Bending metal strips is used in the manufacture of various devices: staples, brackets, clamps and other elements. The main criteria for the quality of bending workpieces are the accuracy of the parameters of the external configuration, maintaining the uniform thickness of the profile of the processed product and its strength during operation.

Strip bending is done on special equipment both from raw materials (aluminum, steel or stainless steel) and from other metal objects (pipes, long products or shaped products). When making bending from finished parts, long rolled products with a profile in the shape of a circle or square are used as raw materials, and a channel or angle is used from the shaped part. Strip bending has the following features:

The strip is bent radially to create a spherical surface. Bending is done across the fibers of the material formed during the rolling process. At the bend, the metal becomes thinner and deforms in cross section. Bending can be done with different radii. The smaller the radius, the larger the area of the workpiece the deformation spreads over. If there is an error in calculating the bend radius, breaks may appear on the surface of the strip or pipe due to excessive compression or stretching of the base. Bending is carried out using a technology that ensures that the shape is retained after exposure to the product.

Bending into a ring also requires precise calculations of the relationship between metal thickness and diameter. Ring bending is performed in several ways: strips or pipes are bent with a constant or variable radius, flat (material width up to 240 mm) or on an edge (material width up to 150 mm). Ring bending is used in cases where it is necessary to maintain the same deformation of the structure along the entire length of the profile elements.

Wave bending of strips. The thickness of the profiles must correspond to the bending radius. To avoid complex calculations, CNC machines are used;

There are different types of bending strips into spirals:

- arc bending is used for decorative parts of different profile thicknesses;

- bending by twisting: one or two strips of identical profiles, clamped at one end, are rotated about their axis. Twisting is also done from round profile rods;

Bending at right angles allows you to make metal structures in the form of a square. The production uses a sheet of steel or stainless steel. It is possible to use aluminum strip;

Bending strips at an acute angle. The strip can be placed either flat or on the edge.

Bending of metal blanks is facilitated by CNC equipment. High-tech equipment significantly increases the accuracy of metal stress calculations and eliminates the impact of random factors on pipe or rolled metal bending. The bending of the processed object becomes better and its performance is significantly improved. Software control is of particular importance when creating decorative elements, making it possible to produce objects of complex configuration with high aesthetic properties.

Bending a metal strip into a ring and onto an edge

When working with metal, you often have to deal with the manufacture of products from steel strip - staples, clamps, brackets.

But not everyone knows how to bend a metal strip without losing strength and achieving the required configuration accuracy. However, this is a fairly simple operation that does not require particularly sophisticated tools. Only in the case of bending a strip on an edge, a rather complex device is needed, which is not easy to make yourself. Bending of the strip at an angle (60, 90, 120 0 ...) towards the plane is done on a regular bench vice if you need to make a single product or several pieces.

In the case of small-scale production, you will need a machine for bending metal strips. If necessary, you can do it yourself.

Types of equipment

For the modern metal bending process, there are many options for the latest devices. In production, presses are usually used , which can be divided into the following types:

- Rotary, bending metal by moving between special rollers. Suitable for the production of large-sized products in small batches.

- Rotary presses bend the plates using bending beams and two plates. The stationary plate is located at the bottom, and at the top there is a rotating plate. The optimal option for processing sheet metal products with a simple relief and small dimensions.

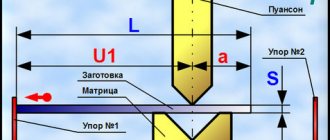

- Standard pneumatic or hydraulic presses are used for mass or small-scale products made of stainless steel or other metal. Bending is done between the punch and the die. Due to this, even thicker products can be processed. It should be noted that hydraulic presses are used more often than pneumatic ones due to their simpler operation and cost.

Of all the types of equipment described above, the most modern is rotary. It operates automatically, and the worker does not need to calculate the optimal force value in advance.

Rotary presses are also considered automated. Here one sheet is sent to the device, which must be positioned as required by the task. Most often used in small enterprises where they work with metal parts.

Bending strips using a vice

First, let's consider the option of bending on a bench vice at an angle of 90 0. To do this, you need a square block of steel. We clamp the strip together with the block so that the block is located on the side of the fixed jaw of the vice and protrudes 1-2 cm above the upper edge.

After such a “sandwich” is firmly clamped, take an ordinary hammer and bend the strip towards the block with light blows. If it is required that the bend surface is not damaged by impacts, then you need to use a copper or brass gasket, which we will hit with a hammer, and from it the force will be transferred to the strip.

In this way, you can bend the strip at any angle; it is only important to select a support block with the desired cutting angle. Without such solid support, achieving the desired angle will be very difficult.

Similar operations are performed in the manufacture of clamps, only in this case we use a thick-walled pipe or rod of the required diameter as a matrix. As in the case of a rectangular bend, blows with a hammer are applied towards the stationary jaw of the vice. This kind of strip bending is a slow process and requires care.

Handmade

This work is usually done with hand scissors . Marks are placed in the right places along which manual bending of the metal will be carried out. The sheet is securely fixed in a vice. The first fold is made with a massive hammer. The product is moved to a new bend location, clamped with a block of wood, and bent in the desired direction.

Upon completion of the work, you must ensure that the product meets the established standards. The check is carried out using a square and, if necessary, defects are eliminated.

Bending strips into a ring

A more complex operation is bending strips into rings. What is needed here is a small and easy-to-manufacture machine, for example, like the one shown in the video. It consists of a base plate on which three rollers are fixed - two support and one drive, on a handle 30-40 mm long. The drive roller can move along a horizontal axis and press the strip against the support. One of the support rollers must be able to move perpendicular to the direction of pressure. In this way the diameter of the resulting ring is adjusted.

The strip is placed between the rollers and pressed using a screw mechanism. When the drive roller rotates, the strip begins to move between it and the support rollers and bend towards the drive. After a complete pass of the strip, an almost perfect ring is obtained. If you make the handle telescopic so that the arm can be made longer, then you can bend strips of almost any thickness onto the ring without much physical effort.

This homemade strip bending machine is practically no different from the factory one. With the right choice of metal for the rollers and clamping device, small-scale production, for example for the manufacture of decorative fences, gates or frames of canopies and awnings, is possible even in a home garage, not to mention a metalworkshop.

Self-production of the machine

Sometimes you need to make a machine at home . This will make bending metal easier and increase productivity. Here you will need a corner, a metal beam, hinges with bolts, clamps, handles, a table and a welding machine. The procedure is as follows:

- The base is made of metal; an I-beam profile is suitable.

- The corner is attached to the top of the beam using bolts.

- Three hinges are welded under the corner using a welding machine.

- We bend the aluminum sheet by turning the corner.

- Two clamps ensure tight pressing of the metal.

- The corner does not have to be removed; you can raise it. Place the product between the profile and the corner. Then a metal sheet is aligned along the edge.

Check the bolts to ensure they are secure. Turn the crossbars and bend them so as to form the desired angle. This will avoid wasting time on angle calculations.

Whatever the devices, the main principles remain the same . By following them, you can obtain products that meet the standards and wishes of the customer.

Bending strips on edge

It is more difficult to make a machine for edge bending. When making metal decor, such an operation is required quite often. The principle of operation of such a device is similar to that described above, but bending a steel strip on an edge requires much greater effort, so the pressure roller does not rotate, but moves back and forth on the lever. In addition, a clamping device must be installed on the strip feed line to keep the strip in position. This device can be a regular clamping block with bolts or studs with a slot through which the strip will pass.

If bending is often done on strips of different widths, then you need to make several blocks with slots corresponding to the gauge that is being processed. But a homemade tool, for all its attractiveness and cheapness, is still inferior to an industrial one, the functionality of which is much higher.

Hand tools are produced in the form of universal devices, in which only the attachments and levers are changed, or in the form of entire sets, where each mechanism performs only one, maximum two functions. An example of such a kit is “Cold forging” of industrial production.

Bend a ring from a metal strip.

There was a need to make several rings from a metal strip 8mm thick and 55mm wide. The outer diameter of the ring is 400mm, and the inner diameter is 300mm. After bending and welding, it is finally processed on a lathe. Maybe someone has encountered a similar problem and can suggest bending technology. Perhaps there are devices for bending similar parts. I would be grateful for advice and suggestions.

Stupid question, but won't thin tape work? In general, I would contact a decent forge with this question.

eug28 wrote: There was a need to make several rings from a metal strip 8mm thick and 55mm wide. The outer diameter of the ring is 400mm, and the inner diameter is 300mm.

Something is unclear, how can this be, the outer diameter is 400 mm, the inner diameter is 300 mm, with a wall thickness of 8 mm? (400-300): 2 = 50mm, the wall thickness should be, not 8mm, if we are talking about a ring. Will scraps of pipes of the required diameter be suitable?

Suever wrote: Something is unclear, how can this be,

The strip should bend along its width, not its thickness, if I understand correctly. For such parameters it is necessary to use something like an industrial pipe bender with a powerful electric drive with appropriate mandrels.

It’s easier to cut it out of an 8 mm sheet using gas and trim it on a machine. If this is not possible, then really go to the blacksmith.

Madman wrote: For such parameters it is necessary to use something like an industrial pipe bender with a powerful electric drive with appropriate mandrels. __________________

In this case, you need to bend it on the “edge”, 8mm on the edge is something not ice, then it’s easier to draw it on an 8mm sheet, and even cut it out with a jigsaw. I understand, but it’s necessary.

In general, try to do this with a cardboard model, manually bend it on its edge, it either folds correctly or breaks, IMHO the same will happen with metal, so it’s better to cut it from a sheet.

Yann: - It’s difficult to bend. Usually cut from sheet. You go to the local boiler house or water utility, take a bottle and go to the mechanics. They are aware of these issues. I have several 400 * 10 mm nickels lying around at home, these are plugs from equipment. But how can I give them to you?

2eug28 Never bend this strip into a flat, smooth ring using any equipment. It is necessary to cut from a single sheet with gas, EMF, a jigsaw, a grinder or directly on a lathe

Vidis wrote: You need to cut from a single sheet with gas,

I think that after gas it will only end up as scrap metal.

You won't be able to bend it. If there is no solid sheet for the ring, you can weld it from a strip - in sectors (chords) with cutting and then on the machine. Something like this, if the width is 55:

Suever wrote: I think after gas he will behave like this

I assure you, it won’t lead.

You just need to make a ring X mm wide Y mm, then cut out a piece (sector) to form a sort of letter C and bend it on an anvil along the diameter until the edges meet... accordingly, do everything on a cardboard model... plus allowances for manual processing, and forward.. They usually make a cone that way.. but in general, to the pipe plant.. just order what you need..

Suever wrote: I think that after gas it will only end up as scrap metal.

Yann: - It doesn’t matter, this is usually done everywhere, and this work itself is well known to welders. You can do it yourself, find a cutter and the necessary hardware. Well, you can bend the rod, weld it and take it to the forge, where it will be heated and flattened. I see the way out as follows: - “Either to the forge, or to the welder.”

Strip metal bending

A series of articles devoted to metal processing continues on our website. We talked about how sheets and rolls from the delivery state are unraveled into strips (strips) in the article “Metal slitting lines.”

Metal bending is done using specialized equipment or manually. We described how this happens with imported equipment using the example of products from the Italian machine tool concern WARCOM. We talked about the use of domestic sheet bending machines for these purposes in an article about the Lipetsk sheet bending plant.

Today we will talk about manual bending of strip metal.

Manual bending of strip metal

Manual processing of metal strips is a labor-intensive operation, in most cases requiring special training of the worker and the appropriate tools. This operation is performed by a mechanic at a specially equipped workplace:

- a mechanic's workbench equipped with an appropriate vice;

- set of locksmith tools.

Let's look at a few simple operations with strip metal.

Right angle bending

We will bend the strip steel in a bench vice. Place the workpiece (clamp it) in a vice.

We do this in such a way that the side with the bending point faces the stationary jaw of the vice (away from the worker). In this case, the mark should be approximately 0.5 mm higher than the jaw of the vice. Hammer blows should be applied in the direction of the stationary jaw of the vice. To avoid injury (if the workpiece springs back), the mechanic, when performing this operation, should not be positioned in the path of the hammer.

Bending at an acute angle

In this case, a mandrel having the required angle is used. It is installed in a vice along with the workpiece, as shown in the figure (with the high side facing the workpiece). The workpiece is deformed by hammer blows until it touches the bevel of the mandrel.

Manufacturing of staples and clamps

To make a bracket, you should use a frame block, the thickness of which will be equal to the opening of the bracket. Next, you should fasten the strip with the mandrel in a vice, as indicated in the figure, and bend first one side, and then the other.

Manufacturing of staples and clamps.

To make a clamp, fix the frame in a vice and bend a strip on it (see figure). Then, bend the ends of the clamp, release the equipment from the vice and use a hammer to give the part its final shape on the workbench table.

Hammer blows should not be applied to the clamp itself, so as not to leave scratches, nicks and dents on it. They should be carried out through a copper plate of small thickness, since it will well redistribute the impact force.

Bending connection

Strip bending is widely used for bending joints of parts. The connection can be completely bendable, as shown in the figure. Here, the fastening force is created by bending one part (often all connected parts are deformed).

In a number of cases, strip bending plays a supporting role. It can, for example, strengthen a threaded connection.

Examples of bending connections.

The figure shows examples of strip bending and strengthening of a nut-bolt threaded connection: a cotter pin and a lock washer.

Edge bending

The operation is performed on the roller machine shown in the figure.

Metal strip bending

Bending metal strips is used in the manufacture of various devices: staples, brackets, clamps and other elements. The main criteria for the quality of bending workpieces are the accuracy of the parameters of the external configuration, maintaining the uniform thickness of the profile of the processed product and its strength during operation.

Strip bending is done on special equipment both from raw materials (aluminum, steel or stainless steel) and from other metal objects (pipes, long products or shaped products). When making bending from finished parts, long rolled products with a profile in the shape of a circle or square are used as raw materials, and a channel or angle is used from the shaped part. Strip bending has the following features:

The strip is bent radially to create a spherical surface. Bending is done across the fibers of the material formed during the rolling process. At the bend, the metal becomes thinner and deforms in cross section. Bending can be done with different radii. The smaller the radius, the larger the area of the workpiece the deformation spreads over. If there is an error in calculating the bend radius, breaks may appear on the surface of the strip or pipe due to excessive compression or stretching of the base. Bending is carried out using a technology that ensures that the shape is retained after exposure to the product.

Bending into a ring also requires precise calculations of the relationship between metal thickness and diameter. Ring bending is performed in several ways: strips or pipes are bent with a constant or variable radius, flat (material width up to 240 mm) or on an edge (material width up to 150 mm). Ring bending is used in cases where it is necessary to maintain the same deformation of the structure along the entire length of the profile elements.

Wave bending of strips. The thickness of the profiles must correspond to the bending radius. To avoid complex calculations, CNC machines are used;

There are different types of bending strips into spirals:

- arc bending is used for decorative parts of different profile thicknesses;

- bending by twisting: one or two strips of identical profiles, clamped at one end, are rotated about their axis. Twisting is also done from round profile rods;

Bending at right angles allows you to make metal structures in the form of a square. The production uses a sheet of steel or stainless steel. It is possible to use aluminum strip;

Bending strips at an acute angle. The strip can be placed either flat or on the edge.

Bending of metal blanks is facilitated by CNC equipment. High-tech equipment significantly increases the accuracy of metal stress calculations and eliminates the impact of random factors on pipe or rolled metal bending. The bending of the processed object becomes better and its performance is significantly improved. Software control is of particular importance when creating decorative elements, making it possible to produce objects of complex configuration with high aesthetic properties.

Basic principles

Metal bending is carried out using various methods. Welding is often used, but temperature exposure can change the shape and properties of the finished product. This reduces performance properties and manufacturing accuracy.

Since when bending metal, the outer layers of the metal stretch, and the inner ones begin to compress, it is necessary to bend part of the rolled metal relative to another by a given angle. The angle can be found using calculations.

The product is deformed to those values that are within the specified limits. They depend on the following parameters:

- Thickness of the metal sheet;

- How much is the bending angle?

- How durable is the material;

- Speed and time of the procedure.

The permissible deformation indicator will depend on them. The next step is to select the type of bending.

Bending parameters and profile requirements

1. Strip - folded on edge

2. Strip – folded flat

| Type | Size mm | Wall thickness, mm | Minimal. radius, mm |

| 30 | 10 | 125 | |

| 45 | 20 | 150 | |

| 50 | 20 | 250 | |

| 60 | 20 | 250 | |

| 70 | 15 | 350 | |

| 120 | 15 | 600 | |

| 30 | 10 | 125 | |

| 45 | 20 | 125 | |

| 60 | 30 | 150 | |

| 100 | 10 | 200 | |

| 150 | 15 | 350 | |

| 260 | 20 | 400 |

These parameters are provided as a guide and always depend on the thickness and type of material.