Advantages of central water supply

Benefits when connecting to a central water supply:

- you will get rid of significant financial costs for pumping equipment (it costs more than two pennies!);

- drilling, pumping and maintaining a well in working condition also means money, time and worries;

- Centralized water supply is a type of activity with a certificate, which guarantees you an uninterrupted supply of water, maintaining (without your efforts) normal pressure in the pipes and drinking quality of water.

You can supply water to a private home with the help of specialists (but this is a financial cost) or with your own, the choice is yours.

House water supply with surface pump

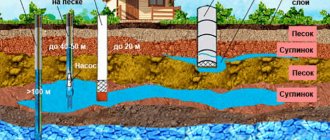

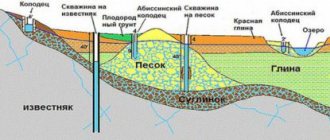

If the well depth is small (no more than 8 meters) or a well is used as a source, then a surface pump is used. Depending on the distance from the source to the house and winter residence, the surface pump is placed either in a caisson (possibly next to the well), or in a shed near the house, or in the house (basement or first floor).

Removing the surface pump from the house, a convenient scheme for the water supply of the house. It is not noisy and allows the use of surface pumps with an ejector (very noisy) for deep wells (up to 12 meters).

In this scheme, the automation unit is installed not on the hydraulic accumulator, but on the water supply side for distribution. We get a separate pump, a separate hydraulic accumulator, a separate automation unit.

This scheme also works with a submersible pump if the well is not remote from the house.

Without documents it will not be possible to supply water to a private house

In order to supply water to a personal household, you will have to run through the authorities to secure permits at all stages. Without this, water will flow into a private house from the central water supply illegally, and for arbitrariness you will have to pay an exorbitant fine, and even dismantle your initiative at your own expense.

This is serious, you need:

- perform research and obtain results;

- draw up technical documents;

- obtain their approval from the relevant institutions.

There is no need to mess up the paperwork - you need to do everything on time and in the correct sequence, otherwise you will have to start over.

Contacting your local surveyor's office

Your first step is to contact a surveyor.

Be sure to take with you documentation confirming your rights to use this land plot.

Within 10 days, employees of the geodetic service must conduct a topographic survey of the area where your home is located and draw up an explication of the site (otherwise known as a situation plan). Significant objects will be marked on the legend, including your home, and the utility network with distances indicated. Based on the situational plan, it will be clear how to optimally deliver water to you.

If you have previously used the services of this service and the explication was compiled, check the date: if more than 1 year has passed since it was compiled, it is invalid and must be compiled again.

How to get technical specifications

TU are technical specifications. To get them to connect to the central water supply, you should contact the structure with whose permission you built the house. From there you will be directed to the water utility. There you will submit your documentation package. It includes:

- application (in 2 copies);

- documents confirming the right of ownership of the house (plot);

- your identity document (passport);

- water consumption balance (it must be prepared by designers);

- building permit (in the form of 2 copies);

- situational plan (7 copies).

After 2 weeks, you will be provided with technical specifications, which will indicate the date of connection and the load allowed for you on the centralized water supply system (and whoever provided it is obliged to connect).

Ordering a water supply project

After receiving the specifications, it’s time to order a project for your future water supply system. Otherwise, it will be impossible to conclude an agreement with the water utility.

Based on the technical specifications, every qualified organization is suitable for the implementation of the project, but approval is possible only at the local water utility. The connection is made according to the project.

It is also necessary to coordinate the project with those who supply you with electricity, gas supply and telephony (their communications are also connected to you, and a new one may interfere with their work). The “final point” in approving the project will be put in the architecture committee.

We lay the water supply ourselves or entrust it to a special organization

Remember that according to the rules, “centralized” plumbing work outside the boundaries of your property is carried out by an organization with a license for this activity. It’s ironic, but such organizations are aware of their own importance and indispensability - and they voice such a price for services that people prefer to pay a fine (a much smaller amount) by doing all the work themselves.

The financial costs of installing a water supply system consist of payments for:

- materials;

- collection fittings;

- installation team services.

You can minimize costs by doing all the work yourself.

Agreement with water utility

Next, we show the documents to the local water utility and enter into an agreement with them. He, for his part, prepares the infrastructure of your household for work and connects to the water supply system; payment for services is required on your part.

We carry out the plumbing ourselves

The most budget-friendly solution is to lay the pipeline yourself. Before running water into any private home, you should draw a diagram (strive for clarity). The diagram should make clear the location of pipes and water intake points, the approximate laying area, taking into account interchanges. Mark the obstacles on the terrain (they will have to be removed before installation; some awkward mound, boulder or stump sticking out of the ground can significantly complicate the installation). Then gradually introduce water into the house.

What is the fine for unauthorized insertion?

Construction of a well at the connection point

Have you noticed that along the central water supply line there are wells with outlets located at intervals of 100 m, making it possible to connect additional lines? TUs are given to the nearest well.

If it is not observed, it would be logical to equip your own well in the same place as the water supply. Possible materials for it:

- gas silicate (but not for long);

- brick (expensive);

- rings made of reinforced concrete (the best option).

For safety reasons, the well must be covered with a lid. Plastic can only be used if vehicles will not pass over its surface (otherwise it will not last long).

Connection to the main pipeline can be made:

- insertion (requires a welding machine);

- without welding - using a clamp (no need to disconnect the central water supply). A clamp is mounted on the supply pipe and drilled through a special hole. Screw an open tap onto the thread of the clamp and close it. If the valve is a ball valve, drilling is done by first installing it.

When using a clamp, dress appropriately and do not use a power drill - everything will get wet.

Digging a trench for laying pipes

To lay and supply water to the house, you need to dig a trench. This can be done in two ways:

- order the work of special equipment (a small excavator will do an excellent job; trenchers are also used);

- dig on your own (it is advisable to do this in a group - with family or friends, otherwise you will face a long and tedious process).

The essence of the trench is that it should not only conceal, but also protect the pipeline from freezing, so it is dug below the freezing point of the soil in a given region. Usually it is from 1.5 to 2 m, unless, of course, you live in the Arctic. (All the nuances of digging)

Then a sand cushion with the addition of crushed stone is created for the pipeline. It will cushion it and prevent groundwater from seeping into it (otherwise the pipes may freeze over in a harsh winter).

If you have a plot of land with special features and it is impossible to dig to the required depth, you will have to additionally insulate the pipes. For this we use:

- foamed polyethylene;

- expanded polystyrene;

- basalt wool.

You can fill the pipeline with expanded clay (it is not thermally conductive).

Creating an entrance to the house

Through the fitting, we connect the pipe to the centralized main (using a shut-off valve and sealed metering devices). After this, we lay the water supply into the house:

- under the foundation - do not forget about depth and insulation;

- through the foundation - punching an inlet hole is required (attention: it should be made 15 cm larger than the cross-section of the pipe to prevent deformation and destruction of the pipeline if the wall sags).

We pay special attention to this area - it can lie in the ground at a shallow depth, this is risky in terms of freezing. Therefore, it must be carefully insulated.

Choosing the best pipe and laying the line to the house

The main element of a plumbing system is pipes. You need to choose the best option. There is a choice:

- galvanized steel are resistant to serious mechanical overloads, but they rust, and their installation involves threading or welding, which is difficult and time-consuming;

- copper pipes are long-lived, but they cost “like a cast-iron bridge” and are difficult to install;

- polymer (polypropylene, HDPE) are easy to install, moreover, they are resistant to aggressive chemical influences and are inexpensive;

- Metal-plastic is also neutral to aggressive chemicals, has excellent throughput, is not afraid of ultraviolet radiation and corrosion, but does not tolerate high temperatures.

When the water supply to your home is completed, do not rush to bury the trench. You need to test the system - run water for testing and make sure that the joints are not leaking. If a leak is found, it must be repaired.

Water supply system elements

In order to organize an uninterrupted supply of water to water collection points and ensure the required pressure, the water supply scheme must include the following elements:

- hydraulic structure;

- pump equipment;

- hydraulic accumulator;

- water treatment system;

- automation: pressure gauges, sensors;

- pipeline;

- shut-off valves;

- collectors (if necessary);

- consumers.

Additional equipment may also be required: water heaters, irrigation systems, etc.

Features of choosing pumping equipment

For a stationary water supply system, submersible centrifugal pumps are most often chosen. They are installed in wells and boreholes. If the hydraulic structure is of small depth (up to 9-10 m), then you can purchase surface equipment or a pumping station. This makes sense if the well casing is too narrow and difficulties arise in choosing a submersible pump of the required diameter. Then only the water intake hose is lowered into the well, and the device itself is installed in a caisson or utility room.

Pumping stations have their advantages. These are multifunctional systems - pump, automation and hydraulic accumulator. Although the cost of the station is higher than that of a submersible pump, the system is ultimately cheaper because There is no need to separately purchase a hydraulic tank.

The most significant disadvantages of pumping stations are the loud noise during operation and limitations on the depth from which they can lift water. It is important to install the equipment correctly. If mistakes are made during the installation of the pumping station, it may become airy, which affects the stability of the water supply.

To organize the uninterrupted operation of the water supply system, in addition to pumps, hydraulic tanks and automatic control units are installed

When choosing a pumping station, you should correctly calculate the required power, productivity and buy equipment with high efficiency

There are cases when it is simply impossible to install a submersible pump and you have to install a surface or pumping station. For example, if the water level in a well or borehole is insufficient to comply with the rules for installing deep-well equipment.

The pump must be installed so that there is a layer of water above it of at least 1 m, and 2-6 m remains to the bottom. This is necessary for good cooling of the electric motor and the intake of clean water without sand and silt. Failure to comply with installation conditions will lead to rapid wear of the pump due to pumping contaminated water or burnout of the electric motor windings.

When choosing a submersible pump for a well, you need to pay attention to the type of design of the device. If a three-inch production pipe is installed, many well owners buy a cheap and reliable domestic “Malysh” pump. The diameter of its body allows the device to be mounted even in narrow pipes. However, with all the advantages, “Kid” is the worst choice. This is vibration type equipment.

Constant engine vibration quickly destroys the production string. Savings on a pump can result in much larger expenses for drilling a new well or replacing the casing, which is comparable in cost and labor intensity to the construction of a hydraulic structure. Vibrating pumps are not suitable for narrow wells due to the design and operating principle. It's better to install a pumping station.

The deep-well pump is lowered into the well on a safety rope. If it is necessary to dismantle it, then it should also be lifted by the cable and under no circumstances should it be pulled by the water-lifting pipe

Hydraulic accumulator - guarantee of uninterrupted water supply

The presence of a hydraulic accumulator tank in the water supply system prevents many problems with the water supply to the house. This is a kind of analogue of a water tower. Thanks to the hydraulic tank, the pump operates with less load. When the tank is filled, the automation turns off the pump and turns it on only after the water level drops to a certain level.

The volume of the hydraulic tank can be any - from 12 to 500 liters. This allows for some water supply in case of a power outage. When calculating the volume of a hydraulic accumulator, it is taken into account that, on average, approximately 50 liters are needed to meet the water needs of one person. About 20 liters are taken from each water collection point every day. Water consumption for irrigation should be calculated separately.

There are two types of hydraulic accumulators - membrane and storage. The first ones are usually small in volume, equipped with a pressure gauge and a check valve. The task of such a hydraulic tank is to provide the required pressure in the water supply. Storage tanks are much larger in volume. When full, they can weigh up to a ton.

Volumetric tanks are mounted in attics, so when designing a water supply system, you should foresee in advance the need to strengthen building structures and consider thermal insulation for the winter period. The volume of water in the storage tank is sufficient so that in case of a power outage there will be enough water for at least a day.

A generator will help ensure a constant power supply, read about this:

There are many designs of hydraulic accumulators. Depending on the location, you can choose a vertical or horizontal model

HDPE pipes - a simple and reliable solution

On sale you can still find water pipes made of any materials - steel, copper, plastic, metal-plastic. Increasingly, owners of country houses prefer HDPE pipes (made of low-density polyethylene). They are not inferior in quality to metal ones, but do not freeze, burst, rust, or rot.

High-quality HDPE pipes can last up to half a century. Due to their low weight, standardized connecting and fastening elements, they are relatively easy to install. This is an ideal option for an autonomous water supply system, and every year more and more home owners choose it. Typically, pipes with a diameter of 25 or 32 mm are purchased for water supply.

Polyethylene is elastic. It stretches and contracts depending on the ambient temperature. Thanks to this, it retains strength, tightness and original shape.