High chair reinforcement clamp

These products are considered the most popular for reinforcing floors, floors and other surfaces. The latch looks like a cylindrical barrel with four grooves. The jumpers located at the top are unbent.

The usual device has four legs, the reinforced one has five. This type of device is ideal for fittings whose diameter does not exceed 1.4 cm.

What forms are there?

There are a variety of forms of retainers. This is due to the need to securely fasten reinforcement or formwork in the most non-standard positions, so that during the grouting process the metal frame remains in a strictly established position. Some types of geometry can be made only from plastic, some from metal, and other spacers are cast only from high-strength concrete. Let's look at the most common types of fasteners - “Christmas tree”, “star”, “snake”, “cone”, “bone”, “snowflake”, “cube”, “frog”, “chair”, “ceiling support” and “triangle” .

Christmas tree

Herringbone-shaped retainers are made of plastic. They are like a stool on four or five supports, with 2-3 inclined lintels in the shape of spruce branches in the upper part. “Christmas trees” serve as vertical posts for the reinforcement mesh of foundations and floors, and are also suitable for installing floor formwork. Such a spacer provides a protective layer of concrete with a thickness of 10-50 mm or more, is made of plastic, but is not designed for large diameter reinforcing bars.

Star

The star reinforcement fastener is considered one of the most common horizontal spacers, connecting metal rods in walls and columns and providing distance between the rods and the formwork frame. The name is fully justified by the shape of the mount, similar to a star. This clamp has a central clamp for reinforcement with a diameter of 4 to 20 mm. The maximum thickness of the protective layer is 75 mm (for the reinforced version). The manufacturing material is PVC plastic, which produces a large percentage of defects for the entire batch of goods.

Snake

The “snake” spacer is an intertwined frame made of metal rods with a diameter of 4-5 mm. It is used for two-layer reinforcement when pouring concrete slabs for foundations and floors. The height of the clamps is 70-120 mm, and the length is determined in accordance with customer requirements. Despite the reliability of such a distancer, the design has the following disadvantages: inflated price and long production time for “snakes” of non-standard length (to order).

Cone

Cone-shaped clamps are made of two materials - plastic and concrete. PVC stands are characterized by fragility and insufficient rigidity of the body, in contrast to concrete ones, which have higher characteristics in terms of strength and corrosion resistance. Such spacers are designed for installation under large-diameter fittings. They provide minimal contact with the formwork due to their cone-shaped shape and reliably fix the position of the reinforcing bars in space due to wire outlets. Concrete “cones” create a protective layer 20-60 mm thick.

Bone

The “bone” reinforcement clamp is also found in two versions – PVC plastic and concrete. The first type usually resembles the shape of a symmetrical bone and is suitable for reinforcing meshes with small diameter rods. Plastic fasteners do not have a variety of uses in large-scale construction - there are concrete “bone” spacers for these purposes. Firstly, they have higher strength and performance characteristics than PVC, and secondly, each side of the stand is made for reinforcement of a certain diameter, which makes the clamp a universal device for any reinforcement frame. The most common are concrete “bones” with cavities for reinforcement with a diameter of 20-25-30-40 mm and 35-40-45-50 mm.

Round: ring/wheel/snowflake

A “ring” spacer looks like a wheel of large or small diameter with many supports around its perimeter. This “snowflake” is made from PVC plastic; it has a tendency to become brittle and crack, despite the reliable fixation of the horizontal reinforcement grid. The round support provides a protective layer with a thickness of 15-30 mm and is designed for the installation of reinforcing mesh with a diameter of 4-32 mm.

Cube

cube type clamp is used not only for monolithic floors - a reinforced support with a round or square base is installed on loose soils, reliably securing the horizontal reinforcing mesh in the design position. Four semicircular grooves for laying metal rods are cut out on the four plastic edges in the upper part. “Cubes” are used for reinforcement with a diameter of 6-18 mm (standard) and up to 28 mm (reinforced). The created protective layer has a thickness of 35, 40, 45, 50, 55, 60, 65 mm. The advantages of the “cube” include low cost, and the disadvantages are a large number of defective elements with low performance properties.

Frog

A “frog” type spacer is reinforcement rods (lever and sticks), welded in such a way as to ensure uniform distribution of the load on the reinforced frame and its stable position in space. These clamps are installed between vertically located horizontal welded mesh in compliance with a number of rules:

- the height of the “frog” is designed to be at least 10 cm less than the thickness of the monolithic slab;

- the lever and the stick must always be 5 cm longer than the frame cell, otherwise the fastening will fail;

- the installation pattern of the “frogs” is checkerboard, with an optimal distance between the clamps of 60 cm (when using reinforcement with a diameter of no more than 12 mm).

Strict adherence to all of the above rules complicates the process of installing “frogs”, placing responsibility not only for the accuracy of the fastener spacing, but also for calculating the geometric parameters of the spacer.

Support chair / table / stool

Supporting “chairs” (“stools”, “tables” and others) made of concrete are the best option for fixing reinforcing mesh and formwork frames in the design position. Firstly, concrete products have better characteristics compared to plastic products: higher strength, resistance to corrosion and temperature changes, and geometric stability. Secondly, they are easily manufactured for non-standard designs with individual parameters. Concrete spacers provide a protective layer thickness for reinforcement from 20 to 70 mm and are suitable for fastening reinforcing mesh with a diameter of 20-50 mm or more.

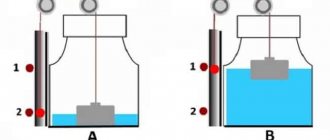

Ceiling support

The ceiling support serves as an intermediate fixation for the reinforcement grids of the floors. It is the same “chair” that connects the lower horizontal mesh to the upper one, like a reinforced spacer, only with grooves for reinforcement at the top and bottom. This type of fastener provides a protective layer from 20 to 60 mm and is suitable for reinforcement with a diameter of 4-40 mm. The main disadvantage is the fragility of the plastic and a large percentage of defective products for the entire batch of goods.

Triangle

Triangular fasteners – “clips” – act as connecting elements and are considered universal reinforcement holders. They are suitable for tying both vertical and horizontal reinforcement bars of different diameters. Their main disadvantage is their limited use: spacers connect metal rods with a cross-section of no more than 10 mm.

What are fasteners made of?

These products are made of durable plastic. Their use makes it possible to maintain stability of shape and size. Thanks to their versatility, fasteners can be easily selected for fittings of any type and size, with various fastening variations.

Similar plastic stands are also used during concreting of structures made from composite raw materials. In addition, the fixing products are interchangeable.

It is also important to remember that plastic retainers are consumables that remain in the “fill.” Although there are also reusable stands, for example, a cone, which is dismantled for further filling of the resulting cavity with solution.

How to choose a retainer - expert advice

When choosing clamps, the quality of the plastic from which they are made is of great importance. Poor quality material will simply burst or jump out under pressure. When purchasing clamps, check their strength during squeezing and pinching; they should not break. Plastic must be flexible and at the same time strong. Do not forget that this type of product requires a certificate of conformity. If everything is in order, buy it.

Watch this video on YouTube

Previous ConstructionProgram for designing a house: tricks that even a schoolchild can master Next Construction BIM design: the pros and cons of visual forecasting technology in construction

Classification of fasteners

Depending on the reinforcement used, supports are divided into:

- supporting;

- wall;

- universal;

- special.

The first ones are used in horizontal planes. The second is in vertical ones. Still others can be used in both of the above options.

The latter type is used in cases where it is necessary to use something like a plug, with which you can create a cavity in the concrete, thereby ensuring the required distance.

Protective layer of concrete

The protective layer of concrete is the part of concrete on which the durability of the resulting structure depends. Essentially, this is the distance from the outer edge of a reinforced concrete element to the nearest reinforcing bar. The thickness of the protective layer of concrete should be selected based on the role of reinforcement in structures. Work or constructive role is taken into account; type of structure, such as column, slab, beam, foundation or wall element; diameter and type of fittings. This is due to the fact that a layer that is too thin will not fully perform its functions, and a layer that is too thick will have a negative impact on the reinforced frame and will increase costs.

The parameters of the protective layer are regulated. To obtain a certificate, compliance with state standards SNiP (building codes and regulations) is mandatory:

- with standard or low humidity in the room, the thickness of the protective layer of concrete should not be less than 20 mm;

- in case of high humidity inside structures, the concrete thickness should be at least 25 mm;

- when constructing buildings whose reinforced concrete parts go into the open atmosphere, the protective layer of concrete should be 30 - 40 mm;

- for floors up to 250 mm thick, the concrete layer must be at least 12 mm. This value varies depending on the diameter of the reinforcement. For thicker floors, the layer thickness increases by 5 mm;

- part of the structure placed in the soil without the use of additional protection must be covered with a layer of concrete from 40 to 76 mm;

- For foundations, a layer thickness of at least 40 mm is provided.

Since reinforced concrete structures are monolithic, magnetic sensors are used to monitor compliance with SNiP rules. They allow you to measure the depth of a metal structure.

Materials for the manufacture of fasteners for fittings

The material for making the clamps is durable plastic, this is primarily due to the fact that it is not subject to corrosion and can easily take any desired shape. It is worth noting that not any plastic is suitable for making retainers. The material must have all of the following properties:

— be resistant to high and low temperatures, as well as to changes in their values;

— are not afraid of the influence of external factors;

- do not deform over time.

How much does a rebar clamp cost?

The price of the reinforcement clamp is low. But when choosing the necessary stands, it is important to take into account all the nuances of where they will be used.

After all, it is precisely such simple objects that help prevent various defects at the time of pouring. Walls, ceilings, floors with clamps are not only smooth, but also as strong and stable as possible.

All manufactured reinforcement clamps meet the requirements of international construction, and this is a guarantee of the reliability and strength of any structure.

Choosing fasteners - advice from an expert

In my 10 years of practice in monolithic construction, I quite often encountered the problem of defective fasteners. After installing them under the reinforcing mesh, and then stepping on it, the stands simply scattered to the sides. They broke in half, and the mesh was lowered onto the formwork. There was also a case with the “star” fasteners; during installation on the reinforcing mesh, they simply flew apart, half the bag was simply thrown into the air. The problem was low-quality plastic; it was fragile.

When purchasing, I advise you to open the bag with plastic stands and check them. If it's a chair, stand on it, it shouldn't break, it might just bend. The fastener is an asterisk, try to put it on something of a suitable diameter, bend it, it should not break. Plastic must be flexible and at the same time strong. If everything is ok, buy it.

Currently, the range of fasteners for fittings is simply huge, and every year it is growing all the time. New companies, new forms appear, but their goal remains the same, which is to provide the necessary protective layer to the reinforcement so that the structure you are building is strong and reliable.

Photos of clamps for fittings

Other types of reinforcement fastening

There are other types of binding for connecting reinforcement bars into a single frame - welding and plastic clamps. You can use these types of connections, but experts often choose the usual wire knitting. Why do builders make this choice? Plastic clamps are a reliable and fast method of tying rods together in a structure. Plastic quickly connects elements and does not require additional components. tools and is also durable after the concrete mixture has hardened. But it has a number of disadvantages:

- cannot withstand different temperatures;

- the price is more expensive than wire;

- unstable connection before pouring concrete.

This connection is quite expensive, and the strength can quickly evaporate before pouring the mixture; under any load, the rods can lead, break the structure and ruin the entire foundation. Such fastening cannot be done in winter; the clamp may not withstand low temperatures. It is more often used in small-volume structures, where all work is carried out quickly.

Why choose knitting rather than welding? Welding requires a welding machine and experience in such work; the connection also turns out to be reliable. This knitting of the frame provides a good connection with a minimum of cost and time. There is a significant drawback to this method of installing reinforcement - the structure can reduce its strength. This occurs due to high temperatures during welding and deformation of the base of the joint. At the first frost, the connection may crack. This connection is used in factory conditions and for large volumes of work, with all calculations and with a specialist. Therefore, the choice is often made towards wire knitting. Plastic reinforcement: how to knit correctly?

How to knit reinforcement to the foundation manually? An alternative option for tying reinforcement is fiberglass. It is in no way inferior to the functions and strength of metal, and its cost is lower. Plastic knitting differs from wire knitting. Before knitting, you need to make thorough calculations on the distribution of forces and loads.

The distance for such knitting should be from 150 to 350 mm; if the structure is light, then 600 mm is accepted. When pouring the base, plastic bosses are used; they help the structure not to sag while pouring the mixture. The style of work is identical to that with wire; special clamps or wire are used. But all work is carried out according to careful calculations.

Important! In order for the fiberglass structure to be stable, it is necessary to use metal elements - they will help prevent the frame from sagging and the occurrence of deformations. Knitting reinforcement is a fairly simple process, but still requires attention to detail. The strength of the entire foundation and building depends on the correct knitting. There are different types of knitting and patterns, but by following the basic rules, you can easily assemble the frame and strengthen the foundation.

Technology for connecting reinforcement with wire

Before knitting reinforcement elements, it is necessary not only to watch the corresponding video, but also to properly prepare the parts to be connected. Such preparation consists of the following:

- cut a piece of wire 20–30 cm long, but you can more accurately determine the required length when you knit several sections of reinforcement;

- fold the cut piece in half;

- wrap the resulting bundle around the joint diagonally twice;

- place the bent end of such a harness onto the reinforcement bar, and also fix the other end on it;

- manually, or using a crochet hook, twist the ends of the resulting wire loop.