What is it and how does it work?

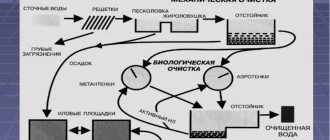

After the mechanical filtration stage (removal of insoluble particles), the wastewater enters biological treatment.

The principle is based on the ability of some microorganisms to break down organic compounds into simple substances - water, carbon dioxide, methane, hydrogen sulfide. Organic matter is a source of energy for bacteria and protozoa.

Wastewater includes nitrates, ammonia, amino acids - they contain nitrogen, which ensures the vital activity of microorganisms.

Phosphorus and potassium are produced by bacteria from mineral salts.

The more of these substances in wastewater, the more intense the proliferation of microorganisms and the more effective the treatment.

What methods of removing pollution exist?

Natural water is a complex disperse system containing a huge amount of dissolved and suspended impurities of various phase compositions, mineral and organic nature. It is impossible to use a universal method to remove such a variety of substances. Water treatment processes involve a whole range of methods and biological technologies for water purification, each of which is focused on eliminating a specific group of substances.

Depending on the direction of exposure and the instruments used, there are four main types of water purification methods:

- Physical methods of water preparation.

- Removal of dissolved pollutants using reagents - chemical methods.

- Combined effects on polluting substances by physical and chemical processes.

- Biological water treatment.

Physical methods of water purification are in demand mainly at the preparatory stage of water treatment. This is filtration, straining, settling. They are aimed at eliminating large inclusions from water volumes that can disrupt the operation of equipment and quickly destroy selective filter materials during further processing and selective purification of water.

Chemical methods are based on the ability of compounds to enter into chemical reactions with each other. By introducing special reagents to trigger certain interactions, it is possible to convert toxic contaminants into non-hazardous compounds, bind them into poorly soluble complexes or insoluble precipitates that can be easily removed by filtration or other separation methods.

Physico-chemical processes combine the combined effects on the water supplied for purification by physical phenomena and chemical reagents. Such methods are based on the properties of the impurities being removed, which are activated by specially introduced substances that initiate chemical and physical processes. With the help of physicochemical purification, both mineral pollutants and organic matter, metal ions, and dissolved gases are removed.

Biological purification methods are relatively new, but promising methods for removing unwanted elements and compounds from water with the participation of living microflora, special bacteria, and fungi. The essence is the selective absorption of pollutants from water by living organisms as a nutrient material for their life activity.

Wastewater treatment methods

Experts distinguish two large groups of bioremediation methods:

- Natural . To improve the quality of wastewater, natural processes occurring in water, soil, and plant ecosystems are used. Contaminants are retained, mineralized, transformed or transported. Natural ecosystems are used for post-treatment of wastewater before it is discharged into water bodies.

- Artificial methods. To implement them, man-made structures are used. Aerobic or anaerobic microorganisms are placed in them and favorable conditions are provided for the processing of contaminants.

Efficiency

Biological wastewater treatment in industrial conditions eliminates 98% of contaminants .

Reference. Septic tanks process only 45-50% of organic matter.

To maintain the process, you need to constantly introduce active microorganisms.

The biological method helps to process the following pollutants and their compounds :

- Ammonium nitrogen;

- Easily oxidizing organic compounds: benzene, glucose, acetone, ethanol, etc.;

- Potassium;

- Phosphorus;

- Calcium;

- Proteins fats carbohydrates.

Wastewater includes industrial and domestic wastewater, as well as precipitation. All these groups necessarily undergo the stage of biological treatment at industrial or local facilities.

Efficiency table: cleaning method

| Footprint | Air requirement | Type of contaminants removed | Possibility of year-round operation | |

| Filter fields | big | Yes | organic | No |

| Anaerobic digesters | big | No | organic | Yes |

| Aero tanks | small | Yes | organic | Yes |

| Biological filters | small | Yes | organic | Yes |

| Purification lagoons | big | Yes | organic | No |

Biological wastewater treatment methods effectively remove organic impurities from liquids. Some of them can be used all year round. Others, using natural water purification mechanisms, are applicable only in the warm season.

It should be remembered that the types of treatment facilities listed above only remove organic contaminants from water. Other filtration units should be used to remove inorganic impurities.

Advantages and disadvantages

Advantages of biological treatment:

- Low amount of waste. After processing, substances are formed (carbon dioxide, water) that are easily disposed of. If methane is released during purification, it is used to generate thermal energy. Recycled sludge is a good fertilizer.

- Biological treatment systems operate autonomously. To service them, you do not need to introduce reagents, and 1 person can control the process.

- The cost of implementing biotechnologies is lower than other methods of water purification.

- Natural reactions create an environmentally friendly cycle of natural use.

Biological wastewater treatment is not without its drawbacks.

The main disadvantages of the method:

- Difficulty in maintaining a constant amount of bacterial biomass. If they are less than normal, the wastewater will not be completely purified.

- A lot of money needs to be invested in the construction of wastewater treatment plants. But over time, the costs pay off.

- The technological cleaning regime must be strictly observed. If there are violations, the effectiveness of the method is significantly reduced.

- Not all organic compounds are recyclable. If there are toxic compounds in wastewater, they must be removed, otherwise the biomass will die.

Interactive scheme of treatment facilities

Hover over image to view description

Deep cleaning units

Deep purification units are vertical cylindrical containers equipped with a central reactor in which the processes of coagulation and flocculation of wastewater take place. After reagent treatment, wastewater passes through settling tanks with thin-layer modules, where it is freed from coagulating suspension.

Biological treatment units

Biological treatment units are cylindrical vertical containers. The blocks contain special equipment that provides biological treatment of wastewater. In the anaerobic and aerobic zones of the blocks, a technological loading is installed, on which active immobilized biomass continuously develops.

UV disinfection units

UV radiation is a physical disinfection method based on photochemical reactions that lead to irreversible damage to the DNA and RNA of microorganisms. As a result, the microorganism loses its ability to reproduce (inactivates). UV radiation acts instantly. Disinfection time in flow mode is 1-10 s.

Blower

The supply of compressed air for technological needs (such as aeration in biological treatment units, regeneration of loads) is carried out by belt blowers.

Reagent facilities

Before biologically treated wastewater enters deep treatment units, it is treated with a coagulant and flocculant to consistently achieve the quality of treated wastewater that meets the established standards for its release into a fishery reservoir.

Dosing of reagent solutions is carried out automatically.

Mechanical grilles

The mechanized screens with 4.0 mm gaps installed in the production building ensure effective removal of coarse waste from wastewater due to the small size of the gaps and the creation of an additional filter layer on the screen steps during their operation, which allows the extraction of small waste, including fibrous waste.

Sand traps

After the screens, wastewater enters blocks of tangential sand traps, where wastewater is freed from sand and similar impurities. The sand retained in the sand traps is periodically discharged under hydrostatic pressure onto the sand pad.

Screw dehydrator

The main component of the dehydrator is the dewatering drum.

The dewatering drum is divided into two parts - a pre-thickening zone and a dewatering zone. Inside the drum, a screw rotates at a constant speed. The pitch of the screw turns decreases from the thickening zone to the dewatering zone. The drum consists of a series of alternating fixed rings, movable rings, and gap spacers made of stainless steel. The design of the self-cleaning system works in such a way that water is used only to wash away sediment from the surface of the drum. Due to the constant movement of the rings relative to each other, the drum does not become clogged.

Mixer with submersible mixers

The homogenizer prevents overloading of process equipment during the hours of maximum wastewater flow and stabilizes the operation of biological treatment facilities in the nitro-denitrification mode with deep removal of ammonium salts and restoration of nitrates to the standard level.

To eliminate sedimentation of suspended solids, the tank is equipped with submersible mixers. In an anaerobic reactor unit (AR) or another denitrifier, wastewater is mixed with continuously recycled activated sludge, which contains a significant amount of nitrates formed at the subsequent stage of aerobic wastewater treatment. Next, the sludge mixture rises up, passing through the biological loading unit (BBL). In the BAR we install the “RUSH” type loading. Under anaerobic conditions, nitrates are decomposed by microorganisms to free nitrogen. In addition, part of the difficult-to-oxidize organic matter is partially decomposed into forms that are easily digestible by microorganisms at the next stage of purification.

From the denitrifier, wastewater flows through the overflow windows of the partition into the aeration tank compartment, a biological treatment unit (BTU), equipped with a technological loading “Polivom” and polymer aerators “Polypore”. The main removal of organic pollutants occurs in the aeration tank. Activated sludge, settling in a settling tank located in the peripheral part of the tank, is continuously returned to the denitrifier using a recirculation pump.

Anaerobic-aerobic conditions created in bioreactors ensure the destruction of organic pollutants and the regime of deep nitro-denitrification of wastewater, which corresponds to the best available technologies according to ITS 10-2015[1]. The nitrogen of ammonium salts is successively biologically oxidized into nitrites, nitrates and, as a result of recycling into the anaerobic zone of the denitrifier, is reduced to molecular nitrogen.

Process mechanism

To improve the quality of wastewater, two methods are used: aerobic and anaerobic biological treatment. In the first case, the process occurs with the help of oxygen, in the second - without it.

Important. In each treatment facility, a specific biocenosis is formed (a set of living organisms capable of processing pollution).

The cleaning mechanism depends on the chosen method and biocenosis.

Technological scheme of aerobic cleaning

The agent is biofilm or activated sludge.

This is a collection of bacteria, fungi, protozoa, representatives of microfauna of one or another genus/group with given characteristics.

The classic aerobic cleaning scheme looks like this:

- Wastewater enters the anaerobic zone of the aeration tank-secondary settling tank. There they are mixed with activated sludge.

- Oxygen is pumped into the installation and, if necessary, components that facilitate processing are introduced.

- Two biochemical processes occur: oxidation of organic carbon and nitrification.

- One or more recycles are carried out: the water is again mixed with activated sludge and enriched with oxygen.

- The processed wastewater settles - gravitational separation of the sludge mixture occurs.

- Excess activated sludge is sent for processing, and part of the mass is returned to its original position.

- Purified water is sent for further treatment or discharged into a reservoir.

The cleaning steps differ in different systems, but the essence of the method remains the same.

Anaerobic

This method is used when the wastewater contains a large amount of organic pollutants, solid sediments and activated sludge. During methanogenesis (the so-called anaerobic treatment process), pollutants are converted into biogas , which consists of methane and carbon dioxide.

Technological scheme of classical anaerobic treatment:

- Wastewater enters the compartment where methane fermentation occurs. After the interaction of anaerobic bacteria with pollution, methane, carbon dioxide, and hydrogen sulfide are formed. These gases are utilized.

- The digested sludge enters the next compartment, where sludge is dewatered in a centrifuge. Then the purified water is discharged into the reservoir.

- The dewatered sludge enters the drum dryer. The released water is disposed of.

- Dry sludge is disinfected and becomes a material for composting.

Natural water purification in nature

Physical processes include the processes of mixing, dilution and dissolution of pollutants, which significantly depend on the speed of the river flow. The insoluble sediment settles to the bottom according to the principle of sedimentation. Ultraviolet radiation from the sun disinfects water.

Chemical processes are expressed through the oxidation of organic and inorganic substances and the saturation of water with oxygen.

Biological processes involve the decomposition of organic substances with the help of microflora.

The self-purification of reservoirs goes through 3 successive stages, called saprobity zones:

- polysaprobic zones

—areas of heavy contamination; characterized by a large amount of organic substances, the absence of oxygen and the presence of anaerobic bacteria in quantities of 1 million per 1 ml. water - mesosaprobic zones

- zones of moderate pollution; nitrification processes occur, the amount of organic substances is average, oxygen is present, the number of anaerobic and aerobic bacteria is from 100 thousand per 1 ml. water - oligosaprobic zones

- zones of pure water; there are few organic compounds, a lot of oxygen, the number of aerobic bacteria is less than 1 thousand per 1 ml. water

Pathogenic microorganisms are present in polysaprobic zones, die off in mesosaprobic zones, and practically do not exist in oligosaprobic zones.

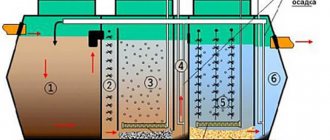

Modern wastewater treatment plants have the same physical and chemical treatment principles as natural biological treatment. However, it is necessary to carefully study the operating principle of biological treatment stations so that there are at least 4 simple filters inside, as well as an air supply inside. At the same time, these stations can be as energy independent as possible and can be easily used for seasonal living.

Photo. The principle of operation of the biological treatment station "Tver".

Help from microorganisms and bacteria

Aerobic bacteria trigger the processes of oxidation and nitrification . For this they need oxygen. Microorganisms live in the temperature range - from +9 to +28 degrees, pH - 5.0-7.0.

Groups of bacteria:

- Pseudomonas - occupy 80% of activated sludge. They process alcohols, fatty acids, aromatic hydrocarbons, paraffins and other organic substances.

- Nitrifying agents - oxidize nitrogen compounds.

- Sulfur bacteria and thionic bacteria - process reduced sulfur compounds.

- Filamentous - oxidize carbon compounds.

- Cellulose decomposing – process cellulose fiber.

Activated sludge also contains:

- yeast,

- molds,

- protozoa,

- rotifers,

- oligochaete annelids.

Anaerobic bacteria do not require oxygen. They trigger the processes of fermentation, anoxygenic oxidation and methane formation.

Reference. Microorganisms can withstand a temperature range from +9 to +37 degrees, the pH value ranges from 6.0 to 8.0.

Groups of anaerobic bacteria:

- Hydrolytics are responsible for the first stage of methanogenesis. Bacteria break down proteins, fats, cellulose compounds, starch, and have ammonifying activity. As a result, glycerol, fatty acids, amino acids, peptides, mono- and disaccharides are formed.

- Acidogenic – responsible for the second stage of methanogenesis. With the help of bacteria, butyric acid, acetone-butyl, propionic, and alcoholic fermentation occurs. Intermediate hydrolysis products are processed.

- Heteroacetogenic - responsible for the third stage of methanogenesis. Bacteria convert organic acids (butyric, propionic) into acetic acid.

- Methanogenic - complete anaerobic treatment. Microorganisms form biogas by processing hydrogen, carbon dioxide and fumes, acetate, methylamine, and methanol.

The composition of the dominant microflora depends on the characteristics of the wastewater.

Nitrification and denitrification

These two processes lead to effective biological treatment.

Nitrification takes place in the aeration tank - the oxidation of ammonia NH4 to nitrites NO2, and then to nitrates NO3.

The chemical formulas of these processes look like this

| Ammonia-oxidizing bacteria | Nitrite-oxidizing bacteria |

| NH4 + 1.5O2 = NO2 + 2H + H2O | NO2 + 0.5O2 = NO3 |

| Nitroso monas europaea Nitroso coccus oceanus Nitroso spira briensis Nitroso lobus multiformis | Nitro bacter winogradskyi Nitro bacter agilis Nitro spina gracilis Nitro coccus mobilis |

That is, nitrification occurs in the presence of oxygen supplied by blowing equipment and distributed through an aeration system.

This is what biological treatment looked like before. Today, due to the increase in the content of ammonia nitrogen in the initial wastewater, the nitrites and nitrates formed during the nitrification process become larger and their concentration at the outlet significantly exceeds the maximum permissible for discharge into a fishery reservoir. Therefore, a denitrifier is included in the scheme. Now the wastewater first enters the anoxic zone, the process of denitrification occurs - a decrease in the concentrations of nitrites and nitrates (activated sludge from the aeration tank, that is, NO2 and NO3, is recycled into the anaerobic reactor). The oxygen contained in these compounds is required by microorganisms to maintain their vital functions in conditions of limited access to it. The result is nitrogen N2, which is released into the atmosphere.

Scheme of nitrogen conversion during denitrification

Systems

For artificial aerobic cleaning, the following structures are most often used:

- An aeration tank is a reservoir in which wastewater is mixed with activated sludge. It is often divided into several chambers where different stages of biotreatment occur. The tank is equipped with an aerator - an oxygen supply system.

- Biotank is a type of aeration tank in which a special loading allows you to increase the total amount of biomass.

- Biofilter is a pool with drainage at the bottom. Wastewater treatment occurs through mineralization. Biocenosis is a film of aerobic microorganisms.

- A biological treatment station is a local structure that is installed where it is not possible to install a common sewage system. Treated wastewater is discharged into the ground, and the waste is used as fertilizer. The stations process wastewater volumes from 5 to 1000 cubic meters. m. VOCs are purified from 98-99% of contaminants.

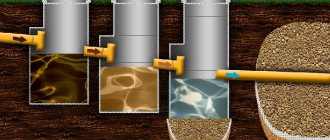

Anaerobic treatment processes often take place in the following traditional facilities:

- An anaerobic lagoon is one or more settling tanks where wastewater is kept from 1 week to 2 months. Gases are released into the atmosphere.

- A septitank is a closed-type settling tank in which the sediment from the resulting solid particles rots and is broken down by anaerobes.

- A digester tank is a structure that looks similar to a septitank. But in the tank there is mixing, heating and control of basic parameters.

BIOLOGICAL TREATMENT FACILITIES

They are a complex of tanks, pumping, blowing and other equipment designed for wastewater treatment by creating special conditions for the development of activated sludge microflora.

Next, we will consider the main types of biological capacitive equipment.

Anaerobic reactors

To treat concentrated wastewater in technological schemes, two-stage anaerobic structures are often used.

Stage I anaerobic reactors of our company are vertical cylindrical containers made of fiberglass and equipped with submersible mixers.

Stage II anaerobic reactors are vertical cylindrical tanks with a conical bottom, equipped with a technological loading on which immobilized active biomass is continuously developed. Material: fiberglass.

When wastewater passes through a technological loading, the organic part of dissolved, suspended and colloidal substances is processed by microorganisms attached to it. The resulting sediment is mineralized and periodically discharged by pumps for mechanical dewatering.

In order to maintain the optimal dose of sludge, there is a continuous return of sludge to the first stage blocks using centrifugal pumps from the second stage blocks.

At the first stage, wastewater is instantly mixed with recirculated activated sludge from the second stage reactors, which ensures their anaerobic treatment and conversion of difficult-to-oxidize substances into forms accessible to subsequent stages.

In the blocks of the first stage anaerobic reactor, high concentrations of anaerobic sludge are created due to its constant return in suspended form. In this case, the sludge mixture is thoroughly mixed mechanically, which ensures uniform distribution of sludge in the water mass and prevents its sedimentation at the bottom and rotting.

Aero tanks

They are divided into mixers and displacers. The former are distinguished by the uniform distribution of wastewater throughout the entire volume of the structure. They carry out complete mixing of wastewater with sludge mass. In displacers, the reduction in the content of pollutants occurs gradually as the liquid moves from the point of entry to the outlet of the purified mass.

Aeration tanks are also divided into aeration tanks and biofilters. In aeration tanks, the mechanism for removing substances from wastewater occurs as a result of the activity of active biomass suspended in water. Aerotanks can otherwise be called biotanks. Biotank is an aeration structure with a special loading that helps increase the total amount of biomass.

The biofilter is equipped with a special filter material on which a biological film is formed - an immobilized form. It adsorbs impurities on its surface, which, under the influence of enzymes, are absorbed by living cells.

Our biological treatment units operate in biofilter mode with a flooded process load and are cylindrical containers, according to technical features, divided into three zones - central, settling and periphery.

A plate loading is installed in the central part, on which attached aerobic-facultative biomass develops, which, together with return activated sludge, ensures the oxidation of organic wastewater contaminants. In the peripheral blocks, additional oxidation of organic components occurs and flows into the settling zones. In them, the wastewater is first filtered through a suspended layer of biocenosis, and then passes through thin-layer modules, where the purified water is separated from the sludge biomass.

Biological ponds

They are artificially created reservoirs in which wastewater is aerated with natural air.

They have a significant drawback in terms of growing an active biocenosis in winter. This is due to the fact that when the temperature drops below 6 0C, all biological processes stop.

In addition, biological ponds require the creation of large sanitary protection zones (up to 200 m).

Therefore, at present, the use of artificially created reservoirs is not widespread.

Biological products

Biological products are used to perform the following tasks :

- Decomposition of organic matter: fats, carbohydrates, proteins;

- Stimulation of activated sludge operation;

- Reducing the volume of by-products in the form of sediment;

- Acceleration of the processing process;

- Decrease in biochemical oxygen consumption (BOD, COD);

- Build-up and restoration of activated sludge.

Manufacturers produce drugs that contain a certain number of strains of natural bacteria.

Each biological product contains different strains of microorganisms , which are selected depending on the composition of the wastewater.

Attention. The manufacturer in the description of its products indicates what kind of pollution it copes with.

Popular biological products:

| Name | Purpose of use | Price |

| Biofos | Domestic wastewater treatment | 43 RUR/25 mg |

| bioExpert BIO STARTER | Stimulation of the development of activated sludge in a septic tank or cesspool | 565 RUR/400 g |

| Unibac (compost, start, winter, effect) | Treatment of domestic and industrial wastewater, build-up of activated sludge | 470-750 rub./0.5 l. |

Additional treatment of household wastewater

In some cases, after the biological stage, water must undergo additional purification.

This is needed when:

- They are planned to be released into low-power reservoirs, especially those intended for fisheries;

- They will be used in industry or for domestic purposes.

A common method of post-treatment is settling in bioponds with natural and artificial aeration . In such reservoirs, favorable conditions are created for the massive development of microorganisms that break down the remaining pollutants and fight pathogens.

Reference. Beneficial bacteria reduce the number of E. coli by 99% and destroy helminth eggs.

The water settles in bioponds for several months and, after satisfactory laboratory analysis, reaches its final destination.

The nuances of working with a biological water purification filter

When interacting with such systems, it should be remembered that they represent real “life”, for the maintenance of which it is necessary to take into account a number of required conditions.

- Strict adherence to temperature conditions is vital for bacteria. Otherwise, they will die and you can forget about effective purification of the aqueous solution.

- Proper humidity levels also need to be taken care of. The optimal rate would be no lower than 60% (but more is better).

- To avoid the death of microorganisms, the presence of a nutrient medium for them should be constantly maintained. They require constant nutrition to develop.