Metal welded I-beams have been used for the construction of structures and floors for a long time. But until this time in Russia its use was strictly limited to the sphere of industrial construction, i.e. when truly grandiose structures are erected, which should not care about anything.

And only in recent years have such types of I-beams begun to appear that can actually be used in the construction of new houses of an ordinary residential building. Are you thinking about just such an overlap? Then we will help you learn all the features of its manufacture!

What is an I-beam

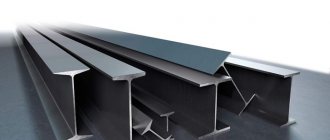

This element is used very often in construction. It is a metal connection consisting of three parts: the upper and lower shelves, between which is a vertical wall. The structure is monolithic. Can be produced by rolling or welding.

Rolled beams are produced in industrial workshops from solid metal beams. The workpiece, preheated to the technological temperature, is passed through rolling loops. As a result, it changes its shape. The result is an I-beam - a solid metal product with a large margin of safety.

Welding of structures is carried out from individual previously prepared elements. The belt and two metal shelves come together. For the production of welded I-beams, different types of steel are used.

Wood and metal processing

Welded I-beams (rods) are part of many elements of steel structures for various purposes.

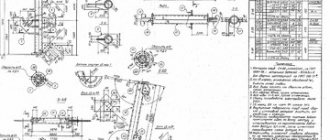

Therefore, the vast majority of factories have specialized workshop sections for the assembly and welding of I-beams. There are four main methods of assembling welded I-beams: by marking, in a jig with a screw or pneumatic clamping device, using an assembly installation and on production lines.

The method of assembling I-beam elements using markings is used when beams are assembled from a small number of identical elements.

The welded rod is assembled according to the markings in the following two ways: on the plate using wedges and on guides using staples.

Before assembly, check the geometric dimensions of the horizontal and vertical sheets and their straightness. Parts with edge curvature (saber-shaped) are often received for assembly. If this curvature does not exceed 1/1000 of the length and no more than 5 mm, then such sheets are suitable for making a rod. If the curvature is greater, the sheets must be straightened.

On horizontal sheets, use a cord to mark the axis of the beam, then grab stops or short corners of small cross-section (displaced relative to the marked axis by half the wall thickness). Having laid a vertical sheet on the guide beams, install horizontal sheets with tacked stops and press them against the vertical wall using wedges or staples. When assembling the rod, make sure that the holes in the rod elements match, or, where there are no holes, align one end. At the same time, the 90° angle between these sheets is also strictly maintained using spacers. Weld the spacers on one side.

Horizontal sheets are welded to a vertical wall using manual arc welding with seams of 5...6 mm in sections of 60 mm every 500 mm.

Beams are removed from assembly racks and transported by chains or ropes with hooks of appropriate load capacity.

It is advisable to use the method of assembling I-beams in jigs with screw or pneumatic clamping devices for large batches of identical elements, since setting up the jig requires a significant amount of time.

The screw jig for assembling welded I-beams has a frame welded from channels and beams installed on the workshop floor. The frame design includes transverse I-beams, the upper flanges of which are in the same horizontal plane. Two rows of stops are mounted on these beams: one row of stops is located at the edge of the beams and is fixedly fixed, the stops of the second row have clamping screws and can move along the frame in the transverse direction. The stops are welded posts, the working edges of which are planed at right angles to the planes of the support plates. Between the stops, two support channels are installed vertically with shelves inward, serving to lay the vertical wall of the assembled element, connected to each other by diaphragm supports. By moving the channel across the frame, you can change the distance between the channels depending on the size of the element being assembled.

Along the jig in its lower part there are vertical screws designed to support the shelves. The screws located near the fixed stops are permanently attached to the cross beam. The screws move across the jig along the angle. They are installed near the movable stops. Fixed and movable stops serve to tightly tighten the element and to ensure a right angle between the wall and the shelves. In the modernized conductors, the clamping devices are replaced with pneumatic ones.

Before assembly begins, workers adjust the jig in accordance with the design of the beam to be assembled. The setup is as follows. The movable stops, freed from the bolts securing them to the frame of the conductor, are moved across the conductor to a position in which the distance from the vertical edge of the fixed stop to the supporting surface of the clamping screws would be 50...75 mm greater than the height of the rod, and in this position the stops are secured with bolts . Then, by turning the handwheels, install the vertical screws so that the distance of the upper plane from the channel flanges to the supporting surface of the screws is equal to half the width of the flange of the assembled element, reduced by half the thickness of the vertical wall.

Proceeding directly to the assembly, first the element wall is placed in the jig, and then shelves are inserted into the gaps between the longitudinal edges of the wall and the jig posts. Using screws, the sheets are lightly pressed against fixed stops. Before finally tightening the section, the ends of the sheets are aligned at one end of the element, after which the assembled sheets of the element are tightly compressed with the screws of the conductor. The assemblers check whether the entire surface of the vertical wall of the element is adjacent to the flanges of the channels and whether a right angle is maintained between the wall and the flanges. If there are bulges on the horizontal sheet, then in these places the sheet is pressed against the channels with a wedge.

The wedge is driven into the gap between the wall and the temporary angle welded to the flange of the element. A clamp can also be used for this. To ensure that the relative position of the sheets does not change during the process of applying the first one-sided welds and during subsequent transportation of the element, assemblers place temporary strips at the ends of the element. After tacks have been placed along both edges of the wall, the jig screws are unscrewed, the element is picked up with the grips and transferred to the welding site.

When assembling I-beams in a jig, access for placing tacks is only on one side of the wall, so it is necessary to ensure that the tacks are strong enough. When welding with an automatic machine, first weld the seams on the side that does not have tacks.

Assembling I-beams using a gantry assembly plant is most common in most factories due to its high productivity and good assembly quality.

The assembly installation consists of a conductor and a portal. The jig is designed to lay the wall and shelves of the assembled beam in the design position; the portal ensures that the shelves and the wall are tightly pressed against each other.

The conductor consists of a frame along which two longitudinal I-beams with retaining posts and vertical adjusting screws are installed. The beam is rigidly attached to the frame. A portal equipped with movable pneumatic and fixed clamps is installed on rails laid along the longitudinal beams of the frame. The portal has an electric drive.

Before starting assembly, the installation is adjusted: the screws are adjusted, the movable beam and fixing posts are installed according to the dimensions of the assembled beam.

Assembly begins by laying the beam wall sheets in a horizontal position and the shelves in a vertical position. After laying out the sheets, align one of the ends of the beam. After this, the portal is installed at the end of the assembled beam, vertical clamps are turned on, and the wall of the assembled beam is pressed against the beams. Then the horizontal clamps are turned on, which press the beam flanges to the wall. After this, the worker grabs the beam with welds in places where it is compressed by its clamps. Having completed the tack, turn off the air, remove the clamps from the product, turn on the portal and, having moved it 500...600 mm along the assembled beam, turn on the air supply in the clamp again and repeat the assembly operation as described above. As a result of sequential repetition of these operations, beams are assembled approximately every meter along the entire length of the installation.

Beam I-beams of standard sizes are produced in industrial quantities; small batches are made according to individual drawings. The welded beam consists of three elements: two walls and an intermediate belt. It is made from branded sheet metal and is used in high-strength metal structures. With little metal input, reliable structures are obtained that can withstand multidirectional loads due to stiffening ribs.

Manufacturing

The production of I-beams by welding is a rather complex process. It is necessary to comply with a large number of regulations, safety regulations and technological requirements. The finished product must have a strictly defined rigidity, strength, density and many other indicators.

Among all the characteristics, density occupies a special place - the higher it is, the better the quality of the beam. Along with this, the issue of careful use of raw materials and energy resources always remains relevant. At the moment, specialized institutes are paying great attention to the development of new types of I-beams. The main direction of scientific work is reducing the metal consumption of a structure while maintaining strength and reliability indicators.

As for the serial production of welded beams, this process is quite economical. Today the technology successfully competes with the traditional rolling production method. The production of welded beams can be divided into several stages:

- The optimal parameters of rigidity and strength of the future structure are preliminarily calculated. The grade of steel that will be used in production is checked.

- Elements of the future I-beam are being prepared. Strips of the required length are cut from a certain grade of metal.

- The ends of the elements of the future structure are milled. This is an important point: it is necessary that the elements are firmly attached to one another. The connection must be as strong and rigid as possible. The ends are processed on special equipment - cross-cutting and milling machines.

- Assembly. It is important to correctly position and fix the element. The shelves should be located parallel to one another, and the wall should be strictly perpendicular. It is necessary to maintain the symmetry of the walls. If we are talking about a small production, then it is advisable to give preference to manual assembly. Serial production is organized on automated assembly lines. For example, in serial production a Z15 mill is used, designed for assembling beams. It is characterized by high performance. The assembly is divided into two stages. The first is to assemble a T-shaped connection from a vertical wall and a horizontal shelf. At the second stage, another shelf is added to it and the result is a full-fledged I-beam.

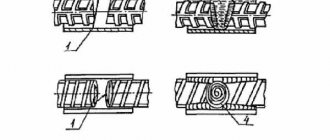

- Next, the assembled beam elements are welded. In this case, various welding technologies can be used. The two most commonly used are:

- welding with an inclined electrode. The method is suitable for simultaneous welding of two seams. You just need to take into account that the heating of the metal will be shallow;

- boat welding method. This option allows you to heat the metal deeply. Accordingly, the seam is more durable. But the time spent on its formation will be large.

- Industrial production uses powerful welding machines that can connect parts under pressure. Currently, there are several options for welding units for mass production of welded I-beams. Such, for example, are welding manipulators. They are characterized by a high degree of automation. Another option is self-propelled tractors designed for welding large workpieces. Although this is a simple and at the same time reliable method, it is not suitable for mass production. Small businesses focus on hand assembly. Therefore, their products are priced noticeably higher.

- Upon completion of all the above cycles, the geometry of the structure is adjusted. During welding, heating and cooling of the walls can lead to a change in the angle between the elements of the product. Geometric shape editing required. Therefore, the I-beam is passed through a special straight line, which is a system of rollers. The output is a finished product with geometrically correct shapes.

Production technology of welded I-beams

Small batches are made using electric arc or argon welding, depending on the grade of metal and its ability to be welded.

To produce welded beams industrially, special welding lines are used. Fluxes are used to protect the melt pool from oxidation.

Welding a beam in automatic mode is similar to manually making an I-beam. Main technological stages:

- cutting rolled sheets into strips of the required width using a thermal cutting machine with program control, average cutting speed 1 m/min.

- end milling on end milling machines reduces the joint gap between the wall and the shelf and improves the quality of welding;

- the process of assembling an I-beam is carried out at high speed on a special machine; metal strips are fixed by clamping devices with hydraulic amplifiers; first a T-shaped joint is made, then the second wall is added; this design is convenient to weld;

- welding work is carried out using portal-type machines of two types: a) two seams are shallowly welded at once using inclined electrodes; b) the boat seam is created in stages: first on one side of the I-beam, then on the other; the metal is boiled to a great depth;

- the final stage is straightening the I-beam on special rollers; minor distortions that arose during assembly and welding of the profile are eliminated.

Welding defects

Defects may occur due to violations of technological process requirements, unscrupulous performance and other reasons. The most common problems arise related to changes in the crystalline structure of the metal under the influence of high temperature. New crystal grains are formed that have completely different characteristics compared to the original ones.

Defects affect the strength and rigidity of the structure, reducing these indicators. The metal's resistance to corrosion also suffers. Taken together, the number of defects makes the operation of the finished product impossible. All I-beams are checked for such defects.

Advantages of using welded beams

Welded I-beams are used in the construction of various types of buildings. Compared to metal structures of other configurations, they have important advantages:

- have no size restrictions, while for prefabricated metal structures and channels such parameters are established;

- the finished product is of high quality, strength, reliability and durability;

- in the production process there is practically no hazardous waste that is dangerous to people and the environment;

- can be made to order with a predetermined length;

- if necessary, the cross-section of the finished product can be changed, which facilitates the creation of complex architectural compositions.

Beams can be welded from steel of different grades. For floors with a small load, you can make a structure from carbon steel, and in places where large mechanical loads are planned, preference should be given to installing I-beams made of alloy steel. This variability allows you to optimize the cost of construction and reduce it compared to if beam structures were made only from high-strength metals. In addition, it is possible to reduce material consumption by optimizing the cross-section of the finished product.

Advantages of I-beams

I-beams have many advantages. They can be used to cover large spans. You don't even need to build a load-bearing wall for this. They are stable and can withstand severe vertical and horizontal loads.

I-beams are resistant to weather changes and corrosion, non-flammable. Their use significantly speeds up the construction of the building. These and many other reasons determine the popularity of I-beams in industrial and private construction.

Obvious shortcomings can only be noticed in rolled I-beams. The maximum size of these is twelve meters. If you need a longer one, you won’t be able to find one, because often factories do not have suitable machines. There is no possibility to make custom-made rentals, and the variety of products on the construction market leaves much to be desired. Due to such problems, consumers are more likely to use butt beams.

Composite I-beams are used more often than rolled ones for several reasons. Such a beam has greater strength with less weight of the structure. Prices for welding products are lower, since they are made from an alloy of different types of steel. The creation of rolled products requires the use of only blanks from one type of steel.

Application area

Welded I-beams are widely used in various fields of construction. They are in demand in creating:

- load-bearing structures: frame, foundation, supports, etc.;

- floors between floors;

- residential buildings;

- bridges, overpasses and overpasses;

- warehouses and shopping centers;

- viaducts and tunnels;

- stadiums and other structures.

Due to the fact that the welded beam has high strength and reliability, it is used in almost all branches of construction.

Possibilities

Thanks to the use of welded I-beams, it is possible to increase the spans between the load-bearing base and, accordingly, reduce the number of joints. Buyers can order the finished product of the desired size and cross-section. There are a large number of GOST standards for the production of I-beams, among which the customer can choose the most suitable option. Welded I-beams can be used in the construction of complex architectural structures.

Their use in various areas of construction is justified due to the large number of advantages. Beams can improve the performance and reliability of a structure.