Fasteners for wooden structures provide reliable fixation at the joints of wooden elements. These parts make it possible to obtain a durable structure that can withstand various vibrations and mechanical loads.

Various types of wood fasteners differ in size and purpose. They have an unusual shape and structure.

How to choose the right metal products that will help create a durable building? The answer to this question is presented in our detailed material.

Types of fasteners for wood

The following types of connecting elements for wood are distinguished. These include:

- connections with perforated base;

- anchor screws;

- "tenon and groove";

- three-dimensional slats;

- "hedgehog";

- self-tapping screws with KonstruX thread.

Each type of product differs in size, shape and material from which it is made.

What are they?

With the help of such supports, the rafters are attached to the supporting beam, resulting in a balanced structure. This part is also used in other cases - when it is necessary to connect several sliding elements with a fixed base.

If you are interested in what a sloping roof looks like, you can see the photo on our website.

Read more about the truss system for a pitched garage roof in a separate article.

In addition to giving the rafter structure additional strength, sliding supports have many advantages, one of which is ease of installation, which does not require special tools or skills.

The use of a sliding support reduces the cost of manual labor during the construction of the roof, since in this case there is no need to manually balance the parts of the roof structure.

Perforated connections

This type of connection is used for fixing wooden and concrete parts. Most often they are hidden deep in the cavity of the structure being built. They are made from durable hardened steel. The thickness of each element ranges from 1.6 to 2.5 mm.

In specialized departments there are products made of low-carbon steel. As a rule, such models have a fairly high cost. They are considered stronger and more resilient.

They are mainly used when laying ceilings and floors. Such hidden fasteners for wood can be used in the construction of houses made of timber.

Drywall - advantages and disadvantages

Although experts recommend covering a house made of logs or timber with clapboards, many opt for a more budget-friendly option - drywall. Light weight, good thermal insulation, it is environmentally friendly and does not place heavy loads on the foundation.

In addition, plasterboard is a universal, fire-resistant material without impurities, which is suitable and used for walls and ceilings, successfully hides all utility lines, lighting cables, eliminates surface unevenness and makes it possible to create any, most original room design, for example, with a beautiful ceiling multi-level lighting, tiles or wallpaper on the walls, interesting three-dimensional designs. Drywall is easy to install, and therefore all construction and installation work can be done independently.

The frame, which is assembled for its fastening, is simultaneously used for installing insulation and waterproofing.

Metal anchors

Anchor screws have huge advantages among most products. They can be used in conjunction with perforated connections. This ratio makes it possible to make the building resistant to climatic disasters.

These products are made from high-strength metal alloys. Most often they are re-hardened and plated with zinc. Galvanized wood fasteners can be used in areas with high humidity. They are resistant to corrosion and deformation during the driving process.

The length of the elements varies from 5 to 10 cm. The diameter is about 6 mm. Such models are used to create roofing or flooring. There is a screw thread along the entire length, which ensures tight fixation inside the wood.

Sheathing with plasterboard

To attach drywall to the frame, you must perform the following steps:

- a sheet of drywall is laid out so that when laid, the joints fall on the vertical posts;

- then an incision is made in the top layer with a mounting knife and the sheet is broken;

- the sheet is bent at an angle, the reverse side of the cardboard is cut off;

- stepping back at least 10 mm from the edge, marking the fastening points is made;

- then another cut is formed and a chamfer at an angle of 45°, which is carefully processed with sandpaper;

- the prepared drywall is mounted in a checkerboard pattern, secured with self-tapping screws;

- the most important thing is to correctly finish the joints where the sheets should overlap and be attached in one place;

- fasteners are carried out at a distance of no more than 25 cm

After completion of the work, the drywall is decorated with tiles, paints, and painting. If wallpapering or plastering is planned, the walls must first be primed.

Tongue and groove system

This variety is produced by a German company. The product is made of durable aluminum alloy. One part has spikes, and the other is equipped with an additional groove. They are installed according to the dovetail principle. Thanks to this connection, it is possible to reduce the load on the building during operation.

A similar model can be used for both hidden and closed connection points. It is recommended to install metal parts in pre-prepared holes. They should be firmly attached inside the wooden base.

The main disadvantage of this model is their high cost. This is directly related to the complexity of the structure and its reliable fixation of wooden parts.

Purpose of fasteners

Fasteners include products of various configurations designed to impart greater rigidity to wooden parts. To manufacture such elements, strong and durable materials are used, for example, galvanized steel (GOST 14918-80) or modern composite alloys. There are parts designed to strengthen the joints of wooden blanks and to create connections between wood and a number of other materials (brick, stone, concrete, metal beams).

Fasteners provide:

- ease of operation;

- quick and reliable connection of several workpieces of different geometries;

- uniform distribution of load, as a result, durability of the frame;

- reduction in the price of the finished product, since the work is performed with a simple tool;

- plenty of options for pairing at different angles;

- significant time savings.

Fasteners vary and are selected depending on the project. There are three main types of metal fasteners:

- perforated elements;

- details for hidden fixation;

- decorative overlays.

The choice directly depends on the specific task. If for the manufacture of a frame shed you can limit yourself to perforated tape and corners, then for decorating the interior it is preferable to have hidden fasteners or decorative details.

3D slats

Specialized departments provide a detailed catalog of the best wooden fasteners. One of these connections is three-dimensional slats. They are connected perpendicular to each other. As a result, a T-shaped connection is formed, which is considered the strongest.

They are made from durable metal alloys that can withstand all kinds of loads. They have a length from 60 to 750 mm. There are cuts and protrusions along the entire plane of the iron model.

Lanyard for rigging workCrab system for profile pipes: features of the selection and use of fastening systems and connecting elements

What is a rigging shackle? Size standards, modern types, rules and features of choice

During the installation process, one edge of the part is fixed in one of the parts of the wooden beam. Next, small cuts are made on the logs, equal in length to the protruding part of the three-dimensional lath.

The choice of such a product should be made in accordance with further loads during operation.

Fasteners for wooden structures: what are they?

Photo: Ingo Bartussek/Fotolia.com

Most of the surviving monuments of wooden architecture were erected without a single nail, using only an axe, and this fact still causes admiration. But over the centuries, fastening systems made of metal and used for the construction of wooden houses have changed greatly, so today there is no point in repeating the “feats” of our ancestors. It must be built simply, quickly and reliably. Let's look at the metal fasteners offered by manufacturers using the example of components and elements that can significantly simplify and speed up the connection of floor joists with beams or wooden walls, and at the same time some other operations.

Photo: ESSVE. The beam shoes are equipped with 5 mm diameter holes (located on both the flange and the flanges) for nails/screws and 9 or 11 mm diameter holes for bolts or cap screws. On the lower surface of the flange there is a hole with a diameter of 7 mm for additional fastening of the log

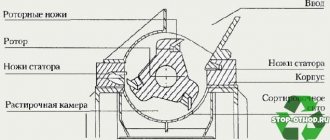

Connecting elements with perforation

Photo: Eurotec. Special elements for performing operations common in wooden house construction: adjusting screw for window frames or sheathing (a); tightening screw (b); Hobotec self-tapping screw for fastening solid boards, blockhouses or imitation timber when covering a wooden house (c)

If beams and floor joists are invisible in the interior, then they can be connected using so-called beam shoes, produced, for example, by Essve. These elements are suitable for fastening wood not only to wood, but also to concrete or brickwork (using appropriate dowels). They are made mainly from hot-dip galvanized steel with a thickness of 1.5 or 2 mm, but there are also more expensive products on the market made from stainless acid-resistant A4 steel. The shoes are available in two versions: with cuffs turned outward or inward. Price: from 50 to 500 rubles. for 1 piece

The manufacturer recommends fastening the beam shoes to the elements being connected with special anchor screws with a diameter of 5 mm (depending on the load, the latter can be inserted into all or some of the holes), and in case of a very heavy load or fixation to “stone” material, also use the holes for bolts. In addition to anchor shoes, the market includes perforated universal clamps (a), rafter fasteners (b), angles (c), plates (d), shown in the figure, etc.

Photo: ESSVE

Advantages of anchor screws

Why do manufacturers of perforated fasteners suggest using anchor screws? How are the latter better than ordinary self-tapping screws or anchor (ruffed) nails used to secure beam shoes and other perforated metal elements?

The advantages are due to the design features of anchor screws.

Firstly, their flat head presses the metal element being fixed more tightly to the wood.

Secondly, the smooth cylindrical part located under the screw head has the same diameter of 5 mm as the holes in the perforated metal elements. It completely fills the hole and therefore completely transfers the load, and also works well for shearing. In addition, thanks to the tapered head, the screw is better centered.

An ordinary self-tapping screw does not always transfer the load completely; it performs much worse at shearing. Well, the anchor nail cannot be dismantled without destroying the part of the wooden element into which it is driven.

But the anchor screw is easily unscrewed and can be screwed into a wooden element in a new place.

Metal tongue-and-groove systems

The Atlas node connector is produced by the German company EuroTec. The element is made of aluminum and consists of two parts, one of which is equipped with a tenon, the second with a corresponding groove. They are fastened to each other according to the “dovetail” principle, which allows for reliable transmission of vertical and horizontal forces, to absorb tensile and compressive forces and even bending moments. The connection can be either visible or hidden, for which both metal parts are recessed into pre-milled grooves. The length of the Atlas node connector is 70–200 mm. Price - 1500–5500 rub. for 1 piece

EuroTec's main competitors on the Russian market are the Austrian companies PITZL and SHERPA Connection Systems, which produce a similar range of connecting elements. The SHERPA system is better known, providing a load-bearing capacity of connections from 5 to 280 kN - a special calculation program allows you to select fasteners for each specific case. Any connector consists of two aluminum parts, which are also fastened using the dovetail principle. The cost of SHERPA elements is from 800 to 12 thousand rubles. for 1 piece

Photo: VV Stanz-und Umformtechnik, PITZL. SHERPA connectors (a - e), made of heavy-duty aluminum alloy, and steel elements BB (f - h) allow you to create not only high-strength and reliable building structures, but also very aesthetic stairs and even furniture

Another competitor of EuroTec is the German company BB Stanz-und Umformtechnik, which developed the BB connecting unit. It is made of galvanized sheet steel 4 mm thick and consists, like its aluminum counterparts, of two parts, fixed to each other according to the dovetail principle. Both halves are attached to the wood with self-tapping screws, the number of which depends on the size of the element. BB connectors are available in 70mm widths and 90, 125, 150 and 190mm lengths. The price is one of the most affordable today: 180–800 rubles. for 1 piece

Connectors allow you to solve problems in a few minutes that require hours or even days in classical construction technologies.

Three-dimensional slats

Photo: Rotho Blaas. Three-dimensional perforated aluminum slats for creating hidden connections: Alumaxi (a), Alumini (b) and Alumidi (c)

The Italian company Rotho Blaas offers to connect parts located both perpendicular to each other in the same plane and at an angle vertically, using T-shaped slats, which are made by extrusion from high-strength aluminum alloy EN AW-6005A. They are available in three modifications, designed for different load levels: Alumini, Alumidi and Alumaxi. Each contains slats with holes in the base and the shelf perpendicular to it, and without holes in the shelf. The slats can have a fixed length (from 80 to 768 mm), and in versions without holes, slats with a length of 2176 mm are available with cuts every 64 mm, which allows you to produce fasteners of any length.

Photo: Rotho Blaas

During installation, the base of the batten is attached to the beam with self-tapping screws, then a groove is made at the end of the log attached to the beam, the dimensions of which correspond to the flange of the batten. If the latter has perforations, then, using the shelf as a jig, holes are drilled in the joist, put it on the shelf and metal pins are inserted into them. If there is no perforation, then put a log on the shelf and fix the connection with self-tapping screws and a drill. Price of rack fasteners: RUB 1,230–18,425. for 1 piece

The connecting system should be selected in accordance with the cross-sectional dimensions of the beams being connected, as well as the static and dynamic loads acting on them.

Hidden elements of the “Hedgehog” type

Photo: Rotho Blaas. Installation of the Hedgehog elements is simple. A recess is made at the end of the log, into which the connecting element is inserted and secured with self-tapping screws twisted at an angle. Next, the log through a pre-drilled hole is attached to the beam with a threaded element screwed into the central hole of the connector

Rotho Blaas Disc connectors are a galvanized carbon steel washer. At the base of the washer there are holes drilled at an angle for self-tapping screws, and in the central part there is a threaded hole. A pin is screwed into the latter, its free end is threaded into a hole pre-drilled in the beam and secured on the opposite side of the beam with a nut with a wide washer placed under it. The resulting connection successfully works both in shear and pull-out. With a heavy load, up to three Disx elements with a washer base diameter of 50, 80 and 120 mm can be simultaneously installed at the end of the joist (the diameter of the threaded holes is M12, M16 and M20, respectively). Price: from 4145 to 9044 rubles. for 1 piece (screws included).

An alternative to Disc connectors are EuroTec's IdeeFix elements. The fastener is made in the form of a hollow cylinder with an outer diameter of 30, 40 or 50 mm, made of aluminum alloy. At the bottom of the cylinder there is a hole with an M12, M16 or M20 thread. In the top there is a conical recess with holes for self-tapping screws, drilled at an angle of 45°. The IdeeFix element is attached in almost the same way as the previous connector, but the joist is fixed to the beam not with a stud, but with a powerful bolt with a wide head (included in the kit along with self-tapping screws). Price - 1500–4500 rubles. for 1 piece

KonstruX full thread self-tapping screws

These unusual products allow you to save not only the time required to assemble the unit, but also money, because connecting metal elements are not needed. Self-tapping screws have a full thread, creating a high resistance to pulling out, and are completely screwed into the wood at an angle of 30, 45 or 60°, which radically changes the usual pattern of their operation. In this case, the screws only work to pull out, which allows them to take on a significant part of the forces acting on the connection. Thus, it is possible to connect parts at an angle (a), unite elements while reducing their deflection (b), and strengthen cutouts in beams and joists (c) (see figure below).

Photo: Eurotec. The special ECS program, which can be freely downloaded on the website of a self-tapping screw manufacturer or a large retailer, helps you select the appropriate KonstruX screw, the fastening pattern of the elements, and also calculate the required number of screws.

There are self-tapping screws with a cylindrical (screw diameter - 6.5, 8 and 10 mm) and countersunk (screw diameter - 8 or 11.3 mm) head. Length - 65–1000 mm. Price - 20–800 rubles. for 1 piece To install screws less than 245 mm in length, no pre-drilling is required, but for longer ones (to prevent slipping to the side), it is recommended to pre-drill holes for the self-tapping screw to a depth of up to ⅓ of its length.

Special screws

Using a Hobotec self-tapping screw, massive boards, blockhouses or imitation timber are fastened. The head of the product is equipped with milling ribs and is easily recessed into the wood, and the tip is made in the form of a drill. A cutter in the middle of the length of the screw increases the diameter of the hole, allowing you to tighten the element being fastened more tightly. Self-tapping screws with a diameter of 3.2 mm and a length of 20 to 60 mm are made of ordinary coated steel (price: 1100–2200 rubles per pack of 500 pcs.) or stainless steel (price: 3500–7500 rubles per pack of 500 pcs. .).

The tension screw is also equipped with a cutter, but its tip is different - it has a special groove that turns the screw into a wood drill. The flat head has a large diameter and is equipped with a countersink head and a hexagonal slot. The self-tapping screw is coated with a special wax coating that reduces friction when screwing in. Product diameter – 3–12 mm, length – 30–600 mm. Price - from 300 to 5 thousand rubles. per pack of 500 pcs.

Photo: Eurotec. A self-tapping screw is a weather vane for attaching wooden sheathing to a steel base. Equipped with a drill tip and special “wings” (located above the tip), which expand the hole in the wood and break when drilling metal. As a result, having cut a thread in the metal, the self-tapping screw is fixed in it, and the head attracts the wooden element to the metal. Length: 32–125 mm. Price: from 500 to 2500 rubles. per pack of 500 pcs.

An adjusting screw is useful, for example, for attaching window and door frames or wooden sheathing to wood, concrete, brick or metal (the element can be equipped with two types of drilling tip). The self-tapping screw is screwed into the box and the wall or power element located behind it in one step. In this case, the ring conical “spikes” located under the head of the screw are firmly fixed in the box (almost like a fishhook), thanks to which its position relative to the wall is easily adjusted by further screwing or unscrewing the fastening element. Length - from 60 to 125 mm. Price - from 2000 to 3500 rubles. per pack of 500 pcs.

Special self-tapping screws can significantly speed up and facilitate the execution of those operations that are necessary when creating wooden structures.

- Country cottage area

How to assemble metal scaffolding: instructions for frame structures and complex facades

Products "Hedgehog"

They are a large washer made of low carbon steel. Galvanic coating is applied along the entire perimeter. They are designed for self-tapping screws. The diameter of the washer is from 50 to 85 mm.

There is a small recess in the upper part, drilled at different angles. This provides different connection depths during the installation of wooden parts.

Finishing the ceiling with plasterboard

More often, plasterboard in a wooden house is used to create original multi-level or simply different, figured ceiling structures. The frame and installation work on fastening are carried out similarly to the walls. In this case, the junction of the wall and ceiling should not be exactly end-to-end; leave it free, with a minimum gap. Having previously placed all the lighting wires under the drywall, think about the recesses in which the lamps or LEDs will be hidden.

A wooden house, although easy to install and inexpensive to build, has a number of specific features. These include its significant shrinkage immediately after the construction of the walls. Therefore, when planning interior decoration, you need to focus on sliding frames, which are the best option for a log house, as they will help protect the cladding from deformation. It is not difficult to install such a structure yourself. Choose high-quality materials and strictly follow the instructions, watch video tutorials, consult or hire a specialist for help, and then your home will turn out not only beautiful, but also durable, reliable and completely safe.

Types of sliding supports

All currently used sliding supports are divided into two groups:

Open type - such structures are composed of two separate elements. The first is the guide attached to the rafter leg. This is a curved steel plate with holes at the ends. There may be two or three of them at each end - the specific number depends on the manufacturer. The stroke length of the moving element also changes. The smallest value should be 60 mm, the largest – 160 mm. The corner (the fixed part of the element) has up to 5 holes.

Closed type - this type of support is not disassembled into its component parts and represents an integral structure. Installation is carried out in assembled form. With this option, the fixed part has the shape of a corner with a special holder on the long side: a fastening bar is threaded into it.