What does a water well consist of?

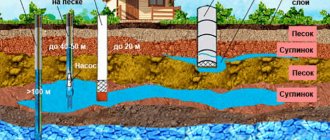

If you look at the well in cross-section, you can see that it is a long and narrow hole, going into the bowels of the earth to the aquifers. It differs from a well in its very small diameter compared to the length (depth) of the channel. The construction of a well depends on its purpose, it can be geological exploration with the study of soil structure, search for natural resource deposits, gas, oil, water production.

We are primarily interested in the design of a water well - what elements it consists of, how and with the help of what equipment water from it is supplied to consumers.

The main components of a water well are the trunk, bottom and mouth.

- A shaft is a vertical opening in the ground into which casing pipes are lowered.

- The face is the bottom of the canal, its lowest part.

- Wellhead is the upper part of the well pipe protruding above the soil surface.

The gap between the outer surface of the casing and the earthen walls of the drilled channel is filled with cement mortar, which makes the structure more durable and seals the well.

It is especially important to seal the upper section of the well, which is in contact with the most contaminated layers of soil. Source strojdvor.ru

The well design is also a casing consisting of several pipes, isolating the water channel from the earthen walls of the shaft and preventing their destruction. Tightness at pipe joints is ensured by their threaded connection.

In the lower water intake part of the well there is a filter that prevents sand, silt and other insoluble particles that pollute the water from entering the channel. And at the top there is a head or an adapter, depending on which pump is used to supply water from the well to the water supply system.

Schematic illustration of a well Source stroybur33.rf

Casing pipes

Casing pipes that seal the trunk of an underground source are made of different materials. Previously, asbestos and metal products were used, mainly from stainless, galvanized or ordinary steel, less often from enameled steel.

Nowadays casing made of HDPE (low-density polyethylene) and PVC (polyvinyl chloride) pipes is more popular. These materials are light in weight and have good strength, unlike asbestos, and are not subject to corrosion and destruction, unlike steel. In addition, they are the most affordable. Therefore, the water well is inexpensive, durable, repairable and does not pollute the water with rust.

Polyvinyl chloride casing pipes Source moyaskvazhina.ru

It is important! Plastic pipes do not withstand dynamic loads well and may not withstand soil pressure at great depths. Therefore, they are used to construct casing strings for relatively shallow domestic wells.

The standard and simplest way to connect pipes into one column is threading, but joining using welding and coupling joints is possible. The pipes themselves have a length of 3 to 6 meters, and their diameter is adapted to the dimensions of borehole submersible pumps, which are the main criterion for choosing the pipe cross-section. Standard cross-section dimensions, which may vary slightly from one manufacturer to another:

- 89 mm;

- 108 mm;

- 114 mm;

- 127 mm;

- 133 mm.

Table with sizes of ECO pumps Source oboiman.ru

See also: Catalog of companies that specialize in water supply, sewerage and related work

Filters

The design of a water well necessarily includes a filter device in the bottom, the task of which is to purify the water from solid impurities before entering the casing. There are several types of such filters.

- Gravel.

This is simply a gravel cushion poured into the bottom of the well, which retains the main contaminants from the bottom. A gravel filter alone is not enough for high-quality water purification; it is used only as an additional barrier.

- Perforated.

If the water intake is made from limestone or pebble rocks that do not contain small impurities, a coarse filter, which is a pipe with round holes drilled in the walls, is sufficient. They trap large particles and debris that could damage the pump.

The perforated part of the casing pipe is a filter Source vodatyt.ru

- Slotted.

Such a filter is usually installed on plastic pipes, making long and thin slits in their walls. Water seeps through them easily, but sand remains outside.

- Reticulate.

When the wellbore is immersed in sandy layers of soil, the operation of the pump causes the movement of sand grains. To prevent them from entering the channel, you need a filter with small holes. It is made of mesh that is resistant to corrosion and abrasion. The material for it can be stainless steel, plastic, fiberglass, nylon. The mesh is mounted on a frame - a perforated pipe of the same diameter and made of the same material as the casing.

Note! Mesh filters seriously restrict the flow of water into the well column, reducing it by 30-40%.

Mesh filter for plastic casing pipes Source 2gis.com

Concept of design and main elements of a well

A well structure is a set of soil excavation elements with a diameter significantly smaller than their length, which ensures durable and reliable creation of a channel between the earth’s surface and the exposed deep reservoir fluid. The main purpose of the borehole channel is geological exploration and assessment of underground resources, study of the structure of the section, maintaining the pressure of the working formation, monitoring the operation of deposits, and extraction of natural resources.

Wells are divided into the following components:

- A wellbore is a soil excavation in which casing and filter pipes are located.

- Wellhead is the beginning of a wellbore from a section of pipe fixed to the surface of the earth.

- Bottom - the lower part of the borehole channel, the bottom.

- The cementing ring is a cement-sand mixture pumped into the space between the walls of the barrel and the casing, which serves as a seal and hardening of the borehole channel.

Rice. 2 Schematic well design

- The filter is the lower section of the well casing pipes, immersed in the formation with the extracted resource. As a filter, a part of the trunk without casing is used, at the bottom of which fine-grained gravel or a special filter device is placed.

- Casing - casing pipes connected together and immersed in the trunk, are needed to isolate the borehole channel from the earthen rock of the trunk. Ensures efficient and reliable operation of the well by preventing soil from entering the channel and protecting it from external pressure.

In the oil and gas industry, intermediate casing strings are used to separate incompatible geological zones that require different drilling modes. The following intermediate well strings are used in the drilling industry:

- Solid. Completely cover the entire trunk, regardless of the location of the main interval.

- Shanks. Columns designed to support only the open interval of the well with partial overlap of the main one.

- Flyers. Special intermediate casing strings that serve only to close defective gaps in the main string without taking into account subsequent casing strings.

Rice. 3 well design - schematic section

Related article:

How to find water on a site for a well - folk and scientific methods . It may be interesting to read an extended article about the options for drilling a well or digging a well on your own and with the involvement of water specialists.

Video description

This video shows how you can make a well filter with your own hands:

The length of the filter part depends on the characteristics of the aquifer. The more small impurities it contains, the longer it is. On average it is 2 meters.

Heading

How the water well is constructed in its upper part depends on which pump is used to draw water, submersible or surface.

The submersible equipment is located directly in the casing at a certain distance from the bottom. To fix it in a given position and prevent water contamination through the mouth, steel, cast iron or plastic ends are used, installed on the upper section of the pipe.

This is a standard design suitable for standard casing sections. It consists of two flanges with a rubber gasket between them, outlets for the pressure pipeline and electrical cable, and a carabiner for attaching the pump to a cable. First, the lower flange is put on the pipe, then the upper flange with the suspended pump is bolted to it through the o-ring.

Steel borehole head Source santechbomba.ru

The “load capacity” of the head depends on the material of manufacture:

- steel can withstand the weight of equipment up to 500 kg;

- plastic – up to 250 kg.

Adapter

If the construction of a water well involves pumping water with a surface pump, then it takes it through a hose or pipeline that enters the casing through its wall. This entrance is made through an adapter - a structure, one part of which is installed inside the well and connected to the pressure pipeline, and the second is screwed onto it from the outside through a hole in the wall and connected to the water main. The tightness of the connection is ensured by rubber gaskets.

Outer part of the adapter Source septik-kirov.ru

How is an artesian well constructed?

This type of well is drilled in loose limestone rocks where there are no continuous layers of water. The depth varies from 30 to 300 meters. Drilling will take a long time.

An artesian well consists of several elements:

- head;

- steel pipe;

- concrete pouring;

- interpipe sealant;

- PVC pipe;

- submersible pump;

- perforated column.

Artesian wells are the most reliable and durable. They have been in operation for more than 50 years. Since there are no small particles in the rocks that can clog the vent, flooding of the well is excluded. The water layer is located throughout the limestone layer, so the water supply does not stop, which can happen with sandy soils. Several houses can be connected to an artesian well, since water is supplied in significant volumes. For domestic needs, the optimal indicator is 5 m3/h, for industrial facilities - 50 m3/h.

Manufacturing and arrangement

A well can supply water to one house or an entire village; its capacity, depth and other parameters determined during design depend on the number of consumers.

The drilling method is selected taking into account the soil characteristics of the site and the length of the future channel. They manage to drill only shallow wells into sand on their own; in other cases, they resort to the services of specialists who professionally determine the optimal principle for drilling wells for water and carry it out with the installation of casing pipes.

The pipes are lowered into the resulting trunk one by one: first the filter, then the first pipe is screwed onto it, when its level drops to the ground - the next one, etc.

To maintain the cleanliness of the well, normal operation of the pumping equipment and your own convenience, the wellhead is equipped with a head or adapter.

When using a submersible or surface pump located directly near the wellhead, a caisson is installed around it - a pit with an insulated lid and sealed walls and bottom.

Arrangement of a caisson around the wellhead Source oboiman.ru

The figure shows what a water well looks like in cross-section, equipped with a submersible pump. There is enough space in the caisson to install a surface centrifugal pump, which is connected to the source via an adapter, and then pumps water into the house through a pipe laid in the ground. The hydraulic accumulator and automatic control are also located here. This scheme is used for houses with permanent residence and allows you to protect the well itself and the water main from freezing.

You can make a caisson with your own hands from concrete rings or monolithic reinforced concrete, or you can buy a ready-made metal or plastic container.

Downhole pumping units and automation

To extract water from wells, surface and submersible electric pumps of a centrifugal operating principle are mainly used. The advantage of this design is the ability to create high pressure in the line, thanks to the use of units with a large number of impellers, which allows increasing the pressure in each subsequent stage.

Household submersible electric pumps can lift water from very great depths (about 200 meters), while surface types are used in sources with a water surface at a depth of up to 9 meters from the surface of the earth. To increase the intake depth of surface models, built-in or submersible ejectors are sometimes used, although their efficiency decreases significantly.

Rice. 11 Centrifugal electric pump

Hydraulic accumulator, relay and pressure gauge

To automate the operation of water intake pumping equipment, an automation system for a well or a pumping station is used, consisting of the following devices:

- Hydraulic accumulator. It is a voluminous metal tank with a rubber bulb inside, which fills with water when the electric pump is turned on. The device allows you to avoid water hammer in the system and optimizes the operation of the electric pump, reducing the number of its on and off cycles.

- Relay. The main element of the automatic control system is a pressure switch, which is connected to the line using a fitting. When pressure appears in the system above its settings, the built-in membrane inside the relay housing through a mechanical system interrupts the supply voltage to the electric pump and it turns off. After consuming water, when the pressure in the system drops, the relay closes the contacts and turns on the electric pump.

- Pressure gauge. The device is one of the main elements in any plumbing system; it allows you to control pressure and configure equipment.

Rice. 12 Automation in the electric pump control system

The design of water wells is not very complicated; the main internal elements that are installed during drilling are casing pipes and a filter in the bottomhole area. To collect water after installing a well, additional equipment and engineering systems (caisson, head, adapter) are used, which make it possible to effectively connect the electric pump to the source, taking into account its location and type.

Advantages of the Abyssinian well

Among the advantages of the Abyssinian well are:

- Relatively cheap: you can make a well yourself, and everything necessary for its construction can be purchased at the nearest construction market;

- High production speed: on average, it takes several hours to install it;

- Simplicity: it can be installed in a limited space (the subfloor of a house, basement or garage is suitable), as well as anywhere on the site;

- Ease of arrangement: no special heavy drilling equipment or access roads for vehicles are required;

- Long Lifespan: A properly constructed Abyssinian plant can provide clean water for many years.

Abyssinian well: necessary conditions

Before you get to work constructing a “needle”, you need to understand whether it is suitable for your area. Therefore, first of all, we find out the depth of the aquifer (even in different areas in the vicinity of Moscow, the depth of the aquifer can vary up to 250 meters) and the type of soil.

When choosing a source of water supply, you should focus on existing water intake wells of a similar design located in close proximity to your site. And in their absence - for exploratory drilling and other reliable geophysical survey methods.

To search for water, different methods are used: from dowsing to geodetic maps, which display soils and aquifers.

Equipment for well construction

To get the well working, you need to use the following elements:

- Pump with safety rope and electrical cable for subsequent connection.

- An automatic device that will regulate voltage and protect the engine from overheating.

- Hydropneumotank. Its task is to protect against water hammer, regulate pressure, and reduce the frequency of turning the pump on and off. Tank sizes vary from 10 to 10,000 liters. The optimal volume for an average home is 100 liters.

- Caisson. The steel tank serves to protect the equipment needed to lift the water. Installed at a depth of 0.5-1 m.

Attention! The structure must be insulated and waterproofed.

- Wire (which ensures uninterrupted supply) and water pipes (lead from the caisson to the house).