A water well is a cylinder-shaped structure that goes deep into the earth and is reinforced with a special rigid frame.

Drilling rig

is a machine for drilling wells, a set of ground equipment necessary to perform well drilling operations.

Depending on the depth of drilling a water well, the geological and climatic conditions of the area, and transport links, drilling rigs are equipped differently, and in all cases they strive for the simplest set of drilling equipment that ensures high-quality, trouble-free construction of the well.

Self-propelled

The main advantage is considered to be that their movement does not require a truck, since they are made on the basis of a self-propelled chassis on tracks or wheels. Various tractors, all-terrain vehicles or trucks can be used as such a chassis.

Most often, a drilling unit is mounted on a chassis, with a hydraulic or mechanical drive; when using the latter, torque is transmitted to the auger from the engine of a car or all-terrain vehicle.

Among the positive qualities stand out:

- Exceptional mobility. The installation can work in any conditions, even in the field. The height of the tower can reach 5–7 meters, so work in the immediate vicinity of power lines may require a work permit.

- The drilling speed increases significantly due to the absence of the need to assemble and disassemble the mechanism, since the installation arrives at the site independently and is almost immediately ready for work.

- Self-propelled devices are easier to maintain and repair.

- Possibility of drilling mines up to 350 meters deep, at a speed of up to 10 m/h, depending on the hardness of the rock.

- Work on all types of soil. For high rock hardness, it is recommended to use drills made of high-strength steel or with diamond tips.

Drilling a well

At the beginning of the process, a pile driver is installed above the drilling point - a tripod made of pipes or logs.

If their length is 6 m, the height of the pile driver will be about 4.5 m, which will allow the use of links up to 3 m long for the drill rod and casing.

For reliability, install the “legs” of the pile driver in the recesses. If they are simply rested against pins driven into the ground, the structure will be unreliable.

The lifting and drilling gates, a block with a hook and a rocking lever are suspended from the pile driver. Next, you should select soil underneath it to a depth of 1.5 m (the dimensions of the excavation in plan are 1.5x1.5 m).

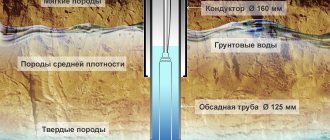

Drilling to a depth of up to 3 m is carried out using an auger, which is very important to keep in a strictly vertical position. If the well is supposed to be made deeper than 7 m, a guide pipe - a conductor - should be installed strictly vertically in the prepared hole.

When manual drilling, only the dry intermittent method is used: the drill bit is removed every 0.5 m of penetration and freed from the soil.

Boulders that are broken with a chisel and dry, dense clay can pose difficulties. If such a layer gets in the way of the drill, you should pour several buckets of water into the well and, after a pause, try to select the clay with a spoon drill or a driving glass.

MGBU

Because of their compactness, they are called small-sized, or, in short, MGBU. They were a real breakthrough. Thanks to MGBU, anyone can drill a well 70–100 meters, even those who have never encountered drilling work before.

These devices are divided into three types: mobile, collapsible and portable. They can be quickly disassembled, loaded into the back of a regular gazelle and brought to their destination. After delivery, the MGBU is easily unloaded, assembled and ready for use within 15–20 minutes.

An electric motor operating at 220 volts is most often used as a drive for small-sized devices.

For example, MGBU-70 weighs only 350 kilograms, but it is capable of drilling wells up to 70 m deep at a speed of 5–7 m/hour, depending on the hardness of the soil.

It does not require much space to operate, as the dimensions are only 115 x 120 x 270 cm.

Equipment for well development

Arranging a well with a caisson is an important step in equipping a water supply source, which is necessary for organizing the effective operation of a system that provides water to residents of country and country houses. After drilling the well, the necessary equipment is installed. The service life of the water supply system depends on its correct selection and quality.

When constructing a water well, appropriate equipment is used.

Pump

There are different models of pumps that differ in power. The correct choice of model is important for the performance of the system and for its stable operation. The appropriate option must be selected taking into account the diameter, depth of the well, maximum water flow and the length of the water pipeline.

Pressure gauge

This device measures blood pressure. It is important that the pressure gauge is different:

- reliability;

- long service life (it is better to choose models with a steel case and a durable mechanism);

- clarity (that is, so that it has a clearly visible scale);

- high accuracy.

Diaphragm tank

This is a container made of metal with a rubber membrane inside, which can differ in different capacities, as well as the presence of a replaceable or non-replaceable rubber partition. The purpose of the membrane block is to accumulate water, supply it at a set time and under appropriate pressure to reduce the load and reduce possible risks. It is recommended to install this device before carrying out work on branching the water supply system. Exposing the tank to additional loads is not allowed. Before installing the tank in the room, the system must be recharged and water drained.

Pressure switch

Designed to maintain optimal pressure in the system, automate the filling of the hydraulic tank and operate the system in autonomous mode.

Caisson

This is the main part of the system in the form of a tank, which can have different sizes. With its help, equipment is protected from freezing and groundwater from entering the well. Thanks to this, the system will function properly regardless of the season. It is possible to install various equipment into the system (filters, pressure switches, automatic devices, adapters). Installation of an adapter is recommended for laying a system designed to provide water supply.

Hydraulic accumulator

It is necessary to maintain stable water pressure in the well and provide protection against water hammer. When choosing a hydraulic accumulator, you need to take into account its volume (for a private house, a hydraulic accumulator with a volume of 45 liters is suitable). The principle of operation of the hydraulic accumulator is to fill its tank with water, after which the pump is used up and the pump is automatically turned on and the tank is filled with water.

Heading

Its installation is carried out at the mouth of the casing to prevent the penetration of rainwater and other pollutants, as well as to provide protection for the submersible pump, which is mounted inside the well. Steel, cast iron and plastic can be used as materials for making heads.

Drilling with flushing

When using both small-sized devices and larger mechanisms, to increase the speed of rock passage, it is recommended to use drilling with flushing. This digging method allows you to increase the immersion speed to 10 m/hour, while the conventional dry method rarely allows you to reach a speed of more than 2 m/hour. There are two types of drilling with circulation, which are simply called direct and reverse methods.

Manual

There are also autonomous drilling devices created on the basis of a walk-behind tractor. They most often have a mechanical drive; it receives torque from the motor drill engine.

The small size of such devices allows you to work with them alone, and the use of a reduction gear allows you to drill wells of even large diameters. Their depth of penetration is much less than that of MGBU and self-propelled mechanisms, and the small size of such a manual drill allows you to make wells near the walls of buildings or fences.

If the aquifer on your site is at a depth of no more than 20–25 meters, then such a device would be an ideal solution for making an Abyssinian, and perhaps even an artesian well yourself. The drilling speed depends on the characteristics of the installed motor and is 3–5 m/hour. Due to their small size and low power, such installations are used on soft, peaty and clay soils.

Derrick

As a rule, these are mast and tower type towers. This tower is necessary for all the most basic actions - lowering and raising the drill string on the surface, holding it suspended during the entire process, placing all the necessary equipment in the well.

Such towers differ from each other in several ways. Firstly, in height. If the well depth does not exceed 1.3 thousand meters, then in this case specialists, as a rule, use drilling rigs whose height is no more than 28 meters. If the required well depth is from 1.3 thousand to 3.5 thousand meters, then a tower with a height of about 42 meters should be used. If a well is created whose depth exceeds 3.5 meters, then the height of the drilling rig can be more than 53 meters.

Homemade

Drilling units are not only of the factory type. They can also be hand-made structures. Although it is worth immediately noting that the independent production of such a device can be justified only if it is used repeatedly or if you have most of the components, tools, welding equipment and a garage available.

If you want to build a drilling rig yourself, then you should pay attention to the simplest auger drill, as you can make it yourself in a few days. It is installed on a base to which guides are welded; an electric motor with a gearbox will rise and fall along them, and a drill will be attached to it using a swivel.

The procedure is as follows:

- You should start by purchasing materials to make bases, rods, and swivels. You also need to purchase a winch, an electric motor (2–2.5 kW) and a gearbox.

- Then the base should be made based on the engine power and gear ratio.

- Next you need to make a swivel and rods. These parts of the device must be purchased; you can order them from a mechanic, he will machine these parts with the required accuracy.

- Then you need to assemble the entire structure and prepare a place for mounting the electric motor.

- Only after this the engine and gearbox are mounted on the frame.

- Next, you need to secure the winch and connect its cable to the engine frame.

Advantages of homemade drilling rigs

Collapsible MGDUs are designed and produced for self-construction of water intakes on land plots of limited size, where access for self-propelled units is difficult.

The machines have a simple design, which allows craftsmen to independently manufacture mechanisms according to drawings.

Homemade structures are successfully used in well development.

The advantages of the equipment include:

- small dimensions and weight of units;

- modular design - installation and dismantling of the machine does not cause difficulties;

- versatility of use of the drive: manual rotation of the drill pipe, connection of the engine to a 220, 380 V electrical network, autonomous power supply from a gasoline or diesel engine;

- reliable design and affordable cost.

Small machines are used for the construction of water intakes, for the construction of foundations, and for assessing the condition of underlying rocks. All work on installation of the machine and its operation is carried out by 2 drillers.

Features of the screw device

They are deservedly popular due to their high drilling speed, excellent functionality, ease of repair and maintenance and low cost of drilling operations. ShBUs are used in construction and utility organizations involved in the installation of communications and power lines. The disadvantages include the rather loud noise that is made during operation.

This unit is in most cases used as a machine for drilling wells in soft rocks, with a depth of no more than 120–150 meters. The waste soil is removed through the hole using a dry auger, although direct washing with water is also possible.

ShBU is irreplaceable:

- When constructing wells for water intake.

- When preparing holes for pile and grillage foundations.

- For communications in areas with high population density.

With the help of such units, not only vertical drilling is carried out, but also inclined, and the angle can be set arbitrarily.

INTERESTING! The auger passage of rock is characterized by increased well cleanliness, which is ensured by dry drilling. The absence of a flushing solution during operation allows the source to be put into operation much earlier. There is no need to wait for the water intake horizon to be cleared of the flushing solution, which is inevitable when drilling with flushing.

Why do you need a head when drilling a well?

The sealed head is installed on the casing pipe. It is made of two steel or cast iron disks, between which a seal is located. On the surface of the disks there are holes for the cable and water-lifting pipe, and brackets for fastening the cable.

Head functions:

- protecting the well from debris, insects, rodents;

- protecting the source from rising groundwater;

- creating additional vacuum due to a sealed circuit and increasing flow rate;

- reducing the likelihood of well freezing;

- protection against theft.

Sealed plastic heads are available. These structures can withstand weights of up to 800 kg and are designed to complete wells with a pump loading depth of up to 100 meters.

Rotor system

These are underwater drilling rigs that drill rock using the method of continuous rotation of the working element - the rotor, on which the cutting bits are attached.

They are widely used due to their relatively small size and ability to work at great depths. In addition, the use of a rotor allows you to easily pass through hard rocks and even permafrost. Such a device will easily pass through limestone, marl, and permafrost soil.

Spent rock can be brought to the surface using one of the following methods:

- Using return water, it is pumped into the shaft under high pressure during the drilling process.

- Using a clay solution, fed through rods using the direct washing method.

- The conventional screw method is also often used.

IMPORTANT! The long-term performance of the drill is ensured by its constant cooling, which is achieved through the pumped aqueous solution.

Rotary drilling

Performed in soils of any degree of complexity. As in the previous version, the drill string rotates during the drilling process, but the rods have smooth walls. Removal of cuttings is carried out by blowing with compressed air or pumping drilling fluid into the well, which brings fine rock to the surface. Destruction of soil at the bottom is carried out with removable crowns and various types of bits, including roller bits - with rotating rollers. Drilling tools are reinforced with hard alloys, technical and synthetic diamonds.

The drill string rotator is driven by an electric motor or the engine of the base vehicle of the installation. A mandatory accessory of the structure is a tower or mast for raising and lowering casing and drill strings. The length of the candle, an assembly of metal pipes, depends on the height of the tackle suspension.

The prevalence of the rotary method is due to its qualities:

- the ability to drill wells with a diameter of 80-1500 mm in rocks of any hardness to a depth of up to a kilometer or more;

- high productivity in difficult mining and geological conditions;

- small dimensions of a self-propelled unit, ensuring drilling near a country house.

The versatility of the method makes it expensive. When drilling deep wells, this disadvantage is eliminated.

How to choose drilling equipment

If you are thinking about the need to purchase a drilling unit, you should determine in advance the main parameters and requirements that you will place on it.

What parameters should you pay attention to:

- Drilling depth. In most cases, they give preference to small-sized equipment and do not overpay for increased power, which is needed only by geologists.

- Load capacity of the lifting mechanism. Based on this characteristic, three main types of drilling rigs can be distinguished: for creating hydrogeological wells, geological exploration of gas and oil, and in-depth exploration drilling.

- Ease of transportation can also play an important role in the choice. Consider whether you need an expensive self-propelled drilling rig or whether a small unit that fits in a regular trailer or truck bed will suffice.

Rent equipment

If purchasing such a unit is not practical for you due to the one-time nature of the work, then you should think about the possibility of renting or leasing a drilling device. Renting allows you to complete the task in the shortest possible time and at the same time save a significant amount. The fact is that the rental price also includes wages for the operator and his assistant, and thus you do not have to send your employees to work unusual for their profile.

The rental price of drilling equipment depends on many factors, including: the volume of work, duration of operation, location, number of workers servicing the system. On average, the cost of one shift starts from 2000–2500 thousand rubles.

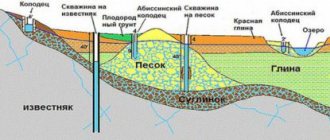

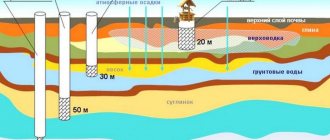

Methods and selection of drilling equipment

A complete, autonomous water supply to a residential building is ensured by the presence of a well on the site. It is possible to do quite complex work with your own hands, but it is not advisable. Drilling technology depends on the characteristics of the geological soil and its occurrence, so it is better to turn to the services of a specialized company that is able to complete the work in a short time and deliver a turnkey well to the customer. So:

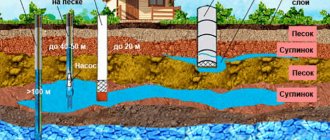

- Powerful equipment for drilling wells under water allows you to get a well anywhere. An artesian well is sometimes drilled up to 200 m, it allows one or several country houses to be provided with water, the service life can last up to 50 years, so owners of cottage estates usually rely on such a structure.

- A nearby aquifer requires drilling an Abyssinian or tube well for water up to 12 m. Dust, dirt, falling leaves and even high water do not get into it.

- A well for sand from 15 to 30 m, if constantly in operation, can last 15 years until it silts up, then it is washed out or a new shaft is drilled nearby.

- Equipment for drilling water wells is selected depending on the drilling method.

Auger drilling method

The final price depends on the method of rock destruction and the methods of delivering destroyed rocks from the shaft to the surface. Even an amateur understands that each option for obtaining a well involves the use of different equipment, which affects the quality. A full assessment of the indicator of any drilling method and the type of installation used will be the cost of 1 m³ of extracted water. The design life of the well and the water extracted from it are also taken into account. So:

- Auger equipment for drilling water wells is one of the simplest and cheapest options. Small-sized installations for the most part use this drilling method. The equipment is built on a classic Archimedean screw called an auger. The process is reminiscent of anglers drilling a hole for ice fishing. This method is suitable for wells with a depth of no more than 10 m; this technology does not require water or drilling fluid to flush the bore.

Attention: The auger method is applicable in dry and relatively soft soils.

- Drilling quicksand or hard rocks, which include rock deposits, cannot be overcome using the auger drilling method (see Auger drilling of wells: what are the features).

- This technology places special demands on the performers; they must not only get through to the water, but also be able to protect the water carrier from wastewater and perched water coming from the surface.

Impact-rope drilling method

Assembly is carried out on site

This drilling method was used until the 40s of the last century. It refers to the old method, labor-intensive to implement, with low penetration productivity.

However, this method allows you to obtain a well with a very high service life, almost up to half a century:

- The installation package for performing cable-percussion drilling (see Do-it-yourself cable-percussion well: how to set it up correctly) includes simple components that are assembled on site.

- Equipment for drilling water wells in this way includes a driving glass, which is made from a fragment of a pipe.

- The lower part of the driving glass is formed with a strong cutting edge with a bevel inside the glass, which allows you to cut deeper and deeper into the ground with each blow. It is driven by a winch.

- The soil is captured by the drill glass and each time a certain part of it is delivered to the surface.

- The impact rod is used to cyclically strike the top of the glass with an anvil, which allows the structure to bite deeper and penetrate into the ground, filling the glass completely before lifting.

- What keeps the soil inside? A physical law called friction force allows an operation to be performed until the desired result is obtained.

- This entire structure is placed directly on the installation frame; you need to stock up on a rope or cable, a winch and a block.

- Drilling a well using the percussion-rope method has been replaced by the rotary drilling method with direct circulation, but this does not mean at all that the previous method has been sent to the landfill and is not used.

Attention: An important condition for percussion-rope drilling is strict adherence to the verticality of the trunk, otherwise it will be difficult to install casing pipes into a curved well.

- To avoid such punctures, the instructions prescribe the use of a long-sized driving glass. The optimal length of the drill pipe, proven by practice and calculations, is about 2 meters.

- With this drilling technology, it is necessary to pay due attention to the quality of the cable. Its tensile properties must be large enough so as not to break under unusual loads.

- There is a possibility that equipment for drilling wells under water may become jammed in the well when solid particles get between the wall of the well and the casing pipe or plug. Here preference is given to a cable with at least 10 mm in diameter.

- Cable-percussion drilling is still attractive because all the necessary components can be prepared by the owner at home.