During work in the garden and in the garden, a large amount of organic waste arises: grass, branch cuttings, bark, etc. Some unwise summer residents throw it all into a neighboring ravine or burn it. Experienced gardeners know that all of these wastes make good composting materials. With the help of composting, you can independently prepare free fertilizer for the next season, which in terms of nutrient content will not be inferior to purchased analogues.

As you might guess, this article will talk about composters, composting and means that speed up the process of obtaining fertilizers.

Subtleties of composting

| The finished compost has a loose structure and does not have an unpleasant odor. |

Fertilizer application is a common agricultural practice for increasing natural soil fertility. All fertilizers are usually divided into two large groups - mineral and organic. Minerals are inorganic compounds or complexes of compounds that are most often produced by the chemical industry (superphosphate, potassium monophosphate, etc.). In organic fertilizers, substances beneficial to plants are contained in organic compounds (manure, mullein, peat, urea). The latter also includes compost.

Composting is the process of decomposition of organic matter under the influence of temperature, moisture and air. Certain types of microorganisms and fungi take an active part in composting; their activity leads to an increase in the temperature in the organic mass to 50 - 70 degrees. During composting, pathogenic bacteria and parasite eggs die, while organic compounds break down into substances that are easier to feed plants. The finished product that has gone through all stages of thermal decomposition is called compost. The product has a loose consistency and contains nitrogen, phosphorus, and potassium. The completion of the processing process is indicated by the absence of an unpleasant odor and the brown tint of the mass.

Types of compost bins

Compost is prepared using aerobic and anaerobic technology. With the aerobic manufacturing method, it is recommended to ensure a constant flow of air to the waste, which ensures the functioning and proliferation of bacteria.

Another way to arrange a cesspool is to seal it. This makes it possible to process organic matter by anaerobic bacteria, which require limited access to oxygen. This ensures the preservation of nutrients and eliminates unpleasant odors in the area.

Compost bins are divided into several types according to their design features. The most convenient is a compost container in the form of a prism. If you make the handle on the side, this will provide the ability to control the flow of air.

When making your own compost bin, it is recommended to place it on a flat surface. When using this design, waste is turned over using a shovel or fork.

It is possible to divide the compost bin into several compartments and add compost in parts at different times of the year. This will allow a person to constantly have ready-made mineral fertilizers on hand.

Types of composters

| A compost pit is a simple, but not very convenient way to prepare fertilizers |

A structure designed for preparing compost is called a composter. In the narrow sense of the word, a composter is precisely a box for preparing fertilizer; in a broad sense, it is any structure for producing compost. Some designs can be easily made with your own hands.

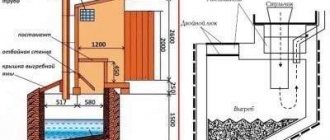

— A compost pit is a budget option for a composter. A rectangular or round hole is dug in the ground. Such a composter is easy to manufacture (you only need a shovel for construction), but it has a number of disadvantages, the main one being the lack of good ventilation, and composting is an aerobic process, i.e. occurs only in the presence of oxygen. In addition, heavy rains can fill the hole with water. On the other hand, the advantages of the pit include the contact of the composted mass on all sides with the soil, which is a supplier of beneficial microflora and earthworms.

| The upper layers of the compost heap become very weathered; to start the composting process, it is necessary to make a cover of film or slate |

— A compost heap is the most unpretentious option for preparing compost. Organic matter is simply piled up and covered with film, slate or roofing felt. The coating must have holes for air access. Fresh manure is usually composted in this form so that it does not “burn” the roots of the plants. At the same time, the process of decomposition in the heap is uneven; the center is the central part, which is not so easy to reach.

| Approximate view of a mesh composter |

- Mesh composter - this design will require a special mesh that wraps around the supports, forming a container. The mesh is easy to install and can be given any shape if desired. The disadvantage is that the outer layers take a long time to decompose due to weathering. The compost in the grid will have to be stirred regularly.

— Box – many people, out of old memory, call such a composting structure a “pit” or a “pile.” You can build a container yourself or purchase a ready-made one. Any materials are suitable for construction. Some people use old boards, sheets of steel, etc. When constructing a container, one should not forget about the ventilation holes, which should go at regular intervals and not be very wide so that the raw materials do not get weathered. After a few years, such a wooden composter will begin to rot on its own, so the boards will have to be replaced.

| A defective board is an excellent material for a composter, so don’t rush to get rid of it |

Ready-made containers for composting have a proven geometry. They are small in size and weight and are easy to move around the site. The service life is not limited to one or two seasons. Manufacturers try to make composters attractive so that their appearance does not spoil the surrounding landscape. Often finished composters have a lid, this prevents the spread of unpleasant odors.

An interesting way to obtain fertilizer is through a composting toilet. Externally, this device is a toilet with a tank with a volume of 100 - 200 liters. Peat acts as a composting and antiseptic agent.

Manufacturing materials

Before making a compost bin for recycling waste with your own hands, select the material for its manufacture, most often consider the following options:

Wood

To make a wooden box, they use boards that are unnecessary in the household, ready-made pallets, timber; there is no point in using plywood, fiberboard or chipboard sheets that have too low resistance to moisture. Since untreated wood will not last too long, it is coated with moisture-repellent materials - various types of paints, varnishes, hydrophobic impregnations, waterproofing mixtures, bitumen mastics.

Note: Economical and effective ways to process wood are to impregnate it with machine or waste oil, you can simply wrap individual boards with plastic wrap and nail them to the frame.

Metal

Using regular steel for a box with high moisture and fertilizer that will be added to the soil to feed edible crops is not a good option, given that rust will contaminate the compost. Therefore, the best option is to use corrosion-resistant materials in the construction of the box, the most inexpensive of which are galvanized sheet (metal profile) and aluminum.

A metal box can be assembled from separate narrow plates or corners (to increase strength), screwed to a wooden frame made of timber treated with water-repellent compounds.

Rice. 6 Polymer composters

Polymers

Making a compost bin or barrel from polymers is the most successful option in terms of corrosion resistance and service life of plastics, reaching up to 50 years. The retail chain sells factory-made composters for dachas that have an aesthetic appearance, a variety of design and color solutions, and a convenient system for accessing the lower layers of humus. The price of plastic composters is not so low, a rather inconspicuous product can be bought for 2,000 rubles, the cost of imported boxes or large-volume products reaches 15,000 rubles.

Other materials

In addition to traditional components, a compost bin can be built from the following materials:

Net . Mesh types of compost containers are sold on the market, providing the best air exchange; similar devices can be made yourself from a chain-link type mesh. During operation, the mesh box will have to be closed on top with a waterproof lid, and during operation it will be difficult to mix the compost mass.

Note: When constructing a composter bin, a synthetic mesh is often used, which closes the gaps between the wooden boards, preventing the contents from falling out; with this design, the distance between the slats can be increased to 50 mm.

Rice.

Slate mesh boxes . Recently, slate has significantly lost its position when used as a roofing material; one of the ways to use it is to construct waste recycling containers from sheets. In many versions of boxes, the walls are made of solid sheets, which prevents air exchange.

Brick .

A reliable and durable box can be made of brick or any building blocks; when laying, it is possible to make cells for air exchange; the main disadvantage of a monolithic structure is the difficulty in mixing and removing ripened masses.

Composter place

| The most popular color for composters is green. It does not attract undue attention and blends in with the vegetation |

Choosing the right location for a composter will help save a lot of effort and nerves in the future. A container with decomposing organic matter is not an item that all owners want to show off to their guests, so it is better not to place the composter, much less a pile, in plain sight.

It’s also not a good idea to place a pile or a hole next to a fence, as this may cause complaints from neighbors, but a neat box is unlikely to raise questions, especially if it is hermetically sealed with a lid and does not spoil the appearance. The location for the composter must be chosen based on the amount of waste that needs to be processed. For large plots of more than 10 acres with a vegetable garden and garden, more than one box may be required, so space must be provided for installing additional composters. In addition, it is convenient to use a wheelbarrow to load and unload raw materials, but working in cramped spaces is not very convenient.

It is difficult to accurately calculate the volume of a composter, so they rely on approximate examples. A composter with a capacity of 1000 liters is completely filled in one season on a plot of 8 acres. After decomposition, organic matter loses part of its volume, so 600 - 700 liters of finished fertilizer is obtained.

It is recommended to place the compost heap or composting bin in the shade. The decomposition process requires a certain level of humidity, and direct sunlight will dry out the raw materials, slowing down the preparation of the fertilizer. However, you still need to supply the compost with water, so a garden hose must reach it.

Container options

This organic fertilizer can be stored in various ways. For example, just dump everything in a pile.

For some gardeners, the easiest way is to make a standard compost bin. An additional advantage is the absence of material costs, just a shovel and some time.

You can also use a factory-made container made of plastic or metal. There is an option to store compost in ordinary barrels, where holes are pre-drilled on the sides and bottom.

However, they are not always suitable in terms of material or may not have the required volume. Therefore, it makes sense to make a box for organic fertilizers with your own hands.

Designs of finished composters

| Convenient lid design: to load raw materials, only half is opened so that the smell does not spread throughout the area |

When composting, various technological problems have to be solved. All this affects the design of composters. Most models are made of frost-resistant plastic and have a collapsible design, so the container can be easily disassembled and assembled in another place.

| A design in which fertilizer is extracted from the bottom, and new raw materials are loaded through the top hole |

— Lid – a container with a lid has certain advantages. The main one is the absence of an unpleasant odor. Thanks to the presence of a lid, the decomposition process will take place unnoticed by the owners of the site and their neighbors. There are wastes that do not produce unpleasant odors when processed. These include grass, branch cuttings and other plant organic matter. When composting food scraps or manure, a lid is required.

— Removing fertilizers from the bottom - the process of compost maturation occurs most intensively in the central and lower part of the mass: it is in contact with the soil. In the lower part of the container, the fertilizer reaches readiness faster than in the upper part and from the edges, which is why many ready-made composting boxes have removable sections, by detaching which you can remove the finished humus from the bottom.

| A rotating composter usually has a small volume so that the load on the frame is not too high |

On some models of sectional composters, it is possible to subsequently increase the volume by purchasing additional sections.

— Stirring is used to create a homogeneous mass and to reduce the temperature in the central part of the pile. This allows you to accelerate the maturation of the outer layers of organic matter. For mixing, special tools are used - compost aerators. They not only penetrate the top layer and improve oxygen supply, but also help mix the layers. To make mixing easier, many manufacturers install containers on a rotating axis. Using the handle, the containers are rotated and the fertilizer inside is mixed. The disadvantage of this design is the lack of connection with the soil, which is why earthworms and beneficial bacteria do not penetrate the humus.

— Mesh bottom – this design element is not found on all ready-made composters.

If a mesh bottom is not provided, you can make it yourself. The mesh allows you to protect fertilizers from mice and other rodents, while the contact of humus with the ground is not disturbed. Beneficial organisms and worms easily enter the composter through the mesh cells.

Humus and compost - what's the difference?

It is a mistake to assume that these two terms have the same meaning. What they have in common is only the essence of obtaining fertilizer, namely the process of decay. The difference lies in the components used, which will lay the basis for feeding and its vitamin and mineral composition.

Humus

This is decomposed manure - cow, horse, rabbit and any other, depending on the household living on the site. The entire process of debate or decomposition takes from 2 to 5 years. The finished humus should have a pleasant, fresh aroma, like soil in a forest. To improve the quality of the fertilizer, manure is mixed with soil, sawdust, straw, adding water if necessary to prevent drying out.

The presence of a heavy ammonia smell indicates that the humus ripening process is not yet complete.

From time immemorial, almost all crops in Rus' were fertilized with manure. It is excellent for sandy loams, retaining moisture in them. It makes clay soils looser and more aerated. Ready-made humus is the same humus that is a fertile component of any soil.

Compost

Not all summer residents have the opportunity to fertilize their plots with humus. In this case, compost will come to the rescue; you can make it yourself using a pit or a special container - a composter.

What not to put in the composter

There is no single list of ingredients for composting, but there are general recommendations that will allow you to get good fertilizer. It's worth starting with those products that should not be put into compost.

- Products with high acidity are not suitable for composting; for this reason, citrus fruits should not be added to future fertilizer.

- Inorganic waste will not be processed into fertilizer, so it is better to dispose of metal, glass, and plastic in another accessible way.

- Weeds with strong rhizomes and seeds may germinate in the future in the bed where the fertilizer was used, so such plants should be added to compost with caution.

- plants affected by diseases . Fruits and leaves affected by powdery mildew, and trimmings with traces of apple cancer must be burned.

What to put in the composter

| A fork can be used as a tool for loading tops and grass into the composter. |

Various types of organic waste are suitable for composting. All ingredients can be divided into catalysts and raw materials. Catalysts speed up the decomposition of organic matter. It is recommended to use ingredients with high nitrogen and carbon content.

- Plant waste (tops, leaves, grass) is the most common ingredient for composting. Lawn mowing residues and weeds without a strong root system are suitable here. A lot of plant waste remains after harvesting. Not only fresh material is suitable, but also dry grass and foliage. The leaves contain carbons and the grass is a source of nitrogen, so the two complement each other perfectly.

It is better to load raw materials into the composter in layers. A layer of dry grass, branches or leaves is placed at the bottom, then fresh waste is placed, and soil or peat (catalysts) is added as the next layer. This order of layers is repeated several times.

- Wood waste contains large amounts of carbon, potassium and phosphorus. They are characterized by low acidity. Wood waste includes branch trimmings, sawdust, bark, shavings, etc. Large branches will take too long to decompose - they are crushed to be added to the compost. To speed up the composting process, wood waste is mixed with acidic, nitrogen-containing ingredients such as manure or droppings.

| Using a garden shredder to produce fine wood chips for composting |

Shredded raw materials are processed faster. The fastest way to prepare branches for composting is to use a garden shredder with a gear cutting system. These devices can turn branches 3 - 5 cm into wood chips. Read more about garden shredders in the article “How to choose a garden shredder.”

— Sludge and algae are plant waste. This organic material is rich in nitrogen, phosphorus and potassium. Garden ponds can become a source of sludge in the country. Sludge combines well with peat and requires virtually no additional processing before putting it into the composter.

— Peat is a universal catalyst for compost. The material is mined in swamps and is formed from rotted moss. The upper layers of peat can have high acidity, while the lower layers are neutral in pH level. The main advantage of peat is its ability to balance the acid-base balance of other raw materials. To activate decomposition processes in peat, nitrogen is needed, so bog material works best with manure and grass. Peat has an antiseptic effect; it neutralizes pathogenic bacteria in humus.

- Manure and other types of waste products are rich in nitrogen, but at the same time have high acidity and an aggressive pathogenic environment (cow manure also contains weed seeds), so compost from such raw materials must “ripen” before use. To do this, manure or droppings are mixed with peat, wood components or dry grass.

| Many composters have thermometers to monitor the temperature. |

Earthworms are active participants in the composting process; they eat organic waste, releasing vermicompost that is nutritious for plants. The design of the composter should not prevent the penetration of earthworms, and on the contrary, access to the composter should be denied to moles, voles and other rodents. Worms love moist, slightly acidic or neutral soil.

Building a box for manure and humus with your own hands

Bird droppings, manure, and plant waste are used to prepare compost. To preserve nutrients, it is recommended to construct the boxes correctly. Fertilizer is stored hot or cold.

With the first method, the waste must be placed in a box and compacted, which will reduce the percentage of air ingress and ensure long-term preservation of nutrients.

When using the cold composting method, it is recommended to build a closed box. In this case, you need to nail the boards tightly so that no gaps form between them. This design requires the construction of a sealed lid. After laying the compost materials, they are covered. For this purpose, grass, straw, and earth are used.

Temperature adjustment

The vital activity of bacteria that participate in the process of decomposition of organic matter leads to an increase in the temperature inside the humus. At the peak phase of decomposition (thermophilic), the temperature can reach 70 - 75 degrees. When the process of fertilizer formation enters the final stage, the temperature decreases.

The high temperature of composting helps to destroy harmful pathogenic bacteria, but excessive “overheating” of the composter can lead to the death of not only harmful, but also beneficial bacteria. To prevent bacteria from “burning out”, the compost is mixed, water is added and opened for ventilation.

Composting accelerators

| Stirring the compost avoids overheating |

Accelerators are biological products that speed up the decomposition process. They contain biobacteria and enzymes that promote the decomposition of organic substances. Some supplements contain amino acids and minerals. Before use, most drugs must be diluted in water and allowed to stand, after which the solution is added to the composter. Organic matter is carefully dug up. Acceleration of composting processes occurs 3-6 times. At the same time, it remains necessary to maintain the temperature regime, maintain the level of humidity and supply the humus with oxygen.

Accelerators can help in composting when all the natural bacteria are “burned out” due to the “overheating” of the humus mass. Accelerators are also required for use in composters that are not connected to the soil.

These products are often referred to as composting products, but this term can be misleading. All the necessary microflora is already contained in organic matter and in the soil, and the introduction of drugs only accelerates the process of humus formation.

How to choose?

Choosing a composter starts with its volume. For small areas (up to 6 acres) or for the disposal of food waste, a design with a volume of 200-300 liters is suitable. For a larger area, a larger capacity will be required - up to 1000

l. Sometimes summer residents purchase two or three composters at once and put organic matter into them one by one, thereby providing themselves with a continuous supply of organic fertilizer.

When choosing a composting device, we focus on its structural details. For example, it is important to pay attention to the presence of a bottom mesh that protects the contents of the container from rodents.

If it is not included in the kit, you should worry about purchasing additional items in a timely manner. Yes, and it won’t hurt to immediately decide whether it will be a summer composter or whether all-season placement of organic matter is planned.

Before purchasing a box, you need to pay attention to the entrance and exit hatches. They should be wide enough to make it convenient to lay armfuls of grass and scoop out fertilizer with a shovel. Having a large loading hatch will make it easier to stir the pile to increase oxygen access. An alternative to the unloading hatch can be a pull-out tray with ready-made fertilizer from the lower layers.

Expert opinion

Yulia Safronenko

Big fan of experiments and personal gardening techniques

Ask a Question

Hatch fastenings are a fly in the ointment for many models. During operation, it is discovered that the doors dangle and tend to fly off due to the wind. Therefore, before purchasing, you need to check how they rotate and how tightly they fit when closed.

The mobility of the composter is important, especially if it is stored for winter or regularly moved. If you plan to compost throughout the winter, a thermal composter with a thermostat, thermal insulation and peat included will be indispensable. For lovers of California worms, a vermicoposter is suitable.