Interesting and useful information about building materials and technologies

Connections of elements of steel structures

The main type of factory connections are welded connections.

Welding significantly (up to 20%) reduces the labor intensity of manufacturing, simplifies the design and, in comparison with previously used riveting, provides significant (up to 15.20%) savings in metal. The resulting internal residual stresses from welding, summed up with the stresses from the action of forces on the element, complicate the stressed state of the welded joint. In particular, when welding thick elements, a volumetric stress state arises, which is especially dangerous under the action of dynamic loads and low temperatures, when it contributes to brittle fracture of the joint. Electric arc (manual, automatic, semi-automatic, gas-electric and electroslag) welding is mainly used in building structures. The use of resistance and gas welding is limited. The advantage of manual arc welding is its versatility. It can be performed in the lower, vertical, horizontal and ceiling positions (Fig. 14.2), as well as in hard-to-reach places. This has led to its widespread use in installations, where the use of mechanized welding methods is difficult. However, manual welding has a number of disadvantages: low depth of penetration of the base metal, low productivity compared to automatic submerged arc welding. To compensate for these shortcomings, refractory coatings are used, which increase welding productivity and increase the depth of weld penetration (welding with deep penetration).

In the case of automatic and semi-automatic welding, the arc closes under a layer of flux, the flux melts and reliably protects the molten metal from contact with air; molten metal under these conditions cools somewhat more slowly, is well freed from gas bubbles and slag, and turns out clean, with an insignificant amount of harmful impurities; the high current strength allowed for automatic welding and better thermal protection of the seam ensure deep penetration of the welded elements and high welding speed, although this type of welding is difficult to carry out in vertical and overhead positions. Electroslag welding (a type of automatic welding) is convenient for vertical butt welds of metal with a thickness of 20 mm or more. It is carried out under a layer of molten slag; The weld pool is protected on the sides by copper slides, cooled by running water. Welding in a carbon dioxide environment does not require devices for holding flux, can be performed in any spatial position, provides high-quality welded joints, although with this welding the weld surface is less smooth than with submerged arc welding; Disadvantages also include the need to protect workers from arc radiation and gas accumulation.

Welds

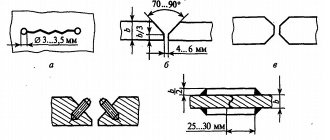

. According to their shape, welds are divided into butt and corner (bead) welds. Butt welds are used to join elements lying in the same plane. They are very effective because they provide the lowest stress concentration, although they require additional cutting of the edges. According to the shape of the edges, butt seams are U-shaped. For U- and V- V- and K-shaped seams welded on one side, welding of the root of the seam on the other side is mandatory - to eliminate possible lack of penetration (Fig. 14.3, a, item 1), which is a source of stress concentration. Various options for butt welds are shown in Fig. 14.3, b. Rolled (corner) welds are welded into the corner formed by elements located in different planes. The seam created in this case has the shape of a roller (Fig. 14.3, c).

Depending on their position in space, welds can be vertical, horizontal or ceiling (see Fig. 14.2). Welding the bottom seams is the easiest to mechanize and gives the best seam quality. Vertical, horizontal and ceiling seams are difficult to mechanize, and when done manually, the quality of the seam is relatively low, so the use of these seams should be avoided if possible.

Welded joints

. There are the following types of welded joints: butt, lap, corner and T (butt). In butt joints, elements are connected by their ends or edges, that is, one element is, as it were, a continuation of the other (Fig. 14.3, d). Butt joints provide the lowest stress concentration when transmitting forces; they are economical and can be most reliably controlled. The thickness of the welded elements in joints of this type is practically unlimited. Butt joints are used mainly for sheet metal and can be made with a straight or oblique seam (left and right, respectively, in Fig. 14.3, d).

In lap joints, the surfaces of the sheets being welded partially find each other (Fig. 14.3, e). They are widely used in welding sheet structures made of steel of small thickness (3.6 mm), in lattice and some other types of structures. Lap joints also include joints with overlays (Fig. 14.3, d, f), used to connect elements made of profile metal and to strengthen joints. Overlapping and overlay connections are simple, although they cause a sharp stress concentration, which limits their use under dynamic loads or low temperatures; in addition, they are more metal-intensive than butt ones.

Bolted connections

. In metal structures, coarse, normal, high-precision, and high-strength bolts with a diameter of 16 to 30 mm are used to connect elements. Anchor bolts with a diameter of up to 90 mm are also used.

The bolts have a head, a body, which is 2-3 mm less than the thickness of the package being connected, and a threaded part on which a washer is put on and a nut is screwed on. Rough and normal precision bolts and nuts for them are made of carbon steel and inserted into holes formed by punching or drilling in individual elements. The edges of the hole usually have a non-smooth surface and misalignment of holes in individual elements, which impairs the performance of the connection. The difference in the diameters of the bolt and hole (by 2.3 mm increases the deformability of the connection, although it makes it easier to fit the bolts and simplifies the formation of the connection.

For high-precision bolts (made of carbon or alloy steel), it is customary to grind the surface of the unthreaded part of the bolt body to a strictly cylindrical shape, and the diameter of the hole for such bolts is equal to the diameter of the bolt plus 3 mm. The smooth surface of the hole is achieved by drilling holes in assembled elements or through special template jigs in individual elements and parts. Such connections are used quite rarely.

High-strength bolts are made from carbon steel 35 or alloy steels 40Х, 40ХФА and 38ХС. The bolts are subjected to heat treatment in finished form. High-strength bolts are placed in holes of a larger diameter than the bolt, and the nuts are tightened with a special wrench, achieving a high tension force on the bolts. The latter tightly tightens the connected elements and prevents their mutual displacement due to friction between the connected elements.

Calculation of bolted connections (except for high-strength ones) is carried out for two cases of operation. When the external force is directed across the axis of the bolt, the connection works in shear, and the bolts work in shear and crushing. If the force acts along the axis of the bolt rod, then the bolts work in tension, and the destruction of the connection occurs after large plastic deformations, as a result of which the force is distributed equally between all bolts.

Types of metal structures and features of their installation

According to the type of connection, metal structures are welded, riveted and bolted.

Welded structures

Installation by welding is the simplest, but not always acceptable. Structures mounted using welded joints are immobile, which means they cannot be disassembled and moved to another location.

The average cost of installing metal structures by welding is determined by the price per ton and is approximately 12 thousand rubles.

Riveting devices

This connection method is not as popular as welding, but it has a significant advantage - reliability at low and ultra-low temperatures. Installation work on bridges and buildings with heavy loads is carried out mainly using rivets.

Bolted connections

Installation of structures using bolts, nuts and washers is called bolted. Its main advantage is its possible disassembly. This installation method is suitable for structures of various types: from mobile racks and stairs to metal trusses and frames of long-span buildings.

After installation of metal structures, they are grounded. You can order the installation of structures made of metal structures by calling. +7-961-777-39-96.

Connection of metal structures

Most modern buildings and structures are created using metal structures. This choice can be explained by their excellent quality, which plays an important role in the reliability and durability of the entire structure.

An equally important stage of construction is the installation of metal structures and their connection. The most difficult moment is connecting the parts, where you need to take into account the operating features of each structure. The connection process is possible in several ways.

Detachable mount

This type of connection involves the use of self-tapping screws and bolts, and it is this type that is most often used when performing various types of work. All other types of connections of metal structures are more complex, labor-intensive, and therefore are used much less frequently.

Rivets

Rivets are used if fastening is required for thin sheet plates. It is important that the base material and the rivets themselves are identical, otherwise the metal will gradually shrink and corrode at the joints due to temperature changes.

Soldering

In this case, soldering with molten solder is used. Due to the complexity of the method and its labor intensity, it is used quite rarely. The solder itself can be medium-, low-, or high-melting, depending on the melting temperature used.

Gluing

This name refers to the fastening technology, i.e. During the joining process, glue (paste, liquid) is used. The choice of adhesive is made based on the materials themselves, as well as the conditions under which the metal structure will be used.

Welding

This method is very common for connecting metal structures. During the welding process, only the same elements (in a molten state) are used for which the fastening is made.

Welding can be used not only for fastening metal structures, but also for joining metal and ceramics. Welding itself is divided into the following types: cold, laser, gas, arc.

In each case, the choice of one or another fastening method depends on the characteristics of the source materials, as well as the conditions under which they will subsequently be used. Well, in order for the structure to be as reliable as possible, for this work it is necessary to involve only specialists who have sufficient experience in connecting metal structures.

Related materials:

| Our partners |

— Alapaevsky Metallurgical Plant — Volgograd Metallurgical Plant (Red October) — Novokuznetsk Metallurgical Plant — Aerok LLC — Samara Metallurgical Plant — Ural Metallurgical Plant

Bonding of metal structures

Bonding is effective for those metals that are quite difficult to weld. This is most often titanium or magnesium. However, in the process of gluing metals a number of difficulties arise:

- The need for spot preparation of the bonded surface;

- Adjustment for overlap gluing;

- Relatively low joint strength;

- Impossibility of breaking work.

Combined types of connections are also used. Among them, riveted-glued and adhesive-welding joints are distinguished. They provide additional strength.

GENERAL INFORMATION

Connections of metal structures are designed to connect individual elements with each other. The choice of connection type depends on the type of stress state of the elements being connected; the magnitude and nature of the acting load; shapes of mating elements; connection operating conditions, etc.

In metal structures, welded, bolted and riveted joints are currently used.

Welded joints are the most common joints. They require less time and metal to manufacture compared to rivet and bolt connections. The use of welding ensures high joint strength, an automated process, and high quality welds when performed not only in the factory, but also in construction. Due to this, welded joints are used in all metal structures.

Bolted connections, like welded ones, are widely used in metal structures. They are used in installation and working connections of prefabricated and stationary structures. Their advantage: simplicity and reliability of connection; disadvantages: increased consumption of metal for the structure due to the weakening of the cross-section of the mating elements by holes, compliance (deformability) of the connection due to the presence of gaps between the bolt and the hole. Currently, connections with high-strength shear and tensile bolts are used. The advantage of these connections is their lower deformability, however, the complexity of such a connection increases.

Rivet connections

currently find limited use, since they are the most labor-intensive and expensive compared to the previous two. However, the reliability of rivet connections under alternating and vibration loads determines the scope of their application in structures with heavy duty operation (railway bridges, industrial shelves under dynamic influences, etc.).

See also:

Although metals are non-flammable, metal structures

buildings must be specially protected from fire. This is explained by the fact that when heated.

metal structures have been widely used

(LMK). The use of LMK in comparison with traditional metal structures reduces.

Metal constructions

must be installed in accordance with the design drawings (

structures

,

metal

, detailing) developed according to the workers.

Metal constructions

are widely used in modern construction in the construction of public and industrial buildings and structures. .

Metal constructions

to protect against corrosion, they are painted with oil paints, pentaphthalic enamels GF-230 and PF-115, nitroglyphthalic enamels NTs-132K, .

Currently, for all developed countries of the world, the leading direction in effective metal construction is the use of light metal structures

. bibliotekar.ru/spravochnik-78/115.htm

Metal constructions

To protect against corrosion, they are painted with oil paints, pentaphthalic enamels GF-230 and PF-115 (GOST 6465-76), and nitroglyphthalic.

Installation of metal structures

.

The methods for installing metal structures

are almost no different from installing reinforced concrete ones. However, performing individual works.

Building metal structures

, mostly operating in humid air, are mainly subject to electrochemical corrosion.

If metal structures

, cannot be replaced, they are covered with varnishes and enamels. The resulting film protects the metal from the action of the external environment. .

Application of riveting

Despite the fact that welding is actively used when connecting parts, riveting is not completely isolated from production. There is only one limitation that can become a problem when riveting: with this procedure it is only possible to make an overlap seam. But there is a possibility of a decrease in the strength of the structure, since the rivets become loose, and drilling holes creates additional problems.

Despite this, riveting is used in the production of airplanes and helicopters, as well as in the construction of bridges. This type of connection is more durable and safer for the structure. Another important factor is that metals are often used that do not weld well together.

At the same time, riveting is partially used in the production of various equipment. However, it is gradually being replaced by spot welding. Similar technology is used in the automotive industry, as well as in their repair.

As a result, these types of metal joining are still used because welding cannot yet cover all areas. However, the development of welding technologies today makes it possible to create integral structures, for example, bridges or airplanes. Probably, in a few years, welding will be able to completely replace other types of joints.

Joining metal sheets

The optimal method of joining metal sheets is selected depending on the characteristics of the rolled product, the planned conditions of its use, the availability of tools and consumables. The traditional option is welding, but in some cases alternatives are required: riveting, seam seams, bolted connections.

Seam joints of thin metal sheets

This permanent, but not rigid connection is often used when installing metal roofs. Seam joining allows you to solve the problem of changing the geometric dimensions of the sheet due to temperature changes, since a rigid sealed connection will lead to stress at the joint and deformation of the metal. There are several types of folds.

Solderable metal parts

The soldering process is technologically similar to welding. In addition, soldering machines are also suitable for welding parts. The only difference is that during soldering the additive melts, while during welding the metal also melts. Such a connection is still inferior in strength to welding.

For example, to connect aluminum parts of bicycles, it is advisable to use welding. This is especially true for mountain bikes. Since they have special requirements, the seams must be strong. Accordingly, welding is the most reasonable choice for this type of vehicle.

Since most of the frame parts are made of aluminum, there will be no problems with welding it. To do this, it is enough to configure the process correctly. After all, if the seam is not strong, the bicycle may be subject to deformation during use.

On the other hand, there is a class of bicycles that are used on flat surfaces. These are track bikes, for road and high-speed racing. In order to lighten the final weight of the vehicle, manufacturers are trying to reduce the thickness of the tubes on the frame. As a result, problems with heat capacity arise.

If such parts are welded, there is a risk of deformation or cracking. Not long ago, bicycle frames were made of steel, which was difficult to weld. Because of this, designers had to use soldering technology. This made the seam stronger, which was an advantage for the bike.

But at the same time, the strength and characteristics of the seam suffered. They were clearly inferior in welding quality. Most frames these days are made from carbon, which means the need for splicing is eliminated or minimized.

Methods for connecting metal structures.

Today I would like to talk about the most common method of connecting metal structures, which is called the welding method. That is, this method uses welding. Methods for connecting metal parts have gone through different stages and at the moment, the main ones are: heating, welding, cutting, soldering and surfacing, several other methods are also possible. Modern technologies can be used both in welding metal structures and in welding various other materials.

The main types of welding at the moment are contact, gas-press, gas, arc, thermite, argon-arc.

Several other methods can be additional ways to connect metal structures. For example, rivets and bolts, glue and forging can be used. Although, most often, preference is given to the welding method.

Let's look at several absolute new products for connecting metal structures:

Liquid fuel plasma cutter - This is a portable device that is designed for plasma cutting of metal. This method is aimed at liquid fuel, not gaseous.

Cold transfer welding - This method is based on electronic control of the welding process associated with the movement of the welding wire. Until recently, this was considered impossible. When using this method, an absolutely even, tight seam is obtained.

Gluing metal structures instead of welding - Gluing has a number of advantages over welding metal structures and other methods of connecting them. When gluing, no heat is used, therefore the seam of the joining structures is softer, without roughness, the structure, as well as the structure of the material itself, does not change. This seam is also vibration-resistant.

Spot welding of metal structure elements by friction - At the moment, this is one of the newest and most promising methods of connecting various elements of metal structures. Let's take a closer look at it. This method is used for joining two or more parts of metal structures. This method does not require any additional materials for fastening, so this method can resemble the riveting method. This method of joining metal structural elements was used mainly for joining magnesia and aluminum. However, over time this list expands.

News and Events Form is a mystery that defies description, but brings pleasure to people.

April 21, 2015 Everything you need to know about protecting metal structures. The article is about ensuring that a metal structure lasts as long as possible and protecting the metal structure from corrosion.

April 4, 2015 Metal fencing is a beautiful necessity. Let's consider metal fencing (fences), the possible positive and negative aspects of this unit of metal structures.

March 11, 2015 Spring is a special time of year. The time when nature comes to life and everything changes. Change is literally in the air, and people have an irresistible desire to try something new.

February 25, 2015 Today I would like to talk about the most common method of joining metal structures , which is called the welding method.

February 02, 2015 Price of the question “How much will the forged product, forged elements, all these railings, canopies, awnings, gazebos, all the forging used in our work cost?”

January 25, 2015 Changing the interior space of a room How global can we fill the interior space of our room, office or home.

January 25, 2015 Amazing forging Forging is returning to our everyday life and never ceases to amaze with its beauty, delicacy of design and ease of the work created.

December 15, 2014 We on social networks our page on social networks has appeared, where you can ask any question and be closer to Prof-Alliance >> we are on VKontakte

November 25, 2014 The gallery has been updated. We have added some more examples of our work. Forged canopies, forged canopies, forged balcony railings, forged grilles and much more >> see all photos

p-Complexes.

In ethylene, the bond is directed perpendicular to the C=C bond axis (a); cyclic olefins can be linked according to scheme b; aromatic rings - neutral, as in benzene C6H6, or charged, as in the cyclopentadienyl anion C5H5- - can be connected according to scheme c. The first and most famous of these “sandwich” compounds, ferrocene (C5H5)2Fe, has a type B structure. Acetylenes can be bonded to two metal atoms according to scheme d. Thousands of p-complexes are known, many of them with complex structures.

How to properly connect metal surfaces

To obtain a strong and durable connection, it is enough to apply glue to the material and compress the parts. Bonding metals consists of a number of procedures, which, as they are completed, can be divided into three stages:

- Preliminary stage. Preparation for gluing. At this stage, the surface of metal parts is cleaned of solid contaminants and rust. Then it is advisable to lightly mat the mating surfaces. This is done for better adhesion of the surface to the material being glued.

- Gluing process. Before applying the adhesive composition to the parts, it must be thoroughly mixed. In the case when a two-component mixture is used, both components are thoroughly mixed in the proportions specified in the instructions. Then the adhesive mass is evenly applied to the previously prepared surfaces to be glued. After applying the glue, the parts are quite firmly pressed together and left while the adhesive composition sets. The setting time is indicated in the instructions and it varies for different compositions.

- At the final stage, a visual inspection of the quality of the seam is carried out. The seam must be cleaned with a file or sandpaper if necessary. If the seam is exposed to high humidity, it is waterproofed.

How to properly connect metal surfaces

This technological process is universal for all compositions and allows you to glue not only metal, but also glass, ceramics, and plastic.

Not a single step of the process should be skipped; this will lead to a disastrous and unpredictable result. It is necessary to take a closer look at the actions performed at each stage.

Improved bonding quality

As mentioned earlier, the preliminary preparation of surfaces has a great influence on how the composition will glue the metal. Using sandpaper, the surface must be thoroughly cleaned of rust and other solid contaminants. The cleaning process also requires removing paint, old glue, and other layers covering the bare metal surface. It is best to use 120–240 sandpaper grit; it will create the necessary scratches on which the glue will cling more strongly. After mechanical cleaning of the surface, it is thoroughly degreased using solvent or acetone. It is not recommended to use gasoline, kerosene or other paint thinners; they leave a thin layer of foreign material on the surface of the workpieces being glued, which will prevent them from gluing well.

Additional measures that will allow metal parts to be glued together better are the use of special primers. They are applied to the surface to be glued before they are directly glued and serve to improve adhesion between the adhesive composition and the material.

Glue BF-2

For example, no matter how good the adhesion between epoxy resin and a metal surface is, BF-2 glue has the greatest adhesion to metal among the available adhesives. Therefore, this primer is widely used among yachtsmen, where it is necessary that the epoxy firmly glues two parts together and the seam is not afraid of moisture. To do this, apply a thin layer of BF-2 to the carefully prepared areas to be glued. Its layer is dried for an hour and a half at a temperature of 130 to 180 degrees. The main thing is that the glue layer dries and does not burn or overheat. Next, you can glue it with epoxy resin according to the instructions; the glued seam with this connection will be much stronger than without the use of BF-2.

How to connect copper and aluminum wires correctly

Knowing the causes and possible solutions to the problem, you can begin to analyze the question of how to properly connect copper and aluminum wires. And here there are several quite logical answers, some of which we have already given in the section above.

Let's start with the question of lubrication. This can be technical petroleum jelly, lithol or any other lubricant that prevents metal oxidation and moisture penetration. But here the question arises with the subsequent isolation of such a connection. After all, electrical tape adheres very poorly to lubricant, and heat shrink can simply squeeze it out.

Note! In any case, twisted connections are prohibited. And for such different metals, twisting can be doubly destructive.

Types of cold welding

On sale you can find cold welding at an affordable price, domestically produced, and more expensive and high quality - imported.

Plastic-like cold welding needs to be softened before use.

There are several types of cold:

- , designed for welding aluminum and copper busbars, handles with aluminum pans; applying copper overlays to the ends of aluminum wires to ensure reliable electrical contacts; manufacturing finned coolers instead of pressed ones for power semiconductor equipment, etc.

- Seam welding is used in the manufacture of sealed housings of various instruments and equipment and large sealed vessels with thin walls. It is carried out using contour punches.

- Butt welding - used to connect the ends of wires and make rings.

- T-welding - used for connecting brass studs to aluminum terminals of transformer windings, corner and T-bar busbars of electric locomotives.

- Shear welding is needed for connecting heating and water supply pipes and adapters in railway power lines.

According to the consistency and adhesive composition, cold welding for metal can be:

- liquid - two-component, when the glue is mixed with the hardener immediately before work;

- plasticine-like, similar to ordinary plasticine and representing a one- or two-layer bar, which should be mixed and kneaded before use.

According to the intended purpose, cold welding can be:

- for working with metal - contains a metal filler and allows you to connect most types of metals;

- for car repair, also containing a metal filler and designed specifically for the repair of automobile parts;

- universal, allowing you to work with different materials (metal, wood, polymer materials), but being the least durable of all types;

- for welding parts in various conditions, for example, under water.

Return to contents

Installation of metal columns

Columns are the basis of the frame of the future building. It is on them that the load-bearing capacity is assigned. Typically, columns are attached to a solid concrete foundation. The most commonly used methods for attaching them are:

- using anchor bolts, after adjustment, the joint is filled with a sufficient amount of concrete mixture to strengthen the adhesion;

- directly with the foundation to the level of the base, no additional concrete screed is required;

- using support sheets, auxiliary cement pouring is carried out if necessary.

When constructing columns, the gaskets used are necessarily welded to the base. On the upper tiers, welding or special fastening systems, as well as bolting, are used to install elements of metal structures (in particular, columns).