Water treatment for a private home

Underground springs are not 100% pure. Moisture accumulates inside rock cracks. Groundwater contains degraded minerals and hundreds of microorganisms.

Underground reserves account for about 98% of the available fresh water on Earth.

Depending on the area, the cleanliness of the well is affected by:

- Natural substances. For example, arsenic, copper, calcium and radon.

- Pesticides, herbicides and other fertilizers.

- Industrial pollution with volatile organic compounds.

- Heavy metals from mining operations or improperly treated waste.

- Faulty sewer systems or septic tanks.

Sanpin prescribes making wells at a distance from the source of pollution:

- Septic tanks 15 meters.

- Livestock yards, silage pits and leach fields 15 meters.

- Oil storage facilities, pesticide and fertilizer warehouses 30 meters.

- Dumps with manure 75 meters.

Water purification from a well for a private home occurs in two stages. First, the liquid is cleaned of large particles - sand and clay. At the second stage, they are freed from salts, bacteria and iron. If the water smells bad and turns yellow in the air, then the filters for ferrous water from the well are not working.

Types of coarse filters for wells

Despite the different designs, each design includes three main elements:

- Filter.

- Above-filter area.

- Sump.

The main task of any filter system is to prevent the penetration of rock impurities into the well pipe and at the same time not to interfere with water intake. In addition, these structures provide additional protection that protects the trunk from collapse. The four most common versions are:

- Hole (perforated) cleaning system.

- Slot design.

- Wire construction.

- Gravel filter.

Let us consider in detail each of the listed types.

Perforated cleaning system

Due to the simplicity of the design, such a system has become widespread. The main structural element is an ordinary perforated pipe, usually made of HDPE. In industrial samples, stainless steel (stainless steel) can be used as a material. The main advantage is high efficiency at low cost. The main elements of this design are presented below.

An example of the simplest design of a perforated filter for a well

This solution can be used for both an Abyssinian well and an artesian well, especially if the latter does not erupt like a geyser, that is, it has low pressure and/or an unstable layer of aquiferous limestone.

How to make a homemade perforated filter?

First of all, you need to acquire a pipe of the appropriate diameter. Oil and geological exploration assortments are ideal for this purpose. As a last resort, you can use a plastic product, provided that it is made of a material that is safe for the human body.

We will also need a drill with a drill bit of the appropriate diameter. It must be selected depending on the granulometric properties of the rock at the drilling site. Having prepared everything you need, you can begin the process of making a homemade rough water purification system. The algorithm of actions is as follows:

- We measure the length for the sump. To do this, lay the pipe horizontally and apply the appropriate markings. Let us pay attention to the following points. The area in which the holes will be drilled must be at least a quarter of the length of the pipe. The perforated area should be located in such a way that when installing the filter, it falls on the place of water intake (water layer).

- We begin to drill holes, their bottom row should be located at a distance of at least a meter from the edge. The location of the holes does not play a big role, but it will be correct if you place them in a checkerboard pattern. This way it is better to control the distance between them. It should be within 10.0-20.0 mm.

The process of perforating a casing for a well

- The holes can be made straight, but ideally the drill should be directed in such a way that an angle of 40°-60° is formed, as shown in the figure

Desired hole angle

- Having completed the perforation process, it is necessary to clean the pipe; the easiest way to do this is to install it vertically. After this, we clean the holes and the burrs formed on them.

- At the final stage, install a plug on the lower edge of the pipe. After this, the filter is ready for use.

Please note that you can slightly increase the efficiency of the design by covering the perforation area with mesh or organza.

Slot design

The main difference from the previous design is that water is taken not through holes, but through specially cut slots. This has a positive effect on throughput. But this type also has a significant drawback, which is expressed in the loss of structural strength. To somewhat reduce this factor, several solid sections are left in the perforated zone; they act as stiffening belts.

Slot filter for well

Making this type of structure is somewhat more difficult than a perforated system. It is almost impossible to manually cut uniform slits; this will require special equipment, ideally a milling machine.

There is no point in presenting the manufacturing algorithm, since it does not differ much from the previous version. As for the sizes of the cracks, they depend on the rock. Their width, as a rule, is from 3.0 to 6.0 mm, length – 25.0-80.0 mm. The arrangement can be waist or checkerboard. After the slots are cut, they need to be cleaned. Next, do not forget to remove debris from the pipe, as described above.

Since this type of filter system is mainly used for sand wells, the installation of an additional external filter is required. A mesh with galloon or square weave is excellent for this purpose. The width of the cells can be from 0.1 to 1.0 mm, it is selected depending on the structure of the sand.

Wire structures

This design consists of a frame on which a special wire of a special profile is wound. The effectiveness of this solution is significantly higher than that of the two previous options. In addition, the wire system is highly reliable and has a long service life. The negative side is the high cost.

Wire (mesh) filters for sand wells

It is almost impossible to independently make such a structure for a well in a country house or cottage, even if you have the necessary materials. The process will require special equipment and a lot of free time.

Gravel filter

In fact, this is not a separate version of the treatment system, but a modernization of the slot design. The principle of such a structure is shown in the figure below.

Gravel filter structure

This cleaning method has proven itself well on rocks with fine sand and large inclusions of clay. The construction technology is simple: wells with a large diameter are drilled, then covered with gravel (from 50-60 mm or more). It is important that its fractions are approximately the same size. Ideally, the gravel should be calibrated. The sizes of its particles should be an order of magnitude smaller than the rock fractions.

What to do if filter clogging occurs?

If the coarse filter is clogged, then further operation of the well is impossible. It is not possible to replace the filter system or clean it (rinse it). Consequently, drilling operations will have to be carried out again. The main sign of colmatation is a decrease in well production.

Filtration of water from a well

A well water purification filter removes impurities and bacteria that are hazardous to health. A well water filtration system uses a chemical, biological process, or physical barrier to control bacteria.

Main filters

There are a dozen techniques for purifying well water for drinking. But you need to decide: do you want to filter only in the kitchen, or when you turn on any tap in the house (bathroom tap, shower)?

This is important to think through because the type of filter will determine the decision. If you only need filtration in the kitchen, then choose a well water purification scheme based on the point of extraction (POU).

Main filters are installed into the water pipes of the house.

But if you want clean water throughout the whole house, then you need to filter water from a well in a private home through a point of entry (POE).

POU filters

As we have already found out, the POU well water purification filter is cleaned through the kitchen faucet. Most units are installed under the sink, but there are also tabletop options.

A tabletop filter system for purifying water from a well does not require the installation of an additional tap. For the bottom drain, a separate tap is placed next to the kitchen faucet.

Pros of POU:

- Removes chlorine, volatile organic compounds, bacteria and heavy metals.

- Reduces scale.

- Complex water purification from a well from 3 to 7 cartridges.

Cons of POU

- Purification of water from a well in a country house and cottage for drinking only.

- Works regardless of pipe pressure.

Prices for main filters for purifying water from a well:

POE filters

Water treatment from a well using the POE system consists of filtering the entire volume of liquid for the household.

POE is cut into a cold water pipe before being distributed throughout the house. This ensures that you get clean water from every tap in the house.

POE well water purification filters can:

- Remove all types of health related pollutants.

- Purify water from a well using multi-stage systems that combine different cartridges.

- Reduce scale.

- Get clean water from every tap.

POEs cannot:

- Fits in small spaces.

- They do not work without pressure in pipes (except ultraviolet ones).

POE is considered more economical and convenient compared to 2 - 3 POUs installed throughout the house.

Well pumping, why is it necessary?

The process of pumping a well, during which it is cleaned, must be performed immediately after drilling.

This is due to the fact that:

- Almost always, the first water coming out of the pipe is cloudy, unsuitable for drinking and requires purification.

- If no measures are taken, it will remain dirty, and over time it will completely silt up and stop working.

- The siltation process never stops due to the fact that not only sand and pebbles are contained in the aquifer, but also a large number of tiny particles that the filter cannot catch.

- They easily pass through the gravel and mesh filters, and then settle at the bottom of the device. As its depth decreases, productivity decreases greatly.

Start of well pumping

- Cleaning the well from clay is carried out immediately after drilling. At first the water flows cloudy, but gradually it brightens, is washed and reaches crystal purity.

- The time period for pumping the device may vary. If it is shallow, it may take 12 hours. In sandy soil, the operation can take several weeks, and in deep ones, it sometimes takes months to clear, which is especially true for limestone or clay soil.

- It is very difficult to pump out a well on clay. When drilling and pressure cleaning such a structure, a clay solution is formed. It seeps deep into aquifers, and it is very difficult to wash it out and will take a lot of time. In this case, you will simply need to pump out more than 500 cubic meters of water, which increases the duration of the process. The more water is pumped out, the more clay, sand and other small particles are removed. Coarse sand that did not pass through the filter settles at the bottom and creates an additional filter layer, as can be seen in the photo.

Tip: It is necessary to rock the well until the unit supplies clean water from it.

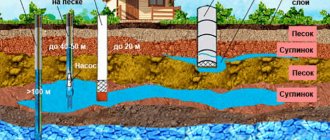

Construction of wells of different depths

Why does water with clay come from an old well?

From an old well that was working properly, water with clay can come out for two reasons:

- The casing string depressurized and clay began to flow into the well from the waterproof layer.

- After the filter broke through, all the turbidity that had previously been retained by it began to go inside.

In both cases it is necessary to carry out major repairs:

- Pull the drill string out of the ground and fix the leak.

- The filter can be repaired.

How to purify well water from sand and clay

Water purification from clay and sand is used in most hydraulic structures. In each type of underground sources, different coarse treatment systems are installed.

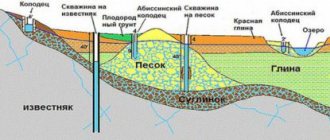

Sandy and Abyssinian well

Such sources are drilled in soft soils, and aquifers lie in sandy soils. Therefore, sources are equipped with a filter.

A perforated sand filter for well water is a weak element. If it gets clogged, we drill it again. Cannot be replaced.

The well filter consists of a base - a perforated pipe. A frame in which a plastic or metal mesh is placed, as well as a settling tank for collecting sludge.

The system can clear sand from well water, but does not solve the problem of bacteria and chemical compounds.

A well filter provides process water, but drinking water requires fine purification.

Artesian well

If the source was drilled into hard rock to a depth of more than 80 meters, then there is no need to install a sand filter at the end of the casing. It remains open. Moisture is purified by seeping through rocks.

Artesian water is clean, fine filtration is sufficient. At great depths there is iron and hydrogen sulfide, which are removed at the softening stage.

How to clean water from clay from a well

They claim that you can do away with the clay water filter. But the cleaning system increases the service life of the well, preventing siltation. If you do not install it, you will have to go down to the bottom and clean the well of clay with a shovel, and this is a labor-intensive procedure.

Bottom filters for purifying water from sand are a simple way to protect against suspended matter. However, it is not necessary to install a cleaning system in all wells.

If there is a spring inside the well, then the bottom filter will disrupt the flow of liquid and reduce the flow rate.

Sandy soil, loose clay or quicksand require cleaning. Clay filter material: expanded clay, sand or anthracite.

To further clean the water from the well from clay, a finely woven metal mesh is placed at the bottom.

How to make a mesh, gravel, wire filter with your own hands. Recommendations

To make a mesh cleaning device, you need to determine the size of the cells. To do this, you need to sift the soil from the well through the mesh options you like. A sample that retains at least 50% of particles is suitable. You can also measure the amount of mechanical impurities by pouring a handful of sand or clay onto graph paper. After this, it will become clear what the size of the cells should be.

Before installing the mesh on the pipe, you need to make a frame by winding steel wire in a spiral at intervals of 2-3 cm. The structure is fastened with a soldering iron. A mesh is wound on top in one layer. It is fixed by welding or a special compound if plastic or fabric material is used.

Strainer Materials

If you want to make a gravel system, first choose the right gravel size. For the most part, it should be several times greater than the amount of mechanical debris from the well. During the construction of the structure, a bag with a load is lowered into the bottom expansion. After this, gravel or river pebbles are poured, compacting the material tightly.

It is more difficult to make a wire type device for water purification with your own hands. In this case, it is easier to buy a filter of the required diameter and attach it to the holey section of the prepared pipe. During the installation of any well cleaning system, it is important to correctly determine the filter capacity. If you are not confident in your abilities, it is better to trust experienced professionals.

Purifying water from a well from iron

Rust speaks of iron. And this is not the hardware that is useful. You should not drink such liquid.

Various iron impurities are dissolved in underground springs:

- The basic element of iron is Fe0. It rusts when exposed to air. Makes the water cloudy with a brownish-red tint.

- Soluble iron Fe2 is divalent. Only a filter from divalent iron retains an element invisible to the eye. You can determine divalent iron in a liquid by taste, or see it after settling, when the color changes from transparent to pink.

- Insoluble iron Fe3 is trivalent. Fe3 looks repulsive: a red-colored suspension. If you let it sit, sediment will fall to the bottom of the dish.

- Iron bacteria are a nasty part of the conversion of Fe2 to Fe3. It looks like a film floating on the surface and remaining on the surface of the dish. Contains a set of bacteria.

Reasons for iron in the well:

- A spring on volcanic rock will produce ferruginous water.

- The wetlands give off an iron taste.

- Industrial enterprises are a source of pollution even for artesian springs.

- Increased soil acidity - pH balance. Violation of acidity is visible after rain - puddles turn red. After the snow melts, the ground is covered with a gray-green coating.

Pure water by Russian standards contains a maximum of 0.3 milligrams of iron and impurities per liter.

How to determine iron:

- The taste is ferruginous water with a characteristic metallic tint that even coffee cannot drown out.

- Rusty stains on plumbing fixtures. Worn out metal pipes inside your home's water supply will also have the same effect.

- Laboratory test results are an accurate indicator. The price will be 3,000 - 4,000 rubles.

- Let the water sit for a day. The crude liquid settles in an open glass container. Observe the color change and the appearance of sediment.

- Impurity tester. Sold in pet stores for monitoring aquariums.

- A weak solution of potassium permanganate mixed with test water in a ratio of 2 to 1 will show purity. A yellowish tint is a sign of impurity content.

Water purification from iron using chemicals

Iron removal with chemical reagents is used in central city water canals. Reagents are poured into dirty water. Then they are oxidized in settling tanks, the sediment is separated and supplied through pipes to multi-story buildings.

To remove iron from water, reagents make dissolved impurities solid. The sediment formed from solid particles can be strained or drained.

Oxidizing agents are added - ozone, potassium permanganate and chlorine, alkaline solutions of lime and soda. Less commonly acidic, hydrochloric and sulfuric.

Ozone installation

Cooled oxygen is sent to the water stream through an ozone generator. This accelerates sedimentation even in running waters. Used for deferrization of large volumes of liquid without settling tanks.

The ozonation method is used to remove iron bacteria and infections with viruses at central water supply points. Ozonation removes iron and disinfects the liquid.

They sell household systems for removing iron from well water for cottages. Disadvantage: Ozonation will not remove phenolic compounds.

Biological method

Used against iron bacteria. Purification of water from iron comes down to neutralizing contaminants by living microorganisms, which are specially released into the liquid for reproduction.

Biological cleaning methods are divided into:

- Aerobic, when microorganisms are added that reproduce with access to oxygen.

- With the anaerobic method, bacteria do not need air.

- Nitrogen, where microorganisms multiply in a nitrogen environment.

The liquid is cleaned with chlorine and irradiated with antibactericidal lamps. The method is used in enterprises.

Catalytic deferrization

Used for cottage villages and dacha SNT. Moisture is driven through a closed container with the active substance. The catalyst takes up the iron.

Mineral fillers of dolomite and glauconite are used as catalysts. Among artificial catalysts, a water purifier from iron from the Birm well is used.

The backfill has to be regularly renewed at a cost of 4,000 rubles per bag. Capacity 1 - 30 cubic meters per hour of operation.

Purifying water from iron in a private house

To remove iron from well water, we recommend deferrization before fine filtration. Otherwise, fine cleaning cartridges will become unusable two to three times faster than the warranty period.

Water filters from iron:

In stores they sell a filter for iron from a well for a summer residence at a price of 7,000 - 8,000 rubles. If purchasing is not part of your plans, you can remove iron from the water with an aerator.

Method #1. Cleaning with a pipe or bailer

Cleaning well water from clay using a bailer (pipe or cylinder with a valve) is carried out in stages.

Raising the deep-well pump to the surface and freeing the well space from equipment and any objects.

Strong fixation of the bailer on the rope (possibly on a steel cable), and its smooth descent to the bottom.

As soon as the bailer reaches the bottom, it is raised on a cable by 50 cm, after which it sharply falls to the bottom under the load of its own weight.

A strong blow to the bottom of a hollow pipe or bailer provokes a shift in the clay layers, and clay and water enter the space of the pipe or bailer, since when it falls, the metal valve of the device opens the intake channel. As soon as the bailer begins to move upward, the valve closes the channel, and clayey water remains in the device. This process is repeated 3-5 times to fill the bailer, after which it is lifted up and released.

In one procedure, a bailer can lift up to 500 clay sediment (not including water). This method is very labor-intensive, takes a lot of time, but gives the greatest result.

Water purification from hydrogen sulfide

A simple method for purifying well water from hydrogen sulfide and iron in a private home. You can get rid of iron using reagents, but aeration is more environmentally friendly.

Aeration is the saturation of a liquid with oxygen.

The principle of cleaning using the aeration method is based on mixing water and air. Moisture mixed with oxygen purifies itself, and iron impurities precipitate.

Video of cleaning water from a well from hydrogen sulfide and iron with a homemade aerator:

Electrochemical aeration is used at water treatment plants. With this method, air is forced through a compressor.

A system for purifying water from a well from hydrogen sulfide with forced air supply costs from 50,000 rubles.

Making filters for a well with your own hands

The size of the holes depends on the characteristics of the soil.

The most common cleaning device used by summer residents and owners of private houses is a perforated system with perforations. By design, it is a pipe with perforations (holes). The device is very simple, but quite effective. For production, you will need a metal or plastic pipe approximately 4.5-5 m long as consumables.

Choose plastic pipes according to the quality certificate so that the material is safe for humans.

When using metal pipes, geological or petroleum grades can be used. Using drills, perforate a section of pipe.

Making a perforated filter with your own hands is carried out using the following technology. Measure the length of the sump, which should be from 1 to 1.5 m. The length will depend on the depth of the well. Markings are applied to the surface of the pipe, taking into account that the perforated section is at least 25% of the length of the entire pipe, and the required length is determined. The length of the pipe also depends on the depth of the well and can be 5 m. Stepping back from the edge of the pipe, holes are drilled. The pitch of the holes is 1-2 cm, the accepted arrangement is in a checkerboard pattern. It is recommended to drill holes not at a right angle, but at an angle of 30-60 degrees with the direction from bottom to top. At the end of the work, the perforated surface of the pipe is cleaned of sharp protrusions. The inside of the pipe is cleaned of chips and closed with a wooden plug. The perforated area is wrapped with a finely woven mesh made of brass, or better yet, stainless steel. The mesh is secured with rivets. Using a mesh allows you to avoid quick clogging of the filter holes.

Types of mesh for filter: a - galloon weaving; b - Square.

High throughput is provided by the slotted filter design. The filter slit area is approximately 100 times larger than the hole area. There are no so-called blind zones on the surface of the filter.

To make a slot filter with your own hands, instead of a drill, you will need a milling tool. Depending on how the holes are made, a cutting torch may be required. The width of the slots is in the range of 2.5-5 mm, and the length is 20-75 mm, the location of the holes is in the waist and checkerboard order. A metal mesh is placed over the holes.

The mesh weave is galloon, the material is brass. The size of the mesh holes is selected experimentally by sifting sand. The most suitable mesh size is one that allows half the sand to pass through when sifting. For particularly fine sand, a suitable option would be a mesh that allows 70% throughput, for coarse sand - 25%.

The size of sand particles determines its composition:

- coarse sand - particles 0.5-1 mm;

- medium sand - particles 0.25-0.5 mm;

- fine sand - particles 0.1-0.25 mm.

Before applying the mesh, stainless steel wire is wound onto the perforated surface with a pitch of 10-25 mm. The wire diameter should be 3 mm. The strength of the structure is ensured by spot soldering of sections of wire along the length of the winding, approximately every 0.5 m. After winding the wire, a mesh is applied and tightened with wire. The wire pitch when pulling is 50-100 mm. The mesh for fixation can be soldered or twisted with steel wire.

A wire cleaning device for a well is distinguished by the complexity of its design. To make such a filter with your own hands, you need to use a wire of a special cross-section shape. The throughput of the system largely depends on the wire winding pitch and the shape of its cross-section.

The winding technology is as follows. The slot design of the cleaning system is being prepared. The size of the holes depends on the size of the natural particles. Before you start winding the wire, 10-12 rods with a diameter of at least 5 mm are applied to the frame.

Winding must be done carefully, following the step. You can use a lathe if you have one.

The simplest filter device has a gravel structure. Such a system is constructed in soils with clayey and fine sand. The process of constructing a filter begins with preparing the well; the diameter of the well should be sufficient for sprinkling with gravel. Gravel is selected in a single-size fraction and poured from the wellhead into the well. The thickness of the coating must be at least 50 mm. The gravel particle size is selected relative to the rock particle size. Gravel particles should be 5-10 times smaller.

How to get rid of lime

The use of a softener affects the family budget and preserves health.

A softener reduces hardness—the amount of minerals in a liquid. To remove lime from well water, sodium or potassium ions are replaced with calcium and magnesium ions. They are the ones who create rigidity.

Three benefits of softeners:

- The lime filter makes the skin and hair soft. Since the softener protects the skin, it also affects the fabric of clothing and bedding.

- Increases service life. The washing machine will be protected from scale and will consume less electricity.

- The softened moisture does not leave stains on the surface. This will make detergents effective, and it will reduce the consumption of household chemicals for cleaning the house.

Salt filters for water softening and lime removal

To clean water from lime and neutralize magnesium and potassium salts, which form scale, install salt filters.

The salt filler does not make the water drinkable.

Salt filter fillers for purifying water from a well are inferior in popularity to coal ones.

Carbon filters

The base is activated carbon, absorbs impurities. The carbon filler removes chlorine and lime.

Prices for carbon filters for purifying water from a well:

Goals

If you plan to use water in everyday life, especially for drinking and cooking, cleaning it from clay is necessary. It allows:

- reduce turbidity - even in small concentrations, clay suspension reduces the transparency of water and makes it unsuitable for drinking;

- soften water and remove impurities from it - water containing dissolved clay, in terms of hardness, as a rule, does not meet the requirements of GOST “Drinking Water”, and is also often unsuitable for domestic needs;

- eliminate odor - drinking water, according to regulatory documents, should not have any foreign odors.

- disinfect water at the initial stage of purification, since clay suspension often contains dangerous microorganisms, algae, protozoa and other biological objects.

Fine removal of manganese

The last stage of cleaning is the removal of manganese. Water treatment devices can remove iron and perform fine cleaning at the same time.

Reverse osmosis

Reverse osmosis membranes remove iron. They produce both industrial and household models that are mounted under the mixer.

Water purification from manganese and iron is based on a micro membrane that allows water to pass through at the molecular level. Impurity molecules larger than H2O are retained.

Osmosis also protects against invisible ferrous iron. The downside is chlorine, which overcomes osmosis. Chlorine molecules are smaller than H2O.

Price of a household water purification station from a well for a cottage with osmosis on Yandex Market:

Excess manganese in the water is blocked with a reverse osmosis membrane under the sink and washed down the pipes.

Filter under the sink

The water purification system from a well under the sink is considered simple due to its easy installation. When a plumber installs an osmosis system under a sink, all the cold water will flow through a separate faucet.

The second installation option supplies pressure to the faucet, which is already on the sink. Since the filter is connected to the cold line, it cannot clean hot water.

Instead of installing two separate taps for cold and drinking water, you can try a simplified system.

Types of contaminants and choice of filters

Water must be submitted for analysis not only when a well is put into operation. Indicators may change due to changes in the characteristics of the water flow and contamination of the filtering equipment.

Contamination of water from a well occurs:

- mechanical (sand, clay, silt);

- chemical (iron, manganese, potassium, magnesium, hydrogen sulfide);

- biological (iron bacteria and pathogenic bacteria).

For example, the analysis showed exceeding the indicators for turbidity, hardness and total iron. This means that the water treatment system will need to include a coarse filter, an iron remover, a softener and a fine filter.

Selecting filters to remove chemical impurities

More complex devices are used to purify water from chemical contaminants. As a rule, it is necessary to install several filters and softeners in series so that the water quality meets drinking water standards and does not harm the plumbing, boiler, or pipes.

Devices can be divided into groups:

- to remove dissolved iron (ferrous);

- to remove iron in the form of solid particles (trivalent);

- to remove calcium and magnesium.

Various schemes and devices are used to remove iron from di- and trivalent iron.

Oxygen is required to convert dissolved iron into the solid phase. Therefore, the first stage of iron removal can be a pressure or non-pressure aerator. The pressure one includes a compressor in the circuit that supplies air to a tank of water, due to which it is vigorously mixed and comes into contact with air. Non-pressure works thanks to the installation of spray nozzles that increase the area of contact between water and air. The first method is more productive. Sometimes, to enhance the effect, an aeration column is a complex of methods: with nozzles and a compressor.

Aerator for oxidation of ferrous iron: 1 - inlet pipe from the well; 2 - compressor and air duct with an aerating stone at the end; 3 — outlet pipe to the fine filter and consumer; 4 - precipitate of oxidized ferric iron

A clear example of an aerator used in industrial wastewater treatment plants

Next, oxidized iron salts that have passed into the solid phase must be captured in reagent or non-reagent type filters. Both of these filters contain a media that keeps solid ferrite salts from entering the water supply. The difference between them is that the reagents include the supply of a strong oxidizing agent (potassium permanganate, chlorine), which accelerates the oxidation of divalent iron to ferric iron. Reagent-free filters must be paired with an aerator, and reagent filters can be the only stage of iron removal when the ferrite content is below 5 mg/l.

Manganese and hydrogen sulfide are captured in the same way as iron, simultaneously with it in the same apparatus.

Removal of calcium and magnesium is required to soften water. The best filter for this is an ion exchange polymer resin, which is located in the reservoir and replaces ions of harmful substances with an equivalent amount of harmless ions (for example, sodium). Depending on the acidity of the water, cation or anion filters are used. Resins are also distinguished by their structure: porous or gel.

When the resin capacity is completely exhausted (there are no more ions for harmless exchange), it is replaced or regenerated with salt.

Many impurities, including dissolved ones, can be removed from water using a reverse osmosis filter. The principle of operation of such a filter is to push exclusively water molecules through a membrane under pressure. All other inclusions, including chemicals and organic compounds, as well as radionuclides with larger molecules, cannot penetrate the membrane. The degree of purification is 90–99%. However, almost 60% of the water is spent only on cleaning the membrane from contaminants and is not supplied to the consumer, being discharged into the sewer.

Household reverse osmosis filter

High performance reverse osmosis purification system

Reverse osmosis is equipped with several sequentially installed finer preliminary filters, which prevent the main filter from becoming too clogged. To clean the membrane, the filter design provides for dividing the water flow, and the second flow is intended for washing ferrite sediment from the membrane into the sewer.

Filters for removing bacteriological impurities

Iron bacteria can significantly contaminate the source, so much so that further filtration cannot be effective. If the aquifer is damaged by these microorganisms, shock chlorination of the source is required. This procedure requires precise calculations and laboratory control of analyses, so it is better to have it performed by a specialized company. When chlorinating a source, it is advisable to add a filter with a carbon cartridge to the water treatment system to neutralize chlorine.

Anaerobic microorganisms and iron bacteria are often found in well water. If the well is shallow, there is a risk of finding pathogenic aerobic bacteria

Pathogenic bacteria that can enter shallow water horizons are safely destroyed by an ultraviolet disinfectant. In the central water supply, this function is performed by chlorination.

An ultraviolet installation is usually built in after the main filters and is equipped with a sensor when the intensity of its exposure decreases. The required calculated radiation dose, indicated in the characteristics of the UV installation, is selected depending on the degree of damage to the water by microbiological organisms. The emitter can be installed vertically or horizontally.

Selection of filters for removing mechanical impurities

Mechanical impurities present in high concentrations, as well as coarse suspended matter (sand), are separated directly in the well. To do this, install coarse filters, the design of which includes a pipe with a perforated surface in the form of a mesh, a wire grid, or round or oblong holes. There can be more than one such filtration layers.

When choosing a filter, it is advisable to give preference to those made of stainless steel. Galvanized elements have a significantly shorter lifespan, while the durability of plastic ones is even lower. However, if hydrogen sulfide and free oxygen are present in the water, it is advisable to choose a filter made of plastic that is neutral to their effects (in agreement with the SES). The choice of filter also depends on the soil surrounding the well and the water horizon. Solid limestone contains little suspended matter, normal acidity, and virtually no biological contaminants - this is one of the cleanest sources of natural water. A well “on sand” must be equipped with a filter, otherwise the rest of the water supply will instantly become clogged.

Coarse wire filters for wells

Coarse slot filters

The height of the filter in the well is calculated using formulas based on the thickness of the aquifer and the fractional composition of the suspension. Approximately, the length for medium-grained and coarse sand is from one to two meters, fine-grained sand is captured by a filter up to 4 m in length, and dusty sediments are up to 6 m (if the thickness of the aquifer allows). The diameter of the pipes must correspond to the well, located in it so as to ensure free flow of water, and is usually 70–150 mm.

Silicon

Silicon water is useful only if it is contained in acceptable quantities (10 mg/l). If there is a lot of the element, it is dangerous to health; it forms brown silicate scale on the pipes. Water purification from flint is carried out using standard devices, but with special fillers. Precipitation with lime, sorption by aluminum and iron oxides, electrocoagulation, and magnesium sorbents are used. These are old methods, but better ones are: ion exchange, ultra and nanofiltration, electrodeionization, osmosis.

The ideal scheme, what is it?

Typical engineering solutions are discussed above. However, some installation methods can be improved with additional tools. Thus, in the presence of ferrous iron impurities in the well, the following accelerated oxidation technologies are used:

- pressure spray;

- pressure-free division of the flow into several small jets;

- forced compressor aeration;

- ozone injection through an ejector.

After pre-treatment, the liquid is sent to a container with catalytic backfill or activated carbon. Mechanical impurities are retained in an additional layer of sand.

Reverse osmosis is comparable in filtration level to high-quality distillation. However, during long interruptions in equipment operation, secondary contamination cannot be ruled out. In order for such a water purification system for a country house to perform its functions flawlessly, the kit is supplemented with a UV treatment unit.

The examples provided explain the need for careful study of all important details of an engineering project. The ideal water treatment and purification scheme exactly corresponds to actual needs. It does not unduly increase the user's responsibilities during operation. To make an accurate economic calculation, take a time interval of at least 10 years. Costs are summed up for the following items:

- service;

- Consumables;

- scheduled repairs (replacement of individual units).

Which water treatment and purification system is best to install in a private home?

When connecting to a deep artesian well, you can count on the removal of most harmful impurities by natural filtration. At the final stage, a jug with a built-in cartridge is used to eliminate residual impurities. However, in such sources there is a high concentration of calcium fractions, which turn into scale when heated.

Local protection of individual pieces of equipment can be organized using a polyphosphate filter. However, it is more convenient to use a general water treatment system for a country house. Hardness salts are retained using an ion exchange system. To save space in a private home, a water treatment system is used. The power of the generator is selected according to the range of the connected pipeline route.

An additional advantage of the electromagnetic “softener” is a simple connection diagram:

- the coil is wound with insulated wire (20-25 turns);

- the main unit is placed on the floor or fixed in a vertical position on the wall;

- connect power from a 220 V network (power - no more than 25 W);

- the operating mode is maintained automatically without settings and careful monitoring.

To prepare drinking water, a reverse osmosis kit is added to the purification scheme of a country house. To saturate the liquid with useful substances, a mineralizer is installed after the membrane.

Bottom line

A typical integrated scheme of a water treatment and water purification system consists of the following functional blocks:

- removal of mechanical impurities;

- deferrization;

- reducing the level of hardness or protecting against scale;

- preparation of drinking water.

To eliminate errors along with unnecessary costs, the composition of impurities is first clarified. If personal design causes difficulties, turn to specialists. Equipment is selected taking into account factory warranties and planned service life.