Anchors, characterized by strength, are suitable for fastening structures of different weights. Areas of application for anchor bolts are construction and industry. It is suitable for fastening materials of different strengths. It is quite in demand in the market due to its versatility. In most cases, anchors are used for installation on durable structures. When it comes to porous, heterogeneous structures, it is better to use specially designed types of durable anchor bolts. This is the only way to ensure reliable fastening.

The anchor bolt is fixed due to several factors:

- friction force. The sleeve is in firm contact with the hole, fixing the position;

- force of the spacer mechanism;

- properties of adhesive components that hold the bolt due to the adhesive base.

Types of anchor bolt

Anchor bolts are not only universal, but also for solving specific construction problems. In these cases, they are endowed with special properties, improving design features. As a result, from the anchor bolt model range you will be able to select fasteners to solve any installation problem.

When choosing an anchor bolt, you need not only to know about the various modifications, their pros and cons, technical features, but also to navigate which option is more suitable for operating conditions.

Popular types of bolts on the market:

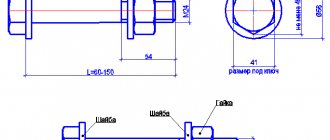

Anchor bolt with nut. This is the most simplified type in its structure. It consists of several elements: threaded studs, a cone-shaped tip, nuts and bushings. The anchor is secured using a nut. The installation diagram is standard. You first need to drill a hole to the diameter of the fastening system. Then secure firmly with a nut. At this point, the tip expands the sleeve, increasing its diameter. This ensures reliable fixation of the anchor bolt in the loophole. Anchor nuts can be used in any operating conditions. Even if we are talking about an aggressive environment, places of high humidity. Bolts are available in a wide range. The diameter of the anchor bolt ranges from 6 to 28 mm. They range in length from 6 to 30 cm. Based on these parameters, it is easy to select the type of fastener to solve various construction problems. Anchoring will only be effective if you are installing the bolt into materials with a strong structure. For example, homogeneous brick or concrete. There are specially designed anchors for working with porous surfaces.

Anchor bolt with hook. Has much in common with the previous view. A curved hook is installed at the end of the rod in this modification. It makes it easier to install suspended structures. For example, elements of suspended ceilings. The function of the nut in a hook bolt is to expand the sleeve, thereby securing the bolt securely in place. When mounting the structure on a hook, it can be easily removed if necessary. This option is suitable for installing plumbing fixtures.

Ring anchor type. A ring or semi-ring is formed at the end of the rod. The rod, similarly to previous types of anchor bolts, plays the role of a retainer, and various household items or structures are attached to the ring. The bolts differ in size, which determines their scope and purpose. It is most convenient to attach cables and scaffolding to the ring.

Spring. This type is often used for renovation work and interior decoration. Anchors are attached by increasing the spring. This anchor bolt is suitable for fastening on thin-walled bases.

Advantage of using anchors

The main advantage of working with wood anchor bolts in comparison with conventional nails or self-tapping screws (screws) is the strength and reliability of fixation. For example, for the fasteners under consideration, the pullout load is 300-350 kg. This parameter is considered a high indicator and allows them to be used to fix almost any heavy object. For comparison, the same figure for a regular carpenter’s nail is no more than 100 kg.

Anchor with a ring for wood Source cki-com.ru

In addition, working with anchors is simple and does not take much time. Although for their installation you first have to drill a hole, taking into account the fact that screwing requires less effort than when working with screws, these hardware are the leaders in this indicator.

All types of anchors have an anti-corrosion zinc coating, which reduces the likelihood of rapid corrosion. Therefore, there is no need to fear for the integrity of the structure. Nails and most screws do not have this effect. In addition, there are special devices designed for use in rooms with high humidity: steam rooms, showers, saunas. This also contributes to the popularization of hardware when compared with possible analogues.

Use of wood anchors Source 8kr.ru

We should not forget about the thickness and corresponding strength of the created structure. For example, the diameter of the shaft of a conventional screw or self-tapping screw is only 3.2-4.5 mm. Anchor bolt sizes start from five millimeters or more. This also affects the final quality of the created connection.

Fastening the Mauerlat with an anchor Source sdelai-lestnicu.ru

Application

Mechanical anchor bolts can withstand heavy loads when connecting to low-porosity surfaces. If we are talking about materials with a non-uniform porous structure, then chemical anchors are suitable.

Domestic concrete anchor bolts are great for installing plumbing fixtures, hanging systems, doors, ceilings and other items.

Wedge bolts are mounted into dense surfaces. If we consider their use in everyday life, sports corners and punching bags are often attached. There are also anchors that can be used to attach to foundations with cracks. When choosing an anchor bolt, you need to take into account not only the features of the product, but also the base on which you want to attach the bolt.

Stud bolts can be attached to monolithic structures and those that have cracked. According to this criterion, the categories HAS and HST are divided. The performance properties of the bolts are indicated on the packaging. There must also be markings according to international standards. Their decoding will provide information about: material, load withstand (tearing and shearing), operating conditions, type, dimensions, technical properties.

Before installation, be sure to calculate the tension force of the walls and ceilings. Since anchors are in demand in the construction industry, they are often used to install massive and large structures.

In terms of cost, the chemical type is considered the most expensive. These are innovative developments that are not yet being tested as actively on the Russian market, unlike the European one. Large construction holdings are already taking advantage of the benefits of chemical anchors.

Advantages and disadvantages

Despite the fact that anchor systems are considered universal, it is more advisable to use them in solid monolithic foundations. If you need to fix the structure on a wooden surface, you can find budget options.

If you install an anchor bolt as intended, you can evaluate its strengths:

- withstands heavy loads. This is the strongest and most reliable fastener, which is in demand in the construction and industrial industries;

- a wide selection of fasteners by size, load-bearing capacity, and installation features;

- material – carbon steel. It is durable and does not corrode;

- easy installation. No special equipment is required to install fasteners;

- in addition to installing new structures, existing ones can be strengthened with anchor bolts;

- the anchor bolt remains motionless even when exposed to constant forces. For example, if there is vibration in the installation area.

The disadvantages include the relatively high cost of bolts. To install all types of anchor bolts, it is necessary to drill a hole, which may seem inconvenient and difficult. Reliable fastening can only be ensured with a competent approach and accurate calculations.

Working with anchors

Working with anchor bolts in wood has its own specifics. The key point here is that if the hole diameter is inappropriate or if there is excessive stress, the wood fibers can break. The installation itself looks like this:

- A hole is drilled at the previously marked point. When using spacer or thrust hardware, their size must match exactly. For screw-in ones, take a diameter 1-2 mm smaller than the anchor (for example, for a 10 mm bolt an 8 mm hole is prepared). Chemical fasteners, on the contrary, imply a larger width, since you will first need to introduce glue, which will expand during the hardening process.

- Next, the hole is cleared of chips. When using screw-in anchors, this step can be skipped. For all other types, cleaning is recommended.

- Hardware, the fixation of which is carried out through mechanical contact with the walls of the hole, requires preliminary lubrication. A small amount of soap solution or a couple of drops of car oil will make the installation process easier. In addition, improving the sliding properties of materials will reduce the likelihood of cracking of wood fibers.

- At the final stage, the wood anchor is installed in the hole and tightened. The method that will be used in each specific case depends on the type of fastener. It must be taken into account that with excessive force, the hardware may turn or be torn out of the soft wood structure.

The principle of working with wood anchors Source krep-komp.ru

Important! The hole for the wooden anchor is drilled to a depth that matches or slightly exceeds the size of the hardware. If this condition is not met, a sharp increase in the force on the fibers will lead to the formation of cracks. In addition, this may not happen immediately, but after some time.

Classification of anchors by type of construction

All anchor bolts are united by the installation principle. When screwed in, the cross-sectional dimension of the bolt increases. Due to this, the fastener is fixed. Depending on the design features, there are several features of the anchor bolt:

- wedge anchor. The bushing expands when screwed in, like other fasteners of this type. There is a nut in the thread area. When attaching a wedge anchor bolt, you will need to tighten the nut using an open-end wrench. Such bolts can withstand heavy loads. The disadvantage of such fasteners is considered to be the increased stress on the surface to which it is attached. Because of this, it is advisable to install the wedge anchor exclusively in homogeneous, durable materials.

- sleeve nut anchor. This is a metal fastener with a fixing part in the form of a sleeve. At one end of the stud there is a head, which moves along the thread during the screwing process. Sleeve anchors can be used on porous surfaces. Even fragile surfaces can withstand minimal stress from an anchor bolt. However, along with the advantages, it is able to withstand not such heavy loads as a wedge one;

- collet. Features an improved bolt sleeve structure. 4 petals are formed on the sleeve. As a result of screwing, the shape of the working surface changes and the friction force increases, which guarantees the strength of the anchor connection. An anchor with a collet is comparable in load capacity to a wedge anchor bolt. It is used for light types of coatings. The price is an order of magnitude more expensive than other types due to great controversy;

- driving. The sleeve in such products has the shape of a cone with slits. Using a hammer, the wedge located inside the sleeve expands the sleeve, fixing the bolt. The most popular bolt when installing concrete structures and foundation work.

Anchor bolt fracture forces

If the permissible loads are incorrectly calculated, the anchor bolt may be affected by fracture forces. There are several of them:

- Slice The risk of its formation exists at the location of the anchor bolt. As a result, the bolt simply breaks.

- Breakout of the anchor bolt. This scenario means that the bolt shank is completely or partially coming out of the hole.

- Ripping out the material itself. In this case, the surface on which the anchor was attached breaks out. This happens because the base cannot withstand the load.

- Bend. Exceeding the maximum permissible loads can lead to deformation of the fasteners.

- Combustion. The bolt shaft changes its shape due to the influence of high temperatures.

- Corrosion. It occurs when the wrong type of durable anchor bolt is selected in accordance with the operating conditions. In some cases, these may be low-quality bolts without quality certificates that have not undergone testing and additional processing to preserve their properties.

All anchors must comply with GOST standards. By marking products, you can find out all the technical features of the product, conditions of use, loads, and properties of the material from which they are made.

Anchors are predominantly used in hard materials. If we are talking about chemical anchor bolts, innovative developments are also suitable for porous substrates. Despite the abundance of species, the principle of fixation is the same. Anchors can guarantee reliable fastenings, durability and resistance to external factors.

Features of installation of anchors for concrete

The reliability of fastening obtained using an anchor bolt is influenced by a number of factors:

- the quality of the material in which the anchor is installed;

- the type and dimensions of the fastening element, which must be selected in accordance with the loads perceived by such a product;

- correct preparation of the site for placing fasteners and compliance with the technology for its installation;

- strength characteristics of the anchor itself.

Sequence of installation operations (click to enlarge)

Installation of anchor-type bolts can be carried out in various structures, the material of which must be of sufficiently high strength. These include, in particular:

- concrete foundations;

- walls and partitions made of concrete and brick;

- floor slabs, which are usually made of concrete.

Mechanical anchor installation diagrams

Objects and structural elements that are fastened with such bolts are usually:

- beams made of rolled metal of various types;

- elements of suspended ceiling structures;

- lamps and chandeliers;

- wooden beams used for installation of floor and ceiling coverings;

- elements of staircase structures;

- load-bearing structures with large weight and dimensions.

Load calculation depending on anchor parameters

As mentioned above, fixing an anchor-type bolt inside a pre-prepared hole can be achieved in two main ways:

- by wedging the spacer sleeve inside the hole;

- due to a special adhesive composition that binds the bolt and the inner walls of the hole (chemical anchor).

There are requirements for holes in the fastened part, which should not exceed the values specified in the table. Large gaps can be filled with mortar