Design features and types of conductors

The drilling jig is actually a template of holes that allows you to make them with maximum accuracy. They can be divided into two types:

- when the drilling axis is at right angles to the surface of the material;

- when the axis passes at an acute or obtuse angle relative to the plane.

Conductor device

The tool has such versatility that it is used in various fields of industry. For several decades it has been very actively used in the engineering and construction industries. After all, it allows you not only to drill holes in the required workpieces at different angles and with excellent accuracy, having different configuration features. With its help, holes can be easily drilled in various building structures, as well as pipes made of any material, etc. The jig is often used in the furniture industry, as it greatly simplifies the process of fastening fittings and assembling its various parts. In fact, this is only a small range of tasks that a conductor can solve.

Classification of conductors

The main function of jigs is to ensure straightness in drilling wooden surfaces throughout the entire depth of the hole. Such devices are used quite often in metal processing and, as a rule, are supplied directly with the machine. Due to the need to create such holes in furniture production in large quantities, such devices are in great demand among craftsmen.

There are the following types of conductors:

Invoices. This type does not require fixation before starting work. They are practical and simple, but they should only be used with one hand unless the drill is mounted on a special stand. You can make such a conductor yourself easily and simply, but it must be used in chipboards.- Rotary. With their help, you can make two holes in planes that are adjacent to each other. This operation is performed thanks to a folding bracket.

- Jig for drilling holes at an angle. This option is used in highly specialized industries. It can be used to drill holes at an angle. Sometimes used in conjunction with slip-on conductors.

- Sliding. They are designed to drill holes in multiple locations while keeping the original settings the same. They are mainly used by professionals and require little experience to operate successfully.

If the jig has sufficient rigidity, then it can be used not only on flat planes, but also for curved pipes, etc. In this case, it is secured with a clamp. But under no circumstances should it be used for fastening on wooden surfaces, as it can damage the furniture. You can buy it in a store, or you can also make it yourself.

The jig is in fact a template for making holes, with the help of which such work can be done with maximum accuracy. Due to the simplicity of the structure, they are often used not only in the areas of furniture production. In particular, they are actively used in the field of mechanical engineering for drilling holes in various workpieces, etc. We should not forget about the furniture industry, where such a device is used for various needs when assembling furniture fittings.

Classification of tools

Based on functionality and design functionality, drilling jigs are divided into types:

- invoices. The name comes from their functional way of working, that is, they are applied to the workpiece or the surface being processed, attached to it with special clamps or held by hand. This device is suitable for drilling flat surfaces, such as boards, MDF boards and chipboards. It is called a furniture jig for drilling holes. Thanks to the use of a jig, the holes themselves are very neat and precise;

- rotary. Such templates are ideal for drilling round or cylindrical surfaces. Thanks to this design, the axis occupies a horizontal, vertical and inclined position to the surface. This is possible thanks to bushings that can guide the drilling line;

- universal. Products of this design are widely popular in small industrial production, where quick adjustment to the existing surface plays an important role. Due to their uniqueness, they are also in demand in the household, when it is necessary to work with different materials, planes and surfaces; tipping. In terms of functionality they are somewhat reminiscent of universal ones. They are necessary when you need to make a hole in different planes and at different slopes. This is very convenient for carrying out some repair work when you need to drill a hole in the wall without a lot of time and at a specific angle;

- sliding. According to its name, such a conductor does not have to be attached to the surface where it is supposed to be applied. It should be noted that such a conductor is inconvenient to use, since it requires constant hand holding;

- fixed. Unlike sliding jigs, they are attached to the place where they are intended to be used. They are much easier to attach, but due to their design they limit the scope of human work. This can be clearly seen when working on walls or vertical planes with only one spindle.

Jig for drilling overhead holes

Universal drilling jig

Jig for drilling holes, fixed

Rotary hole drilling jig

Types of drill jigs

There are several ways to classify the devices in question. As a rule, they are divided based on design features:

- Invoices. The simplest model, the name reveals the principle of operation of the mechanism. It is a jig for perpendicular drilling. It is applied to the work surface and secured using special clamps. Budget models must be held manually. Most often used in the furniture industry for drilling sheet-type workpieces: boards, chipboards and OSB boards.

- Rotary. Used for processing cylindrical products. The rotation axis can be vertical, horizontal or inclined relative to the working plane. Guide bushings determine the direction of drilling.

- Universal. The most popular type of design. Such devices are especially in demand on assembly production lines and other facilities where various types of surfaces are processed. Universal jigs allow you to quickly adjust processing parameters to suit existing conditions.

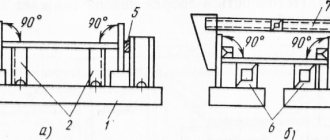

- Tiltable. Used to process parts in several planes. The most common design is a device for drilling in two mutually perpendicular planes.

- Sliding. Such conductors do not have a mechanism for attaching to the working plane. They are used to make several holes with the same parameters. Due to the fact that you have to hold it during work and also move it along the plane manually, handling the tool requires skill. For this reason, the design is not widely used and is used mainly by professionals.

- Pinned. Unlike sliding conductors, this type has a locking mechanism. This makes the master’s work easier, but limits the scope of action. This creates certain inconveniences when processing workpieces on drilling machines with one spindle.

Scope of application

It should be noted that the drilling jig is used almost everywhere where there is a need to regularly drill holes. These areas could be:

- furniture manufacture. When making furniture, it is very often necessary to drill holes for fastening materials, fittings and accessories. The further appearance of the furniture, its presentability and marketability depend on the accuracy and correctness of the hole made;

- construction. When carrying out construction and repair work, it is often necessary to drill walls, pipes and other surfaces. Without templates, this is very difficult to do, and correcting subsequent errors will take a lot of time. Thanks to the templates, all drilled holes will have the desired shape and be at the desired angle;

- mechanical engineering. Working without templates here is also quite difficult, since all blanks and parts undergo standardization, that is, they all must have the same dimensions, the same position of some parts, including holes;

- mass production. Stamp production also requires the unification of some components. Templates simplify tasks in this regard. You can be sure that all holes drilled will be the same size and the same slope, or will be directly perpendicular to the surface;

- household. You often have to repair something at home, so the need arises to drill holes in walls, parts or some workpieces, where the particular accuracy of the holes is very critical.

Nowadays, conductors are produced both universal and specialized for specific areas of work. Some are inexpensive, so there is no need to make such products yourself.

Conductor for cylindrical blanks or pipes

For cylindrical surfaces, rotary or universal types are most suitable, since when drilling a pipe or any other object that has a spherical shape, the drill can move, causing the hole to be of irregular shape.

Conductor for cylindrical blanks or pipes

Such templates allow you to maintain perpendicularity between the pipe or sphere and the drill itself. It is very important.

Additional accessories

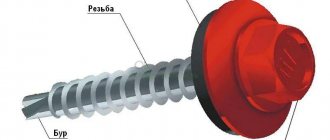

To work with such a system, you may need various drills costing about $4

If anyone is interested, plugs and screws 100 sets, different colors - $7.99

or separately self-tapping screws 100pcs for $3.48

In addition, there are drills that allow you to cut out the plugs yourself, although I haven’t seen them on Ali

so I can't offer a link. But if you come across such a drill with a reasonable price and you share it, I’ll post it here for everyone’s benefit

That's probably all!

Good luck and good mood to everyone! ☕

Furniture jigs for drilling holes deserve a separate description.

In furniture production, it is practically impossible to do without jigs or similar templates, especially when assembling all the structural elements of future furniture. First of all, they correct such an error as an incorrect angle of entry of the drill into the workpiece. As you know, correcting such an error is very difficult, sometimes even impossible, and if possible, it takes a lot of time. The jig not only allows you to position the drill relative to the part, but also allows it to move away from the intended drilling direction during work.

Furniture jig for drilling holes

They are used when you need to drill holes for fasteners. In this case, a conductor for confirmants or dowels is used. Without them, drilling such holes is simply impossible. And how often does it happen that when assembling furniture, a shortage of a certain number of holes is discovered that is necessary for final assembly.

How to use the device

To make it clearer how the device works, let’s connect two pieces of plywood with an “oblique screw”

We measure the thickness of the material in which we will drill holes.

In fact, a regular ruler will be enough to take measurements. Particularly high accuracy is not required...

Particularly high accuracy is not required...

We set the resulting dimensions (material thickness) on the jig and clamp them with a clamp

insert the drill into the jig and set the drill depth limiter.

We secure the jig with the workpiece with a clamp

Drilling holes

The result is a couple of wonderful seats for screws

We connect two blanks

It is believed that special screws are required to use such a connection. Perhaps in some ways they are better, but from practice, I fasten them with ordinary ones - as long as nothing falls apart or cracks. In fact, the main difference is in the screw head - it has a slightly different shape

Although yes, there are a decent number of varieties of them (as well as simple self-tapping screws), but I suppose to a large extent this is just marketing. Buy special ones or use regular ones - it's your choice!

It turned out to be a very strong and neat connection - I personally like it!

Jig for angled holes

A jig for drilling holes at an angle is used for assembling furniture. It is often used for drilling not too thick MDF boards or chipboards, plywood. Also used in production. They can be manufactured either in a specialized design, for specific operations, or in a more universal form. They reduce the time required to make inclined holes. Moreover, it will not be possible to make them exactly the same by eye.

At home you don’t often have to drill at an angle, but the need arises. This kind of conductor can be made independently, or you can buy it. The reason is that if you do not engage in mass production, then preparing templates for non-standard holes will most likely not justify the costs. It will be easier and cheaper to try to drill the hole as needed, but with small deviations, than to make templates. It may never be useful again. It's up to the owner to decide.

Drilling at an angle

When manufacturing various parts and products, sometimes it becomes necessary to drill holes at angles. In this case, the accuracy must be maximum. It is difficult to achieve this without the use of special devices for the following reasons.

- Axial rotation of the tool is accompanied by increased friction on the cutting edges. It tends to move the drill to the side. This is especially noticeable when starting to drill holes at right or other angles. The situation is aggravated by the curvature of the workpiece or workpiece. Naking does not always help.

- It is very difficult to maintain the exact direction. When drilling holes at angles other than 90°, this is almost impossible.

- While drilling holes, the drill bit may move to the side. This occurs under the influence of a force arising from uneven friction on the surface.

- The difficulty increases to the maximum level when it is necessary to drill a large diameter hole at an angle.

The use of various devices helps reduce the influence of the above negative factors. To drill holes at angles, attachments and jigs are used (depending on the design features, they can be called overlays and templates), as well as improvised means.

Dowel hole jig

The jig for drilling holes for dowels is one of the simplest templates in its design. However, you should know that such templates should simplify the work of the master, and not complicate it when he is forced to use complex instruments.

Dowel hole jig

Used for assembling furniture. Should allow simultaneous drilling of holes without changing the device. For manufacturing, different materials are used that have different strength characteristics. The most durable unit can be considered a steel unit.

Conductor to confirm the variety and the possibility of manufacturing

Also the simplest jig for drilling a hole for confirmation. Such a conductor can be assembled at home without much difficulty. It makes sense to assemble it yourself if you are engaged in professional furniture manufacturing. It is not practical to drill one or two holes.

Conductor for confirmation

More complex drawings can be taken from any sources on the Internet. As the design of the device becomes more complex, its range of uses expands. In order not to bother with structurally complex devices, you can make them from readily available materials, such as metal plates, wooden beams, fittings or corners. To work with metal, you may need welding materials, although you can attach the fixing elements to threaded bolts.

Advantages and disadvantages

According to its functional purpose, the jig acts as a template according to which it is necessary to drill a hole in the required material with maximum accuracy to the original. This template greatly facilitates the work of the master when he needs to drill a strictly vertical, horizontal or inclined hole.

The master no longer needs to make sketches and measurements, having such a tool with him. The drill is positioned strictly at the required angle, which is necessary during the work process and cannot deviate. This improves the accuracy of the work, which can be seen in deep holes.

To work with furniture, the conductor must meet the following requirements:

- it should help and speed up the furniture assembly process and not require the use of complex equipment;

- allow you to make several holes at once without the need for manual markings;

- improve work with a drill;

The materials from which conductors are made have different strength characteristics. These are mainly plastic and glass made from organic raw materials. But the strongest ones are made from metals, namely steel. Therefore, when choosing, you should pay attention to the following characteristics:

- minimal deformation under heavy loads;

- clear drill direction axis;

- no heating during operation.

In furniture production, lighter conductors are used that are easy to handle. Factory or homemade options can be used.

It should be noted that a real master has a trained eye, so often he does not need all these devices to make the hole correctly.

A clear advantage of such tools is ease of use. With their help, even an inexperienced person can perform all the work at the level of a skilled worker. Here you don’t even need to do any complex calculations or have enormous experience. Its main purpose is to speed up the work process many times over.

Homemade conductor devices

A DIY jig for drilling holes is an excellent alternative to store-bought options. Because the store does not always have exactly the option that is required at the moment. You can assemble it yourself at home.

Let's consider a more popular and standardized option, suitable for more frequently performed work, such as furniture assembly.

Diagram for assembling the conductor

Diagram of a conductor device for drilling holes

Reinforcement with a diameter of 10 mm or more will be required. Using a cutting tool, such as a grinder, cut into pieces of the required length. Clean the workpieces with sandpaper. According to the standard, all drilled holes have a distance of 32 cm from each other. Make marks and drill holes. The next stage involves creating reference points for our blanks. A plate made of any metal is perfect for these purposes. Thickness from 1 mm. It is unwise to use a thicker plate, since it only increases the weight of the entire device. They are connected together and then places for threaded fastening are outlined. They are connected and secured to each other. That's all, the device is ready to use.

The main purpose of the jig, which is also the most important thing, is to simplify the work with the drill and reduce the time of assembling furniture. The difference between a purchased device and a home-made device is its adjustment to the specific needs of the master.