The main competitors of Lessmann wire brushes are Osborn wire brushes. To achieve success, Lessmann is pursuing the path of winning customers by offering wire brushes with new quality and safety indicators. Lessmann metal brushes are produced in Germany using the latest unique equipment, which has no analogues in the world. Lessmann stripping brushes use higher quality cold drawn steel wire than our closest competitor stripping brush manufacturers. An important advantage of any Lessmann brush is the self-sharpening wire, thanks to which the brush works until it is completely worn out, unlike the metal brushes of competitors, which after a short period of work grind in and begin to leave dark spots, and the effectiveness of grinding is reduced to a minimum. Lessmann technical wire brushes have several technical features that increase the resistance and durability of the cleaning brush when grinding welds, removing burrs, and cleaning surfaces. Lessmann wire brushes for machining are produced in the form of wheel brushes, cup brushes, cylindrical brushes, brush rollers, conical brushes, pin tool brushes, end brushes, brush brushes. For manual surface treatment, Lessmann produces hand brushes with metal and plastic bristles. A large place in the program is devoted to brushes for removing dust, brushes for sweeping floors in production workshops. The Lessmann brush fits perfectly in your hand and makes cleaning the room easy and relaxed. A brush with a wooden or plastic handle is made not only from steel wire, like a disk brush for an angle grinder or cleaning brushes for a machine. The hand brush is available with bristles made of steel, brass, polypropylene, horsehair, and coconut. In the Osborn brush catalog you can also find decent models for solving special problems.

Lessmann places great emphasis on the safe use of brushes when cleaning welds. The Lessmann disk wire brush for welders flawlessly cleans the weld seam, which is confirmed by numerous test reports during the inspection of cleaned welds during pipeline construction. The weld seam after treatment with a wire brush for welders is not weakened and has every chance of passing laboratory tests.

In order to select and buy effective technical brushes to solve your problems, you can send a request or call the office of the Abrasivkomplekt company.

Hide

Types of hardness

The work performed depends on the pile. The following wires are distinguished:

- Corrugated. This brush reduces machine vibration and applies gentle pressure to the surface. This happens due to the fact that the brush has springing properties;

- Twisted. The bristles curl and give a harsh action on the plane. The brush has great strength;

- Smooth. The brush quickly loses its shape and over time is unable to do its job.

All brushes differ in their cup diameter.

Types of iron brushes for metal: steel, brass

The wide range of functions performed by cord brushes makes them in demand among craftsmen of various qualifications. Therefore, manufacturers offer a wide range of brushes. Next, the main types of tools with metal bristles are reviewed and analyzed . For more detailed information about each type, it is recommended that you read other publications referenced in the article.

It is important to know that metal brushes include tools made from the following materials:

- steel: alloy, carbon, stainless, brass;

- alloys: brass.

In addition, it is worth remembering this important nuance. Often metal (or, more precisely, steel) brushes are called iron brushes. But this is not entirely true, since nothing is produced from pure iron. Alloys of iron and carbon are used to manufacture metal products. Depending on the amount of the second element, the result is either strong and brittle cast iron, or soft or ductile steel. In publications on our website, when we talk about iron brushes, we mean devices with steel bristles.

Reference. Brushes are included in the All-Russian Product Classification (OKPD) and are a separate group.

For an angle grinder

Metal brushes for grinders, also called attachments, are a universal solution. With their help, it is possible to carry out various processing operations.

Cup brush for angle grinders with bristles made of twisted metal wire. Photo MATRIX

The product is equipped with a special hole designed for attaching the brush to an angle grinder.

Important! The dimensions of the nozzle and the parameters of the unit must match. This also includes the rotation speed of the angle grinder.

Cord brushes for grinders (link to article about them) have different shapes and sizes.

For drill

Metal brushes for drills have some design features compared to attachments for grinders. Such products are equipped with a pin-type fastening , which is placed in a chuck (like a drill) and secured.

Flat brush for drill with metal twisted bristles. Photo MATRIX

Using a tool with such an attachment, you can grind, polish, and clean metal, concrete, stone, wood and other surfaces. Brushes for drills (link to an article about them) have more compact sizes (diameter) than attachments for grinders.

For screwdriver

Another popular type of attachment is screwdriver brushes. This type of device is often combined into one category with cord brushes for drills. Depending on the shape of the chosen brush, the performer has the opportunity to process various products.

Manual: five-row, small and others

Hand brushes are independent tools for work . Their operation does not require any additional equipment. The criteria for classifying metal cord brushes are:

- number of rows: from one to six:

Hand wire brush. Photo VseInstruments.ru

- material from which the body is made: plastic, plastic, wood, combined models are in demand;

Manual four-row metal brush TM Cobalt with a plastic body. Photo VseInstruments.ru

- size: standard and small hand brushes.

Hand brush with metal bristles and wooden handle, standard size. Photo STAYER MASTER

You can learn more about manual metal brushes here.

Harness

Brushes of this type are products whose pile is twisted into strands . The bristles are characterized by increased hardness and cruelty. Wire brushes allow you to perform particularly complex cleaning work, remove stubborn dirt and solve labor-intensive tasks. Wire cord brushes have a self-sharpening effect.

Radial brush for angle grinders with bristles made of twisted steel wire. Photo Practice

Round

There are a variety of types of attachments for power tools. One of the main criteria for classification is the shape of the product.

Cup metal brush for drill. Photo VseInstruments.ru

Despite the large number of models, all types of cord brushes: cup, conical, radial, disk - have a round configuration. It is important to remember that this statement does not apply to hand tools, which have completely different shapes.

Disk

Disc cord brushes (along with cup-shaped ones) are the most common. They allow processing of surfaces located in narrow and hard-to-reach places.

Disc brush for drill with bristles made of twisted steel brass-plated wire, diameter 100 m. Trademark DEXX. Photo Instrumentomania