The majority of owners of country houses and dachas who want to provide themselves with the required amount of water for domestic needs and watering plants on their plots on a permanent basis have to solve the problem of arranging an autonomous water supply system. The most important elements of such systems are an underground water source (well or well) and pumping equipment, which is most often a submersible centrifugal pump. In order to avoid situations in which pumping equipment does not work correctly, does not work at all, or does not provide the required parameters of the generated fluid flow, you need to know how to choose such devices correctly, as well as follow the rules for their operation and maintenance.

Submersible pump for well

Purpose of pumping equipment

An autonomous water supply system, the main task of which is to deliver the required amount of water to specified points, includes several elements. Each of them performs its own function. Such elements, in particular, are:

- a source of water, which can be a well or well;

- pipes connected into a single system;

- mechanisms that ensure pumping water from an underground source and transporting it through a pipeline under a certain pressure.

General diagram of water supply to a house from a well pump

In order for such a system to work effectively and not cause problems during operation, it is necessary to pay special attention not only to its design, but also to the selection of elements with which it will be equipped.

The main element of an autonomous water supply system, as mentioned above, is a water pump, which is designed to solve problems such as:

- lifting water located in an underground source at a certain depth and supplying it to the pipeline system;

- transportation through a pipeline system of a certain volume of liquid medium under the required pressure;

- ensuring uninterrupted operation of the autonomous water supply system;

- ease of maintenance and the ability to automate the management of the serviced system.

Submersible centrifugal pumps optimally meet the above requirements, which is why they are the most common hydraulic machines used to equip wells and wells.

In addition to good performance characteristics, centrifugal-type submersible pumps are characterized by their simplicity of design, and therefore ease of operation and maintenance. Depending on the depth of the underground source, centrifugal submersible pumps of various capacities are purchased.

Among the wide variety of submersible pumps, you need to choose a model that is suitable in terms of technical parameters and price-quality ratio

How to choose and what to pay attention to?

When choosing a pump for a well, you should pay attention to the following criteria:

- Productivity . The pump for the well must cover at least 50% of the total water consumption in the water supply system and at the same time not exceed the flow rate of the well (so as not to suck water out of the well faster than it is collected there). The well flow rate can be viewed in the installation passport.

- Maximum immersion depth . Here we mean the depth of immersion under water, and not generally into the well. For example, if the well has a total depth of 50 m, but from the surface to the water table is 20 m, then there is 30 m of water space, and if you want to lower the unit almost to the very bottom, then its maximum immersion depth should be at least 30 m.

- Power cord length . The power cord must be at least as long as the total depth of the well (if lowered to the very bottom) plus the distance to the outlet.

What types of submersible pumps are divided into?

A submersible (or deep) pump is practically indispensable in cases where water needs to be pumped out from underground sources whose depth exceeds 10 meters. Submersible pumps differ from surface-type equipment in a number of advantages:

- almost silent operation;

- ease of installation and operation;

- high performance;

- reliability and long service life.

According to their design, submersible pumps are divided into several categories:

- centrifugal pumps for wells and wells;

- vibration type devices;

- vortex pumps for water.

Types of submersible pumps for wells

The simplest in design and, accordingly, the most inexpensive of all the above devices is a vibrating submersible pump, the basis of which is an elastic membrane and a piston. The latter is driven by a rod connected to an armature, which is attracted to the coil core and repelled from it (an alternating electric current passes through the turns of the coil). For intensive work, vibration pumps are not used, as they are not highly reliable.

The most reliable and productive equipment for a water well is considered to be a centrifugal submersible pump, the main working part of which is a wheel - an impeller. On the outer surface of the impeller there are fixed blades that move the pumped liquid medium through the internal chamber of the device.

The impeller of a centrifugal pump is made of non-ferrous alloys, stainless steel, high-strength cast iron or composite materials

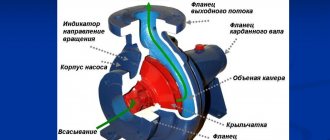

Vortex pumping equipment can be considered one of the modifications of a centrifugal submersible pump, since such pumps are very similar both in design and in operating principle. The main working body of vortex pumps is also a wheel with blades, when rotating together with the pumped liquid, the latter is affected by centrifugal force. In addition, there are special grooves on the walls of the internal working chamber of the vortex pump, which make it possible to impart additional acceleration to the pumped liquid.

Vortex pump diagram

Rating of the TOP 15 best models

| Place | Name | Price |

| TOP 5 best pumps for wells up to 20 meters | ||

| 1 | UNIPUMP MINI ECO-2 (550 W) | 15 000 ₽ |

| 2 | VORTEX CH-60 (800 W) | 11 000 ₽ |

| 3 | GILEKS Water cannon PROF 55/50 (600 W) | 12 000 ₽ |

| 4 | GILEKS Water cannon PROF 40/50 (520 W) | 8 000 ₽ |

| 5 | VORTEX CH-60V (370 W) | 5 000 ₽ |

| TOP 5 best pumps for wells up to 50 meters | ||

| 1 | VORTEX CH-135 (1800 W) | 16 000 ₽ |

| 2 | BELAMOS TF3-60 (800 W) | 12 000 ₽ |

| 3 | BELAMOS TF3-80 (1000 W) | 13 000 ₽ |

| 4 | Aquario ASP 1E-30-90 (450 W) | 9 000 ₽ |

| 5 | VORTEX CH-50 (750 W) | 9 000 ₽ |

| TOP 5 best pumps for wells from 70 meters | ||

| 1 | BELAMOS TF-100 (1300 W) | 16 000 ₽ |

| 2 | Grundfos SQ 3-105 (2540 W) | 55 000 ₽ |

| 3 | BELAMOS TF3-40 (550 W) | 8 000 ₽ |

| 4 | Aquarius BCPE 0.5-100U | 19 000 ₽ |

| 5 | UNIPUMP ECO MIDI-2 (550 W) | 11 000 ₽ |

Operating principle and classification of centrifugal pumps

How does a centrifugal type submersible pump work? To understand this, you must first understand its design. Considering the fact that such a pump, when operating in wells or wells, is located in the thickness of the liquid medium, the most important requirement for its design is the tightness of the housing, which, in addition, must be made of anti-corrosion materials. The power element that powers this equipment is an electric motor, which requires absolute waterproofing to avoid breakdowns.

If we consider the design of a well pump in its classic design, we should highlight such structural elements as:

- power part, the main unit of which is an electric motor (the rotation of its shaft drives the impeller);

- the blade compartment, which performs the main function of the hydraulic machine - pumping a liquid medium from a well or well to the surface;

- inlet and pressure pipes through which the liquid medium is sucked in and pushed out into the pipeline system under a certain pressure.

Design of a centrifugal well pump

For the manufacture of the casing of borehole centrifugal pumps, which are subject to increased requirements for corrosion resistance, high-strength polymer materials or stainless steel are used. The inlet pipe of a borehole centrifugal pump is equipped with a mesh filter that prevents solid inclusions contained in the pumped liquid from entering their internal part.

The operating principle of a centrifugal well pump is as follows.

- The moving pumped liquid medium, under the action of centrifugal force, is thrown towards the walls of the internal chamber, acquiring a certain pressure.

- Under the influence of pressure generated by centrifugal force, the liquid medium is pushed through the pressure pipe.

- In the central part of the working chamber, after the liquid medium is thrown towards the walls, an air vacuum is created, which facilitates the absorption of liquid through the inlet pipe.

Scheme of operation of a centrifugal pump

To optimize the operation of a centrifugal electric pump, various additional elements can be used, which, in particular, include a check valve, a liquid level sensor in the source, its presence in the system, etc. Such elements, certain types of which are already present in the standard configuration of many models of modern submersible pumps centrifugal type, allow you to organize the operation of equipment in automatic mode.

Centrifugal pumps for wells are divided into various types and according to their technical parameters. Thus, depending on the number of impellers, a centrifugal submersible pump can be single- or multi-stage. Multistage pumps, which can have up to ten impellers, are capable of creating a fluid flow with higher pressure than single-stage models. That is why, when choosing pumping equipment for wells characterized by great depth, preference should be given to multi-stage pumps.

Multistage centrifugal pump design

Depending on the location of the axis of the drive motor shaft and the impeller, centrifugal pumps are divided into vertical and horizontal. It should be noted that the design of a deep-well pump assumes only a vertical position of the shaft axis of its drive electric motor and an impeller with blades.

Submersible centrifugal pumps are divided into various categories according to the method of their installation in the serviced well. So, depending on this factor, a submersible centrifugal pump for a well can be a rod pump, for installation of which a special design is used in an underground source, and a rodless pump (ESP), mounted in the shaft of an underground source using a tubing string.

The best pumps for wells up to 20 meters

UNIPUMP MINI ECO-2 (550 W)

Submersible well pump UNIPUMP MINI ECO-2 (550 W) is used for autonomous water supply of country houses, for organizing watering of gardens and vegetable gardens, small farms.

The pump body is made of stainless steel, the impellers are made of wear-resistant polycarbonate.

“Floating” impellers guarantee a long service life of the hydraulic part and reduce the likelihood that it will jam when pumping liquid with mechanical impurities.

Main functional characteristics:

- submersible borehole;

- maximum productivity - 3 m³/h;

- maximum head - 65 m;

- immersion depth - 20 m;

- vertical installation.

Advantages:

- performance;

- low noise level;

- water pressure.

Flaws:

- not specified by users.

VORTEX CH-60 (800 W)

The borehole pump VORTEX CH-60 (800 W) is used for pumping clean and slightly contaminated water . Designed to supply water to the house and garden.

Stainless steel body, chrome plated pump part.

The 800 W motor allows pumping up to 3000 l/hour . The wear-resistant case easily withstands intensive use.

The thermal relay reliably protects the engine from possible overheating.

Main functional characteristics:

- submersible borehole;

- maximum productivity - 3 m³/h;

- maximum head - 60 m;

- immersion depth - 50 m;

- vertical installation.

Advantages:

- water pressure;

- performance;

- low noise level.

Flaws:

- short wire.

GILEKS Water cannon PROF 55/50 (600 W)

The pump GILEKS Vodomet PROF 55/50 (600 W) is intended for supplying clean water from wells, reservoirs and open reservoirs, used for watering the garden and vegetable garden..

The operation of the device is automatically regulated according to the liquid level, due to the fact that it is equipped with a float switch.

To fully automate the water supply system at home, you must separately purchase the appropriate parts.

Main functional characteristics:

- submersible borehole;

- maximum productivity - 3.3 m³/h;

- maximum head - 50 m;

- immersion depth - 30 m;

- vertical installation.

Advantages:

- water pressure;

- performance;

- low noise level.

Flaws:

- poor build quality.

GILEKS Water cannon PROF 40/50 (520 W)

The GILEX Vodomet PROF 40/50 pump (520 W) has a capacity of 2.4 m3 and a water pressure of 50 meters, the diameter of the device body is 98 mm.

The equipment is used for wells with low flow rates. Designed for pumping clean water from wells, wells, reservoirs and open reservoirs.

Pump operation is manually adjusted.

The motor thermal relay protects the equipment in case of emergency operation.

Main functional characteristics:

- submersible borehole;

- maximum productivity - 2.4 m³/h;

- maximum head - 50 m;

- immersion depth - 30 m;

- vertical installation;

- weight - 8.5 kg.

Advantages:

- low noise level;

- performance;

- light weight.

Flaws:

- not noted by buyers.

VORTEX CH-60V (370 W)

Submersible pump VORTEX CH-60V (370 W) is used to supply water from wells, wells, reservoirs and open reservoirs for domestic needs and watering plants.

In terms of protection against electric shock, the pump is classified as IPX8 equipment and can operate completely submerged in water to a depth of 35 meters.

In this case, the distance from the bottom of the well to the device should not be less than 0.6 meters.

Main functional characteristics:

- submersible borehole;

- maximum productivity - 1.5 m³/h;

- maximum head - 60 m;

- immersion depth - 35 m;

- vertical installation;

- weight - 10 kg.

Advantages:

- performance;

- water pressure;

- long wire.

Flaws:

- high noise level.

Main characteristics

When wondering how to choose the right centrifugal pump, you should first understand what basic parameters it is characterized by. The parameters that are most often taken into account when choosing submersible centrifugal pumps include:

- power (the determining criterion for selection);

- productivity, characterizing the volume of liquid medium that the pump is able to pump per unit of time;

- the height of the water column created by the equipment (it determines the depth of the well from which the pump is capable of pumping out the liquid medium), as well as the length of the horizontal part of the pipeline through which the device is able to transport the liquid it pumps;

- the presence of additional elements in the package to optimize the operation of the pump.

The selection of a pump is influenced by the well parameters and the required equipment performance, depending on the actual water flow

The body of most submersible centrifugal pumps is made of stainless steel. Only for low-power models, body parts are made from high-strength polymer materials.

How does a sand well work?

Sand wells are the most common sources because they are located in the first formation. This design requires careful pump selection. The resulting water will initially be heavily contaminated with sand, so not every unit will be able to pump it effectively. This will create additional load on the pump, so a sand source requires the use of special powerful equipment.

The aquifer is represented by sand deposits. The porosity of the material is large, therefore the mobility of each grain of sand is also great. Sandy water flow creates additional stress on the pump. The device cannot pump dirty water for a long time, so it quickly burns out. It cannot be repaired. What to do in such a situation? The reason for the rapid failure of equipment is a low-quality pump.

Experts in the field of water supply have developed a method for additional protection of water and equipment from sand. When arranging a hydraulic structure, a natural filter made of fine crushed stone or pebbles is used. This is a good way to slow down any erosion or movement of sand throughout the well. For greater efficiency, a mesh type of filter is mounted at the end of the casing pipe.

Benefits of use

The design and operational advantages of centrifugal submersible pumps, when compared with other types of devices, are:

- compact dimensions and light weight (these characteristics are ensured by the fact that the power part of the pump is directly connected to its blade assembly);

- ease of installation, operation and maintenance;

- operational reliability and long service life;

- formation of a smooth and continuous flow of liquid medium in which there are no hydraulic shocks;

- the ability to be used for pumping liquid media that contain insoluble solid inclusions.

The borehole centrifugal pump housing is made of durable stainless steel

Surface pump

Although this type of unit is suitable for working in shallow wells (up to 8-9 meters deep), it cannot process dirty water. Even the smallest percentage of sand inclusion in water can damage the unit once and for all. Moreover, such sensitivity to various components in water is inherent in both vortex and centrifugal units.

Important: surface pumps are an ideal solution for a small summer cottage and a well (well) with a low flow rate.

terms of Use

In order for centrifugal submersible pumping equipment to meet all the requirements placed on it, it is necessary to know not only how to select a well pump of this type correctly, but also how to operate such a device. The conditions under which a centrifugal submersible pump must operate are usually specified in the instructions for such equipment. These include:

- composition and temperature of the pumped liquid medium;

- the degree of contamination of the liquid for pumping which it is planned to use a submersible pump;

- stability of the parameters of the voltage supplied to the pump drive motor.

Accessories for pumps extend the life of the equipment and make the operation of the water supply system more comfortable

To prevent voltage surges in the electrical network from having a negative impact on the operation of the submersible centrifugal pump, it is recommended to use a stabilization unit when connecting such a device.

General design features

All types of submersible pumps for equipping wells, as mentioned above, have common design features. Since submersible (or deep) pumps during use are located in the thickness of the liquid medium they pump, they are equipped with a sealed housing that protects the electric motor from contact with the liquid.

The housing of submersible pumping equipment, which can vary in size and weight for different models, usually has an elongated cylindrical shape and a relatively small diameter. This form of the body of deep-well (submersible) pumps is optimally suited for placing them in casing columns, in which they are located during their operation.

An elongated cylinder is a design feature of submersible well pumps

The following design features are also common to all types of submersible pumps:

- the presence of a coarse filter installed on the suction pipe (the main purpose of such a filter is to protect the inside of the device from the ingress of solid impurities contained in the pumped liquid);

- equipped with a check valve (many modern models of submersible pumps for wells have such an element that prevents the pumped liquid from moving in the opposite direction; if it is not included in the basic configuration of the pump, then it is purchased additionally and installed on the equipment, for which a special threaded connection is provided) .

At the top of the submersible well pumps there is an outlet pipe, a power cable outlet and cable securing clamps

Recommendations for installation and maintenance

After the well has been drilled, a submersible pump should be correctly installed in the underground source. If the deep pump is planned to be used to service the well, then when installing it it is also necessary to adhere to the requirements specified in the instructions.

To secure a submersible pump in an underground water supply at a certain depth, a safety cable is used, the material of which has the following requirements:

- high resistance to the development of corrosion processes;

- exceeding the breaking load of the weight of the device being held by at least five times.

Securely fastening the safety rope

You cannot use only a power cable to fix a submersible pump in a well at a certain depth; the main load from the weight of the equipment being held in such cases must fall on the safety cable. The upper end of the cable is attached either to a special beam installed on the surface of the earth, or to the walls of a well or borehole.

The instructions for pumping equipment stipulate the timing of preventive maintenance. Such work, in particular, includes:

- checking the tightness of the housing;

- replacement of rubber seals installed on the drive motor rod;

- cleaning the contacts through which the pump is connected to the power supply.

It should also be taken into account that many modern models of submersible centrifugal pumps are equipped with coarse filters, which need to be regularly replaced as they become dirty.

The best pumps for wells from 70 meters

BELAMOS TF-100 (1300 W)

The BELAMOS TF-100 (1300 W) well pump is used to organize autonomous water supply in private homes and watering plants, as well as in agriculture to create irrigation systems.

The 1300 W electric motor is designed for intensive work with increased loads and provides a capacity of 4500 liters per hour.

Thermal relay protects the device from overheating.

The pump part is made of high quality stainless steel.

Main functional characteristics:

- submersible borehole;

- maximum productivity - 5 m³/h;

- maximum head - 100 m;

- immersion depth - 80 m;

- vertical installation;

- weight - 22.1 kg.

Advantages:

- performance;

- water pressure;

- build quality.

Flaws:

- not specified by buyers.

Grundfos SQ 3-105 (2540 W)

The Grundfos SQ 3-105 (2540 W) borehole pump is designed for water supply to private houses, pumping water from reservoirs, irrigation hydraulic systems and small waterworks.

The single-phase permanent magnet electric motor is capable of high efficiency over a wide power range.

The electric motor is equipped with a removable cable connector.

Main functional characteristics:

- submersible borehole;

- maximum productivity - 4.2 m³/h;

- maximum head - 147 m;

- installation horizontal and vertical;

- weight - 6.5 kg.

Advantages:

- performance;

- water pressure;

- low noise level.

Flaws:

- not noted by buyers.

BELAMOS TF3-40 (550 W)

Submersible pump BELAMOS TF3-40 (550 W) is used for pumping clean water from great depths into the house or for watering plants.

The design of the pump part allows for independent maintenance (cleaning) of the pump part, without going to a workshop.

To disassemble the pump part, simply unscrew the top cover or bottom flange of the pump part.

The device is supplied with a cable and a plug with a grounding contact.

Main functional characteristics:

- submersible borehole;

- maximum productivity - 2.7 m³/h;

- maximum head - 42 m;

- immersion depth - 80 m;

- vertical installation;

- weight - 9.4 kg.

Advantages:

- performance;

- build quality;

- water pressure.

Flaws:

- not identified by users.

Aquarius BCPE 0.5-100U

The submersible pump Aquarius BCPE 0.5-100U consists of a single-phase electric motor and a multi-stage pumping part, created in the form of a monoblock, as well as a remote condensate box, which is attached to a power cord with a plug.

The electric pump has a thermal relay that effectively protects it during emergency operating conditions.

The volumetric flow of a submersible pump depends on many factors - the depth of water, the length and diameter of the hose being used, etc.

Main functional characteristics:

- submersible borehole;

- maximum productivity - 3.6 m³/h;

- maximum head - 150 m;

- immersion depth - 100 m;

- vertical installation;

- weight - 25 kg.

Advantages:

- performance;

- water pressure;

- build quality.

Flaws:

- not specified by users.

UNIPUMP ECO MIDI-2 (550 W)

UNIPUMP ECO MIDI-2 borehole pump (550 W) is used to supply water from sources with a diameter of at least 98 mm.

Using a deep-well pump, an automated water supply system can be organized at a summer cottage, in a country house, in production, etc.

“Floating” wheels are made of wear-resistant carbonate.

They minimize the risk that the pump will jam when pumping liquid with mechanical impurities.

A special filter prevents large abrasive particles from penetrating into the pump part.

Main functional characteristics:

- submersible borehole;

- maximum productivity - 3 m³/h;

- maximum head - 73 m;

- immersion depth - 100 m;

- vertical installation.

Advantages:

- water pressure;

- low noise level;

- performance.

Flaws:

- not detected by users.